Professional Documents

Culture Documents

Pages From ICC 2015 IBC-2

Uploaded by

YaserOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Pages From ICC 2015 IBC-2

Uploaded by

YaserCopyright:

Available Formats

FIREANDSMOKEPROTECTIONFEATURES

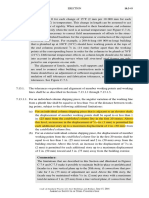

TABLE721.1(2)—continued

RATEDFIRE-RESISTANCEPERIODSFORVARIOUSWALLSANDPARTITIONSa,o,

h. See Note b. The equivalent thickness shall be permitted to include the thickness of cement plaster or 1.5 times the thickness of gypsum plaster applied in

accordance with the requirements of Chapter 25.

i. Concrete walls shall be reinforced with horizontal and vertical temperature reinforcement as required by Chapter 19.

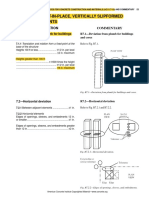

j. Studs are welded truss wire studs with 0.18 inch (No. 7 B.W. gage) flange wire and 0.18 inch (No. 7 B.W. gage) truss wires.

k. Nailable metal studs consist of two channel studs spot welded back to back with a crimped web forming a nailing groove.

l. Wood structural panels shall be permitted to be installed between the fire protection and the wood studs on either the interior or exterior side of the wood

frame assemblies in this table, provided the length of the fasteners used to attach the fire protection is increased by an amount not less than the thickness of the

wood structural panel.

m.For studs with a slenderness ratio, le/d, greater than 33, the design stress shall be reduced to 78 percent of allowable Fc. For studs with a slenderness ratio,

le/d, not exceeding 33, the design stress shall be reduced to 78 percent of the adjusted stress Fc calculated for studs having a slenderness ratio le/d of 33.

n. For properties of cooler or wallboard nails, see ASTM C 514, ASTM C 547 or ASTM F 1667.

o. Generic fire-resistance ratings (those not designated as PROPRIETARY* in the listing) in the GA 600 shall be accepted as if herein listed.

p. NCMA TEK 5-8A shall be permitted for the design of fire walls.

q. The design stress of studs shall be equal to a maximum of 100 percent of the allowable F'c calculated in accordance with Section 2306.

TABLE721.1(3)

MINIMUMPROTECTIONFORFLOORANDROOFSYSTEMSa,q

THICKNESSOFFLOOROR MINIMUMTHICKNESSOF

ROOFSLAB CEILING

FLOORORROOF ITEM (inches) (inches)

CEILINGCONSTRUCTION

CONSTRUCTION NUMBER

4 3 2 1 4 3 2 1

hours hours hours hour hours hours hours hour

1. Siliceous aggre-

1-1.1 7.0 6.2 5.0 3.5 — — — —

gate concrete

2. Carbonate

2-1.1 6.6 5.7 4.6 3.2 — — — —

aggregate concrete Slab (no ceiling required). Minimum cover over nonpre-

3. Sand-light- stressed reinforcement shall be not less than 3/4" b.

3-1.1 5.4 4.6 3.8 2.7 — — — —

weight concrete

4. Lightweight

4-1.1 5.1 4.4 3.6 2.5 — — — —

concrete

Slab with suspended ceiling of vermiculite gypsum plaster

5-1.1 over metal lath attached to 3/4" cold-rolled channels spaced 3 2 — — 1 /4

3

— —

12" on center. Ceiling located 6" minimum below joists.

3

/8" Type X gypsum wallboardc attached to 0.018 inch (No.

25 carbon sheet steel gage) by 7/8" deep by 25/8" hat-shaped

galvanized steel channels with 1"-long No. 6 screws. The

channels are spaced 24" on center, span 35" and are sup-

ported along their length at 35" intervals by 0.033" (No. 21

5. Reinforced galvanized sheet gage) galvanized steel flat strap hangers

concrete having formed edges that engage the lips of the channel.

5-2.1 The strap hangers are attached to the side of the concrete — — 21/2 — — — /8

5

—

joists with 5/32" by 11/4" long power-driven fasteners. The

wallboard is installed with the long dimension perpendicu-

lar to the channels. End joints occur on channels and sup-

plementary channels are installed parallel to the main

channels, 12" each side, at end joint occurrences. The fin-

ished ceiling is located approximately 12" below the soffit

of the floor slab.

(continued)

--`,,,``,``,,,,,,,```,`,,,`,``,`-`-`,,`,,`,`,,`---

®

Copyright International2015INTERNATIONALBUILDINGCODE

Code Council 165

Provided by IHS under license with ICC Licensee=University of Texas Revised Sub Account/5620001114

No reproduction or networking permitted without license from IHS Not for Resale, 10/11/2015 14:29:21 MDT

You might also like

- CIE 430 - Assignment No 2 - Fall 2017Document3 pagesCIE 430 - Assignment No 2 - Fall 2017oluwatobi ajayiNo ratings yet

- BQ Building Works (r2)Document55 pagesBQ Building Works (r2)Hamizan Saary100% (3)

- Boq For Box CulvertDocument2 pagesBoq For Box CulvertDaniel Okere100% (1)

- Dramix - JointlessDocument25 pagesDramix - Jointlesswidayat81100% (1)

- Boq For Box CulvertDocument4 pagesBoq For Box CulvertDaniel OkereNo ratings yet

- f906 PDFDocument3 pagesf906 PDFαlιf GamersNo ratings yet

- How to Build a Global Model Earthship Operation II: Concrete WorkFrom EverandHow to Build a Global Model Earthship Operation II: Concrete WorkNo ratings yet

- Ram ConceptDocument1,242 pagesRam ConceptYaserNo ratings yet

- Solution of The Differential Equation of Simple Harmonic MotionDocument6 pagesSolution of The Differential Equation of Simple Harmonic MotionAriyan Abrar SaifNo ratings yet

- CIGRE TB 273-Safe Design Tensions - ASCR ConductorsDocument43 pagesCIGRE TB 273-Safe Design Tensions - ASCR ConductorsArogya Raju Pudhota100% (1)

- Guide to attaching exterior wall coverings through foam sheathingDocument7 pagesGuide to attaching exterior wall coverings through foam sheathingAdam JonesNo ratings yet

- BOQ Abiyot Phase 1 B+G+4 4BIDDERDocument5 pagesBOQ Abiyot Phase 1 B+G+4 4BIDDERKeire HussenNo ratings yet

- Guide Specification For Portland Cement Plaster - Aggregate FinishDocument3 pagesGuide Specification For Portland Cement Plaster - Aggregate FinishMark RamnarineNo ratings yet

- Bethlehem Steel Sheet PilingDocument49 pagesBethlehem Steel Sheet Pilingakut61100% (1)

- Additional Structural Design Notes: CVEN 4830/4434 University of Colorado, Boulder Spring Semester 2008Document10 pagesAdditional Structural Design Notes: CVEN 4830/4434 University of Colorado, Boulder Spring Semester 2008bilalgsmNo ratings yet

- Estimate For The Work of Providing Plastering and Painting For Ladies' Toilet Room Coming Under AEE-CH-3 SUB-Division BWSSB TataguniDocument3 pagesEstimate For The Work of Providing Plastering and Painting For Ladies' Toilet Room Coming Under AEE-CH-3 SUB-Division BWSSB TataguniKailash LikithNo ratings yet

- ASME Section VIII Division 1 Surface Finish RequirementsDocument1 pageASME Section VIII Division 1 Surface Finish RequirementsAkhtarcmti1342No ratings yet

- Foundation QTYDocument99 pagesFoundation QTYachillies bautistaNo ratings yet

- AM Breeze Block DesignDocument92 pagesAM Breeze Block DesignRezvine Vincene ManalotoNo ratings yet

- Accidental DamageDocument29 pagesAccidental Damagestan80No ratings yet

- G+3 Mixed Use Building Summary and Bill of QuantitiesDocument14 pagesG+3 Mixed Use Building Summary and Bill of QuantitiesWossen DemissNo ratings yet

- AM Breeze Block DesignDocument92 pagesAM Breeze Block DesignMattNo ratings yet

- Proportioning Concrete MixesDocument7 pagesProportioning Concrete MixesJennifer DamascoNo ratings yet

- VICWEST Hi-Bond Composite Floor Deck Design ManualDocument42 pagesVICWEST Hi-Bond Composite Floor Deck Design ManualMike Smith100% (1)

- Presentation On Analysis and Design of Small Reinforced Concrete BuildingsDocument29 pagesPresentation On Analysis and Design of Small Reinforced Concrete BuildingsPuneeth H GowdaNo ratings yet

- The Reinforced Concrete Buildings Design: For Wind and Earthquake Loads ResilienceDocument62 pagesThe Reinforced Concrete Buildings Design: For Wind and Earthquake Loads Resiliencemido medoNo ratings yet

- Sarojini Nagar Under The Guidance of MR Laksham HansdashDocument37 pagesSarojini Nagar Under The Guidance of MR Laksham HansdashShubhanshu MishraNo ratings yet

- BOQ Sample - PDF Version 1Document5 pagesBOQ Sample - PDF Version 1Rhoderick MiqueNo ratings yet

- Boq 2000Document24 pagesBoq 2000Girum YebelayNo ratings yet

- Notes Api650Document6 pagesNotes Api650MasoodMiyanNo ratings yet

- Bill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRDocument34 pagesBill of Quantities Riyadh - An Nakheel General Requirements Item No. Description Unit QTY Unit Price Amount SRmahmoud sayedNo ratings yet

- Troškovnik Građevinskih RadovaDocument6 pagesTroškovnik Građevinskih RadovaMario ŠunjićNo ratings yet

- Interior Fit-Out Summary GurgaonDocument14 pagesInterior Fit-Out Summary GurgaonTaranjot SinghNo ratings yet

- ACI 318-19 RequirementsDocument62 pagesACI 318-19 RequirementsZhiwar oramariNo ratings yet

- Code requirements for concrete cover thicknessDocument2 pagesCode requirements for concrete cover thicknessrealchicNo ratings yet

- CEB 711 - Structural Design II: Semester 2, 2020 2Document32 pagesCEB 711 - Structural Design II: Semester 2, 2020 2Asnil PrakashNo ratings yet

- Ss Bottom Plate Thickness MinmumDocument1 pageSs Bottom Plate Thickness MinmumSUNNY GUPTANo ratings yet

- Scrap Bridge Allowance in Sheet Metal Strip Layout ProcedureDocument4 pagesScrap Bridge Allowance in Sheet Metal Strip Layout ProcedureVenkateswaran venkateswaranNo ratings yet

- 33 Concrete BeamDocument48 pages33 Concrete BeamMario Sajulga Dela CuadraNo ratings yet

- BOQ CrushDocument3 pagesBOQ CrushBikila Tolessa100% (2)

- Galvanizing 2Document1 pageGalvanizing 2Kartik MahajanNo ratings yet

- 3 - Module 8 RoofingDocument35 pages3 - Module 8 RoofingallankatenguddoNo ratings yet

- Compliance SheetDocument4 pagesCompliance Sheetمحمد عبدالرحيمNo ratings yet

- Project & Contract Management (Lab) : Name # Bashir Ahmad REG NO # 2016-CIV-130Document33 pagesProject & Contract Management (Lab) : Name # Bashir Ahmad REG NO # 2016-CIV-130MikoNo ratings yet

- Assignment 1 - Group 3Document22 pagesAssignment 1 - Group 3shu jouNo ratings yet

- Method Statement of Permanent BridgeDocument21 pagesMethod Statement of Permanent BridgeKAmi KaMran100% (2)

- Cladding & Freestanding Walls: Design Guide SeriesDocument32 pagesCladding & Freestanding Walls: Design Guide SeriesBozo IvanovicNo ratings yet

- 14 Design Notes For Masonry Industrical Warehouse BuildingDocument57 pages14 Design Notes For Masonry Industrical Warehouse BuildingTH YungNo ratings yet

- Belgard Permeable Paving Detail PICP Full Infiltration Plaza DesignDocument1 pageBelgard Permeable Paving Detail PICP Full Infiltration Plaza DesignNavraz DhunganaNo ratings yet

- Nova Gabion CatalogDocument20 pagesNova Gabion CatalogPearl ZhaoNo ratings yet

- Specification Text Reinforced FloorsDocument3 pagesSpecification Text Reinforced FloorsPop Marius BogdanNo ratings yet

- Technical Manual: Eurodek™Document12 pagesTechnical Manual: Eurodek™jparsbNo ratings yet

- Take OffDocument33 pagesTake OffAhmed KelifNo ratings yet

- Gabion & Mattress Construction SpecificationDocument8 pagesGabion & Mattress Construction SpecificationAkmarn Makmur100% (1)

- Prestressed Wall ConcreteDocument20 pagesPrestressed Wall ConcreteKiara Ticangan ArgelNo ratings yet

- LHB ShellDocument62 pagesLHB Shellcts kgpNo ratings yet

- A - Sub Structure: 1. Excavation & Earth WorkDocument8 pagesA - Sub Structure: 1. Excavation & Earth Workኢትዮጵያ የ 3ሺ አመት እመቤትNo ratings yet

- solidworks ขั้นพื้นฐานDocument74 pagessolidworks ขั้นพื้นฐานChonTicha'No ratings yet

- Tesfa, BoqDocument52 pagesTesfa, BoqAbel TegeneNo ratings yet

- 33 Concrete BeamDocument45 pages33 Concrete BeamTarek FarahNo ratings yet

- Recipes_of_cement_slurries_for_sealing_casing_in_dDocument17 pagesRecipes_of_cement_slurries_for_sealing_casing_in_dhasan fırat AltınyüzükNo ratings yet

- 222.3R-11 Guide To Design and Construction Practices To Mitigate Corrosion of Reinforcement in Concrete StructuresDocument32 pages222.3R-11 Guide To Design and Construction Practices To Mitigate Corrosion of Reinforcement in Concrete StructuresYaserNo ratings yet

- 364.9T-03 (11) Cracks in A Repair (TechNote)Document3 pages364.9T-03 (11) Cracks in A Repair (TechNote)YaserNo ratings yet

- 364.16T-18 Physical Properties and Characteristics Affecting The Sensitivity To Cracking of Cementitious Repair Materials TechNoteDocument6 pages364.16T-18 Physical Properties and Characteristics Affecting The Sensitivity To Cracking of Cementitious Repair Materials TechNoteYaserNo ratings yet

- ACI 304.4R-95 Placing Concrete With Belt ConveyorsDocument15 pagesACI 304.4R-95 Placing Concrete With Belt ConveyorsmalenikrivasNo ratings yet

- 364.7T-02 (11) Evaluation and Minimization of Bruising (Microcracking) in Concrete Repair (TechNote)Document3 pages364.7T-02 (11) Evaluation and Minimization of Bruising (Microcracking) in Concrete Repair (TechNote)YaserNo ratings yet

- Coptic Treasures WebsiteDocument422 pagesCoptic Treasures WebsiteYaserNo ratings yet

- FIGURE C26.5-1 Maximum Speed Averaged Over T S To Hourly Mean SpeedDocument2 pagesFIGURE C26.5-1 Maximum Speed Averaged Over T S To Hourly Mean SpeedYaser100% (1)

- International Size ChartsDocument1 pageInternational Size ChartsIrfan MohammadNo ratings yet

- 364.5T-10 Importance of Modulus of Elasticity in Surface Repair Materials (TechNote)Document3 pages364.5T-10 Importance of Modulus of Elasticity in Surface Repair Materials (TechNote)YaserNo ratings yet

- Pages From ACI 117-10Document1 pagePages From ACI 117-10YaserNo ratings yet

- Aci 445Document86 pagesAci 445Yaser100% (1)

- Pages From 190704 RWDI Project 1901537 Al Mulla Tower Structural Draft ReportDocument2 pagesPages From 190704 RWDI Project 1901537 Al Mulla Tower Structural Draft ReportYaserNo ratings yet

- Pages From 315R-18 Guide To Presenting Reinforcing Steel Design DetailsDocument1 pagePages From 315R-18 Guide To Presenting Reinforcing Steel Design DetailsYaserNo ratings yet

- Pages From UBC 1997 - Uniform Building Code 5Document1 pagePages From UBC 1997 - Uniform Building Code 5danieldumapitNo ratings yet

- Seismic Ground Motion Maps and Risk CoefficientsDocument6 pagesSeismic Ground Motion Maps and Risk CoefficientsYaserNo ratings yet

- Basic Data:: Calculation of Gust Effect FactorDocument1 pageBasic Data:: Calculation of Gust Effect FactorYaser ShabasyNo ratings yet

- Extended End Plate Moment Connection DesignDocument6 pagesExtended End Plate Moment Connection DesignYaserNo ratings yet

- Comments ReferencesDocument4 pagesComments ReferencesYaserNo ratings yet

- Pages From ACI 117-10Document1 pagePages From ACI 117-10YaserNo ratings yet

- ETABS Concrete Frame Design: ACI 318-19 Column Section DesignDocument2 pagesETABS Concrete Frame Design: ACI 318-19 Column Section DesignYaserNo ratings yet

- Extended End Plate Moment Connection DesignDocument6 pagesExtended End Plate Moment Connection DesignYaserNo ratings yet

- Extended End Plate Moment Connection DesignDocument6 pagesExtended End Plate Moment Connection DesignYaserNo ratings yet

- MC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPDocument12 pagesMC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPdonnybtampubolonNo ratings yet

- MC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPDocument12 pagesMC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPdonnybtampubolonNo ratings yet

- MC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPDocument12 pagesMC-Top Flush Beam IPE360 Column HEA240 W Stiff W DPdonnybtampubolonNo ratings yet

- Pages From AISC 303-2016Document1 pagePages From AISC 303-2016YaserNo ratings yet

- Extended End Plate Moment Connection DesignDocument6 pagesExtended End Plate Moment Connection DesignYaserNo ratings yet

- Extended End Plate Moment Connection DesignDocument6 pagesExtended End Plate Moment Connection DesignYaserNo ratings yet

- FAQ-Revitalizants en SDocument24 pagesFAQ-Revitalizants en SsyafiqNo ratings yet

- ASME VIII Lethal Service Requirements GuideDocument3 pagesASME VIII Lethal Service Requirements GuideNasir Khan Jadoon0% (1)

- High-Rise PrecastDocument7 pagesHigh-Rise PrecastAshu JainNo ratings yet

- YC6K12 Diesel Engine Cylinder Block Parts CatalogDocument79 pagesYC6K12 Diesel Engine Cylinder Block Parts CatalogJimmy ManagaraNo ratings yet

- Effects of Soil Layering On The Characteristics of Basin-Edge Induced Surface Waves and Differential Ground Motion - J. P. Narayan, S. P. SinghDocument20 pagesEffects of Soil Layering On The Characteristics of Basin-Edge Induced Surface Waves and Differential Ground Motion - J. P. Narayan, S. P. SinghStructural SpreadsheetsNo ratings yet

- Hänchen Testing Technology Overview Product RangeDocument13 pagesHänchen Testing Technology Overview Product RangeSympatyagaNo ratings yet

- ASTM 재질분류표Document106 pagesASTM 재질분류표오덕환Oh Duckhwan100% (1)

- Pipe Rheometer PR-100 2010 04Document2 pagesPipe Rheometer PR-100 2010 04Richard AmorinNo ratings yet

- Vaccum Pump DatasheetDocument6 pagesVaccum Pump DatasheetQuietRideNo ratings yet

- Design and Analysis of Piston Design For 4 Stroke Hero Bike EngineDocument3 pagesDesign and Analysis of Piston Design For 4 Stroke Hero Bike EngineKathan ShahNo ratings yet

- Divider Valves: Quicklub Lubrication SystemsDocument4 pagesDivider Valves: Quicklub Lubrication SystemsBehi BshNo ratings yet

- 6-09-223 Wiring Diagram SHT 1 4001012Document60 pages6-09-223 Wiring Diagram SHT 1 4001012Wilson AdrianoNo ratings yet

- Thesis ReportDocument187 pagesThesis ReportRediff mailNo ratings yet

- Engine Sensors and SystemsDocument14 pagesEngine Sensors and Systemsalex generalNo ratings yet

- Cherne Catalog PDFDocument72 pagesCherne Catalog PDFNissam SidheeqNo ratings yet

- Surtac 2000Document1 pageSurtac 2000Bibhudutta JethyNo ratings yet

- N2000 Spec SheetDocument2 pagesN2000 Spec SheetJavier GarciaNo ratings yet

- Barksdale Valve 4 WayDocument2 pagesBarksdale Valve 4 WayDwiki RamadhaniNo ratings yet

- Arc Catalog of Products: Protec Tion Against Corrosion, Abrasion, Impac T, and Chemical at TackDocument40 pagesArc Catalog of Products: Protec Tion Against Corrosion, Abrasion, Impac T, and Chemical at TackcesarNo ratings yet

- Audi Allroad Compressor Strip & Repair How ToDocument5 pagesAudi Allroad Compressor Strip & Repair How Tocalypso_ri100% (1)

- RP1001916 - Joint Modelling Methodology Using AbaqusDocument24 pagesRP1001916 - Joint Modelling Methodology Using AbaqusgeppolaNo ratings yet

- TokaiWeld PDFDocument16 pagesTokaiWeld PDFshaNo ratings yet

- Experiment Instructions: HM 284 Series and Parallel Connected PumpsDocument98 pagesExperiment Instructions: HM 284 Series and Parallel Connected PumpsDrEmadEl-SaidNo ratings yet

- Technical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3Document17 pagesTechnical Article SSAB Structural Hollow Sections For Functional Design According To Eurocode3sharunnizamNo ratings yet

- Electrohydraulic Control SystemDocument8 pagesElectrohydraulic Control SystemSagar Kumar100% (1)

- GEA Hilge FB HYGIA Brochure A4 EN V012015 PDFDocument4 pagesGEA Hilge FB HYGIA Brochure A4 EN V012015 PDFShawn AngNo ratings yet

- Aeb01091 Gas Natural AutomotrizDocument6 pagesAeb01091 Gas Natural AutomotrizJuan Carlos Callas GarayNo ratings yet