Professional Documents

Culture Documents

Method Statement For Installation of Hume Pipe

Uploaded by

Đặng Quang HuyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Method Statement For Installation of Hume Pipe

Uploaded by

Đặng Quang HuyCopyright:

Available Formats

FOR APPROVAL

A 17.06.2020 L.C.Hai Y.H.Lee J.T.Seo For Approval

Rev Date Prepared Checked Approved Details of Revision

Owner

Owner’s Engineer

Contractor

DOOSAN HEAVY INDUSTRIES VIETNAM

Sub-Supplier

Bă)c Miê+n Trung Consultancy Investment Construction

And Trading Joint Stock Company

Project

NGHI SON 2 BOT THERMAL POWER PLANT PROJECT

(2 X 600 MW)

Title

(Housing Complex)

Method Statement for Installation of Hume Pipe

Document No. Rev. Page No.

NS2-DD09-P0UYK-770020 A 22 Pages

RECORD OF REVISIONS

Rev. Date Page Affected Description of Revision

A 17.06.2020 All First Issue

Table of Contents

1 PURPOSE ........................................................................................................................ 1

2 CODE AND STANDARD .................................................................................................. 1

3 MACHINERY & EQUIPMENT .......................................................................................... 1

4 PREPARATION ................................................................................................................ 2

4.1 Survey work ................................................................................................................ 2

4.2 Material ....................................................................................................................... 2

4.3 Delivery, Storage and Handling .................................................................................. 2

5 EXECUTION..................................................................................................................... 2

5.1 Excavation of trench ................................................................................................... 2

5.2 Compaction of Subgrade ............................................................................................ 4

5.3 Installation of cradle .................................................................................................... 4

5.4 Installation of hume pipe ............................................................................................. 5

5.4.1 Lying of hume pipe ............................................................................................... 5

5.4.2 Jointing of pipes .................................................................................................... 6

5.5 Backfill ...................................................................................................................... 10

6 ENVIRONMENT, HEALTH AND SAFETY (EHS) ............................................................11

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

1 PURPOSE

This Method Statement describes the process of installation of Hume Pipe for Storm Water

System of Housing Complex Work of Nghi Son 2 Thermal Power Plant Project located at

Nghi Son, Tinh Gia District, Thanh Hoa Province.

The statement consists of Site preparation, Equipment Supply and Installation, Material

Supply, Construction Procedure, Inspection Procedure, and Quality Assurance related to

Subcontractor’s responsibility for implementation of the whole Housing Complex Work

Package following requirements mentioned in Specification and Designs as well as the

relevant standard of the Project.

2 CODE AND STANDARD

QCVN 07-02:2016/BXD “National Technical Regulation. Technical Infrastructure Works

Sewerage”;

22TCN 266:2000 “Standard for construction and acceptance of bridges and culverts”;

TCVN 4447: 2012 “Earth works - Construction, check and acceptance”;

TCVN 9113:2012 “Reinforced concrete pipes for water draining”;

TCVN 10799:2015 “Precast concrete support blocks”;

Drawing No. NS2-UT01-P0UYK-762001[Housing Complex](Storm Water System)Pipe

Arrangement Plan;

Drawing No. NS2-VK02-P0UYK-762001[Housing Complex](Storm Water System)Manhole

Plan, Section and Re-bar;

Drawing No. NS2-VK02-P0UYK-762002[Housing Complex](Storm Water System)Details;

MAR No. NS2-DE00-P0ZEN-169268 “MAR of Hume Pipe for Drainage System”;

TCVN 4055: 2012 “Organization of construction activities”;

46/2015/NĐ-CP “Decree of quality management of construction works.

3 MACHINERY & EQUIPMENT

No Description Q’ty

1 Excavator

2 Dump Truck

3 Compactor

4 Truck Mounted Crane

5 Total Staion

6 Barrier

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 1 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

4 PREPARATION

4.1 Survey work

Benchmark of the project includes:

Benchmark system provided by the contractor;

Secondary benchmark system.

Position point coordinate must be set out by total station and marked by suitable stakes.

4.2 Material

All reinforced concrete hume pipes must be new and perfectly sound, free from cracks,

cylindrically straight and comply to design nominal diameter and length with even texture.

4.3 Delivery, Storage and Handling

Delivery, storage and handling shall be according to the manufacturer’s recommendations,

along with the following provisions:

Transportations, storage and handling shall at all times be performed in a manner to avoid

product damage.

The strength of concrete sample reaches over 70% of designed strength (R28), those

products can be delivered to the site.

Only soft slings shall be used for lifting products. Steel chains, clamps or cables shall not

be allowed lifting purposes.

The product shall be protected during handling against impact, shocks and free fall to avoid

cracks and damages.

Any products found to be incorrectly fabricated shall be marked and set aside.

Any products damaged during delivery, storage or installation shall be marked by the

Contractor and set aside.

Transportation and stack of hume pipe must comply to safety requirement and under control

of contractor to minimize the inconvenience affected to the traffic and other construction

activities.

The subcontractor shall be fully responsible for the safety and security of materials transported

and stacked in the working area

5 EXECUTION

5.1 Excavation of trench

Excavation work will be performed as per approved method statement (Refer to NS2-

DD09-P0UYK-770002 “MS for Excavation and Backfill Work”).

Any unsuitable soil or rock, bounder, stone… which could cause point load on pipe surface

must be removed if they are encountered in trench bed. Replaced material should be

screened sand as general backfilling procedure.

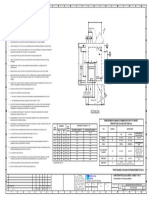

The dimensions and shape of trench as below (Table 9 of TCVN 4447:2012):

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 2 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Where:

W = Do + 0.8 for Rein. Concrete Pipe D400

W = Do + 1.2 for Rein. Concrete Pipe D600 & D800

Do: The outer diameter of Rein. Concrete Hume Pipe

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 3 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

5.2 Compaction of Subgrade

Flatten the bottom of trench;

Compact the bottom trench by compactor;

Adjust elevation and final check;

Inspection of this work with density test K ≥ 95%;

The temporary drainage must be prepared and kept in whole time of installation work for

hume pipe.

5.3 Installation of cradle

Marking location of cradle by total station.

Use truck mounted crane to install cradles.

Adjust the elevation of cradles before laying the hume pipe.

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 4 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

5.4 Installation of hume pipe

5.4.1 Lying of hume pipe

Laying and assembly of pipes shall conform to reference documents. Both ends of pipe

must be close controlled the elevation to comply with design;

The bell end should point upstream and the spigot or tongue should point downstream.

This helps prevent bedding material from being forced into the bell during jointing and

enables easier coupling of pipe sections;

Saddle shall be used for supporting pipes during installation. The elevation and slope of

pipeline is most determined by saddle;

The ends of the pipes shall be kept closed to keep dirt, mud and foreign materials out. In

case of flooding condition, contractor shall take into account to proper method to prevent

from floating of pipe;

Proper care shall be taken to prevent damage to the pipe’s edges;

Laying of pipes shall commence from the lowest point of the pipeline.

Excavator buckets shall not be used to push pipes together;

Each successive pipe shall be kept in alignment with the previous pipe. Proper care shall

be taken to maintain true alignment during pushing a new pipe into the edge of an already

laid pipe for ease of installation, as well as to avoid any damage to the sealing element;

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 5 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

After cutting a pipe for construction requirements, all sharp edges shall be smoothened by

means of grinding with suitable disc or any equivalent brush;

Use only soft slings for lifting with position of sling as below:

5.4.2 Jointing of pipes

Rubber ring Gasket shall be provided by manufacturer, which is inserted between bell of

this pipe and spigot of other pipe to prevent from leakage;

Connecting bell and spigot joints that are sealed with rubber ring gaskets may require

substantial force to push the pipes together;

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 6 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Steps for jointing of pipes

Clean Bell

Clean Spigot

Lubricate bell (if needed)

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 7 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Lubricate spigot (if needed)

Lubricate Gasket (if needed)

Install the Gasket

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 8 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Align pipe

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 9 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

5.5 Backfill

Backfilling work will be performed to comply with approved method statement (Refer to NS2-

DD09-P0UYK-770002 “MS for Excavation and Backfill Work”) and approved drawings.

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 10 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

6 ENVIRONMENT, HEALTH AND SAFETY (EHS)

Prior to commencement of the works, DVN will ensure that both PTW and START Procedure

are instigated, together with safe system work, practices and requirements.

For safety analysis (work description and the hazard) and how to minimize the risk

Job safety analysis

List of All Job Steps List of All Known Hazards How to Eliminate Hazards

1.Materials receiving/ Traffic incident/accident. All materials must be inspected and

Temporary storage.

secure prior enter the site.

Falling of materials.

Assign traffic controller/ escort during

Slip, trip, fall, body injury of

delivery materials by trailer.

workers.

All lifting Equipment/devices must be

Crane over-turn.

inspected by equipment daily checklist.

Collision with equipment &

Lifting Operation PTW for all lifting

human.

activities must be done prior works

execution.

Provide sufficient of competent

riggers/flagmen/signalmen and

supervision for every lifting activity.

Provide barricade, warning tapes,

signboards for lifting zone and storage

area.

Provide safe access for workers.

2.Survey Works. Fall, slip, trip during location Always wear full PPE at all time.

marking.

Provide safe access at workplace.

Stuck into the muddy area.

Focus and concentrate all the time

Pegs splatters into the eyes. during work execution.

Always beware and walk on

designated access.

3.Installation of cradle Slip, trip and fall of workers. Implement method statement /

and pipe work.

procedures on safe crane works.

Falling object from cradle,

pipe and crane. Sufficient and strict supervision during

works execution.

Cradle, pipe falling down by

incidents/damageable of Always wear full PPE including special

crane. PPE such as: ear plugs...

Electric shock during using Assign licensed and experienced

the power tools. operator/ riggers.

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 11 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Equipment and human Assign experienced and trained

collision. personnel /workers/Flagman/

signalman.

Oil spillage/leakage from

machine. Keep exclusion distance. Only

authorized persons stay in working

Fire incidents from machine

zone.

or hot work activities.

All pipe protections must be inspected

prior using. All poor quality of pipe

protection must be removed out of the

site.

Generator, crane must be inspected by

daily inspection checklist to

prevent/repair any damageable.

Oil spill kit and fire extinguisher must

be available at workplace.

All hot work activities must be assigned

competent persons with sufficient of

special training and fire watcher.

Provide safe access ways.

4. Excavation works. Excavator toppled down Ensure safe access is provided to

deep hole excavation. personnel, use hard barricades, sign

boards.

Human caught between

moving parts of excavator. All power tools and electrical

equipment to be inspected and color

Excavator collision with

coded.

human & other equipment.

Flagman must be assigned for each

Soil collapsed.

heavy equipment.

Falling object.

Suitable means of access and egress

Fall down deep hole to be provided

excavation.

Operators have to warn prior using

Oil leakage during operation heavy equipment to any personnel

equipment. within the excavation area.

No standing inside the radius of

excavator.

Operator can’t get off the excavator

until the engine is turned off and

property parked.

Essential PPE must be worn.

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 12 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Heavy machinery should have

automatic reverse alarm, beacon light.

Separate entrance/exit for vehicles

5. Backfilling Works Slip, trip and fall of workers Implement method statement /

during works execution. procedures on safe backfilling works.

Collision between heavy Sufficient and strict supervision during

Equipment/ human. backfilling works.

Wearing full PPEs at all time.

Assign licensed and experienced

operator.

Assign experienced and trained

workers/ flagman.

6. Soil Compaction. Equipment movement. Assign competent operator, flagman,

signal man.

Equipment collision.

Provide barricade, signboards, safe

Oil leakage/ spillage.

access at workplace.

Noise.

Sufficient of supervision.

Wearing full PPE (Including special

PPEs such as: ear plugs...) at all time.

7.Environmental Extreme environmental Implement safety procedures &

Conditions During

condition such as high guidelines on heat stress.

Excavation and

backfilling Works. temperature & humidity and

Inspect excavation and adjacent areas

strong wind.

for possible hazardous atmosphere

and any other condition that may

present a hazard.

Suspend / stop all operations during

extreme temperature & humidity and

high wind.

8.Night Works. Working operation of the Must provide sufficient of illumination

equipment may cause injury at working area and access ways.

to personnel due to poor

All Equipment must be fitted with

visibility of the area.

appropriate safety device and ensure

Insufficient of illumination at all lights are operational not obscured

workplace. by dirt and mud.

Status of worker’s healthy. Supervisor and safety personnel shall

always be present for the necessary

Slip, trip, fall of workers

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 13 of 19

Work Item : Infrastructure Works

(Housing Complex)Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

because lack of illumination working.

for access and workplace.

All workers must be worn visible PPE.

Regular check & monitoring of the

equipment prior to use.

Provide food and drinking water for

workers.

Emergency response plan should be

prepared

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 14 of 19

Work Item : Infrastructure Works

(Housing Complex) Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

People at RFN RRN

Job/Task Cause of Adverse Effect Adverse Effect L1 S1 Mitigating Controls L2 S2 Assessment

Risk ** *

1.Mobilization Driver Over speed/taking Traffic collision 4 4 U Truck is not to be o o M Injury/ fatality &

the equipment during transporting. with other overloaded. damage equipment

Pedestrian

to the site.

Equipment on the equipment and All equipment must be tied

trailer truck are not human. and wedged carefully.

secured. Equipment falling Truck shall move with low

down from the speed and do not

trailer truck. overtake.

2. Survey Surveyor & Holding survey Instrument falling 3 4 M Holding instrument o o T Near Miss

work Supervisor instrument un down and hit carefully.

. carefully. workmen. Wearing full PPE & Full

Survey instrument set Fall from height. body safety harness.

up at un-safe location. Set up survey instruments

Un-safe survey at safe location.

making location.

Without fall protection

3. Lifting and Crane Non-compliance Falling object. 4 4 U S.T.A.R.T Meeting prior o o M Injury/ Damage

Unloading work. with lifting procedure. start lifting works. equipment/

Operator. Crane over-

Environment

Rigger. Using lifting devices turning. Comply with lifting contamination

improperly. Crane collision procedure/Prepared/

Signalman.

Poor supervision. with power line/ Planned.

Supervisor

Non-compliance with other equipment. Daily inspection for crane

Worker.

barricaded & warning Electrocution by & lifting devices prior start

area. lightning strike/ operation.

In-competent rigger & collision with Strict control &

operator. power line. supervision.

Weather in bad Human caught Establish the working area

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 15 of 19

Work Item : Infrastructure Works

(Housing Complex) Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

condition (strong wind between moving by barricade/ sign boards

≥ 8-10m/s, lightning, parts of crane. & watch man.

raining...) Wire rope/ web Keep away from power

Oil leakage from sling broken. line at least 6m.

crane during Environment Competent rigger &

operation contamination. operator.

Weather in good condition.

Regular monitoring of the

equipment in order to

control and prevent oil

leakage and other engine

trouble

Oil spill kit available.

Inspect oil hose condition

of crane

4. Installation Crane Non-compliance with Falling object. 4 4 U S.T.A.R.T Meeting prior o o M Injury/ Damage

work. lifting procedure. start Installation works. equipment.

Operator. Crane over-

Rigger. Un-inspection the turning. Comply with lifting

lifting equipment. Crane collision procedure/ Prepared/

Signalman.

Poor supervision. with power line/ Planned.

Supervisor

Non-compliance with other equipment. Daily inspection for crane

Worker.

barricaded & warning Electrocution by & lifting devices prior start

Welder. operation.

area. lightning strike/

In-competent rigger & collision with Follow load chard of crane.

operator. power line/ using Generator & electric

power tools. equipment must be

Weather in bad

condition (strong Human caught inspected.

wind ≥ 8-10m/s, between moving Strict control &

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 16 of 19

Work Item : Infrastructure Works

(Housing Complex) Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

lightning, raining...). parts of crane. supervision.

Oil leakage from Wire rope/ web Establish the working area

crane during sling/ RCP by barricade/ signboards &

operation. broken. watch man.

Un-inspection of Environment Keep away from power

equipment & electric contamination by line at least 6m.

control panel/ oil leakage. Competent rigger &

generator. Noise. operator.

Fire incident. Weather in good condition.

Provide drip tray, minimum

Oil Spill Kit for each

machine.

Inspect oil hose condition

of crane.

Keep away from

installation zone.

Only authorized persons

stay in installation zone.

Inspect quality of RCP,

cradle prior start

installation.

Provide competent rigger

& operator.

5. Excavation Operator Non-compliance with Excavator 2 4 4 Ensure safe access is o o M Injury/ Damage to

works. Method statement. toppled down provided to personnel, use equipment

Supervisor

Un-authorized deep hole hard barricades, sign

Flagman

access. excavation. boards.

Worker

Un-authorized Human caught All power tools and

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 17 of 19

Work Item : Infrastructure Works

(Housing Complex) Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

entry persons. between moving electrical equipment to be

Un-inspected the parts of inspected and color coded.

equipment. excavator. Flagman must be assigned

Without fall protection, Un-inspected the for each heavy equipment.

barricade and safe equipment. Suitable means of access

access. Without fall and egress to be provided.

protection, Operators have to warn

barricade and prior using heavy

safe access. equipment to any

personnel within the

excavation area.

No standing inside the

radius of excavator.

Operator can’t get off the

excavator until the engine

is turned off and property

parked.

Essential PPE must be

worn.

Heavy machinery should

have automatic reverse

alarm, beacon light.

Separate entrance/exit for

vehicles.

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 18 of 19

Work Item : Infrastructure Works

(Housing Complex) Method Statement for Installation of Hume Pipe

NS2-DD09-P0UYK-770020

Frequency Severity Risk Factor Number (RFN) Residual Risk Number (RRN)

1: Unlikely/Improbable 1: Negligible 1-2: Trivial/Acceptable 1-2: Trivial/Acceptable

2: Remote 2: Slight 3-5: Tolerable 3-5: Tolerable

3: Quite Possible/Occasional 3: Moderate 6-9: Moderate/Acceptable with review 6-9: Moderate/Acceptable with review

4: Likely/Probable 4: Critical/High 10-15: Substaintial 10-15: Substaintial

5: Very Likely/Frequent 5: Catastrophic/Very High 16-25: Intolerable/Unacceptable 16-25: Intolerable/Unacceptable

* Prepare Job Safety Analyis and Safety Verification

Check list when RRN is ≥ 6

** Prepare Safety Verification

Check list when RFN is ≥ 6

L1: Likelihood as is

L2: Likelihood with mitigating controls in place

S1: Severity as is

S2: Severity with mitigating controls in place

Project : Nghi Son 2 BOT Thermal Power Plant( 2 x 600MW) Page 19 of 19

Work Item : Infrastructure Works

You might also like

- PPI - Handbook of Polyethylene Pipe (2nd ED)Document626 pagesPPI - Handbook of Polyethylene Pipe (2nd ED)card89100% (5)

- 04.method Statement For Shoring & DewateringDocument5 pages04.method Statement For Shoring & DewateringPja Shantha100% (3)

- Method Statement For Roof, Wall and Floor WorkDocument27 pagesMethod Statement For Roof, Wall and Floor WorkĐặng Quang HuyNo ratings yet

- Method Statement For Roof, Wall and Floor WorkDocument27 pagesMethod Statement For Roof, Wall and Floor WorkĐặng Quang HuyNo ratings yet

- Method Statement For Excavation and Backfilling WorksDocument15 pagesMethod Statement For Excavation and Backfilling WorksĐặng Quang Huy100% (6)

- Method Statement For Casting, Prestressing & Grounting of PSC GirdersDocument15 pagesMethod Statement For Casting, Prestressing & Grounting of PSC Girdersrohit singhNo ratings yet

- Method Statement For Construction of Concrete Batching Plant (Combined)Document72 pagesMethod Statement For Construction of Concrete Batching Plant (Combined)NP Dien100% (1)

- Method of Statement For Road Crossing WorkDocument7 pagesMethod of Statement For Road Crossing WorkAnonymous voA5Tb0No ratings yet

- Prestressing Methodology Girder Casting MethodologyDocument7 pagesPrestressing Methodology Girder Casting MethodologyAkhilesh DwivediNo ratings yet

- Method Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly OverDocument8 pagesMethod Statement For Casting of Segment: Name of The Project: Construction of Four Lane Fly Overvenkateswara rao Pothina100% (2)

- Method Statement - Roof Installation 06.01.22Document24 pagesMethod Statement - Roof Installation 06.01.22Md Reyazuddin100% (3)

- Method Statement For Shrinkage CracksDocument2 pagesMethod Statement For Shrinkage Cracksluvvie87No ratings yet

- METHOD Statement of BRIDGE (Major STR)Document6 pagesMETHOD Statement of BRIDGE (Major STR)venkateswara rao Pothina100% (2)

- 1.method Statement Dewatering PDFDocument5 pages1.method Statement Dewatering PDFشاز إياس100% (3)

- Is 458-1988Document46 pagesIs 458-1988Rajashekhar Katta100% (2)

- Method Statement For GunitingDocument2 pagesMethod Statement For GunitingAlsonChin100% (1)

- Method Statement Fo Method Statement For Precast Boundary Wall Worksr Precast Boundary Wall WorksDocument5 pagesMethod Statement Fo Method Statement For Precast Boundary Wall Worksr Precast Boundary Wall Workscprelator100% (3)

- Method Statement For RCC WorksDocument10 pagesMethod Statement For RCC WorksSagar AliasjackeyNo ratings yet

- QAP For Road WorksDocument25 pagesQAP For Road WorksBhawesh AshuNo ratings yet

- Method Statement Drainage WorksDocument6 pagesMethod Statement Drainage WorksShua Chuah100% (4)

- Methodology For Installation of Paver Block WorkDocument3 pagesMethodology For Installation of Paver Block Workkunalji_jain50% (6)

- Method Statement For Road and Paving WorkDocument32 pagesMethod Statement For Road and Paving WorkĐặng Quang Huy100% (7)

- JSA Appendix Cutting, Grinding ConcreteDocument8 pagesJSA Appendix Cutting, Grinding ConcreteĐặng Quang Huy100% (1)

- l230 Service ManualDocument2,037 pagesl230 Service Manualcody100% (2)

- Samsung Servicemanual DVM Eco Utomhusdel PDFDocument69 pagesSamsung Servicemanual DVM Eco Utomhusdel PDFCristian Camilo Rincon LopezNo ratings yet

- Hume Pipe Laying DocumentsDocument7 pagesHume Pipe Laying DocumentsamaravathiaspNo ratings yet

- Methodology For Pile Foundation 08-09Document4 pagesMethodology For Pile Foundation 08-09Jeremy Jenkins86% (7)

- Methodology For RCC Rectangular DrainDocument4 pagesMethodology For RCC Rectangular DrainAkash Yadav100% (2)

- Methodology For Dry Lean Cement Concrete (D.L.C)Document3 pagesMethodology For Dry Lean Cement Concrete (D.L.C)Anish Panchal100% (2)

- Pile Build UpDocument6 pagesPile Build UpHimalFernando0% (1)

- Method Statement For Granular Sub BaseDocument5 pagesMethod Statement For Granular Sub Basemadhu arepelli100% (1)

- Method Statement For Wet Mix MacadamDocument7 pagesMethod Statement For Wet Mix Macadammadhu arepelliNo ratings yet

- Hume Pipe Method StatementDocument2 pagesHume Pipe Method StatementDurgawati Mishra67% (3)

- DMC Pile MethodologyDocument6 pagesDMC Pile MethodologyKaustav Sain100% (3)

- Method Statement Wet Mix Macadam PatelDocument2 pagesMethod Statement Wet Mix Macadam Patelp.v.n. lakshman0% (1)

- GID-253-CV-GTPP-SITE-016 Ironite IPS FlooringDocument6 pagesGID-253-CV-GTPP-SITE-016 Ironite IPS FlooringAkash SharmaNo ratings yet

- PART B Method StatementDocument32 pagesPART B Method StatementSyed Umair HashmiNo ratings yet

- 0089-Methodology (Extension of Pipe Culvert)Document2 pages0089-Methodology (Extension of Pipe Culvert)Anish PanchalNo ratings yet

- Hilti Chemical Anchoring MethodologyDocument3 pagesHilti Chemical Anchoring MethodologyEgg Pegg (Pegg)100% (1)

- 2020-06-25 Method Statement of RCBC Construction CH402+737Document33 pages2020-06-25 Method Statement of RCBC Construction CH402+737施智捷100% (2)

- Method Statement For Installation of Kerbstone and Pavers in UAEDocument18 pagesMethod Statement For Installation of Kerbstone and Pavers in UAEGhayas JawedNo ratings yet

- Dewatering Method StatementDocument3 pagesDewatering Method StatementSalama ShurrabNo ratings yet

- Procedure For Sectional Field Hydrotest For Di Pipes: Jainco Buildcon Pvt. Ltd.Document11 pagesProcedure For Sectional Field Hydrotest For Di Pipes: Jainco Buildcon Pvt. Ltd.AjayNo ratings yet

- Bitumen Mastic Laying MethodologyDocument3 pagesBitumen Mastic Laying Methodologyvenkateswara rao PothinaNo ratings yet

- Method Statement For BC From RAP MaterialDocument6 pagesMethod Statement For BC From RAP Materialvenkateswara rao Pothina100% (1)

- PQC - Road ConcreteDocument10 pagesPQC - Road Concretemangeshshinde124100% (1)

- PCC & RCC Work MSDocument19 pagesPCC & RCC Work MSjonesNo ratings yet

- Method Statement For Safety and Maintenance Steel Grating WalkwayDocument10 pagesMethod Statement For Safety and Maintenance Steel Grating WalkwayEnviron SupportNo ratings yet

- Methodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering CorporationDocument10 pagesMethodology For Minor Bridges / Under Passes 1.0 Scope: Continental Engineering Corporationvenkateswara rao PothinaNo ratings yet

- Method Statement Fo Reinforcement Works BlogDocument8 pagesMethod Statement Fo Reinforcement Works BlogMohasin Khan100% (1)

- Methodology For Precast RCC Rectangular DrainDocument8 pagesMethodology For Precast RCC Rectangular DrainAkash YadavNo ratings yet

- Method Statement For Random Rubble Masonry WorkDocument4 pagesMethod Statement For Random Rubble Masonry WorkarunaNo ratings yet

- Method Statement FOR Sanitary SewerageDocument42 pagesMethod Statement FOR Sanitary Seweragemd_rehan_2100% (4)

- Method of Statement Hanging BracketDocument9 pagesMethod of Statement Hanging Bracketmuhammad syauqi shaidan100% (2)

- 09 Method Statement of RR MASONRYDocument6 pages09 Method Statement of RR MASONRYvsshayan_237420762No ratings yet

- Methodology For Filter MediaDocument3 pagesMethodology For Filter MediaLaxminarayana Sastry100% (1)

- Checklist For Design & Drawing of Compound Wall and Main GateDocument2 pagesChecklist For Design & Drawing of Compound Wall and Main GateRupesh KhandekarNo ratings yet

- Methodology For Emb With Pond AshDocument10 pagesMethodology For Emb With Pond Ashjitendra100% (4)

- Methodology For PSC GirdersDocument5 pagesMethodology For PSC GirdersvnilNo ratings yet

- Construction of Valve ChamberDocument20 pagesConstruction of Valve ChamberAristotel C. Cabais, RN50% (2)

- Method StatementsDocument186 pagesMethod StatementsKoti Rathnakar YamarthiNo ratings yet

- MS-Minor BridgesDocument5 pagesMS-Minor Bridgesvenkateswara rao PothinaNo ratings yet

- Method Statement For Installation of Hume PipeDocument26 pagesMethod Statement For Installation of Hume PipemanishsinghqcmccNo ratings yet

- Method Statement For Pile Head Treatment WorksDocument12 pagesMethod Statement For Pile Head Treatment WorksĐặng Quang Huy100% (1)

- Method Statement For External Painting Work With Using Suspended PlatformDocument22 pagesMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyNo ratings yet

- For Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyDocument11 pagesFor Approval: Bac Mien Trung Consultancy Investment Construction and Trading Joint Stock CompanyBui Van DiepNo ratings yet

- Method Statement For General HVAC WorkDocument19 pagesMethod Statement For General HVAC WorkĐặng Quang HuyNo ratings yet

- Method Statement For General HVAC WorkDocument19 pagesMethod Statement For General HVAC WorkĐặng Quang HuyNo ratings yet

- Method Statement For Pile Head Treatment WorksDocument12 pagesMethod Statement For Pile Head Treatment WorksĐặng Quang Huy100% (1)

- Method Statement For External Painting Work With Using Suspended PlatformDocument22 pagesMethod Statement For External Painting Work With Using Suspended PlatformĐặng Quang HuyNo ratings yet

- Method Statement For Testing Piling WorksDocument91 pagesMethod Statement For Testing Piling WorksĐặng Quang Huy100% (2)

- JSA Appendix Backfilling Soil, Welding HDPEDocument8 pagesJSA Appendix Backfilling Soil, Welding HDPEĐặng Quang HuyNo ratings yet

- Catalogue: A Company As FL Exible As Its Product..Document28 pagesCatalogue: A Company As FL Exible As Its Product..bahrowiadiNo ratings yet

- FRP PipesDocument20 pagesFRP PipesThomasFrenchNo ratings yet

- Ultrasonic Examination of The Weld Zone of Welded Pipe and TubingDocument4 pagesUltrasonic Examination of The Weld Zone of Welded Pipe and TubingERNESTO ENRIQUE FERNANDEZ BAPTISTANo ratings yet

- Method Statement For Tank ErectionDocument8 pagesMethod Statement For Tank Erectionmanish pathrabeNo ratings yet

- Failure Code Manual PDFDocument13 pagesFailure Code Manual PDFMa DiNo ratings yet

- GB-Cat Supply Systems PDFDocument232 pagesGB-Cat Supply Systems PDFzoran cukovicNo ratings yet

- 304 Stainless SteelDocument3 pages304 Stainless Steelnum fistismNo ratings yet

- MSS-SP-118 (1996)Document25 pagesMSS-SP-118 (1996)mubs997No ratings yet

- 2020 Annual Book of Astm Standards: Exclusive BSB Edge Offer 15% Discount On All The Publications!Document5 pages2020 Annual Book of Astm Standards: Exclusive BSB Edge Offer 15% Discount On All The Publications!anil73No ratings yet

- Temp-Pro: Thermowell CatalogDocument26 pagesTemp-Pro: Thermowell CatalogSaeed VuNo ratings yet

- Notes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0MDocument1 pageNotes:: Reinforcement in Manhole Chamber With Depth To Obvert Greater Than 3.5M and Less Than 6.0Mسجى وليدNo ratings yet

- WQT Form From Aws d1 1Document2 pagesWQT Form From Aws d1 1didi sudiNo ratings yet

- Instruction Manual Exh. Hose Reel Series - 169518Document122 pagesInstruction Manual Exh. Hose Reel Series - 169518Valentin MalihinNo ratings yet

- Owner Manual Model 5400 FansDocument22 pagesOwner Manual Model 5400 FansMiguelNo ratings yet

- Process Industry Practices Process Control: Pip Pcign100 Instrument Pipe Support Installation DetailsDocument12 pagesProcess Industry Practices Process Control: Pip Pcign100 Instrument Pipe Support Installation DetailsEdison FerreiraNo ratings yet

- KITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFDocument16 pagesKITZ XJ Series Aluminum Butterfly Valves E-232-04 PDFYulita Ika PawestriNo ratings yet

- Auction Info and Inventory Valuation Global Energy ServicesDocument125 pagesAuction Info and Inventory Valuation Global Energy ServicesGOKUL PRASADNo ratings yet

- Rupture of Piping and Fire in Syn LoopDocument14 pagesRupture of Piping and Fire in Syn Looparunanshu palNo ratings yet

- May Nong Unibell PDFDocument332 pagesMay Nong Unibell PDFhuuquocNo ratings yet

- RFI Antenna Catalogue PDFDocument207 pagesRFI Antenna Catalogue PDFChristianGuevaraNo ratings yet

- MSS SP-75 2014Document33 pagesMSS SP-75 2014white9013No ratings yet

- QR5 Draft Annex07aDocument171 pagesQR5 Draft Annex07aShobha KunduNo ratings yet

- Upvc Pipe SpecificationDocument14 pagesUpvc Pipe Specificationsaif ullahNo ratings yet

- PR-1 Series: Adjustable Pressure Reducing RegulatorDocument2 pagesPR-1 Series: Adjustable Pressure Reducing RegulatordmerinosanchezNo ratings yet

- CRS 2017.18 Product CatalogDocument120 pagesCRS 2017.18 Product CataloghevenessaNo ratings yet

- JOJO Water Storage Solutions Installation Guide - 29.07.21Document9 pagesJOJO Water Storage Solutions Installation Guide - 29.07.21DN CoNo ratings yet

- Saes L 131Document10 pagesSaes L 131samsurendran_mech4020No ratings yet