Professional Documents

Culture Documents

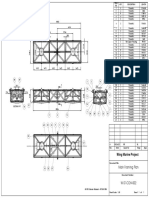

Round Bar Suppot Plate Design Calculation

Uploaded by

innovativekarthi0 ratings0% found this document useful (0 votes)

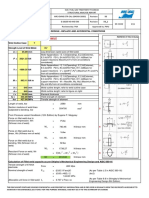

66 views3 pagesThe document provides calculations for the design of a round bar support plate. It includes:

1) Design conditions like maximum static sling force and angles.

2) Dimensions and materials of the plate including thickness and yield strength.

3) Stress calculations for bearing, shear, tension and bending at different points to ensure stresses are below allowable limits.

4) Weld size calculation to withstand bending and tension/compression forces from the applied load.

The calculations show the design meets stress requirements and the selected weld size is sufficient.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

XLS, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe document provides calculations for the design of a round bar support plate. It includes:

1) Design conditions like maximum static sling force and angles.

2) Dimensions and materials of the plate including thickness and yield strength.

3) Stress calculations for bearing, shear, tension and bending at different points to ensure stresses are below allowable limits.

4) Weld size calculation to withstand bending and tension/compression forces from the applied load.

The calculations show the design meets stress requirements and the selected weld size is sufficient.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

66 views3 pagesRound Bar Suppot Plate Design Calculation

Uploaded by

innovativekarthiThe document provides calculations for the design of a round bar support plate. It includes:

1) Design conditions like maximum static sling force and angles.

2) Dimensions and materials of the plate including thickness and yield strength.

3) Stress calculations for bearing, shear, tension and bending at different points to ensure stresses are below allowable limits.

4) Weld size calculation to withstand bending and tension/compression forces from the applied load.

The calculations show the design meets stress requirements and the selected weld size is sufficient.

Copyright:

© All Rights Reserved

Available Formats

Download as XLS, PDF, TXT or read online from Scribd

You are on page 1of 3

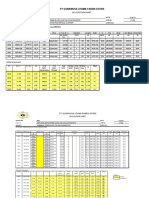

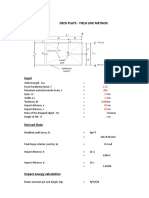

PROJECT NAME

ROUND BAR SUPPORT DOCUMENT NAME

PLATE DESIGN

CALCULATION DOCUMENT NO.

REV. NO

Round Bar Support Plate Design Calculation

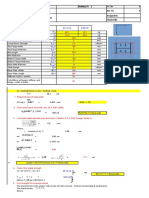

1 DESIGN CONDITIONS

Max Static Sling Force base on Gross Weight PSling = 68.67 kN

Padeye design force, PSling x CF P = 68.67 kN

Total Lifting load factor CF = 1

Sling angle to horizontal plane q1 = 60 Deg

Sling alignment angle to padeye q2 = 5 Deg

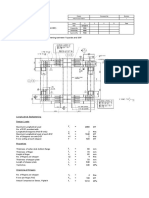

2 DIMENSION & MATERIALS

Plate Materials TYPE-IV

Yield Strength Fy = 245 N/mm2

Pin Diamater Dp = 55 mm

Padeye hole diameter Dh = 56 mm

Hole center to deck Hh = 75 mm

Main plate radius Rm = 75 mm

Hole to main plate left Lm1 = 75 mm

Main plate length Lm = 150 mm

Main plate thickness Tm = 16 mm

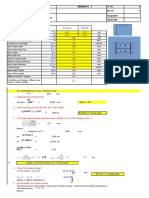

3 STRESS CALCULATION

Horizontal force on padeye Ph = P*Cosq1*Cosq2 = 34.20 kN

Vertical force on padeye Pv = P*Sinq1 = 59.47 kN

i). Bearing stress check (Eye Portion)

Bearing Stress on Eye Portion fp = P /((pi()/4)*Dp*(Tm+Tc1*2+Tc2*2)) = 99.36 N/mm2

Allowable bearing stress Fp = 0.9*Fy = 220.5 N/mm2

Nominal stress check (fp/Fp) = 0.45 < = 1, OK

ii). Shear stress check (Eye Portion)

Shear Area on Eye Portion As = ((Rm-Dh/2)*Tm+(Rc1-Dh/2)*Tc1*2+(Rc2-Dh/2)*Tc2*2)*2 = 1504.00 mm2

Shear Stress on eye portion fs = P/As = 45.66 N/mm2

Allowable shear stress Fs = 0.4*Fy = 98 N/mm2

Nominal stress check (fs/Fs) = 0.47 < = 1, OK

iii). Tensile and bending stress check

Tensile area for padeye A= Tm*Lm+(Ws1*Ts1+Ws2*Ts2+Ws3*Ts3+Ws4*Ts4) = 2400 mm2

Shape center to hole center line e= 0.00 mm

("+" means shape center on right, "-" means on left)

Out plane inertia moment (Ixx):

Out plane inertia moment Ixx = 51200 mm4

In plane inertia moment(Izz):

In plane inertia moment Izz = 4500000 mm4

Force for out plane Po = 0.05*P + P*cosq1*sinq2 = 6.43 kN

In plane bending moment Mi = Ph*Hh = 2565.33 kN-mm

Out plane bending moment Mo = Po*Hh = 482 kN-mm

Stress Check for Point A

Tensile stress fa = Pv/A = 0.025 kN/mm2

In plane bending stress fbi = Mi*(Lm/2 + abs(e))/Izz = 0.043 kN/mm2

Out plane bending stress fbo = Mo*(Tm/2 )/Ixx = 0.075 kN/mm2

Nominal stress check (fa/0.6Fy)+(fbi/0.66Fy)+(fbo/0.66Fy) = 0.899 < = 1.0, OK

Von Mises stress fvon = ((fa+fbi+fbo)2+3*fsi2)0.5 = 0.145 kN/mm2

Von Mises check fvon / (0.8*Fy) = 0.740 < = 1.0, OK

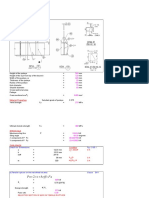

5. WELD CALCULATION FOR LIFTING LUG (Filled Weld)

Length of weld Aw= 2*(Lm+Tm) 332.000 mm

Distance from Hole center to bottom

C= Hh 75.000 mm

of lifting lug

Moment Mw= Ph*C 2565.326 kN-mm

Section Modulus of weld lines

Sw= (Lm*Tm)+(Lm2/3) 2485.333 mm2

subjected to bending moment

Bending force fb= Mw/Sw 1.032 kN-mm

Tension or Compressive force ft= Pv/Aw 0.179 kN-mm

Shear force fv= Ph/Aw 0.103 kN-mm

Resultant Force fr= Sqrt((ft+fb) +fv )

2 2

1.216 kN-mm

Weld size D= fr/(1.856/Min.Safety factor = 3) 1.965 mm

Plate No h b A (mm2) X (mm) Z (mm) dx (mm) dz (mm)

(mm) (mm)

1 0 0 0 0 8 0 8 0 point of cordinate X,Z is center of h

2 0 0 0 0 -8 0 -8

3 0 0 0 0 8 0 8

4 0 0 0 0 -8 0 -8

5 0 0 0 0 8 0 8

6 0 0 0 0 -8 0 -8

7 0 0 0 0 8 0 8

8 0 0 0 0 -8 0 -8

9 150 16 2400 0 0 0 0

2400 0 0

Iz-z = 4500000 In Plane

mm4

Ix-x = 51200 Out Plane

0 point of cordinate X,Z is center of hole

You might also like

- Base Plate Design for Column Base ConnectionDocument6 pagesBase Plate Design for Column Base ConnectionThuyTranNo ratings yet

- Section Properties: Design of Padeye As Per Aisc 360-2005Document5 pagesSection Properties: Design of Padeye As Per Aisc 360-2005Fadil WimalaNo ratings yet

- App 10 Longitudial Shear 2 UC 283Document3 pagesApp 10 Longitudial Shear 2 UC 283yuNo ratings yet

- Padeye DolphinDocument38 pagesPadeye DolphinMuhammad FadelNo ratings yet

- BOX Sec-Beam-Column-AiscDocument6 pagesBOX Sec-Beam-Column-AiscWintun73No ratings yet

- Input Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingDocument6 pagesInput Parameters: 1.1. Input Surface Areas 1.1.1. Above Mudline Without Corrosion Protection CoatingThomas StephenNo ratings yet

- Lifting Analysis Report - Mahadi KurniawanDocument31 pagesLifting Analysis Report - Mahadi KurniawanDian SasNo ratings yet

- Design Calculation Sheet: Jebel Ali Refinary ExpansionDocument4 pagesDesign Calculation Sheet: Jebel Ali Refinary ExpansionAnish PuthusseryNo ratings yet

- (Joint 1760) : PT - Technip IndonesiaDocument12 pages(Joint 1760) : PT - Technip IndonesiariandiNo ratings yet

- Calculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationDocument8 pagesCalculation Note Stabbing Guide Design Design Code Check:Api RP 2A Check For Tubular Ø 323.9 X 12.70 Due To Boatlanding InstallationSai SushankNo ratings yet

- Load Out FixDocument47 pagesLoad Out FixAnonymous SC5fatrFM3No ratings yet

- MarineDocument9 pagesMarineTirthGanatraNo ratings yet

- Seismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleDocument8 pagesSeismic Co-Efficient Calculation As Per NBCC - Equivalent Static Force Procedure For Structures Satisfying The Conditions of ArticleVEERAM AJITHNo ratings yet

- Padeye - 01Document9 pagesPadeye - 01ramNo ratings yet

- Dokumen - Tips - Perhitungan Pondasi TCDocument7 pagesDokumen - Tips - Perhitungan Pondasi TCAlex MartiknoNo ratings yet

- HRD Process Platform Seafastening Design CalculationsDocument6 pagesHRD Process Platform Seafastening Design CalculationsSai SushankNo ratings yet

- Atasehir Gardens Podium OF: Member: LocationDocument7 pagesAtasehir Gardens Podium OF: Member: LocationAlphyl BalasabasNo ratings yet

- Cylindrical Member DesignDocument5 pagesCylindrical Member DesignolomuNo ratings yet

- Towing Design Rev2Document19 pagesTowing Design Rev2Ludovic LandemaineNo ratings yet

- Hand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF FreeDocument24 pagesHand Out Rigging Design For Offshore Heavy Lifting Leefmans PDF Freeel000011No ratings yet

- PADEYE Design AnalysisDocument9 pagesPADEYE Design AnalysisRamesh SelvarajNo ratings yet

- Design Lifting Hook Plate LiftingDocument3 pagesDesign Lifting Hook Plate LiftingSaravan KumarNo ratings yet

- Aisc Asd Gusset Plate Aisc341 16Document12 pagesAisc Asd Gusset Plate Aisc341 16Zarna Modi100% (1)

- API WSD Punch CodeCheckDocument7 pagesAPI WSD Punch CodeCheckKhải TrươngNo ratings yet

- Sea Inersia (15 Nov 2021)Document4 pagesSea Inersia (15 Nov 2021)nurhabiebNo ratings yet

- Bending Moment Diagram CalculationDocument97 pagesBending Moment Diagram CalculationCharles HutabaratNo ratings yet

- Plan Elevation: D D B P M T T ADocument18 pagesPlan Elevation: D D B P M T T ASai SushankNo ratings yet

- THAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ADocument15 pagesTHAIOIL - VER BRACING-L SECTION - BOLTED - 003 - Rev ACivil StructureNo ratings yet

- Multi Lift Point CalcsDocument3 pagesMulti Lift Point CalcsPhan Trọng NghĩaNo ratings yet

- Lashing FormulaDocument1 pageLashing FormulaMuhammad FitrahNo ratings yet

- Appendix A1Document22 pagesAppendix A1Thomas StephenNo ratings yet

- Design Base Plate For I Beam - Bottom BracketDocument1 pageDesign Base Plate For I Beam - Bottom BracketCon CanNo ratings yet

- Dent Depth CalculationDocument1 pageDent Depth CalculationSai SushankNo ratings yet

- NODE PLATE STRESS CALCULATIONDocument14 pagesNODE PLATE STRESS CALCULATIONparvej0% (1)

- SEA - TRANS - REACTION PAU-106-104B - Preliminary IssueDocument4 pagesSEA - TRANS - REACTION PAU-106-104B - Preliminary IssueUMER AZIQNo ratings yet

- Weld Design - Inplace and Accidental Conditions: InputDocument2 pagesWeld Design - Inplace and Accidental Conditions: InputinnovativekarthiNo ratings yet

- List CalculationDocument7 pagesList CalculationTavy TavyNo ratings yet

- Chapter J Design of ConnectionsDocument16 pagesChapter J Design of Connectionsghosh73No ratings yet

- Tinh Vat Lieu Han-19-3Document35 pagesTinh Vat Lieu Han-19-3thienthanh81No ratings yet

- Horizontal Lifting LugDocument1 pageHorizontal Lifting LugTushar MangratiNo ratings yet

- Strength Calculation For PlatformDocument2 pagesStrength Calculation For PlatformRaghNo ratings yet

- Padeye PATIDocument43 pagesPadeye PATIbayu_23RNo ratings yet

- Seainp - ZULF EDP-1 OBSDocument37 pagesSeainp - ZULF EDP-1 OBSRamesh SelvarajNo ratings yet

- Buoy Calculation Depth 14M Calculation Navigation Buoy DataDocument34 pagesBuoy Calculation Depth 14M Calculation Navigation Buoy DataDIANTORONo ratings yet

- Mathcad - Laydown Area Deck PlateDocument3 pagesMathcad - Laydown Area Deck PlatePradeep ChitluriNo ratings yet

- Stability CritariaDocument9 pagesStability CritariaAbu Bakar Siddke RumiNo ratings yet

- Annex A:Lifting Lug CalculationDocument3 pagesAnnex A:Lifting Lug CalculationVilas AndhaleNo ratings yet

- Jeddah South Thermal Power Plant Stage-I: OwnerDocument23 pagesJeddah South Thermal Power Plant Stage-I: OwnerAmr AbdeinNo ratings yet

- #754 v-3103 Spreader & Lifting 60 DegreeDocument12 pages#754 v-3103 Spreader & Lifting 60 DegreeHafizi HZnumismatic100% (1)

- Technical Standards and Commentaries For Port and Harbours Faclilities in JapanDocument5 pagesTechnical Standards and Commentaries For Port and Harbours Faclilities in JapandalifyNo ratings yet

- ECCENTRICALLY LOADED WELD GROUP ANALYSISDocument11 pagesECCENTRICALLY LOADED WELD GROUP ANALYSISSneyder NeyNo ratings yet

- PT Gunanusa Utama Fabricators: Calculation SheetDocument25 pagesPT Gunanusa Utama Fabricators: Calculation Sheetriandi100% (1)

- Section A: 2.1. Sling Design Load and SelectionDocument30 pagesSection A: 2.1. Sling Design Load and SelectionThomas StephenNo ratings yet

- Calculation Sheet: Tubular Brace ParametersDocument52 pagesCalculation Sheet: Tubular Brace ParametersRamesh SelvarajNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Inplace Analysis: Check Print For Submission To Client As RequiredDocument4 pagesInplace Analysis: Check Print For Submission To Client As RequiredRamesh SelvarajNo ratings yet

- AISC2005 Anchor Bolt5 Pin Connection NewDocument6 pagesAISC2005 Anchor Bolt5 Pin Connection NewThuyTranNo ratings yet

- Padeye Design CheekDocument1 pagePadeye Design CheekPawan ShettyNo ratings yet

- LIFTING LUG DESIGN CALCULATIONDocument7 pagesLIFTING LUG DESIGN CALCULATIONSudar MyshaNo ratings yet

- Anchor Bolt-Pinned ConnectionDocument7 pagesAnchor Bolt-Pinned ConnectionThắngg TrịnhhNo ratings yet

- PR02-SPOG Resp-04May2021Document1 pagePR02-SPOG Resp-04May2021innovativekarthiNo ratings yet

- MERO-FGS - Blast Load CalculationDocument1 pageMERO-FGS - Blast Load CalculationinnovativekarthiNo ratings yet

- Static CheckDocument2 pagesStatic CheckinnovativekarthiNo ratings yet

- Fatigue Design CalculationDocument3 pagesFatigue Design CalculationinnovativekarthiNo ratings yet

- Mr3-Svme-Str-Cal-2045xx-30001 - B0 - S20 - Fuel Gas Treatment Package - Structural Analysis ReportDocument473 pagesMr3-Svme-Str-Cal-2045xx-30001 - B0 - S20 - Fuel Gas Treatment Package - Structural Analysis ReportinnovativekarthiNo ratings yet

- E2419-M-SOW-001 Rev. 0Document9 pagesE2419-M-SOW-001 Rev. 0innovativekarthiNo ratings yet

- Siemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300Document36 pagesSiemens SGT-300 MD. Brian M Igoe Product Manager SGT-300. Trevor Mapleston Project Manager SGT-300benlahcene100% (1)

- M30 FE Location RED MarkupDocument5 pagesM30 FE Location RED MarkupinnovativekarthiNo ratings yet

- Wing V12 W-ST-CON-002Document1 pageWing V12 W-ST-CON-002innovativekarthiNo ratings yet

- Steel Design (Track 2) Beam 1 Check 1: Job No Sheet No RevDocument1 pageSteel Design (Track 2) Beam 1 Check 1: Job No Sheet No RevinnovativekarthiNo ratings yet

- Weld Design - Inplace and Accidental Conditions: InputDocument2 pagesWeld Design - Inplace and Accidental Conditions: InputinnovativekarthiNo ratings yet

- Steel Design Tension Members - Example 1Document1 pageSteel Design Tension Members - Example 1innovativekarthiNo ratings yet

- Crosby ShacklesDocument12 pagesCrosby Shacklesj_herndzNo ratings yet

- Stp-Ardwg-020003 - Reva Gad Complete STP FacilityDocument1 pageStp-Ardwg-020003 - Reva Gad Complete STP FacilityinnovativekarthiNo ratings yet

- SPOG Flare Tower Lifitng PlanDocument11 pagesSPOG Flare Tower Lifitng PlaninnovativekarthiNo ratings yet

- Torgue CalculationsDocument1 pageTorgue CalculationsinnovativekarthiNo ratings yet

- GTG forces on I-section beamDocument22 pagesGTG forces on I-section beaminnovativekarthiNo ratings yet

- Arkansas Legislation On Seismic CriteriaDocument2 pagesArkansas Legislation On Seismic CriteriainnovativekarthiNo ratings yet

- Vessel seismic design calculationDocument11 pagesVessel seismic design calculationinnovativekarthiNo ratings yet

- Eil Spec For Architechture-6-75-0051 - Rev 0Document14 pagesEil Spec For Architechture-6-75-0051 - Rev 0innovativekarthiNo ratings yet

- 2117 PST PDFDocument196 pages2117 PST PDFVỸ TRẦNNo ratings yet

- M1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)Document2 pagesM1 195 C195 AO34-4-07-X00-MC-0-DD-S164: (MM) (MM) (MM) (MM) (MM) (MM)innovativekarthiNo ratings yet

- Vendor Forces Drawing AnalysisDocument21 pagesVendor Forces Drawing AnalysisinnovativekarthiNo ratings yet

- Plate Design - Yield Line MethodDocument3 pagesPlate Design - Yield Line MethodinnovativekarthiNo ratings yet

- Offshore Structures - Analysis and Design by Dr.S.nallayarasuDocument115 pagesOffshore Structures - Analysis and Design by Dr.S.nallayarasumariusz19781103100% (9)

- ISO 19900, Petroleum and Natural Gas Industries - General Requirements For Offshore StructuresDocument65 pagesISO 19900, Petroleum and Natural Gas Industries - General Requirements For Offshore StructuresinnovativekarthiNo ratings yet

- Spec 6011 - For BLDG Module-14.03.13-Final-1Document37 pagesSpec 6011 - For BLDG Module-14.03.13-Final-1innovativekarthiNo ratings yet

- Le Sik Kennedy 1988Document90 pagesLe Sik Kennedy 1988Fabián Martínez MuñozNo ratings yet

- Lashing Lug Round Bar Design: 1. GeneralDocument3 pagesLashing Lug Round Bar Design: 1. GeneralinnovativekarthiNo ratings yet

- Design strength of steel connectionsDocument9 pagesDesign strength of steel connectionsCrisnico PeligrinoNo ratings yet

- NBCC (INDIA) LIMITED CANDIDATE USER ID TEST REPORTDocument25 pagesNBCC (INDIA) LIMITED CANDIDATE USER ID TEST REPORTSudarshan bhadaneNo ratings yet

- Stress in Boiler DrumDocument8 pagesStress in Boiler DrummuhdjusriNo ratings yet

- 02 - RC and PSCDocument7 pages02 - RC and PSCMohamed AliNo ratings yet

- Legit Multivector Review and Training Center Online Self-Assessment ExaminationDocument6 pagesLegit Multivector Review and Training Center Online Self-Assessment ExaminationJunnar Jay Abaño100% (1)

- Engineering Structures: Thomas JaegerDocument11 pagesEngineering Structures: Thomas JaegerxyxtofNo ratings yet

- Natural Gas Storage TankDocument10 pagesNatural Gas Storage TankSurya Budi WidagdoNo ratings yet

- Metallic Angled Orthopedic Fracture Fixation Devices: Standard Specifications and Test Methods ForDocument12 pagesMetallic Angled Orthopedic Fracture Fixation Devices: Standard Specifications and Test Methods ForRed RedNo ratings yet

- Rock Mass Model: Scale Typical Roughness Profile JRC20 JRC100 Intermediate MinorDocument6 pagesRock Mass Model: Scale Typical Roughness Profile JRC20 JRC100 Intermediate MinorOrlando BolañosNo ratings yet

- SolidWorks Simulation Student Guide-EnGDocument44 pagesSolidWorks Simulation Student Guide-EnGSam LowNo ratings yet

- ATENA Engineering 3D TutorialDocument97 pagesATENA Engineering 3D Tutorialahmad.zaki84No ratings yet

- RC2 MeDocument11 pagesRC2 MeZelalem AberaNo ratings yet

- NR 322102 Aerospace Structures IIDocument13 pagesNR 322102 Aerospace Structures IISrinivasa Rao G100% (2)

- Abaqus FaqDocument73 pagesAbaqus FaqTaufiq SaidinNo ratings yet

- c0 and c1 ContinuityDocument7 pagesc0 and c1 ContinuityGamini SureshNo ratings yet

- Solved SSC JE Civil Engineering 2012 Paper With SolutionsDocument53 pagesSolved SSC JE Civil Engineering 2012 Paper With Solutionsthe world webNo ratings yet

- Analisis of Suspension Arm PDFDocument6 pagesAnalisis of Suspension Arm PDFSantiago UrgilesNo ratings yet

- Somom PDFDocument429 pagesSomom PDFChandan ChawanNo ratings yet

- Elog Brazil Lightweight Equipment - CompressedDocument51 pagesElog Brazil Lightweight Equipment - CompressedMarcelo SouzaNo ratings yet

- 1965 (Q1) - Lessons From Crane RunwaysDocument5 pages1965 (Q1) - Lessons From Crane RunwaysCesar RjszvlNo ratings yet

- Chapter8 Buckling PDFDocument8 pagesChapter8 Buckling PDFdroessaert_stijnNo ratings yet

- HW1 TorsionThinSectionsDocument1 pageHW1 TorsionThinSectionsAjay KotwalNo ratings yet

- CIVL 5830 Advanced Mechanics of Materials - Final Exam (Spring, 2020)Document3 pagesCIVL 5830 Advanced Mechanics of Materials - Final Exam (Spring, 2020)Shan RatnayakeNo ratings yet

- (1996) 3D Simulation of Bolted Connections To Unstiffened Columns I. T-Stub Connections PDFDocument19 pages(1996) 3D Simulation of Bolted Connections To Unstiffened Columns I. T-Stub Connections PDFMohammad AshrafyNo ratings yet

- Aluminium Shear-Links Enhance Seismic ResistanceDocument28 pagesAluminium Shear-Links Enhance Seismic ResistancesmootherboyNo ratings yet

- Section 1: Engineering Mathematics: Linear AlgebraDocument9 pagesSection 1: Engineering Mathematics: Linear AlgebraBrajesh KumarNo ratings yet

- V2 I20 10Document7 pagesV2 I20 10Anu PathakNo ratings yet

- 9781439873847Document3 pages9781439873847Dele TedNo ratings yet

- ShaftsDocument3 pagesShaftsMalibongwe NgcoboNo ratings yet