Professional Documents

Culture Documents

Plant Cold Start

Uploaded by

Minh Hoang NguyenCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Plant Cold Start

Uploaded by

Minh Hoang NguyenCopyright:

Available Formats

PLANT COLD START-UP

A.PLANT COLD START-UP READY

- MCWS A On and MCWS B On

- CCWS Normal

- Air Compressor Sys Normal

- Gen Stator Cooling Water Sys Normal

- Auxiliary Steam Sys Normal

- HP Bypass Hydraulic Sys Normal

- LP Bypass Hydraulic Sys Normal

- Water Level In Storage Condenser Normal

- Water Level In Feedwater Storage TNK is Normal

- MECH CLNG is In Service

- U1 Chlo Sys On

- LDO Forwarding Sys In Service

- Condenser Water Box Vacuum Sys In Service

- Condenser Sys In Service

- Circulating Water Sys In Service

- CPP In Service

- Scanner Cooling Air Fan In Service

- BFPT A Lube Oil & Turning Gear In Service

- BFPT B Lube Oil & Turning Gear In Service

- TBN LUBE Oil Sys Normal

- Generator Seal Oil Sys Normal

- H2 Gas Fill Up Complete In Gen

- Steam Turbine Turning Gear In Service

- ACW Sys In Service

- DM Water Storage & Transfer Sys In Service

- Service Water & F/F Sys In Service

- CEMS Normal

- TBN Steam Seal Sys Normal

- Operation Verification

- Unit In Cold Start Mode

Node: The Operator shall verify the following Condition before Plant Start-up Sequence

- Water Treatment System Normal

- Condensate Storage & Transfer Sys Normal

- Condenser Hot Well FW Storage TNK Filled

- CTCS In Service

- Debris Filter In Service

- All Manual Valves In all System Properly Positioned

- All Equipment (Train Group, Pumps) Preselected

- BLR Fill Up Complete

- Clean Up of Condensate Sys Complete

- BLR Flushing Complete

- Flow Path FW 1,2,3,4 Available

- ESP Heating Complete

- Sampling System Normal

B. STEP BY STEP

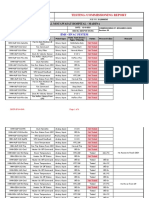

Step Conditions Step by Step

No

01 - PB Start - Common Sys Group Auto

- Plant Cold Start Ready

02 - Auxiliary PRDS Group Auto Mode - Delay 2s to Next Step

- DM Water SPLY PP Group

Control Auto Mode

- COND XFP Group Control Auto

Mode

- PW PP Group Control Auto Mode

- Service WTR PP GRP CTL Auto

Mode

- DO FWD PP GRP CTL Auto

Mode

- CCW GRP CTL Master Auto

Mode

- FGD CCWP GRP CTL Master

Auto Mode

- ACW GRP CTL Master Auto

Mode

- CVP GRP CTL Master Auto Mode

03 - - Start CVP Sys

04 - Any CVP Running - Delay 2s to Next Step

05 - - Verify Roto Pre-warming Start

06 - Roto Pre-warming In Progress - Start Deaerator Heating

07 - FW Storage TNK Heating PCV - Main Steam & Reheat Drain Sys Auto

Auto Mode

- T FW STOR TNK > 110oC

08 - Main Steam & Reheat Drain Sys In - Line-Up Flow Path FW HTR #6,7,8

Auto

09 - Flow Path FW HTR #6,7,8 Line- - FW HTR Vent Sys To Start-up Position

Up

10 - FW HTR Vent Sys In Start-up - Start S-U BFP

Position

11 - S-U BFP Running - Set FW HTR EXT STM DRN SYS to

Start Position

12 - FW HTR EXT STM DRN SYS In - Start Automatic Boiler Sequence

Start Position

- Rotor Pre-Warming Complete

13 - Automatic Boiler Sequence In - Delay 10s Nest Step

Process

14 - - Reset STG

15 - STG Reset Complete - Start ESP Sys

- ESP A RDY to Start-up

- ESP B RDY to Start-up

- Remode Mode Selected

16 - ESP A Running - HP/LP Bypass to Start Mode

- ESP B Running

17 - HP BP Auto Mode - Start FGD Sys

- HP BP A M/A Auto Mode

- HP BP B M/A Auto Mode

- LP BP Auto Mode

- LP BP A M/A Auto Mode

- LP BP B M/A Auto Mode

- FGD Sys Ready

- FGD Sys Remote

18 - FGD Sys Running - Start Fly Ash Handling System

- Fly Ash Handling System Start

Permissive

19 - Fly Ash Handling System Start - Start SDCC for BAHS

- SDCC for BAHS Start Permissive

20 - SDCC for BAHS Running - Verify TBN Chest Warming Start

21 - TBN Chest Warming Completed - BFPT A Reset CMD

- All TBN Drain VLV Opened - BFPT B Reset CMD

- TBN Ready to Start - STG Auto Start

22 - TBN Rolling In Reverse Flow - Verify TBN Speed 2600 rpm

Mode

23 - TBN Speed > 2600 rpm - Verify TBN Speed 3000 rpm

24 - TBN Speed > 3000 rpm - LP FW HTR #2, 3. 4 Start Vent MOV

Closed at HTR LVL Normal

25 - FW HTR 4 Vent MOV Closed - Release to STG Synchronization

- FW HTR 3 Vent MOV Closed

- FW HTR 2 Vent MOV Closed

26 - STG Synchronized - Delay 10s to Next Step

27 - - Enable UMC Command

28 - TBN In UMC Mode - Set TBN Master Control Auto

29 - TMC Auto Mode - Set BLR Master CTL Auto

- Both HP Bypass VLV Closed

30 - BMC Auto Mode - Set UMC Target 50% Load

31 - TBN Actual MW > 150 MW (25%) - Start 1ST TBN Driven BFP

- BFPT A Duty Selection

- BFPT A RDY to Start

- Or BFPT B Duty Selection

- BFPT B RDY to Start

32 - BFPT A Duty Selection - Verify Motor Driven Stop

- And BFPT A Running

- Or BFPT B Duty Selection

- And BFPT B Running

- BFP Discharge Pres Equlized

33 - S-U BFP Stopped - Verify FW 100% MOV Open

34 - FW HTR to Economizer Inl MOV - Set UMC Target 100% Load

Opened

35 - TBN Actual MW > 240%(40%) - Start 2nd TBN Driven BFP

- BFPT A Duty Selection

- BFPT A RDY to Start

- Or BFPT B Duty Selection

- BFPT B RDY to Start

36 - BFP B Running - Start 2nd CEP

- BFP A Running

37 - More Than Two CEP Running - Verify 50% Load (300MW) Reach

38 - TBN Actual MW > 300MW(50%) - Verify 70% Load (420MW) Reach

39 - TBN Actual MW > 420MW(70%) - Verify 90% Load (540MW) Reach

40 - TBN Actual MW > 540MW(70%) - Verify 100% Load (600MW) Reach

- Plant Cold Start-up Complete

You might also like

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Plant Warm StartDocument5 pagesPlant Warm StartMinh Hoang NguyenNo ratings yet

- A.Plant Hot Start-Up ReadyDocument5 pagesA.Plant Hot Start-Up ReadyMinh Hoang NguyenNo ratings yet

- SOP TG Rolling and SynchronisationDocument13 pagesSOP TG Rolling and Synchronisationmoovendan pNo ratings yet

- Presentation On NSTPS VISITDocument46 pagesPresentation On NSTPS VISITACHAL AGRAWALNo ratings yet

- RTR RHSG Start-Up Time Chart (Cold Start-Up)Document8 pagesRTR RHSG Start-Up Time Chart (Cold Start-Up)Sarah FrazierNo ratings yet

- HP LP Bypass System (MB Power) 10june15Document18 pagesHP LP Bypass System (MB Power) 10june15dilbagh_scribd100% (3)

- HP-LP Bypass FDocument16 pagesHP-LP Bypass FSolaiNo ratings yet

- TURBINE Logics and InterlocksDocument62 pagesTURBINE Logics and Interlockskalyanm20351586% (7)

- 500MW Starting ProceduresDocument38 pages500MW Starting Proceduresthangarajm1984No ratings yet

- 500 MW Unit Startup ProcedureDocument39 pages500 MW Unit Startup ProcedureMohammad Asif50% (2)

- Turbine Prestartup ChecklistDocument4 pagesTurbine Prestartup ChecklistSCE SOLAPURNo ratings yet

- Adani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorDocument4 pagesAdani Power Limited: Rolling and Synchronising Check List For 660MW Steam Turbo GeneratorBryan ScofieldNo ratings yet

- Cold Srat UpDocument21 pagesCold Srat Upthiagu1989100% (1)

- Power Plant EmergencyDocument22 pagesPower Plant Emergencysekhar_ntpc75% (4)

- Lecture On ATRS & Speed-Load ControlDocument44 pagesLecture On ATRS & Speed-Load Control06nikhil100% (1)

- 660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCDocument6 pages660 MW Warm Startup Procedures Warm Start Up After 36 Hrs Shutdown and HPC Temperature 340 C and Ipc 320 C With Boiler PR 1 To 30 KSCdjfffNo ratings yet

- CMCDocument28 pagesCMCHemant Patil100% (1)

- TURBINE Logics and Interlocks PDFDocument62 pagesTURBINE Logics and Interlocks PDFLakshmi Narayan100% (1)

- Gas Turbine Start-UpDocument36 pagesGas Turbine Start-UpHeryanto Syam100% (2)

- Presentation OnDocument28 pagesPresentation OnAnonymous umnT4ZZcuNo ratings yet

- Main Turbine: 1 General LayoutDocument16 pagesMain Turbine: 1 General LayoutPrakash Choudhary100% (1)

- Cold Startup and ShutdownDocument28 pagesCold Startup and ShutdownFSTPS Switch-YardNo ratings yet

- Inst Mar 2016Document102 pagesInst Mar 2016Dhilip AnNo ratings yet

- Power Plant Emergency Operation InstructionDocument2 pagesPower Plant Emergency Operation Instructionvyrman1208No ratings yet

- DDCP SF 04 04aDocument6 pagesDDCP SF 04 04aMohammad FarajNo ratings yet

- Idamalayar Hydro Electric ProjectDocument100 pagesIdamalayar Hydro Electric ProjectRajesh TKNo ratings yet

- A Brief Idea About Automatic Process Control: Controlling What?Document33 pagesA Brief Idea About Automatic Process Control: Controlling What?Shiva Kotamraju100% (1)

- Co Ordinated Master Control (CMC) : by V.HariayyappanDocument25 pagesCo Ordinated Master Control (CMC) : by V.HariayyappanRavi Satyapal100% (2)

- Improved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric LocomotivesDocument38 pagesImproved (Ccb2) Knorr Bremse Brake System Fitted in 3phase Electric Locomotivesjohn peter100% (11)

- CCPP Cold Start ProcedureDocument3 pagesCCPP Cold Start ProcedureSahariar Bin ShafiqueNo ratings yet

- Tata Projects Limited: Doc. No: Operation & Control PhilosophyDocument10 pagesTata Projects Limited: Doc. No: Operation & Control Philosophyvenkatraman JNo ratings yet

- Sop 01-Turbine Cold StartupDocument12 pagesSop 01-Turbine Cold Startuptpplant100% (1)

- Unit Start UpDocument8 pagesUnit Start UpDebabrata TantubaiNo ratings yet

- Stg-2 Turbine - Fast - Cooling CHECKLISTDocument7 pagesStg-2 Turbine - Fast - Cooling CHECKLISTscentpcbarauni BARAUNINo ratings yet

- Power PlantDocument42 pagesPower PlantMuhammad Faizan100% (1)

- Submitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegDocument7 pagesSubmitted To GM/BTPP: Sub: NLC-BTPP-2X125 MW-Write-up On HP-LP BYPASS SYSTEMS - RegPrakash ChoudharyNo ratings yet

- Check List GT Ready To Start Condition: No. Item Keterangan Status CatatanDocument9 pagesCheck List GT Ready To Start Condition: No. Item Keterangan Status Catatanmail_mulyadi5151No ratings yet

- HRSGDocument4 pagesHRSGnivasssvNo ratings yet

- 60 Ton Per HR Advance Empire Boiler Operation ManualDocument15 pages60 Ton Per HR Advance Empire Boiler Operation Manualrozg788152100% (1)

- Start Up SequenceDocument4 pagesStart Up Sequenceajieakbar1No ratings yet

- Engine Room Simulator: Ers-L11 Man B&W-5L90Mc VLCCDocument36 pagesEngine Room Simulator: Ers-L11 Man B&W-5L90Mc VLCCJøn Bilbao Mallona100% (1)

- Procedure For Condenser Vacuum PullingDocument4 pagesProcedure For Condenser Vacuum PullingPulkit AgarwalNo ratings yet

- BFP Changeover ProcedureDocument10 pagesBFP Changeover ProcedureDevendr Prakash100% (1)

- Ioties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3Document23 pagesIoties Document No:-Mccpl-Pctl-Acc-Doc-M-0001 - Rev. P3pramodtryNo ratings yet

- Pre-Flight Inspection 5. Run-Up / Pre-Take-Off: Cirrus N543DM Check ListDocument1 pagePre-Flight Inspection 5. Run-Up / Pre-Take-Off: Cirrus N543DM Check ListGourav DasNo ratings yet

- Npti Training ManualDocument34 pagesNpti Training Manualsanju0156No ratings yet

- Index-Sop & SMPDocument44 pagesIndex-Sop & SMPNilamani Umashankar JenaNo ratings yet

- Control & Automation For Super Critical UnitsDocument46 pagesControl & Automation For Super Critical Unitsbsiva9No ratings yet

- FS2Crew PMDG MD11 Quick Start by Aberg V1.0Document6 pagesFS2Crew PMDG MD11 Quick Start by Aberg V1.0someguy366No ratings yet

- 2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Document59 pages2 - 1!01!02 - Basic Operation Concept For Turbine and Auxiliary Plant - r00Tiara Noir100% (2)

- 210 MW Generator Operating Instructions Stage-2Document9 pages210 MW Generator Operating Instructions Stage-2raghavendran raghuNo ratings yet

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul ranaNo ratings yet

- 2 SOP of Cold Start UPDocument7 pages2 SOP of Cold Start UPOmprakash DansenaNo ratings yet

- Plant Start-Up - 1111Document5 pagesPlant Start-Up - 1111KorichiKarim100% (1)

- Closed Cooling Water SystemDocument29 pagesClosed Cooling Water Systemrahul_choubey_9100% (1)

- Interlocks & ProtectionsDocument7 pagesInterlocks & ProtectionsPRAVEEN KUMAR SINGHNo ratings yet

- ProductionTech Trip HandoverDocument20 pagesProductionTech Trip HandoverDaniel GrabovskyNo ratings yet

- Duties & Responsibilities of Shift EngineerDocument35 pagesDuties & Responsibilities of Shift EngineerNaveen ChodagiriNo ratings yet

- Plant Shutdown: Step No Conditions Step by StepDocument2 pagesPlant Shutdown: Step No Conditions Step by StepMinh Hoang NguyenNo ratings yet

- SH1.RFP - P4 OTR - Ch2 Design Concept & System Description - 140601Document28 pagesSH1.RFP - P4 OTR - Ch2 Design Concept & System Description - 140601Minh Hoang NguyenNo ratings yet

- SH1.RFP - P4 OTR - Ch1 General Description - 140530Document18 pagesSH1.RFP - P4 OTR - Ch1 General Description - 140530Minh Hoang NguyenNo ratings yet

- 44 Agenda - Weekly Tech Meeting Oct 31Document5 pages44 Agenda - Weekly Tech Meeting Oct 31Minh Hoang NguyenNo ratings yet

- RFI For Close Punch List of Transfer Tower 4&5Document2 pagesRFI For Close Punch List of Transfer Tower 4&5Minh Hoang NguyenNo ratings yet

- Short Report of WTP-WWTP-Air Comp-CCWDocument5 pagesShort Report of WTP-WWTP-Air Comp-CCWMinh Hoang NguyenNo ratings yet

- Short Report 6-12-2019Document6 pagesShort Report 6-12-2019Minh Hoang NguyenNo ratings yet

- Short Report of WTP 28-11Document4 pagesShort Report of WTP 28-11Minh Hoang NguyenNo ratings yet

- ECC Acceptance Protocol Status - 11-Oct-2019Document4 pagesECC Acceptance Protocol Status - 11-Oct-2019Minh Hoang NguyenNo ratings yet

- (SH1) CCC Package - LLMEDocument2 pages(SH1) CCC Package - LLMEMinh Hoang NguyenNo ratings yet

- Temporary Cooling Water System ConceptDocument1 pageTemporary Cooling Water System ConceptMinh Hoang NguyenNo ratings yet

- HP LP Bypass System: Ravi Pal SinghDocument36 pagesHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenNo ratings yet

- YOKOGAWA DCS Training Power Point For System EngineeringDocument689 pagesYOKOGAWA DCS Training Power Point For System EngineeringSerdar Aksoy92% (24)

- Song Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionDocument20 pagesSong Hau 1 Thermal Power Plant (2X600Mw) : Document Submission Status: For ConstructionMinh Hoang NguyenNo ratings yet

- YOKOGAWA DCS Training Power Point For System EngineeringDocument689 pagesYOKOGAWA DCS Training Power Point For System EngineeringSerdar Aksoy92% (24)

- YOKOGAWA DCS Training Power Point For System EngineeringDocument689 pagesYOKOGAWA DCS Training Power Point For System EngineeringSerdar Aksoy92% (24)

- Method StatementDocument16 pagesMethod StatementMinh Hoang Nguyen100% (1)

- Instruction Manual For Thermo Probe - Rev.1Document64 pagesInstruction Manual For Thermo Probe - Rev.1minhhoang091No ratings yet

- Sh1 Dhi p1hbk e m01 Dal 1637 Layout For Lighting and Receptacle Boiler - Rev.1Document174 pagesSh1 Dhi p1hbk e m01 Dal 1637 Layout For Lighting and Receptacle Boiler - Rev.1Minh Hoang NguyenNo ratings yet

- Turbine TestDocument43 pagesTurbine TestNiraj WanjariNo ratings yet

- CHAPTER I Lesson II Seven Environmental PrinciplesDocument17 pagesCHAPTER I Lesson II Seven Environmental PrinciplesTrixie jade DumotNo ratings yet

- Buddha Mind PDFDocument32 pagesBuddha Mind PDFVishal GadeNo ratings yet

- Bhavesh ProjectDocument14 pagesBhavesh ProjectRahul LimbaniNo ratings yet

- Matutum View Academy: (The School of Faith)Document14 pagesMatutum View Academy: (The School of Faith)Neil Trezley Sunico BalajadiaNo ratings yet

- Iso Iec 25030 2007 eDocument44 pagesIso Iec 25030 2007 eAngélica100% (1)

- Task of ProjectDocument14 pagesTask of ProjectAbdul Wafiy NaqiuddinNo ratings yet

- 1id Abstracts Season 2 Episode 6Document406 pages1id Abstracts Season 2 Episode 6Jennifer BrownNo ratings yet

- AVEVA LFM - Data Summary v2Document6 pagesAVEVA LFM - Data Summary v2Joshua HobsonNo ratings yet

- CLT Apllications NewestDocument49 pagesCLT Apllications NewestMackBrideNo ratings yet

- Rosewood Case AnalysisDocument5 pagesRosewood Case AnalysisJayant KushwahaNo ratings yet

- NA ReadingStrategies U5M11L03Document1 pageNA ReadingStrategies U5M11L03Lila AlwaerNo ratings yet

- MCFKTP G3 S2 SC Number Pattern PuzzlesDocument5 pagesMCFKTP G3 S2 SC Number Pattern PuzzlesEric GoNo ratings yet

- The Other Twelve Part 1Document5 pagesThe Other Twelve Part 1vv380100% (2)

- Democracy or Aristocracy?: Yasir MasoodDocument4 pagesDemocracy or Aristocracy?: Yasir MasoodAjmal KhanNo ratings yet

- Anykycaccount Com Product Payoneer Bank Account PDFDocument2 pagesAnykycaccount Com Product Payoneer Bank Account PDFAnykycaccountNo ratings yet

- Panera Bread Case StudyDocument28 pagesPanera Bread Case Studyapi-459978037No ratings yet

- Intercultural Personhood and Identity NegotiationDocument13 pagesIntercultural Personhood and Identity NegotiationJoão HorrNo ratings yet

- C103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratoriesDocument19 pagesC103 - General Checklist - ISO-IEC 17025:2017 Accreditation of Field Testing and Field Calibration LaboratorieshuidhyiuodghNo ratings yet

- Chapter 3 Extension - Game Theory-StDocument25 pagesChapter 3 Extension - Game Theory-StQuynh Chau TranNo ratings yet

- Baby DedicationDocument3 pagesBaby DedicationLouriel Nopal100% (3)

- Economics - Economics - Cheat - SheetDocument1 pageEconomics - Economics - Cheat - SheetranaurNo ratings yet

- QSasDocument50 pagesQSasArvin Delos ReyesNo ratings yet

- AN44061A Panasonic Electronic Components Product DetailsDocument3 pagesAN44061A Panasonic Electronic Components Product DetailsAdam StariusNo ratings yet

- Chapter 4 Signal Flow GraphDocument34 pagesChapter 4 Signal Flow GraphAbhishek PattanaikNo ratings yet

- Details Philippine Qualifications FrameworkDocument6 pagesDetails Philippine Qualifications FrameworkCeline Pascual-RamosNo ratings yet

- Ims DB DCDocument90 pagesIms DB DCpvnkraju100% (1)

- Batron: 29 5 MM Character Height LCD Modules 29Document1 pageBatron: 29 5 MM Character Height LCD Modules 29Diego OliveiraNo ratings yet

- NCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Document8 pagesNCERT Solutions For Class 10 Maths Chapter 5 Arithmetic Progression (Ex 5.1) Exercise 5.1Akash DasNo ratings yet

- Adigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011Document16 pagesAdigwe J. C.: ATBU, Journal of Science, Technology & Education (JOSTE) Vol. 3 (1), January, 2015 ISSN: 2277-0011AnnyNo ratings yet

- S3 U4 MiniTestDocument3 pagesS3 U4 MiniTestĐinh Thị Thu HàNo ratings yet