Professional Documents

Culture Documents

Prestressed Concrete Floors

Uploaded by

masterumOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Prestressed Concrete Floors

Uploaded by

masterumCopyright:

Available Formats

R E P O R T PRESTRESSED CONCRETE FLOORS

A FAR-REACHING TECHN

Market necessities, force of habit

BONDED PRESTRESSING is made up of strands enclosed in

and the culture of the sector a sheath injected with a rigid product (such as cement grout).

have favoured the growth of floor

prestressing in many countries,

but have not allowed it to develop

in France. This situation could

change with the introduction of

new regulations in 2006 and thanks

to concerted efforts at Freyssinet.

comments Fernand De Melo,

Freyssinet’s Technical Director in

France who, having worked abroad

for a long time naturally mentions

Australia, South East Asia, Singa-

pore and Hong Kong, regions

where the combination of rapid

urban growth and a lack of space

have favoured the technique.

"But," he emphasizes, "much

closer to home, Great Britain is a

key example, if not a model." (see

page 13). "On the one hand, the

advantages of the technique are

THE MALAYSIA TELECOM glaringly obvious," continues the

TOWER in Kuala Lumpur UN-BONDED PRESTRESSING is made up of sheathed greased

Technical Director, inviting us to strands directly installed within the floor slab or inserted into

(Malaysia): 76 floors,

230,000 m2 (1997). compare two photos of car parks, sheaths injected with a flexible product (wax, grease, etc.).

one conventional, with a forest of

pillars, the other astonishingly spa-

ORE THAN HALF A CENTURY cious and clearly better able to

M LATER the opposition encoun-

tered to prestressed floors in

facilitate traffic movements and

parking. "In fact," explains Fer-

France is a reminder at Freyssinet of nand De Melo, "the advantage of

the opposition Eugène Freyssinet prestressing, which is found in civil

had to overcome at the time of his engineering and the building trade

invention. Of course, this time it is with this type of floor, can be

not a question of bringing about summed up in two terms: increase

acceptance of an idea or a new of span, which in this case can be

material, but of changing design up to 15 m as opposed to 7 to 8 m,

and implementation habits in and the weight reduction of struc-

order to allow the technique to tures (floor thicknesses can be

extend its field of application reduced from 40 to 20 or 25 cm)".

beyond the few cases where it is This brings a whole range of advan-

absolutely necessary. "Luckily tages such as the reduction of

there’s no shortage of references", expansion joints and the cost of

10 Soils & Structures Second half of 2005

DOSSIER

IQUE A Full Range of Solutions

TWO TECHNIQUES...

There are two types of technique for prestressed floors: pre-

stressing by bonded post-tensioning, in which the bare strands in

a smooth or ribbed sheath are injected with cement grout after

being tensioned and un-bonded prestressing, which uses strands

remaining free inside a sheath, where they are protected from

corrosion by a grease.

Un-bonded prestressing is often more economical for floors not

subjected to excessive loads. It is less advantageous if a high

level of prestressing is needed (premises subjected to significant

loads such as archive buildings) or if there is a risk that floor

openings will be made after pouring, since un-bonded prestress-

ing requires the recreation of anchors after the tendons are cut.

In certain cases, the two techniques are combined: bonded pre-

stressing in beams and un-bonded prestressing in slabs.

…TWO SORTS OF STRAND, SEVERAL TYPES OF ANCHOR

The two diameters of strand used are 15.70 mm (T15 strand)

and 13 mm (T13). Depending on the diameter and the number of

strands they receive (1, 3, 4, 5), the anchors are given code

names that are easy to decipher: 1E15 (1 strand of 15), 3E13,

3E15, 4E13, 4E15, etc.

IMPLEMENTATIONS

Unlike subcontract packages that do not interfere with the ’criti-

cal path’ of the project, floor prestressing involves cooperation

between the main structure contractor, who frequently carries out

the main work (formwork, passive reinforcement and concrete

placement), with the Freyssinet teams responsible for installing,

inspecting and stressing the post-tensioning materials. Comply-

ing with the positioning tolerances within the slab thickness is

critical to the execution phase. It has led Austress Freyssinet to

develop a range of "chairs" making it possible to guarantee the

positioning of the sheaths to a close tolerance. These are now

also used in Great Britain.

can be gained every 20 to 25 floors. France,” Fernand De Melo believes.

Finally, structural simplification “On the one hand, this is because

equals savings on materials and a construction design offices are not

reduction in overall cost – advan- used to designing using the tech-

tages that companies can’t ignore nique, and on the other hand its

when preparing their responses to because general contractors that

maintaining them, etc. The bene- favourable for creating open invitations to tender. Freyssinet could turn to specialist design

fits of the technique in terms of spaces that are easy to fit out and estimates that savings of the order firms are reluctant to do so for fear

applications follow on very logi- are highly suitable for office build- of 15 to 20% can be made. Paradox- of losing control.” “It also suffers

cally from this basic data. ings, as well as facilities such as ically, since its appearance in the from a special technical status that

shopping centres, airports and car 1980’s as an adaptation of the tech- limits it to such cases where there

Vast Platforms parks. For building owners, this nique used for civil engineering are large spans, unusually heavy

For architects and project man- space saving also translates very structures, floor prestressing has live loads and to what are known as

agers, this makes it possible to firmly into extra square metres of never really taken off in France. ’transfer floors’, where it represents

“save space” with vast column free space, particularly in the case of “Prestressing is not part of the the necessary alternative to rein-

platforms, which are very very tall buildings, where one level building construction culture in forced concrete,” explains

▼

▼

Second half of 2005 Soils & Structures 11

R E P O R T PRESTRESSED CONCRETE FLOORS

1 2

5

3 4

6 7

Christian Lacroix, Freyssinet neering structures but has been duction of the Eurocode. More innovative and competitive.

▼

▼

Regional Director for Île-de- shown to be unfavourable for pre- favourable to the technique, this “The Freyssinet technical depart-

France. Regulations have also been stressed concrete floors, where it regulation drafted within the Euro- ment dedicated to prestressed

a hindrance. The BPEL (béton pré- leads to an increase in passive steel pean framework could restart a floors consists of a manager at each

contraint aux états limites / pre- quantities and consequently the process by allowing companies to of Freyssinet France’s regional

stressed concrete at limit states) cost price. use the services of design firms offices and is responsible for ensur-

calculation method used as a refer- In this apparently static context an applying the new calculation ing that expertise is pooled and

ence by the technical inspection important change will nevertheless method, enabling them to make that we function as a network,”

services is applicable to civil engi- occur as from 2006 with the intro- their designed structures more says Fernand De Melo, “and we

12 Soils & Structures Second half of 2005

DOSSIER

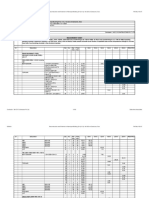

For bonded prestressing, the

strands are delivered to site on

reels (weighing around 3 tonnes).

They are unwound, cut to length

The Technique Saves Space and

and threaded into the sheaths

before concreting (2).

For un-bonded prestressing, the

Reduces the Overall Cost of Projects.

cables (1) are usually delivered

prefabricated (fitted with anchors

at the ends). They are installed

directly in the reinforcements (3), “Belgium: a 25-year lead, but the same obstacles”

on the chairs placed on the

Over the last ten years, Freyssinet Belgium’s achieve- stressed floors and established contacts with very

formwork.

ments in Belgium and Luxembourg must represent active design firms. Our first projects were office

The cables can be tensioned

an average of 30,000 m2 of prestressed floors per buildings in Belgium and Luxembourg (offices for For-

using a light monostrand jack,

year," estimates Edouard Henrard, Sales Director of tis Banque, Brussels National Airport, the Social and

generally three days after

Freyssinet Belgium. This figure simply reflects the Educational Institute and hospitals, car parks and

concreting, thus allowing for the

adaptation of companies to their markets: in France, shopping centres, open space offices, etc.). For all

removal of the formwork (4-7).

the development of the motorways generated a good that, we encountered the same obstacles as in

deal of activity until 1985; this was not the case in France at all levels of the process. In France there is

Belgium, which is a small country where work of this an additional handicap due to the considerable devel-

type was completed in 1970. Necessity knowing no opment of prefabrication and the market share of

law, it is now over 25 years since we turned to pre- that technique in car parks and short-span buildings.”

Great Britain: regulations

change everything

Over the last 20 years, the annual production volume of boosted by the increase in the aver-

prestressed floors in Britain is estimated to have increased age height of buildings. In 2004 in

from less than 50,000 m2 to 1.3 million m2. At the end Manchester, Freyssinet Ltd made

of a 2005 business year with a particularly large number of 31,350 m2 of prestressed floors for a

projects completed in Britain and Ireland, Patrick Nagle, 47-storey building, which is more

Managing Director of British subsidiary Freyssinet Ltd., than 170 m high and will house the

and Paul Bottomley, Technical and Sales Director, answered Deansgate Hilton Hotel.

three questions for Soils & Structures.

Are British regulations favourable

How do you explain the success of This success is the fruit of the long- to this technique?

prestressed floors in Great Britain? term work undertaken by Freyssinet PAUL BOTTOMLEY. – The obligation

Is it a recent phenomenon? Ltd. and other companies to change you have in France to use a mini-

hope to be able to rely on Belgium, PATRICK NAGLE. – 10 years ago we had mentalities and culture in the United mum amount of passive steel in

where Edouard Henrard has been to canvass architects and consulting Kingdom - and it took some time. defined locations does not exist to

working with a design firm for some engineers, as it seems you have to do Another explanation, linked to a the same extent in the UK. Here,

time.” Before the new regulations in France with your partners, in more recent phenomenon, is that the rules for the design of pre-

come into force, this department order to convince them of the the increase in labour costs and steel stressed floors are defined by

will also benefit from the calcula- advantages of floor prestressing. prices has also increased the attrac- British Standard BS8110, supple-

tion expertise of two specialist Those days are all but gone and tion of prestressing. I would also add mented by technical report no. 43

engineers. In this field, support since the end of the 1990s, the trend the time saved on the site compared published by the Concrete Society.

for the French team will come has changed and so have mentali- with a reinforced concrete solution, These recommendations are in fact

from across the Channel, where ties. Today, people approach us to which accordingly represents a very favourable to the technique,

the British work according to a cost solutions that incorporate pre- financial saving for the general con- since they make it possible to

regulation (the British Standard) stressing right from the design stage. tractor and the space saving offered reduce the conventional reinforce-

similar to the Eurocode and have Cases come to us in the form of pre- by prestressed floors. In fact, within ment to a minimum. In practice we

agreed to provide advice and sup- liminary designs (slab configuration, the same “shell”, the designer can can often remove all the passive

port in the selection and use of cal- thickness, loads) to be finalized, plan for additional floors. Finally, I steel in the bottom mat and most of

culation software. which is what our design office does. would say that the success has been it in the top. This is completely

▼

▼

Second half of 2005 Soils & Structures 13

R E P O R T PRESTRESSED CONCRETE FLOORS

1

3

1. 72,000m2 of prestressed slabs were produced

for the Neder-over-Heembeek water treatment plant

in Vilvoorde (Belgium).

2. National Bank Tower in Abu Dhabi (United Arab

Emirates).

3. In the heart of London (United Kingdom), the

prestigious Esso Glen office complex has a total of

50,000m2 of prestressed floors.

4. A car park without prestressed floors, with its forest

of columns and cramped parking spaces.

5. The car park at Atatürk airport in Istanbul (Turkey),

designed with prestressed slabs, has large open

spaces.

6. Prestressing was used for the hemicycle at the

European Parliament in Strasbourg (1998) to reduce

the height of the structure (thinner floors), provide

stability and earthquake-resistant monolithic

behaviour, and optimise the spans between shells.

7. The prestressed slabs used for the new ExCel

exhibition centre in London give the building a high

load-bearing capacity.

“The Strength of Freyssinet Ltd. is its Considerable

Expertise and its Design Office.”

14 Soils & Structures Second half of 2005

6 7

different from what is custom-

Emirates: a technique

▼

▼

ary and permitted in France. As well

as that, the strength of Freyssinet

Ltd. in this field is its considerable

expertise and its design office,

that meets a need

which enable it to design and calcu- In the United Arab Emirates, floor prestressing has ects, our design office studies the

late prestressed floor solutions. been in regular use since the 1990s. Khalil Doghri, solutions to offer for the contrac-

Managing Director of Freyssinet Middle East in Dubai, tors and quantifies the savings that

In practice, how is your work on and Khalid Rabadi, Building Prestressing Division can be made. These optimized

sites organized, in particular with Manager, explain why. solutions represent 50 to 60% of

the contractor in charge of the the contracts we handle. Once the

main structure? What are the most important facts of the use of space and layout. This contractor is awarded the con-

P. N. – Sometimes, particularly in about Freyssinet Middle East’s is exactly the type of span permit- tract, we provide assistance with

Ireland, we are involved with the floor prestressing business? ted by our technique, which also implementation and materials,

general contractor, but more often KHALIL DOGHRI. – The technique, brings many other advantages, such as cables, sheaths, anchors,

than not our customer is in fact the which is limited to bonded pre- such as reduced floor thickness, etc. Our site superintendents

”frame” contractor who is respon- stressing, began in the region in elimination of beams, reduction in supervise the general contractor’s

sible for the formwork, reinforcing the 1990s after being introduced building height, ease of installa- workers, who install the prestress-

and placing the concrete. We work by the Australians. Today it is tion for air conditioning equip- ing, but we are responsible for the

with them to produce the slabs. widely used in the Emirates, espe- ment, etc. The technique is also work and are present at the time of

Unlike in France, where small areas cially in Dubai which is going attractive for main structure con- pouring. Beyond the technical

are worked on with daily rotations, through a building boom – the tractors as it allows them to build aspects we emphasize quality of

we work on larger pour areas, world’s tallest tower is being built more quickly using less steel and service, which is an integral part of

sometimes greater than 1000 m2 there. Floor prestressing is part of at a lower cost. As far as the spread technical quality and the warranty

with a cycle time of 4 to 6 days. Our the offering of many companies, of the technique is concerned, we given for the work. In practice, this

role consists of installing the pre- some of which are from Asia, Aus- are in the opposite situation to the assumes faultless organization so

stressing elements, tensioning the tralia, India, etc., including one or one in France, but for the same that the materials are supplied

strands and injecting the ducts two general contractors that have reason; force of habit, the culture exactly when they are required.

with the cement grout. The tech- acquired the know-how for of engineers and the way compa- We also have to coordinate our

nique has not disrupted the organ- smaller projects. nies build have ensured the devel- involvement with the work on the

ization of sites as we are relatively opment of prestressing in the main structure, which not all sup-

independent in relation to the How do you explain this success? building floors. pliers can do. We could doubtless

other operations. We are the ones K. D. – Buildings with spans of improve our command of this

who adapt, and that’s why the main more than 7 m are being suggested How is your cooperation with the service and our competitiveness

structure contractors use our increasingly often by architects for general contractors organized? by sharing our experiences more

services. their greater convenience in terms KHALID RABADI. – Upstream of proj- at a Group level. ■

Second half of 2005 Soils & Structures 15

You might also like

- Specifications For Concrete Construction ACI 301-20: Field Reference ManualDocument6 pagesSpecifications For Concrete Construction ACI 301-20: Field Reference ManualIRFAN NAZIR50% (2)

- Insulation System Comparison VPI Versus Resin RichDocument9 pagesInsulation System Comparison VPI Versus Resin Richrifal1990No ratings yet

- Paper 009Document9 pagesPaper 009masterumNo ratings yet

- Grinding With Tube MillDocument43 pagesGrinding With Tube MillrecaiNo ratings yet

- Asoc Japonesa Del Jet GroutingDocument28 pagesAsoc Japonesa Del Jet Groutingponta10No ratings yet

- Cement Mill ReportDocument13 pagesCement Mill ReportYhaneNo ratings yet

- Jet Grouting For Soil ImprovementDocument7 pagesJet Grouting For Soil ImprovementkaistengineerNo ratings yet

- Water Leakages in Subsurface Facilities: Required Watertightness, Contractual Matters, and Methods of RedevelopmentDocument10 pagesWater Leakages in Subsurface Facilities: Required Watertightness, Contractual Matters, and Methods of Redevelopmentpujan gurungNo ratings yet

- Advantages of Steel Fibre Reinforced Con PDFDocument5 pagesAdvantages of Steel Fibre Reinforced Con PDFAce NovoNo ratings yet

- Polymer Composites-Student PresentationDocument26 pagesPolymer Composites-Student Presentationafia rahman100% (1)

- 3d Panel SystemDocument25 pages3d Panel Systemprobir100% (2)

- 2015 - Segmental Linings A Vision For The FutureDocument15 pages2015 - Segmental Linings A Vision For The FutureJoeNo ratings yet

- CIB Report 24 Tolerances On Blemishes of ConcreteDocument4 pagesCIB Report 24 Tolerances On Blemishes of ConcreteKhaled NassarNo ratings yet

- 309.2R-98 Identification and Control of Visible Effects of Consolidation On Formed Concrete SurfacesDocument11 pages309.2R-98 Identification and Control of Visible Effects of Consolidation On Formed Concrete SurfacesKalidas MuthusamyNo ratings yet

- Post Tensioning in Building StructuresDocument21 pagesPost Tensioning in Building StructuresLuan Truong VanNo ratings yet

- Composite Shell Lining For Tunnels and Mined StationsDocument7 pagesComposite Shell Lining For Tunnels and Mined StationsDEBASIS BARMANNo ratings yet

- 915 Mapesonic-Cr GBDocument4 pages915 Mapesonic-Cr GBTheFreeSpiritNo ratings yet

- GE March 1984 - Geotextiles As FiltersDocument9 pagesGE March 1984 - Geotextiles As FiltersMahmoudNo ratings yet

- Single Shell Lining For Road TunnelsDocument2 pagesSingle Shell Lining For Road TunnelsDebasis BarmanNo ratings yet

- 10 1680@gigdar 26056 0050Document9 pages10 1680@gigdar 26056 0050ishaq AllalNo ratings yet

- AD 2015 3sDocument76 pagesAD 2015 3sBhupendra Singh ButolaNo ratings yet

- Textile Reinforced ConcreteDocument6 pagesTextile Reinforced ConcreteHiệpNo ratings yet

- Functions and Installation of Paving Geosynthetics: S.K. ShuklaDocument8 pagesFunctions and Installation of Paving Geosynthetics: S.K. ShuklamojeebmashalNo ratings yet

- Engineering Structures: SciencedirectDocument17 pagesEngineering Structures: SciencedirectAndy GarciaNo ratings yet

- DEPROTEC R - PUR Product Information PR00218808-1Document2 pagesDEPROTEC R - PUR Product Information PR00218808-1pedro davilaNo ratings yet

- World Pipelines - For The Best Protection Against Corrosion 02Document8 pagesWorld Pipelines - For The Best Protection Against Corrosion 02Pammy JainNo ratings yet

- The Practice of Warping Double TeesDocument17 pagesThe Practice of Warping Double Teesunix0123No ratings yet

- Automation in Construction: Taylor Marchment, Jay Sanjayan TDocument12 pagesAutomation in Construction: Taylor Marchment, Jay Sanjayan TficuniNo ratings yet

- Concrete Construction Article PDF - Mortarless Block Systems PDFDocument4 pagesConcrete Construction Article PDF - Mortarless Block Systems PDFsurabhi s vNo ratings yet

- MiTek Guide To PosiStrut Floor CassettesDocument12 pagesMiTek Guide To PosiStrut Floor CassettesAndraz HrovatNo ratings yet

- Fachada de Doble Piel PorosaDocument14 pagesFachada de Doble Piel PorosaKenneth Ayala CastroNo ratings yet

- Tunnelling and Underground Space Technology: M. Ramoni, G. AnagnostouDocument19 pagesTunnelling and Underground Space Technology: M. Ramoni, G. AnagnostouFederico MalteseNo ratings yet

- The New and Current Statutory Directors' DutiesDocument3 pagesThe New and Current Statutory Directors' DutiesEudkrenutNo ratings yet

- Decoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesDocument6 pagesDecoding Multi-Purpose Waterproofing, Crack Isolation, Sound Reduction and Uncoupling MembranesibrahimNo ratings yet

- FBS Ii enDocument10 pagesFBS Ii enunsalNo ratings yet

- NSPFEM2D: A Lightweight 2D Node-Based Smoothed Particle Finite Element Method Code For Modeling Large DeformationDocument16 pagesNSPFEM2D: A Lightweight 2D Node-Based Smoothed Particle Finite Element Method Code For Modeling Large DeformationShu-Gang AiNo ratings yet

- Conceptual Stability Check For PilingDocument5 pagesConceptual Stability Check For PilingEudkrenutNo ratings yet

- AnchoringDocument20 pagesAnchoringjack21abNo ratings yet

- Aircrete - Movement JointsDocument3 pagesAircrete - Movement JointsAntonino MancinelliNo ratings yet

- U Boot BetonDocument23 pagesU Boot BetonMegha KallihalNo ratings yet

- Behaviour of 3D-Panels For Structural Applications Under General Loading: A State-Of-The-ArtDocument10 pagesBehaviour of 3D-Panels For Structural Applications Under General Loading: A State-Of-The-ArtVirat DesaiNo ratings yet

- Ultra Thin WhitetoppingDocument21 pagesUltra Thin WhitetoppingChetan PatilNo ratings yet

- Fosroc Renderoc Tgxtra: Constructive SolutionsDocument2 pagesFosroc Renderoc Tgxtra: Constructive SolutionsVincent JavateNo ratings yet

- New Technology Spurs Market For Large Panel Precast Concrete BuildingsDocument13 pagesNew Technology Spurs Market For Large Panel Precast Concrete BuildingsBrenton ThompsonNo ratings yet

- 2019 - JCEA - Design of Industrial Floors - TR34 and Finite Element Analysis (Part2)Document11 pages2019 - JCEA - Design of Industrial Floors - TR34 and Finite Element Analysis (Part2)Juhász KPNo ratings yet

- Technology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemDocument8 pagesTechnology Profile Glass Fibre Reinforced Gypsum (GFRG) Panel Building SystemShanmuga SundaramNo ratings yet

- Fosroc Renderoc Laxtra Plus: Constructive SolutionsDocument2 pagesFosroc Renderoc Laxtra Plus: Constructive SolutionsVincent Javate0% (1)

- Large Underground Constructionfor MetroDocument4 pagesLarge Underground Constructionfor MetroIndesign SPANo ratings yet

- D-Product Watch Crigler Post Tension Revisit1Document4 pagesD-Product Watch Crigler Post Tension Revisit1khx2No ratings yet

- Joint Free Slabs On Grade: Warwick ColefaxDocument13 pagesJoint Free Slabs On Grade: Warwick Colefaxmohannad eliassNo ratings yet

- Littlejohn 1970Document12 pagesLittlejohn 1970George HaileNo ratings yet

- Compaction Grouting: Prospekt 66-01EDocument12 pagesCompaction Grouting: Prospekt 66-01EehraulNo ratings yet

- Bai Bao Xac Dinh ModulDocument9 pagesBai Bao Xac Dinh ModulThái Trân LêNo ratings yet

- SPE 100747 Expandable Sandface Completions-Design and Performance Review of Single-Zone Applications and Journey To Next-Generation Multizone SystemsDocument8 pagesSPE 100747 Expandable Sandface Completions-Design and Performance Review of Single-Zone Applications and Journey To Next-Generation Multizone SystemsyasamanNo ratings yet

- RENDEROC HSXtraDocument2 pagesRENDEROC HSXtratalatzahoorNo ratings yet

- En Remak X Ig 2021Document20 pagesEn Remak X Ig 2021Munkhtur BNo ratings yet

- 1-Structural Behavior of Precast Tunnel Segments Under TBM Thrust ActionsDocument10 pages1-Structural Behavior of Precast Tunnel Segments Under TBM Thrust Actionssbaia amineNo ratings yet

- Viscous Dampers PDFDocument4 pagesViscous Dampers PDFdxzaberNo ratings yet

- IRJET-Solid Flooring by Using Tremix Method-Literature ReviewDocument4 pagesIRJET-Solid Flooring by Using Tremix Method-Literature ReviewKavitha BVNo ratings yet

- Expoband One: Flexible Expansion Joint MembraneDocument3 pagesExpoband One: Flexible Expansion Joint MembraneSure Tech TrivandrumNo ratings yet

- Fischer Concrete Screw: The High-Performance Concrete Screw For Absolute Installation EaseDocument10 pagesFischer Concrete Screw: The High-Performance Concrete Screw For Absolute Installation Easechong pak limNo ratings yet

- Bridge Report Barrette PilesDocument4 pagesBridge Report Barrette PilesJJ AustriaNo ratings yet

- SHA316Document6 pagesSHA316masterumNo ratings yet

- Paper 015Document7 pagesPaper 015masterumNo ratings yet

- Paper 004Document8 pagesPaper 004masterumNo ratings yet

- Paper 181Document13 pagesPaper 181masterumNo ratings yet

- Paper 086Document12 pagesPaper 086masterumNo ratings yet

- Paper 013Document8 pagesPaper 013masterumNo ratings yet

- Paper 007Document8 pagesPaper 007masterumNo ratings yet

- EFCA Future Scenarios Report 2021Document28 pagesEFCA Future Scenarios Report 2021masterumNo ratings yet

- BureauVeritas - Building Tech ControlDocument2 pagesBureauVeritas - Building Tech ControlmasterumNo ratings yet

- MEAT Booklet FinalDocument32 pagesMEAT Booklet FinalmasterumNo ratings yet

- EFCA Guideline Good Practices - March 2021Document14 pagesEFCA Guideline Good Practices - March 2021masterumNo ratings yet

- Construction 2050 Paper - Final2Document10 pagesConstruction 2050 Paper - Final2masterumNo ratings yet

- EFCA Trends Booklet - Final Version - 05 06 2018Document22 pagesEFCA Trends Booklet - Final Version - 05 06 2018masterumNo ratings yet

- EFCA Sector Review 2021 - 0Document12 pagesEFCA Sector Review 2021 - 0masterumNo ratings yet

- Artigo Michel PorterDocument100 pagesArtigo Michel PortermasterumNo ratings yet

- One Metro World Jug CerovicDocument254 pagesOne Metro World Jug CerovicmasterumNo ratings yet

- I S S U E O N E 1 9 9 8: Batam-Tonton Cable-Stayed BridgeDocument16 pagesI S S U E O N E 1 9 9 8: Batam-Tonton Cable-Stayed BridgemasterumNo ratings yet

- EFCA Liability and Insurance Booklet - 0Document76 pagesEFCA Liability and Insurance Booklet - 0masterumNo ratings yet

- Your Solution Network: North East AsiaDocument20 pagesYour Solution Network: North East AsiamasterumNo ratings yet

- Strategies For Packages Environmental Friendly Foundations Full Span Pre-Casting in TaiwanDocument32 pagesStrategies For Packages Environmental Friendly Foundations Full Span Pre-Casting in TaiwanmasterumNo ratings yet

- News 1990 2Document16 pagesNews 1990 2masterumNo ratings yet

- International: Stainless Steel in Structural Applicationsturais Arestalfer Exports Steel Composite Bridge To MadagascarDocument52 pagesInternational: Stainless Steel in Structural Applicationsturais Arestalfer Exports Steel Composite Bridge To MadagascarLuísNo ratings yet

- Metalica International 03Document55 pagesMetalica International 03masterumNo ratings yet

- Metalica Internacional 7 PDFDocument105 pagesMetalica Internacional 7 PDFLuísNo ratings yet

- Metalica Internacional 4Document52 pagesMetalica Internacional 4bluefish80No ratings yet

- Freyssinet Magazine 207Document20 pagesFreyssinet Magazine 207masterumNo ratings yet

- Freyssinet Magazine 208Document20 pagesFreyssinet Magazine 208masterumNo ratings yet

- Freyssinet Magazine 216Document24 pagesFreyssinet Magazine 216masterumNo ratings yet

- Irc 059-1976Document21 pagesIrc 059-1976kruttika_apNo ratings yet

- 14 - Appendix 1 PDFDocument7 pages14 - Appendix 1 PDFAnonymous qAPTE8REmnNo ratings yet

- Concrete TechnologyDocument5 pagesConcrete Technologykamardeen mustafa100% (1)

- Product Offer Letter SAMPLEDocument4 pagesProduct Offer Letter SAMPLESam SamNo ratings yet

- CONCRETEDocument60 pagesCONCRETEAnna KateurinaNo ratings yet

- Design For DCM ColumnsDocument2 pagesDesign For DCM ColumnsTruong Phuoc TriNo ratings yet

- C Ce 200Document59 pagesC Ce 200hanieh rezapourNo ratings yet

- Megaflow Sp1: High Range Water Reducing SuperplasticiserDocument2 pagesMegaflow Sp1: High Range Water Reducing SuperplasticiserEsmaelDawudNo ratings yet

- Shotcreting Method Statement - RMZ The VaultDocument3 pagesShotcreting Method Statement - RMZ The VaultRakesh ReddyNo ratings yet

- CSA Product InformationDocument3 pagesCSA Product InformationAbdul Falahitawan UfalNo ratings yet

- Aggregate Gradations For Concrete Pavement Mixtures: "Moving Advancements Into Practice"Document4 pagesAggregate Gradations For Concrete Pavement Mixtures: "Moving Advancements Into Practice"laura julieth sanchezNo ratings yet

- Concrete Properties SlidesDocument10 pagesConcrete Properties Slidesaksh007No ratings yet

- Holcim Cements: Holcim Sanstha: The All-Purpose Cement Ideal For ConcreteDocument4 pagesHolcim Cements: Holcim Sanstha: The All-Purpose Cement Ideal For ConcreteInoshan Madushika JayawickramaNo ratings yet

- Cellular Light Weight Concrete Using Glass FiberDocument5 pagesCellular Light Weight Concrete Using Glass Fibermidhila vkNo ratings yet

- Roof Beam Design CalculationDocument5 pagesRoof Beam Design CalculationArnold VercelesNo ratings yet

- Xxx... CSE 224-Engineering Materials IIDocument5 pagesXxx... CSE 224-Engineering Materials IICidy ByronNo ratings yet

- Unit Weight of Building Materials Used in Construction WorksDocument3 pagesUnit Weight of Building Materials Used in Construction WorksifyNo ratings yet

- Signage Costing Concrete Text 0192893Document3 pagesSignage Costing Concrete Text 0192893Jeremy BuelbaNo ratings yet

- Flex Design Ch05Document19 pagesFlex Design Ch05gbf2009No ratings yet

- U.S. Shotcrete Standards Update: by Charles HanskatDocument3 pagesU.S. Shotcrete Standards Update: by Charles HanskatmalikNo ratings yet

- Surigao State College of TechnologyDocument5 pagesSurigao State College of TechnologyJea MosenabreNo ratings yet

- Reinforcement Steel FormatDocument18 pagesReinforcement Steel FormatRASCON BUILDNo ratings yet

- PARIDocument2 pagesPARIWilman OngNo ratings yet

- OPSS - PROV 1350 Ontario Specs 1305Document28 pagesOPSS - PROV 1350 Ontario Specs 1305hahaerNo ratings yet

- HOD-P & QC Work BookDocument6 pagesHOD-P & QC Work BookvinodsnNo ratings yet