Professional Documents

Culture Documents

Algeria in Amenas Project: Rotating Equipment Job Plan

Algeria in Amenas Project: Rotating Equipment Job Plan

Uploaded by

Kama Bena BenarousOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Algeria in Amenas Project: Rotating Equipment Job Plan

Algeria in Amenas Project: Rotating Equipment Job Plan

Uploaded by

Kama Bena BenarousCopyright:

Available Formats

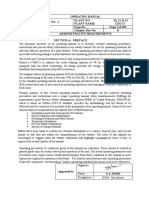

Algeria

In Amenas Project

ROTATING EQUIPMENT JOB PLAN

JOB PLAN NO M116-01_ENG

JOB PLAN TITLE WEEKLY ROUTINE INSPECTIONS AND MAINTENANCE TASK LIST

Responsibility MAINTENANCE

Conditions for Work PLANT SHUTDOWN

Reason for Work SAFETY

Duration 0.00

Task ID Task Description Key Points

Work Instructions

00 ASSOCIATED TAGS:

01 05-X-602-P1, FOAM CONCENTRATE PUMP

05-X-602-PM1, FOAM CONCENTRATE PUMP HYDRAULIC MOTOR

10 PRE-WORK INSTRUCTIONS

11 Before commencing any work, ensure that the installation is isolated from

any remote power supply and controlling equipment. Inform the area

authority and obtain any necessary permit(s) required to carry out the

scheduled maintenance task.

12 Ensure that all tools and maintenance manuals, spare parts and

consumables to carry out the planned routine are available

13 Check and verify all technical data on name plates against data listed on

Job Card and record any changes or additions as necessary and forward to

the maintenance planner for Maximo up-date. Ensure that all data held in

Maximo is valid and up to date.

14 NOTE: FIRE & GAS LOCKOUTS:

Ensure that the correct/appropriate fire and gas lockouts are in force prior to

all function testing.

20 ISOLATE THE PUMP

21 Ensure that the safety instructions in Documents PSE01-XXXX, Operations

and Maintenance Manual and IAP/HSE safety policies have been complied

with.(See Note 4 in Special Tools)

22 Before carrying out any work on all equipment i.e. vessels, pipework, etc.

containing process fluid, ensure that all machinery has been depressurised

and purged.

30 WEEKLY ROUTINE INSPECTIONS AND MAINTENANCE TASK LIST

31 Check the foam pump skid to ensure that there are no visible signs of

damage, oil leakage, product leakage or any other obvious abnormality.

32 Pay particular attention to main and auxiliary pipe work connections and to

mechanical seal locations.

33 Check that there are no loose or frayed cables and that all cables are

securely fastened to the cable tray or anchor points. Ensure that the main

earth cable is securely fastened at each connection point.

MAINTENANCE DATA DEVELOPMENT

10 North Silver Street, Aberdeen AB10 1RL, Scotland UK t | +44 (0)1224 639988 e | team@xpd8solutions.com Page 1 of 3

Algeria

In Amenas Project

ROTATING EQUIPMENT JOB PLAN

JOB PLAN NO M116-01_ENG

JOB PLAN TITLE WEEKLY ROUTINE INSPECTIONS AND MAINTENANCE TASK LIST

34 Check all indicating instruments for correct functioning and unusual

readings.

35 Check the hydraulic oil level in the pump hydraulic drive motor and

replenish as necessary.

36 Check for unusual noise, vibration and bearing temperature for any

abnormality.

37 Check the main and reserve tank level indicator block valves are open and

the tank vent valves are closed. Confirm satisfactory levels in both foam

tanks.

38 Check that the foam pump outlet valves, the foam pump test isolation

valve, the foam system isolation valves and the foam header pressure

control valve isolating valve are open.

39 Record any unusual visible or audible abnormality or change on the Maximo

job report for this task.

70 REINSTATE THE PUMP

71 Re-instate any controlling equipment and power supply that was isolated in

Task 011

72 Ensure that no tools, spares, replenishment fluids or cleaning materials have

been left in the work area, and are returned to the appropriate stores.

73 Record any unusual visible or audible abnormality or change on the Maximo

job report for this task.

74 Return any permit taken out and inform the area authority of the completion

of this routine.

80 Refer to Manufacturer's Operations and Maintenance Manual, PSE01-XXXX

currently unavailable in BP Documentum.

90 SPARE PARTS REQUIRED TO SUPPORT CORRECTIVE MAINTENANCE ONLY

MAINTENANCE DATA DEVELOPMENT

10 North Silver Street, Aberdeen AB10 1RL, Scotland UK t | +44 (0)1224 639988 e | team@xpd8solutions.com Page 2 of 3

Algeria

In Amenas Project

ROTATING EQUIPMENT JOB PLAN

JOB PLAN NO M116-01_ENG

JOB PLAN TITLE WEEKLY ROUTINE INSPECTIONS AND MAINTENANCE TASK LIST

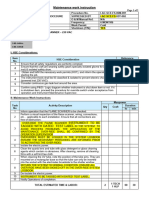

Resources

Task ID Task Durations Resource

(Hours)

10 1 I-MECH

10 1 I-SAFETY

20 1 I-ELEC

20 1 I-MECH

20 1 I-SAFETY

30 1 I-ELEC

30 1 I-INST

30 1 I-MECH

30 1 I-SAFETY

70 1 I-ELEC

70 1 I-MECH

70 1 I-SAFETY

Spares

Task ID Part Number Spare Description

10 No Spares Listed or Identified from available Technical Documentation

Special Tools

Task ID Part Number Tool Description

10 Note 1 No specialist tools are required to carry out these inspections.

10 Note 2 NOTE:- Major disassembly and re-assembly is beyond the scope of these routines and should only be

carried out by manufacturers service personnel

10 Note 3 These routines should only be carried out in accordance with the detailed instructions in the relevant

section of the Maintenance and Operating Manual,Document No.PSE01-XXXX. This document is

unavailable in BP Documentum.

10 Note 4 This job plan has been constructed/produced by the use of the vendors "Knowsley SK" technical

specifications; i.e Pumped Foam Proportioning Skid documentation.

MAINTENANCE DATA DEVELOPMENT

10 North Silver Street, Aberdeen AB10 1RL, Scotland UK t | +44 (0)1224 639988 e | team@xpd8solutions.com Page 3 of 3

You might also like

- CDU II Operating ManualDocument562 pagesCDU II Operating ManualRajeshwar Telang92% (12)

- A Detailed Lesson Plan in English III EssayDocument3 pagesA Detailed Lesson Plan in English III Essayanthony50% (12)

- Rivertrace Engineering Smart Cell Bilge ManualDocument29 pagesRivertrace Engineering Smart Cell Bilge ManualTaufiq Omar Hasan100% (1)

- Instruction Manual For Power TransformersDocument215 pagesInstruction Manual For Power Transformersmohan k100% (1)

- Manual Centrifuga UniversalDocument35 pagesManual Centrifuga Universallebiatan89No ratings yet

- Lynx 20-200 Atex Oim ManualDocument243 pagesLynx 20-200 Atex Oim ManualGiorgiana RosuNo ratings yet

- Ce - HC50 N°11817 00Document48 pagesCe - HC50 N°11817 00Hugo100% (1)

- Manual de Operación Mantenimiento y Partes P375WCU P250WCUDocument160 pagesManual de Operación Mantenimiento y Partes P375WCU P250WCUPercy Cárdenas100% (2)

- Operation Manual Videoline 2000Document34 pagesOperation Manual Videoline 2000Diego Arturo Oblitas GilNo ratings yet

- Mapua University: Experiment No. 3BDocument12 pagesMapua University: Experiment No. 3BGeojanni PangibitanNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- MJR For 30M Maintenance Check of Check ValvesDocument9 pagesMJR For 30M Maintenance Check of Check Valvesxtremewhiz100% (1)

- Ma8750 Manual Eu enDocument28 pagesMa8750 Manual Eu enAcruzbNo ratings yet

- m0919 - Multi-Voltage Coolant Level ModuleDocument12 pagesm0919 - Multi-Voltage Coolant Level ModulecarlosNo ratings yet

- Earthing & Lightning Protection System TrainingDocument25 pagesEarthing & Lightning Protection System TrainingNaushad Haider100% (1)

- P3 Electronic Vac Plant Standard O&M Rev 10Document34 pagesP3 Electronic Vac Plant Standard O&M Rev 10anfalapNo ratings yet

- 025.0593 0 SRP 3015 3020 3030 3050 Anal. Ingl. SOA 02 07Document48 pages025.0593 0 SRP 3015 3020 3030 3050 Anal. Ingl. SOA 02 07Douglas SchusterNo ratings yet

- 304421-000 1995 - October PDFDocument492 pages304421-000 1995 - October PDFduongpnNo ratings yet

- Maintenance Work Instruction: Instrument To Be Tagged With Dated Test LabelDocument2 pagesMaintenance Work Instruction: Instrument To Be Tagged With Dated Test Labelhobam3297No ratings yet

- CCU Unit TrainingDocument34 pagesCCU Unit TrainingNaushad HaiderNo ratings yet

- Operating Instructions MPEB VT STD EnglDocument148 pagesOperating Instructions MPEB VT STD EnglИгорьNo ratings yet

- Bilge Water Separator - MPEB-VT-std-englDocument151 pagesBilge Water Separator - MPEB-VT-std-englmedgit karlukNo ratings yet

- 0Document8 pages0Brian NolascoNo ratings yet

- P130 P175 P185WJDU JUL02 CPN22478358 GBDocument49 pagesP130 P175 P185WJDU JUL02 CPN22478358 GBAgeng A. PooNo ratings yet

- L-K Industries: Benchmark C ManualDocument16 pagesL-K Industries: Benchmark C ManualOcid Sodikin100% (1)

- MPEB Bilge Water SeparatorDocument162 pagesMPEB Bilge Water SeparatorMarek NiewiadomskiNo ratings yet

- 1Y Low Voltage Board MaintenanceDocument2 pages1Y Low Voltage Board MaintenanceOGBONNAYA MARTINSNo ratings yet

- Kodiak's ManualDocument28 pagesKodiak's ManualMichael SymchukNo ratings yet

- Compressor KD5508WDocument22 pagesCompressor KD5508WjorgeNo ratings yet

- SD-010404-01 - Test Stump Operating ManualDocument15 pagesSD-010404-01 - Test Stump Operating ManualFam Escalante OnofreNo ratings yet

- Final Report Piston Engine Practical IiDocument18 pagesFinal Report Piston Engine Practical IiLubi Adam FakihNo ratings yet

- Operation and Maintenance ManualDocument375 pagesOperation and Maintenance ManualAndrew YuNo ratings yet

- MPM 312 01 50Document2 pagesMPM 312 01 50Mousa PetrolNo ratings yet

- D-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011Document255 pagesD-Erection Manual Vol.1 of 2 Maaden TCM A00226 Rev.0. 2011ganesan 00110% (1)

- Water Pump InstallationDocument4 pagesWater Pump InstallationNikkikumarNo ratings yet

- Operator Manual 260 - 280 TJDocument144 pagesOperator Manual 260 - 280 TJsingoNo ratings yet

- User Manual: ATEQ D570Document120 pagesUser Manual: ATEQ D570dionatas serafim do nascimentoNo ratings yet

- Cogen ManDocument31 pagesCogen ManircasinagaNo ratings yet

- Iveco N60 ENT M37 Install 977723Document58 pagesIveco N60 ENT M37 Install 977723Alexandros KontosNo ratings yet

- Bhr240n Iom Rev 0Document60 pagesBhr240n Iom Rev 0Saipavan ChanduNo ratings yet

- HIGHPRESSUNIT-MS2059 - Operation & Maintenance ManualDocument33 pagesHIGHPRESSUNIT-MS2059 - Operation & Maintenance Manualzulu80No ratings yet

- FIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectDocument44 pagesFIN Nal Operat Tion and Ma Orden D FMC Aintenanc E Compra C Technol E Manual - H336073-PM Ogies Proj - Mina Minis M031/A 45011 JECT B6042 Stro Hales 90525 S ProjectEdgarNo ratings yet

- Manual ATQ G620Document34 pagesManual ATQ G620Andres RoblesNo ratings yet

- IOM DUrcoDocument28 pagesIOM DUrcoAlex RodriguezNo ratings yet

- F420Pb U3Document88 pagesF420Pb U3dionatas serafim do nascimentoNo ratings yet

- Ese 00528 enDocument36 pagesEse 00528 enHoàng Minh ÁiNo ratings yet

- Gear Pump SIS CAT 2Document53 pagesGear Pump SIS CAT 2iliuhinNo ratings yet

- 109080-q Smart Cell - Bilge - ManualDocument29 pages109080-q Smart Cell - Bilge - Manualabuzer1981No ratings yet

- 727 PosrvDocument7 pages727 Posrvtxlucky80No ratings yet

- Pompe Beam 435Document24 pagesPompe Beam 435Agustin FavaNo ratings yet

- Glotech Corporation: Submersible Screw Centrifugal Pumps Installation, Operation, and Maintenance ManualDocument21 pagesGlotech Corporation: Submersible Screw Centrifugal Pumps Installation, Operation, and Maintenance ManualdeborazoletNo ratings yet

- G520d U2Document102 pagesG520d U2DaniloRodriguesNo ratings yet

- 025Document3 pages025Sylvester JunirNo ratings yet

- 28 The Facility Files 3 12Document1 page28 The Facility Files 3 12sajuhereNo ratings yet

- Ingersoll Rand hp600wjdDocument98 pagesIngersoll Rand hp600wjdEdgarNo ratings yet

- Jphil Bolting and Unbolting Procedure Rev 1Document21 pagesJphil Bolting and Unbolting Procedure Rev 1Mark Darrel AranasNo ratings yet

- Mellitah Plant: Western Libya Gas ProjectDocument662 pagesMellitah Plant: Western Libya Gas ProjectAnas AhmedNo ratings yet

- Suspension Will Not Lower C1a13-64Document3 pagesSuspension Will Not Lower C1a13-64Febina MisriyaNo ratings yet

- Mission Magnum I Pumps: Installation, Operation and Maintenance InstructionsDocument44 pagesMission Magnum I Pumps: Installation, Operation and Maintenance Instructionsfeka niniNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- CL GL Hal Ni 205Document4 pagesCL GL Hal Ni 205LismiantoNo ratings yet

- Technical Description Fuel Tank Iveco AstraDocument3 pagesTechnical Description Fuel Tank Iveco AstraKama Bena BenarousNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- Algeria in Amenas Project: Rotating Equipment Job PlanDocument2 pagesAlgeria in Amenas Project: Rotating Equipment Job PlanKama Bena BenarousNo ratings yet

- KDP57WS655Document4 pagesKDP57WS655scribdlogosNo ratings yet

- Acupunct Med 1986 Bischko 18 9Document3 pagesAcupunct Med 1986 Bischko 18 9Faiz Naik VespaaeNo ratings yet

- Autocad Structural Detailing 2012Document18 pagesAutocad Structural Detailing 2012Siva Senthil50% (2)

- Paranormal Day by SlidesgoDocument53 pagesParanormal Day by SlidesgoNeo WinstonNo ratings yet

- Mesl Elements 5Document8 pagesMesl Elements 5Backup Review Files YbanezNo ratings yet

- Sound: 1) Longitudinal Wave Motion and 2) Transverse Wave MotionDocument31 pagesSound: 1) Longitudinal Wave Motion and 2) Transverse Wave MotionVinothNo ratings yet

- PUMPSDocument25 pagesPUMPScharmaine fosNo ratings yet

- Government of India Ministry of External Affairs Passport Application Form (No.1) (For New / Re-Issue/ Replacement of Lost/Damaged Passport)Document6 pagesGovernment of India Ministry of External Affairs Passport Application Form (No.1) (For New / Re-Issue/ Replacement of Lost/Damaged Passport)rajNo ratings yet

- BU2508AXDocument8 pagesBU2508AXcongiu lucianoNo ratings yet

- CICASA Election Form 2019-20Document3 pagesCICASA Election Form 2019-20Mohnish SharmaNo ratings yet

- Kcet 2014 Chemistryr1 PDFDocument14 pagesKcet 2014 Chemistryr1 PDFAnweshaBose80% (20)

- VECTRUS EMPLOYEES Stay-Home LISTING Updated 25 MarDocument6 pagesVECTRUS EMPLOYEES Stay-Home LISTING Updated 25 MarstefanieNo ratings yet

- Guidelines For National Green Highways Policy 2015 PDFDocument60 pagesGuidelines For National Green Highways Policy 2015 PDFMuralidhar PVNo ratings yet

- General Instructions:: Section-A (Each Question Carries 2 Marks From Question No. 1 To 7)Document4 pagesGeneral Instructions:: Section-A (Each Question Carries 2 Marks From Question No. 1 To 7)Jessica GoelNo ratings yet

- Study Guide Consumer Behavior Exam 1Document4 pagesStudy Guide Consumer Behavior Exam 1Eric BumgarnerNo ratings yet

- Midterm Examination in Statistics and Probability (GRADE 11)Document9 pagesMidterm Examination in Statistics and Probability (GRADE 11)Andrea MoragaNo ratings yet

- Deployment GuideDocument424 pagesDeployment GuideAbhilash RavindranNo ratings yet

- Grade 9 de 77 (236-239)Document4 pagesGrade 9 de 77 (236-239)Big BunnimalNo ratings yet

- RIBER - RF Plasma Source For Hydrogen - RF H 600Document3 pagesRIBER - RF Plasma Source For Hydrogen - RF H 600Javed KarimNo ratings yet

- IELTS Exam Form and Answer Sheet SamplesDocument39 pagesIELTS Exam Form and Answer Sheet SamplesNay AungNo ratings yet

- Chapter 1 Theories and MovementsDocument4 pagesChapter 1 Theories and MovementsJamie Ann ManalastasNo ratings yet

- Saljnikov AleksandarDocument8 pagesSaljnikov AleksandarMatias MancillaNo ratings yet

- Characteristics: Compact Size Ideal For Any Type of UseDocument3 pagesCharacteristics: Compact Size Ideal For Any Type of Usefabio alexander torres amayaNo ratings yet

- A Yan'an Pharmaceutical CoDocument44 pagesA Yan'an Pharmaceutical Co1123qazxsaqwNo ratings yet

- Naveen ResumeDocument1 pageNaveen ResumeSumit Pandey100% (1)

- E37, E38 & E67. Operating System Compatibility Reference ListDocument6 pagesE37, E38 & E67. Operating System Compatibility Reference Listjavier hurtadoNo ratings yet

- Deutsche For Infogs Page Final 1Document2 pagesDeutsche For Infogs Page Final 1jayNo ratings yet

- Present-Simple-3rd-Person - Sory Heidy Polanco#24Document2 pagesPresent-Simple-3rd-Person - Sory Heidy Polanco#24yendry laureano100% (1)