Professional Documents

Culture Documents

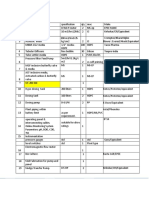

Additional Emergency Lighting Requirement in Plant Area: No. Location Point No Purpose

Uploaded by

Siva Kumar0 ratings0% found this document useful (0 votes)

19 views2 pagesThe document lists 8 locations in the CP plant and 5 locations in the utility and ETP areas that require additional emergency lighting. For each location, it provides the location, point, light number, and purpose. The emergency lighting is needed to monitor equipment, drain lines, close valves, clear cutters, and for operating diesel pumps.

Original Description:

lighting

Original Title

Emergency light requirment

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document lists 8 locations in the CP plant and 5 locations in the utility and ETP areas that require additional emergency lighting. For each location, it provides the location, point, light number, and purpose. The emergency lighting is needed to monitor equipment, drain lines, close valves, clear cutters, and for operating diesel pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views2 pagesAdditional Emergency Lighting Requirement in Plant Area: No. Location Point No Purpose

Uploaded by

Siva KumarThe document lists 8 locations in the CP plant and 5 locations in the utility and ETP areas that require additional emergency lighting. For each location, it provides the location, point, light number, and purpose. The emergency lighting is needed to monitor equipment, drain lines, close valves, clear cutters, and for operating diesel pumps.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 2

Additional Emergency lighting requirement in plant area

No. location Point No Purpose

1 CP 0 m Inlet CP 0 m 1 monitor EG vessel

2 CP 0 m Past pump /monomer pump 1 Drain monomer / close valve

3 CP 7 m Prepolymer pump 58-P01/02 1 Drain polymer line /close valve

4 CP 7 m cutter 1 clear cutter

5 CP 14 m near PP1 1 Drain line ES1 to ES2

6 CP 21 m Additive room 1 close valve MEG after prepare additive

7 biomass near diesel pump 1 for operate diesel pump

8 biomass top of biomass 1 open valve circulation loop

Total 8

CP Plant:

Utility & ETP

No. location Point No Purpose

1 CP 0 m Inlet CP 0 m 1 monitor EG vessel

2 CP 0 m Past pump /monomer pump 1 Drain monomer / close valve

3 CP 7 m Prepolymer pump 58-P01/02 1 Drain polymer line /close valve

4 CP 7 m cutter 1 clear cutter

5 CP 14 m near PP1 1 Drain line ES1 to ES2

6 CP 21 m Additive room 1 close valve MEG after prepare additive

7 biomass near diesel pump 1 for operate diesel pump

8 biomass top of biomass 1 open valve circulation loop

location Point Purpose

1 CP 0 m Inlet CP 0 m 1 monitor EG vessel

2 CP 0 m Past pump /monomer pump 1 Drain monomer / close valve

3 CP 7 m Prepolymer pump 58-P01/02 1 Drain polymer line /close valve

4 CP 7 m cutter 1 clear cutter

5 CP 14 m near PP1 1 Drain line ES1 to ES2

6 CP 21 m Additive room 1 close valve MEG after prepare additive

7 biomass near diesel pump 1 for operate diesel pump

8 biomass top of biomass 1 open valve circulation loop

No Location Point Numbers Purpose

1 UT1 Air compressor area 1 -

2 UT1 Absorption chiller area 1 -

3 UT1 Cooling water pump area 1 -

4 UT2 Fire water pump area 1 -

5 UT2 Working room at fresh water tank 1 -

Total 5

Additional Emergency lighting requirement in plant area

You might also like

- Modern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantFrom EverandModern Power Station Practice: Mechanical Boilers, Fuel-, and Ash-Handling PlantA. SherryRating: 4 out of 5 stars4/5 (5)

- Establish Daily ChecklistDocument2 pagesEstablish Daily ChecklistRischa Br.TampubolonNo ratings yet

- Gases and Vacua: Handbook of Vacuum PhysicsFrom EverandGases and Vacua: Handbook of Vacuum PhysicsA. H. BeckNo ratings yet

- WTP - Batching Plant CHPPDocument4 pagesWTP - Batching Plant CHPPmaarifNo ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- Qatar Petroleum Ngl-1 Operating Manual: 1. GeneralDocument49 pagesQatar Petroleum Ngl-1 Operating Manual: 1. Generalvaratharajan g rNo ratings yet

- Standard Operating Procedure FOR Vacuum PumpDocument7 pagesStandard Operating Procedure FOR Vacuum Pumpsambhu100% (2)

- Hydraulics Questioner-Part 2Document4 pagesHydraulics Questioner-Part 2Jenif JollyNo ratings yet

- List of Spare Parts BoilerDocument18 pagesList of Spare Parts BoilerJules BarcelloNo ratings yet

- Fuel System - MCRSDocument129 pagesFuel System - MCRSDevid Waladan Sholehan100% (1)

- QSKV50 Fuel SystemDocument84 pagesQSKV50 Fuel SystemEvander SarraffNo ratings yet

- CMM10 0enDocument8 pagesCMM10 0enLê Viết TrungNo ratings yet

- SOP of Turbine StartDocument4 pagesSOP of Turbine StartAlok DoshiNo ratings yet

- FeedwaterDocument55 pagesFeedwaternaresh977977No ratings yet

- Punch ListDocument8 pagesPunch ListJamal BakhtNo ratings yet

- Barrier Health Management - For SirDocument12 pagesBarrier Health Management - For Sirkrishna kumar TiwariNo ratings yet

- Boiler Hydro Test 1Document7 pagesBoiler Hydro Test 1sambhu100% (1)

- Rab Revitalisasi PMKDocument16 pagesRab Revitalisasi PMKFire Suppression Lyon Terra EnergiNo ratings yet

- Installing Lube Oil System Feed Pump Lube OilDocument10 pagesInstalling Lube Oil System Feed Pump Lube OilRatha KongNo ratings yet

- Z-16-319 R4 CB20SG Accessories.S+EDocument14 pagesZ-16-319 R4 CB20SG Accessories.S+EBashir AliNo ratings yet

- Shutdown Report July 10Document21 pagesShutdown Report July 10sakthiwab4No ratings yet

- Standard Operating Procedure FOR Gland Steam ChargingDocument6 pagesStandard Operating Procedure FOR Gland Steam Chargingsambhu100% (1)

- Daily Report Environment - 13.11.2022Document7 pagesDaily Report Environment - 13.11.2022Eco Care EngineeringNo ratings yet

- Eid Maintenance UpdateDocument27 pagesEid Maintenance UpdateTanvir Ahmed FahimNo ratings yet

- Fuel Change Over Procedure-1Document4 pagesFuel Change Over Procedure-1Radu IchimNo ratings yet

- S.NO. Quality Control and Testing of Polymer LabDocument2 pagesS.NO. Quality Control and Testing of Polymer Labaharish_iitkNo ratings yet

- Shift LogDocument4 pagesShift LogRohith kumarNo ratings yet

- Specification For Gas Fired Boiler PDFDocument7 pagesSpecification For Gas Fired Boiler PDFmjmehta81No ratings yet

- Report UluwatuDocument3 pagesReport UluwatuNelly SusantiNo ratings yet

- Aquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvDocument5 pagesAquachem Enviro Engineers Pvt. LTD: Civil Unitlist (BY Client) Section-IvNitin GajmalNo ratings yet

- List Monitoring Preparation Oil Purifier: ( - ) Spv. Electrical CEP Date: NoteDocument3 pagesList Monitoring Preparation Oil Purifier: ( - ) Spv. Electrical CEP Date: NoteAfandi AffanNo ratings yet

- Experiment No.3: Exp Name: Boiler (Steam Generator) Description and ApplicationDocument7 pagesExperiment No.3: Exp Name: Boiler (Steam Generator) Description and ApplicationAywb Kh HamadNo ratings yet

- Proposal Change Design Request FixDocument22 pagesProposal Change Design Request FixDito NarendraNo ratings yet

- 1.2test Package Information SheetDocument4 pages1.2test Package Information SheetIrshad mbNo ratings yet

- Fluid Machinery - Eng - Pump - Part2 (Compatibility Mode)Document65 pagesFluid Machinery - Eng - Pump - Part2 (Compatibility Mode)ณัฐวัศ มั่นบุญสมNo ratings yet

- 2way On of Control ValveDocument13 pages2way On of Control ValveRahul DasNo ratings yet

- Plant Start UpDocument8 pagesPlant Start UpIEPL BELANo ratings yet

- HAROS 10 M Cube Per Day PQDocument5 pagesHAROS 10 M Cube Per Day PQAhmed BadweNo ratings yet

- Automation Equipment 200 & 80 KLDDocument2 pagesAutomation Equipment 200 & 80 KLDRohan ChauguleNo ratings yet

- ZhongtaiDocument4 pagesZhongtaivietsdsNo ratings yet

- Presentation On NSTPS VISITDocument46 pagesPresentation On NSTPS VISITACHAL AGRAWALNo ratings yet

- Warranty and Spare Part DetailsDocument2 pagesWarranty and Spare Part DetailsUzair QuraishiNo ratings yet

- Flood Test of CondenserDocument6 pagesFlood Test of CondensersambhuNo ratings yet

- Materi Pengenalan Pengoperasian Dan Perawatan Fire PumpDocument48 pagesMateri Pengenalan Pengoperasian Dan Perawatan Fire PumpBALLYNo ratings yet

- LPG and Propane Pumps LPG & PROPANE Piping and AccessoriesDocument7 pagesLPG and Propane Pumps LPG & PROPANE Piping and AccessoriesOmar WardehNo ratings yet

- Solenoid Valve CPV10-M1H-5LS-M7: Catalogue PageDocument6 pagesSolenoid Valve CPV10-M1H-5LS-M7: Catalogue PageAbraham PerezNo ratings yet

- Tusuka Complex Limited: Sl. Section Description of Work Status RemarksDocument1 pageTusuka Complex Limited: Sl. Section Description of Work Status RemarksMohammed Nayem UddinNo ratings yet

- Lab Manual - FM and M LabDocument64 pagesLab Manual - FM and M LabRavichandran GNo ratings yet

- CC Pump Isolation & PurgingDocument2 pagesCC Pump Isolation & PurgingSunilKChandilaNo ratings yet

- Technical Principles of Valves: Symbols and Circuit FunctionsDocument9 pagesTechnical Principles of Valves: Symbols and Circuit Functionsanon_436633026No ratings yet

- Oil Pump Type BFP 52E Size 3 and 5: General Data SheetDocument2 pagesOil Pump Type BFP 52E Size 3 and 5: General Data SheetCedric ChatonNo ratings yet

- NTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Document5 pagesNTPC/SMPP Operation Department REV:0.00 Area-Tg TDBFP Isolation & Normalization Procedure UNIT-1/2 Date: 27.07.2010Balaji AllupatiNo ratings yet

- 16 - Mortuary Freezer PDFDocument19 pages16 - Mortuary Freezer PDFWan Arif Wan NasirNo ratings yet

- CEP Isolation & Normalisation ProcedureDocument2 pagesCEP Isolation & Normalisation ProcedureVishal GuptaNo ratings yet

- TENG781 публикация англDocument6 pagesTENG781 публикация англanon_433139120No ratings yet

- DatasheetDocument2 pagesDatasheetmuhammad ardiansyahNo ratings yet

- Solenoid Valve CPV10-M1H-2x3-GLS-M7: Catalogue PageDocument6 pagesSolenoid Valve CPV10-M1H-2x3-GLS-M7: Catalogue Pageabrap_dNo ratings yet

- Mars BMS Siemens DPSDocument375 pagesMars BMS Siemens DPSPrashant SawantNo ratings yet

- Experiment 2: CPD 30302 Pilot Plant Operation 2 JULY 2018Document10 pagesExperiment 2: CPD 30302 Pilot Plant Operation 2 JULY 2018Muhammad Al-baihaqiNo ratings yet

- Pneumatic Schematics: Using Graphic Symbols To Illustrate Basic Circuit DesignsDocument45 pagesPneumatic Schematics: Using Graphic Symbols To Illustrate Basic Circuit DesignsAhmed AhmedNo ratings yet

- InventoryDocument4 pagesInventorySiva KumarNo ratings yet

- FileDocument2 pagesFileSiva KumarNo ratings yet

- Unit ConversionDocument1 pageUnit ConversionSiva KumarNo ratings yet

- InventoryDocument4 pagesInventorySiva KumarNo ratings yet

- Daily Production Report December - 2019 (24.12.19)Document51 pagesDaily Production Report December - 2019 (24.12.19)Siva KumarNo ratings yet

- Planned Order TemplateDocument1 pagePlanned Order TemplateSiva KumarNo ratings yet

- Intrument Range ListDocument5 pagesIntrument Range ListSiva KumarNo ratings yet

- SDS For Water Column OverheadDocument11 pagesSDS For Water Column OverheadSiva KumarNo ratings yet

- SSP Pending Jobs SL No Points Responsible Target DateDocument2 pagesSSP Pending Jobs SL No Points Responsible Target DateSiva KumarNo ratings yet

- Technical Specifications: 50Hz Powered by Perkins SeriesDocument4 pagesTechnical Specifications: 50Hz Powered by Perkins SeriesSiva KumarNo ratings yet

- Storage location-SCM: SL No Department Material Type Storage Location NameDocument3 pagesStorage location-SCM: SL No Department Material Type Storage Location NameSiva KumarNo ratings yet

- Plant Capacity 220 Heater Design DataDocument4 pagesPlant Capacity 220 Heater Design DataSiva KumarNo ratings yet

- AMP Color Testing MethodDocument1 pageAMP Color Testing MethodSiva KumarNo ratings yet

- School FormDocument3 pagesSchool FormSiva KumarNo ratings yet

- Haccp 06 PDFDocument13 pagesHaccp 06 PDFSiva KumarNo ratings yet

- C4054 UIF PR 1010 DB 00006 0 OM V1 6 Schedule For Pre CommissioningDocument1 pageC4054 UIF PR 1010 DB 00006 0 OM V1 6 Schedule For Pre CommissioningSiva KumarNo ratings yet

- 1 Solid State Polymerization of Poly Ethylene Terephthalate I Experimental Study of The Reaction Kinetics and Properties PDFDocument16 pages1 Solid State Polymerization of Poly Ethylene Terephthalate I Experimental Study of The Reaction Kinetics and Properties PDFSiva KumarNo ratings yet

- Pet Polycondensation Side ReactionsDocument6 pagesPet Polycondensation Side ReactionsGeorge MarkasNo ratings yet

- Insane ProjectDocument220 pagesInsane ProjectsurajphilipsNo ratings yet

- Pet Polycondensation Side ReactionsDocument6 pagesPet Polycondensation Side ReactionsGeorge MarkasNo ratings yet

- Final Project Report Plastic Bottle ManufactureDocument101 pagesFinal Project Report Plastic Bottle Manufactureaskaridumbo82% (33)

- New Doc 2018-02-27 - 1 PDFDocument1 pageNew Doc 2018-02-27 - 1 PDFSiva KumarNo ratings yet

- c4054 Uif PR 1015 DB 00001 0 Om V2a 05 CPC Sts PreparationDocument13 pagesc4054 Uif PR 1015 DB 00001 0 Om V2a 05 CPC Sts PreparationSiva KumarNo ratings yet

- C4054 Uif PR 1010 FB 00001 2Document1 pageC4054 Uif PR 1010 FB 00001 2Siva KumarNo ratings yet

- C4054 UIF PR 1010 DB 00001 0 General Process DescriptionDocument64 pagesC4054 UIF PR 1010 DB 00001 0 General Process DescriptionSiva Kumar100% (1)

- C4054 UIF PR 1010 DB 00001 0 General Process DescriptionDocument64 pagesC4054 UIF PR 1010 DB 00001 0 General Process DescriptionSiva Kumar100% (1)

- DEG TankDocument2 pagesDEG TankSiva KumarNo ratings yet

- INVENTORY FOR THE PERIOD: March 2016 ClosingDocument4 pagesINVENTORY FOR THE PERIOD: March 2016 ClosingSiva KumarNo ratings yet

- Cutting Defect FormatDocument1 pageCutting Defect FormatSiva KumarNo ratings yet

- RTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWDocument1 pageRTHB 215-450: Helirotor Compressor Liquid Chillers 620 To 1370 KWMohamed MohamedNo ratings yet

- 09MY XF Quick GuideDocument20 pages09MY XF Quick GuideAnonymous PbQVvdeNo ratings yet

- 19xr Catalog CarrierDocument28 pages19xr Catalog CarrierAhmad Faiz At-TamimiNo ratings yet

- Control Interfaces and Displays Dc50 Comfort Display Override 3 HoursDocument10 pagesControl Interfaces and Displays Dc50 Comfort Display Override 3 HoursCretu Stefan-DanielNo ratings yet

- Model LB-C PDFDocument5 pagesModel LB-C PDFKarthikeyan Sankarrajan0% (1)

- MJ8Document58 pagesMJ8cmpettyNo ratings yet

- 81me1194 Manual Tehnic Util OrigDocument196 pages81me1194 Manual Tehnic Util OrigLuca PanaNo ratings yet

- RMG Industry Expert - K. M. MUNIR HUSSAINDocument4 pagesRMG Industry Expert - K. M. MUNIR HUSSAINAshish J. GeorgeNo ratings yet

- Institutional PDF NewDocument11 pagesInstitutional PDF NewRosalina ObiasadaNo ratings yet

- Green Building Rating System: Energy Performance of Buildings in NigeriaDocument8 pagesGreen Building Rating System: Energy Performance of Buildings in NigeriaBuzz BuddyNo ratings yet

- Manual de Aire Acondicionado CarrierDocument11 pagesManual de Aire Acondicionado Carriersamwriter2010No ratings yet

- Adwea Approved Vendors ListDocument317 pagesAdwea Approved Vendors ListAhmed BakrNo ratings yet

- HVACDocument248 pagesHVACvictorinox dlcbNo ratings yet

- Orbis Medisch Centrum Sittard NL Better Care Greater Comfort Lower Costs A6V10309765 HQ enDocument4 pagesOrbis Medisch Centrum Sittard NL Better Care Greater Comfort Lower Costs A6V10309765 HQ enToanNo ratings yet

- ASHRAE Design Guide For Air Terminal Units Selection, Application, Control, and CommissioningDocument249 pagesASHRAE Design Guide For Air Terminal Units Selection, Application, Control, and Commissioningtran duy75% (4)

- Building Commissioning ProfessionalDocument98 pagesBuilding Commissioning ProfessionalDaniel Andrés GutiérrezNo ratings yet

- LEED Safety First Getting Started GuideDocument19 pagesLEED Safety First Getting Started GuidemariaNo ratings yet

- 30RC 1TDocument256 pages30RC 1TJasser Sotela BravoNo ratings yet

- 05 Samss 002Document8 pages05 Samss 002Eagle SpiritNo ratings yet

- Design Fires For Use in Fire Safety Engineering 9781848061521 CompressDocument76 pagesDesign Fires For Use in Fire Safety Engineering 9781848061521 CompressNik PanayoNo ratings yet

- Heating and CoolingDocument33 pagesHeating and CoolingCrystal Gaile PadrigaoNo ratings yet

- Colombia - Floor Ceiling Yfk (J) e (18-55) BZT (V) Mcmorx 191127Document6 pagesColombia - Floor Ceiling Yfk (J) e (18-55) BZT (V) Mcmorx 191127NOITIER ALBERTO GARANADOS ANo ratings yet

- 1.operation manual for 40ST Series of water-cooled stars water chillers 40ST系列螺杆式水冷机组操作手册-ENDocument47 pages1.operation manual for 40ST Series of water-cooled stars water chillers 40ST系列螺杆式水冷机组操作手册-ENNissar HussainNo ratings yet

- ANEP-25 (Environmental Factors For Surface Ships)Document81 pagesANEP-25 (Environmental Factors For Surface Ships)Bahadır HarmancıNo ratings yet

- Carrier 511 69NT40-541. From 300 To 499.Document182 pagesCarrier 511 69NT40-541. From 300 To 499.Сергей ЛымарьNo ratings yet

- Firewater Pumphouse PackagesDocument21 pagesFirewater Pumphouse PackagesJames Zhang100% (1)

- Pre Qualification Down LoadDocument169 pagesPre Qualification Down LoadSaaed EllalaNo ratings yet

- Brochure of MR Engineering & ConstructionDocument65 pagesBrochure of MR Engineering & ConstructionKiriti MitraNo ratings yet

- Electrolux EW23BC71IS0 Refrigerator Tech SheetDocument2 pagesElectrolux EW23BC71IS0 Refrigerator Tech SheetEdison EspinalNo ratings yet

- Service Manual: 635 / 680 / 790 / 900 Active Smart Refrigerator/Freezer R134a & R600a SystemsDocument145 pagesService Manual: 635 / 680 / 790 / 900 Active Smart Refrigerator/Freezer R134a & R600a SystemsMr KhanNo ratings yet