Professional Documents

Culture Documents

Method Statement Store: Editable Documents Catalog

Uploaded by

BAWA ALEXOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement Store: Editable Documents Catalog

Uploaded by

BAWA ALEXCopyright:

Available Formats

Method Statement Store

Download Editable Construction Document Files

Editable Documents Catalog

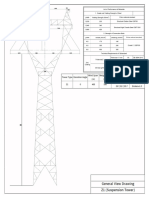

Trench Preparation Excavation and

Backfill Method Statement for Electric

Underground Cable Laying

The purpose of this document is to specify the

procedure for excavation backfilling and trench

preparation for installation of 132 kV cables and fiber

optic Cables.

Roles & Responsibilities

Project Manager: Lead all construction activities and

enforce strict adherence to all procedures.

Site Manager: Lead the construction activities at site

and report to the Project Manager.

Field Engineer: Ensure that all related works are

carried out in accordance with the approved drawing

and project specification. Report to the site manager.

QA/QC Engineer : Responsible for the necessary

quality control implementation by following the

customer specification.

Supervisor : Supervise field installations and report to

the field engineer.

HSE Officer : Ensure that all the site activities are

carried out in accordance with the project health and

safety plan.

Necessary Tools and Equipment’s

Hand tools for Excavation

Hand Shovels

Plastic Buckets

Wheel Barrows

Equipment’s

Jack hammer for removing hard strata like asphalt

and Rocks

Crane & Buckets – shall be used to remove

excavated material from pit where pit is not

accessible by other methods.

Plate compactor, Mechanical Tampers to compact

the backfilling materials.

Air compressors

Water tankers

Excavation & Backfilling

Preparations and Preconditions

Permit to Work (PTW) shall be raised for the

excavation clearly mentioning the location of work,

size of excavation and levels.

Excavations area shall be surveyed and marked to the

lines and levels as shown on the drawings.

The area of excavation will be cordoned off using

safety barricading to stop trespassers.

Assign sufficient banks men, helpers and supervisors

at the site prior to start of excavation.

Required sign boards such as “DEEP EXCAVATION”

“MEN WORKING” “DANGER” and warning boards will

be placed to indicate the excavation work.

Ensure the working area at any confined space is free

from any Hazardous Gas by proper Gas testing using

the Gas testing instrument.

Proper temporary supports shall be provided to the

adjacent structure prior to start excavation.

Fences and minor structures of any character or upon

within the limits of the works and not necessary for

the construction shall be removed carefully and stored

neatly for reinstating after the construction works.

If any Survey points, bench marks, boundary stones

and markings falling on the area shall be removed only

with the client’s written consent and shall be stored

and reinstated according to their instructions.

Check the area of excavation to find out any

underground facilities other than listed in

topographical survey by:

Using appropriate detective equipment, such as cable

detector, metal detector etc.

Check existing exposed excavation nearby area to find

out existing underground facilities.

Refer available As-built drawings from the consultant,

other agencies, other contractors doing projects

nearby areas and mark in the area.

Take trial/ test pits to find out existing underground

pipes, structures.

Check the indication marks, signs, manholes nearby

area and find out the path of services.

Trial Pit and Excavation Procedures

Prior to star of any excavation, the area shall be

checked for the existing services/utilities by obtaining

the approvals with reference to the relevant drawings.

The necessary excavation activities shall start only

after getting the notice intent from the client /

customer.

Excavation of the trial pits shall be done manually as

per the size indicated in the approved drawings up to

the required length and level.

In open areas the excavation shall be carried out by

using the machineries, the exact location of each

trench and pit being subjected to the prior approvals.

Manual excavation will be carried out to expose the

existing utilities, if any, which has to be identified.

The trenches shall be kept dry during cable

installation operation. The contractor shall deal with

the dispose of water so as to prevent any risk to the

cables and other materials.

Contractor shall provide suitable dewatering methods

as explained in section 6.0 while performing the works

according to the scope of work.

The required control measures shall be developed and

implemented while performing the works and more

importance will be given for public safety and

environmental issues.

While performing the work the trenches shall be

straight, free from any sharp objects/edges likely to

injure the cable or accessories and filled with soft

sand and sieved sand to form smooth bedding before

the cables are laid.

The contractor shall take the necessary precautions to

prevent damage to the road or ground surface due to

a slip or breaking away from the side walls of the

trench including the pedestrian safety as well.

The vehicle entry shall be restricted on the specified

work area by prior approval from the concerned

agencies.

Where ever there is a crossover of the existing

services/utilities, these shall be protected with utmost

care with the prior permission of concerned

authorities and approved methods. The contractor

shall obtain the necessary approval from the client /

consultant or the concerned authorities to according

to the scope of the work.

Excavate the area by using only hand tools as per the

markings and levels with proper protection of sides. If

excavation depth exceeds 1.2 m proper shoring and

shuttering should be provided as per the safety norms

or the excavation shall be stepped, wide enough to

get stable slope on sides of wall from soil sliding.

Excavations in sand shall be to a slope of 1:3, one

vertical to three horizontal. If any permanent slope is

to be kept in the sand it shall be stabilized by one of

the following means,

Mass concrete blinding

Cement/sand mixture

Bituminous/cement mixture

Trim and form the edges of soil to profiles and levels

as indicated in drawings.

If the excavation level is below the local water table

level suitable dewatering system (well point method

and/or pump and sump method, refer section 6.0)

shall be designed and installed in such a way that

alterations and extensions to the system during

operations are possible.

For Rock excavation hard excavation shall be carried

out by ripping, excavation, wedging, chiseling using

jack hammers, or by other recognized methods

approved by consultant. Blasting will not to be

adopted under any circumstances for rock excavation.

In trench excavation the bottom width of at least in

800 mm plus the dimension of pipes, conduits, ducts,

etc to be installed.

The bottom of the excavation shall be levelled and

trimmed to receive the permanent works. The bottom

of the excavation shall be moisture conditioned to +

2% of optimum and mechanically compacted to a

density of not less than 95% of the maximum dry

density.

Precautions shall be taken to protect the bottom of

the excavation and, if the bottom of the excavation

becomes unsuitable either by exposure to weather

conditions, water, or due to any other reasonably

foreseeable event, it shall be removed and replaced

with suitable materials.

Provide proper rigid barriers around excavations

include provision of ladders, emergency escape way,

adequate side slopes or shoring and shuttering,

detours.

If fossil content is noticed during excavation shall be

brought in notice of the OWNER.

The top width of excavation shall be increased or

depend upon the depth of excavation , It is required

to provide suitable slope to side of excavation to avoid

soil sliding, then the top trench width shall be

increased accordingly by step cutting method. If the

top width of excavation is restricted due to

existing facilities then protect the side of excavation

with proper shoring.

If the bottom of excavation is loose strata then

excavate 300 mm more to select fill materials to form

a hard and compacted grade strata for construction.

If the bottom of excavation is below the water table

level, provide proper shoring prior to excavate below

the water table level then excavate 300 mm more to

fill Aggregates or Gravel to form a hard grade strata.

Excavation Adjacent to Underground Services

Excavation near the existing electrical cables,

instrumentation and control cables, sewer line, gas

lines and any other service line shall take all necessary

precautions to protect the services with proper

supports & covers.

All existing structures, foundations, pipes and cables,

if any, which are to be incorporated into the final work,

shall be adequately protected from damage.

All underground services located during excavation

shall be mapped for consideration during construction

of the works.

If any underground service is noticed other than

specified in the area during excavation shall be

brought in notice of the client.

Excavation shall not be carried out adjacent to or near

existing building foundations, without suitable

shoring/sheet piling.

Over Excavation

In case excavations executed beyond the established

levels, backfill the over excavation with lean concrete

or other approved material.

The volume corresponding to the over excavation shall

not be carried out adjacent to or near existing building

foundations, until suitable shoring/sheet piling has

been installed.

Stockpiles and Disposal

Excavation material shall be removed, stockpiled or

deposited away from the excavation area for reuse, or

disposed in the approved dumping area as directed by

OWNER/Engineer’s.

Debris, rocks and unusable materials shall be removed

on daily basis from the site to approved dumping area

or final destination whether in the work or in the waste

areas, including any necessary temporary stockpiling

and the additional loading and transporting.

Only permitted materials or selected materials from

excavation shall be stored or stockpiled for re-use.

Refilling of Excavation

The refilling of excavations shall be started as soon as

practicable after the permanent works have been

tested and approved by the consultant.

Refilling of trenches over pipes shall be done by hand

to a depth of 300 mm above the crown of the pipe

with dune sand or lightly compacted selected

excavated material free from large stones, rock, clay

lumps or other substances which may cause damage

to the permanent works.

Refill the leftover portions with suitable backfilling

material in 300 mm per layer which shall be fully

compacted by mechanical tamper/plate

compactor/roller and tested in accordance to project

requirements.

Backfilling of Trenches

Backfilling area shall be backfilled with approved

material compacted in layers by suitable equipment

like plate compactors, vibratory roller compactors,

etc., until the specified density has been obtained to

the satisfaction of the client.

Compacting shall be carried out with special care by

means of mechanical tampers of a type approved by

client to avoid damage to structures.

Areas to be backfilled shall be prepared so as to

obtain a soil density at least equal to 95 percent of

Standard Proctor test (ASTM D 698).

Backfilling Materials

Backfilling materials shall be free from stones or rocks

larger than 50 mm, or other material which might

prevent proper compaction or cause the compacted

fill or embankment to perform inadequately.

Backfilling materials shall be free from fossil content,

clay, vegetations and its roots, waste materials,

Material containing gypsum or other soluble salts

greater than the allowable limits.

Following classified materials shall not be used for

backfilling.

Organic material, logs stumps and perishable

materials.

Material susceptible to spontaneous combustion.

Materials with undefined properties.

Materials having moisture content greater than the

maximum specified.

Building rubble and domestic and industrial wastes.

Soils and rock susceptible to deterioration/change

of their properties.

Clay, silt and other loose or soft soils not in

accordance with compaction criteria.

Dredged material.

Rock materials

Filling of Materials

Fill material shall be spread and compacted in 300

mm layers, with a compacted layer thickness not

exceeding 300 mm where mechanical compactors like

vibratory plate/drum compactors are used.

The thickness of fill material shall not exceed 150 mm

where manual compaction methods are adopted.

If the thickness of loose fill layers required to exceed

300 mm written approval including methods of

compaction shall be required from the client.

If the surfaces receiving fill layers is smooth, then

scarified to obtain a good friction/key between the

new fill layer and the sub grade.

Rock fill or aggregate fill materials shall be deposited

under water with the client’s permission. Fill materials

like cohesive soil (i.e. soils that possess low shear

strength, are plastic and compressible, deforms

plastically under constant load, changes volume in the

presence of water) shall not be permitted deposit

under water.

Where swamps, bogs or other similar wet areas must

be traversed by the works, they shall be drained as

directed by the client according to the material and

conditions encountered. Prior to the formation of

embankments, fill, etc. any unsuitable material

occurring on the site shall be removed to such depths

and widths as may be directed by the client and

approved excavations shall be properly backfilled with

suitable and approved excavated materials and shall

be deposited and compacted to the satisfaction of the

client. Similarly, soft or weak spots encountered will

be removed and, as with any voids, will be backfilled

as specified.

Final layer of backfilling shall not contain soft rock

fragments exceeding 50mm upon placement to the

satisfaction of the OWNER/ENGINEER’S.

Trench backfilling containing pipes shall be properly

packed at the sides with sand which shall be well

rammed with narrow wooden rammers before filling

further. The filling shall then be carried up to 150 mm

above any sand or concrete surround with fine

selected material and well watered and rammed. The

remainder of the trench shall then be refilled in layers

not exceeding 300 mm thickness, watered and

rammed until the ground is thoroughly consolidated.

No mechanical rammer shall be used with 300 mm of

the top of any pipe or surround and material shall not

be drooped from a height.

The top surface area shall be dense and level without

any protruding rock fragments in excess of 50 mm,

recesses or soft spots, to the satisfaction of the client.

Tolerance level shall be maintained as per the

specifications

Excavated materials may only be used for backfilling

after obtaining satisfactory approved lab test results;

otherwise fill materials shall be imported to the site.

Formation of Cable Trench

The formation of the trench shall be in accordance

with applicable standard and specifications.

The trench shall be excavated upto the required depth

of 1.3m from the existing ground level.

Dune sand bedding shall be done for a thickness of

150mm at the bottom of the trench using TR tested

and approved dune sand, prior to the installation of

cables.

Cables and the 4” uPVC pipes for the FO Cables are

laid over the dune sand bedding

Sand Filling

TR tested and approved sand (Max 120°C cm/W) is

filled in the trench to the required level as per

approved drawing.

Sufficient Water is poured to match the required

Moisture content and to get 95% MDD

Cable protection tiles are laid above the dune sand

filling

Final Backfilling

Ensure the Concrete Cable Tiles are securely placed.

Selected sieved materials from the excavated soil shall

be backfilled for a thickness of 250mm above the

cable protection tiles. Care shall be taken to avoid

stones and boulders mixing with the backfill material.

Install 132kV Cable Warning Tape at a height of

250mm from top of the concrete cable tiles

Backfill to the required level in similar way.

Ensure Proper Compaction of soil is done after every

150mm layer laid.

Reinstate the area as to its original situation.

Compaction of the Back Filling Material

The required density shall not be less than 95%

Modified Proctor under Roads and pavements. This

shall be obtained by compaction in layers by means of

rollers and/or dozers, applying as many passes as may

be necessary and to the approval of the consultant.

Sweet water or portable water from a source approved

by the company shall be sprayed on the placed

material prior to compaction where necessary to

achieve the optimal moisture content.

Brackish or salt water is not allowed to be used in

compaction.

The density of each placed and compacted layer shall

be established by testing prior to the placement of

subsequent layers. If the results of test indicates that

the required density is not being achieved further

tests shall be carried out.

Compacted Soil Testing

All the testing shall be carried out to the satisfaction

of client. All such tests shall be carried out at a

laboratory approved by clients. Results of all tests

shall be approved by client. Filling of subsequent

layers shall not commence till approval from

consultant is obtained.

Field density testing shall be in accordance with

BS1377 at a minimum frequency of one per 5000 m2

per layer shall be achieved.

Tolerance limit for the permanent finished earth work

shall be included as stated in specifications.

The top surface area of the finished surface shall be

dense and level without any protruding rock fragment

in excess of 50 mm, recesses or soft spots, to the

satisfaction of client.

Share via:

Facebook Twitter LinkedIn

More

Related Posts:

Method Construction

Statement for Quality Control

Cable Laying and Procedure for

Termination for Excavation Earth

Control and Work and Back

Signal Cables Filling

(Foundations)

Concrete Works Honeycombing,

Method Shrinkage

Statement for Cracks, Tie-Rod

Construction Holes and

Project Blowholes

Concrete

trench

cable

preparation

trench backfill

Repairing Method

for

direct

cable

burial

, underground

cable

cable

Statement

, ,

" Back Filling , backfill meaning , cable laying ,

Electrical Method Statement

! Construction Method Statement ,

#Previous Next

$

SEARCH

Join for Latest Method Statements

Enter your email address:

SUBSCRIBE

Delivered by FeedBurner

Street Light Pole Foundation Construction Method Statement

Control Panel and Electrical Junction Box Installation Electrical

Work Method

Sca!olding Shuttering Formwork Erection, Removal and

Dismantling Method Statement

AC Air Duct Cleaning Procedure

Grease Trap Installation Procedure

Storm Drainage Water Piping Network Method Statement

My Selected Documents

Browse by Category

Civil Method Statements

Electrical Method Statements

Mechanical Method Statements

Discounted Method Statement Packages

Plumbing Method Statements

HVAC Method Statements

Project Plans

Testing and Commissioning Method Statements

Project Management

Commercial & Finance Management Procedures

Corporate Management Procedures

HSE Procedures

Construction Risk Assessment

Quality Management Procedures

Fire Fighting Method Statements

Latest Additions

Road Works Method Statements & Supporting …

$9.99

Process Control Management Procedure for Co…

$2.99

Extension of Time Schedule EOT Project Manag…

$3.49

You might also like

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- WMS-HAND EXCAVATION & BACKFILLING - Rev1Document10 pagesWMS-HAND EXCAVATION & BACKFILLING - Rev1nice hossainNo ratings yet

- Lanco Infratech Limited: Proposed Methodology of Construction 1. Collection of DrawingsDocument9 pagesLanco Infratech Limited: Proposed Methodology of Construction 1. Collection of Drawingslinesh3No ratings yet

- Trench Preparation Excavation and Backfill Method Statement For Electric Undergr 2024-02-13 07 - 31 - 03Document16 pagesTrench Preparation Excavation and Backfill Method Statement For Electric Undergr 2024-02-13 07 - 31 - 03Tomas Casillas-GerenaNo ratings yet

- Ek 29 Boru Hattı Montaj Uygulama Planı (Pipeline Erection Method Statement) ÖrneğiDocument6 pagesEk 29 Boru Hattı Montaj Uygulama Planı (Pipeline Erection Method Statement) ÖrneğiMohamed100% (1)

- Excavation Work Guidelines For Irrigation and Water Supply ProjectsDocument9 pagesExcavation Work Guidelines For Irrigation and Water Supply ProjectsKaram MoatasemNo ratings yet

- Method Statement For Installation of Sanitary Vent and Storm Drainage PipingDocument5 pagesMethod Statement For Installation of Sanitary Vent and Storm Drainage PipingDong VanraNo ratings yet

- 2750 - MS For Cable Crossing Under ORPIC PipelinesDocument6 pages2750 - MS For Cable Crossing Under ORPIC PipelinesGeeks PondNo ratings yet

- Mos - RPR Pipe JackingDocument11 pagesMos - RPR Pipe Jacking7e1a8821No ratings yet

- Install Sanitary Vent Storm Drain PipingDocument6 pagesInstall Sanitary Vent Storm Drain Piping721917114 47No ratings yet

- Flood Protection Method - StatementDocument4 pagesFlood Protection Method - Statementthowchin100% (1)

- Method StatementsDocument131 pagesMethod StatementsRavi MishraNo ratings yet

- Detailed Specifications - EarthworkDocument10 pagesDetailed Specifications - EarthworkKishan KumarNo ratings yet

- Method Statement For Excavation Compaction and BackfillingDocument8 pagesMethod Statement For Excavation Compaction and BackfillingIna RoseNo ratings yet

- Method Statement For Compaction and BackfillingDocument8 pagesMethod Statement For Compaction and BackfillingJohn MofireNo ratings yet

- Section 801 Excavation Backfilling and Compaction For Sanitary SewersDocument17 pagesSection 801 Excavation Backfilling and Compaction For Sanitary SewersTAHER AMMARNo ratings yet

- Methodology For TrenchingDocument6 pagesMethodology For Trenchinginsk0% (1)

- 30.01.23 MS For Excavation of Trial Pit - Trench - R1 - From GLCPL - FinalDocument8 pages30.01.23 MS For Excavation of Trial Pit - Trench - R1 - From GLCPL - FinalsuratNo ratings yet

- Excavation PlanDocument8 pagesExcavation PlanNajim Habib100% (2)

- Method Statement of Pipeline WorksDocument13 pagesMethod Statement of Pipeline Worksमनिसभेटुवाल86% (21)

- SPECIFICATIONSDocument4 pagesSPECIFICATIONSHimani NagarNo ratings yet

- Construction of Proposed Paarth Republic Tower -1 Plot GH-1 KanpurDocument76 pagesConstruction of Proposed Paarth Republic Tower -1 Plot GH-1 KanpurPushp RanjanNo ratings yet

- Construction of Proposed Paarth Republic Tower -1 Plot GH-1 KanpurDocument76 pagesConstruction of Proposed Paarth Republic Tower -1 Plot GH-1 KanpurPushp RanjanNo ratings yet

- WMS (Earthwork)Document5 pagesWMS (Earthwork)PUI CHEE KHIANNo ratings yet

- Excavation and Backfilling MethodDocument14 pagesExcavation and Backfilling MethodHasann MaawiaNo ratings yet

- Concrete Foundation Installation MethodDocument11 pagesConcrete Foundation Installation MethodAung Naing Latt AungNo ratings yet

- Method Statement For Raft FootingDocument5 pagesMethod Statement For Raft FootingLokesh SaranNo ratings yet

- Contec Project FinaleDocument15 pagesContec Project FinaleephragekaroNo ratings yet

- General Inspector Training 20180727 Rev BDocument39 pagesGeneral Inspector Training 20180727 Rev BYusuff YuzuakkNo ratings yet

- Method for Alumina Fluride Storage Foundation WorkDocument5 pagesMethod for Alumina Fluride Storage Foundation WorkMD AbdullahNo ratings yet

- City of Olathe Revised June 1, 2007 TS/60-1Document9 pagesCity of Olathe Revised June 1, 2007 TS/60-1Hizbar ArsjadNo ratings yet

- Qap R1Document63 pagesQap R1Rohit NegiNo ratings yet

- MS Manhole ChambersDocument24 pagesMS Manhole ChambersAbdul Muneer PalapraNo ratings yet

- EARTHWORK SpecificationDocument3 pagesEARTHWORK Specificationczarjeff3497No ratings yet

- MS Cable InstallationDocument32 pagesMS Cable InstallationTariq KhanNo ratings yet

- Excavation Procedure & Permitting GuideDocument4 pagesExcavation Procedure & Permitting GuideTengku & Wan ResourcesNo ratings yet

- Multi-purpose hall construction methodDocument9 pagesMulti-purpose hall construction methodMuhammadWazimAkramNo ratings yet

- Civil SpecificationsDocument65 pagesCivil SpecificationsmrkssastryNo ratings yet

- GD Earth Works R2Document22 pagesGD Earth Works R2sivaprasad_2k11No ratings yet

- 33 0401 UTIL Underground Pipe InstallationDocument5 pages33 0401 UTIL Underground Pipe InstallationfaissuNo ratings yet

- Method Statements for Construction WorksDocument17 pagesMethod Statements for Construction Worksmangeshshinde124No ratings yet

- Excavation and Sewer ConnectionDocument8 pagesExcavation and Sewer ConnectionMustafa SütcüoğluNo ratings yet

- A General1Document26 pagesA General1alep azizNo ratings yet

- Work Methodology, Road WorksDocument14 pagesWork Methodology, Road WorksFRANCIS KAGUANYUNo ratings yet

- Risk and Personnel SafetyDocument16 pagesRisk and Personnel SafetyCamille Andrea SequitinNo ratings yet

- Carriage and Stacking of Construction MaterialsDocument23 pagesCarriage and Stacking of Construction MaterialsHarshVardhanJoya100% (1)

- Drainage InstallationDocument5 pagesDrainage InstallationParvin RzayevNo ratings yet

- Method Statement For EmbankmentDocument5 pagesMethod Statement For EmbankmentAlbertyNo ratings yet

- Culvert Repair Method StatementDocument12 pagesCulvert Repair Method StatementAhmed GamalNo ratings yet

- Construction: Planning and Alignment: Planning Is A Fundamental and Challenging Activity in TheDocument4 pagesConstruction: Planning and Alignment: Planning Is A Fundamental and Challenging Activity in TheNisha PrakashNo ratings yet

- Safe excavation works plan for Cherrywood Project Phase 1Document46 pagesSafe excavation works plan for Cherrywood Project Phase 1Sajid ShahNo ratings yet

- Method Statement Pipe JackingDocument7 pagesMethod Statement Pipe Jackingsinthian88% (8)

- MS Boundary Relocation - Rev01Document3 pagesMS Boundary Relocation - Rev01Cameron MayNo ratings yet

- Method Statement For Installation of PVC uPVC Drainage Piping Under or Above GroundDocument7 pagesMethod Statement For Installation of PVC uPVC Drainage Piping Under or Above GroundDong VanraNo ratings yet

- Pipe Road Crossing MSDocument7 pagesPipe Road Crossing MSJeffrey WeyNo ratings yet

- CE 60 Project: 3-Storey Commercial Building DesignDocument123 pagesCE 60 Project: 3-Storey Commercial Building DesignAlex Joshua MaglasangNo ratings yet

- Specification & Quantities Estimating: Lecturer Maha MuhaisenDocument17 pagesSpecification & Quantities Estimating: Lecturer Maha MuhaisenCheng EngiNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Sewage Disposal Works: Their Design and ConstructionFrom EverandSewage Disposal Works: Their Design and ConstructionNo ratings yet

- Design of RCC Drain and Cable TrenchDocument4 pagesDesign of RCC Drain and Cable TrenchAmarendra Keerthi80% (5)

- Naypyitaw 1 & 2 DWG To SendDocument5 pagesNaypyitaw 1 & 2 DWG To SendBAWA ALEXNo ratings yet

- Final Report Edited R0Document17 pagesFinal Report Edited R0BAWA ALEXNo ratings yet

- STABILITY CHECKSDocument4 pagesSTABILITY CHECKSBAWA ALEXNo ratings yet

- Final ReportDocument10 pagesFinal ReportBAWA ALEXNo ratings yet

- Membership: Constitution of The Savings GroupDocument7 pagesMembership: Constitution of The Savings GroupBAWA ALEXNo ratings yet

- Standard Technical Specification 1657263134Document156 pagesStandard Technical Specification 1657263134BAWA ALEXNo ratings yet

- Sea Bed Near - Google SearchDocument1 pageSea Bed Near - Google SearchBAWA ALEXNo ratings yet

- Single-Column Pantograph Disconnectors For Outdoor Installation Type TFB - Three Poles InstallationDocument29 pagesSingle-Column Pantograph Disconnectors For Outdoor Installation Type TFB - Three Poles InstallationBAWA ALEXNo ratings yet

- TANESCO SOIL DESIGN DATADocument3 pagesTANESCO SOIL DESIGN DATABAWA ALEXNo ratings yet

- Code Blocks Free Download For Windows 10: Get Into PCDocument1 pageCode Blocks Free Download For Windows 10: Get Into PCBAWA ALEXNo ratings yet

- EOI - EDSA - NB-Review 2Document4 pagesEOI - EDSA - NB-Review 2BAWA ALEXNo ratings yet

- Ayebale Wilson and Bawa Alex Final Year Project 2019 BcivDocument101 pagesAyebale Wilson and Bawa Alex Final Year Project 2019 BcivBAWA ALEXNo ratings yet

- Soil Investigation Design Specification - 5.17Document6 pagesSoil Investigation Design Specification - 5.17BAWA ALEXNo ratings yet

- Foundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21Document22 pagesFoundation Design For 66kV Steel Poles Bo-Kenema-SOIL CLASS 2A-08-11-21BAWA ALEXNo ratings yet

- Design, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedDocument23 pagesDesign, Supply, Installation, Testing and Commissioning of Extension For Sgr-1 220Kv Transmission Line From Kingolwira To Msamvu Sinohydro Corporation LimitedBAWA ALEXNo ratings yet

- Cast in Place Pipe Anchor Pole FoundationDocument2 pagesCast in Place Pipe Anchor Pole FoundationBAWA ALEXNo ratings yet

- New China Standard-Q345B Changed To Q355BDocument1 pageNew China Standard-Q345B Changed To Q355BBAWA ALEXNo ratings yet

- 66kV SS TypeTower Foundation DrawingDocument2 pages66kV SS TypeTower Foundation DrawingBAWA ALEXNo ratings yet

- 66kv Ha & de Type Tower Foundation DrawidngDocument2 pages66kv Ha & de Type Tower Foundation DrawidngBAWA ALEXNo ratings yet

- 66kV SS TypeTower Foundation DrawingDocument2 pages66kV SS TypeTower Foundation DrawingBAWA ALEXNo ratings yet

- 66kV SS TypeTower Foundation DrawingDocument2 pages66kV SS TypeTower Foundation DrawingBAWA ALEXNo ratings yet

- Screenshot 2022-03-22 at 10.22.32 AMDocument1 pageScreenshot 2022-03-22 at 10.22.32 AMBAWA ALEXNo ratings yet

- How To Take Screen Shot Iphone 8 Plus - Google SearchDocument1 pageHow To Take Screen Shot Iphone 8 Plus - Google SearchBAWA ALEXNo ratings yet

- WP contentuploads202008UHDE Specs - Section 1 - Earth Work PDFDocument1 pageWP contentuploads202008UHDE Specs - Section 1 - Earth Work PDFBAWA ALEXNo ratings yet

- Electrical Analysis Tools: Power Line SystemsDocument10 pagesElectrical Analysis Tools: Power Line SystemsBAWA ALEXNo ratings yet

- Passports & Other Travel Documents Directorate of Citizenship and Immigration ControlDocument1 pagePassports & Other Travel Documents Directorate of Citizenship and Immigration ControlBAWA ALEXNo ratings yet

- Electrical Analysis Tools: Power Line SystemsDocument10 pagesElectrical Analysis Tools: Power Line SystemsBAWA ALEXNo ratings yet

- Screenshot 2022-03-31 at 3.14.55 PMDocument1 pageScreenshot 2022-03-31 at 3.14.55 PMBAWA ALEXNo ratings yet

- FARAJA MAHENGE TyrDocument78 pagesFARAJA MAHENGE TyrBAWA ALEXNo ratings yet

- Pilkington Profilit Techn Info enDocument12 pagesPilkington Profilit Techn Info enSalmonelo Abdul RamosNo ratings yet

- AMD DEL: Popat / Hitul MR AI0817Document1 pageAMD DEL: Popat / Hitul MR AI0817Mahan YadavNo ratings yet

- CIVL 222 AXIAL MEMBERSDocument27 pagesCIVL 222 AXIAL MEMBERSskhan247100% (1)

- Citect SCADA 2018 R2 - Configuration - Study GuideDocument19 pagesCitect SCADA 2018 R2 - Configuration - Study GuideAlex Sales0% (1)

- BLRBAC Emergency Shutdown Procedure (February 2012)Document18 pagesBLRBAC Emergency Shutdown Procedure (February 2012)SubburajMechNo ratings yet

- Mil STD 1686CDocument18 pagesMil STD 1686CNam NguyenNo ratings yet

- Mayne Pharma Annual Report 2012Document78 pagesMayne Pharma Annual Report 2012Deepa DevanathanNo ratings yet

- Odoo JS Framework Rewrite Brings New Views and TestingDocument68 pagesOdoo JS Framework Rewrite Brings New Views and TestingglobalknowledgeNo ratings yet

- Column:C2 900X900: Basic Design ParametersDocument2 pagesColumn:C2 900X900: Basic Design ParametersAnonymous tBhJoH5wgMNo ratings yet

- Cameron VBR-II (Variable Bore Ram) PackerDocument2 pagesCameron VBR-II (Variable Bore Ram) Packerjuan olarteNo ratings yet

- The Beatles Album Back CoverDocument1 pageThe Beatles Album Back CoverSophia AvraamNo ratings yet

- Juno Gi BrochureDocument2 pagesJuno Gi BrochureJerry VagilidadNo ratings yet

- Blue Assured Individual Health PlanDocument5 pagesBlue Assured Individual Health PlanahsanNo ratings yet

- Ssnt Question BankDocument32 pagesSsnt Question Bankhowise9476No ratings yet

- Cis Bin Haider GRP LTD - HSBC BankDocument5 pagesCis Bin Haider GRP LTD - HSBC BankEllerNo ratings yet

- More User Manuals OnDocument78 pagesMore User Manuals OnNicolae HincuNo ratings yet

- Meita Juniar - 41921200002 - Teknik Sipil Reg b2 Uas English For EngineerDocument18 pagesMeita Juniar - 41921200002 - Teknik Sipil Reg b2 Uas English For EngineerREG.B/41921200002/MEITA JUNIARNo ratings yet

- Greenville Chapter NRHS Aug 2009 NewsletterDocument8 pagesGreenville Chapter NRHS Aug 2009 Newsletterjshopper1No ratings yet

- L4 Examples - Exact Differential Equations PDFDocument16 pagesL4 Examples - Exact Differential Equations PDFCarlo EdolmoNo ratings yet

- GUEST REGISTRATION CARDDocument1 pageGUEST REGISTRATION CARDRasmi Ranjan Kar100% (1)

- Handling Precautions: Butterfly Valves (Common To All Models)Document9 pagesHandling Precautions: Butterfly Valves (Common To All Models)xaaabbb_550464353No ratings yet

- Rate of Grease Penetration of Flexible Barrier Materials (Rapid Method)Document3 pagesRate of Grease Penetration of Flexible Barrier Materials (Rapid Method)DanZel Dan100% (1)

- How To Sell Hillstone 306. Cloudhive v2.8Document98 pagesHow To Sell Hillstone 306. Cloudhive v2.8Emmanuel CoriaNo ratings yet

- DAA UNIT-3 (Updated)Document33 pagesDAA UNIT-3 (Updated)pilli maheshchandraNo ratings yet

- What is Cultural Heritage and Why it's ImportantDocument3 pagesWhat is Cultural Heritage and Why it's ImportantMiguel A. González LópezNo ratings yet

- 11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsDocument1 page11 Ways To Encourage Stakeholder Participation:: Writing Good Consultation QuestionsLuz Alinsunurin DulogNo ratings yet

- Analyzing Air Asia in Business Competition Era: AirasiaDocument14 pagesAnalyzing Air Asia in Business Competition Era: Airasiashwaytank10No ratings yet

- 12.CEH Module 3 Assignment 3.1Document7 pages12.CEH Module 3 Assignment 3.1piyuhNo ratings yet

- Somya Bhasin 24years Pune: Professional ExperienceDocument2 pagesSomya Bhasin 24years Pune: Professional ExperienceS1626No ratings yet

- Excerpt: "Railroaded" by Richard WhiteDocument38 pagesExcerpt: "Railroaded" by Richard Whitewamu885No ratings yet