Professional Documents

Culture Documents

Draft: 304/304L SS 304/304L SS

Draft: 304/304L SS 304/304L SS

Uploaded by

kaliya12Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Draft: 304/304L SS 304/304L SS

Draft: 304/304L SS 304/304L SS

Uploaded by

kaliya12Copyright:

Available Formats

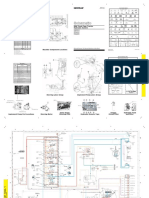

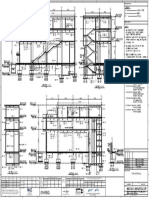

DWG Number 139T6950 Rev - Page 1 of 6

Revision History

Date

Rev Description Approved

(YYYY-MM-DD)

-

NOTES:

14. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL ENSURE THAT THE

1. ALL DIMENSIONS ARE IN INCHES, UNLESS OTHERWISE SPECIFIED. FUEL GAS AND FEED WATER ARE MANUALLY VENTED FROM THE VESSEL(S)

DIMENSIONS IN [] ARE IN MILLIMETERS. METRIC DIMENSIONS PRIOR TO CONDUCTING ANY INSPECTIONS OR MAINTENANCE.

SHOWN ARE NOMINAL EQUIVALENTS FOR REFERENCE ONLY.

15. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL INSULATE ALL

2. THE FOLLOWING TOLERANCES APPLY UNLESS FUEL GAS PIPING, COMPONENTS AND VESSEL SURFACES TO MAINTAIN

OTHERWISE NOTED IN THE DRAWING: SURFACE TEMP BELOW 140°F [60° C].

LARGE BORE(> 2.00) 16. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL INSULATE ALL THE HP/IP

PIPE FLANGE LOCATIONS: 0.50 [12.70], 0.3 DEGRESS WATER PIPING AND COMPONENT SURFACES (INCLUDING FUEL GAS PERF FG193

T

HEATER VESSEL(S)) TO MAINTAIN SURFACE TEMP BELOW 140°F [60°C].

SMALL BORE (< = 2 .00) FG274

PIPE CONNECTION LOCATIONS: 6.00 [152,4] 17. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL HEAT TRACE ALL THE GAS FG191

PERF HP/IP WATER PIPING AND COMPONENT SURFACES [INCLUDING FUEL FG187

ELECTRICAL JUNCTION BOX LOCATIONS : 2.00 [50,8] HEATER VESSEL(S)] TO PREVENT FREEZING IF THE MINIMUM SITE AMBIENT

TEMPERATURE IS BELOW 40°F [4°C].

FG185 HEAT EXCHANGER

LIFTING LUG / TRUNNION LOCATIONS: 6.00 [152,4]

SEE MLI 1095

18. REFERENCE DOCUMENTS: MLI ITEM 4002 - SCHM, FUEL GAS PERFORMANCE HEATER.

CENTER OF GRAVITY: 6.00 [152,4] FG192

19. APPROXIMATE UNIT WEIGHT: 76,000 LB [34,473 KG].

3. ALL FLANGE AND PIPE CONNECTION SIZES SHOWN ARE 2)

(SH

NOMINAL PIPE SIZE (NPS) PER UNITED STATES ANSI STANDARD 20. FOR LIFTING AND RIGGING INSTRUCTION THE PLANT DESIGNER AND/OR B

AND INSTALLED ACCORDINGLY. NO METRIC EQUIVALENTS EXIST PLANT INSTALLER SHALL REFER THE EQUIPMENT SUPPLIER'S OUTLINE DRAWING.

AND HENCE ARE NOT SHOWN. FLANGE BOLT HOLES SHALL CABLES, SLINGS, TURNBUCKLES, SPREADER BARS, AND ANCHOR SHACKLES ARE

STRADDLE AND BE SYMMETRICAL ABOUT CENTERLINE. NOT SUPPLIED BY GE. THEY MUST BE SUPPLIED BY THE PLANT DESIGNER AND/OR

F

PLANT INSTALLER. DO NOT ALLOW SLING / CHAIN / STRAP TO TOUCH THE

4. DELETED. EQUIPMENT BEING LIFTED UP DURING LIFTING.

5. THE PURPOSE OF THIS DRAWING IS TO DEFINE INTERFACE 21. FOUNDATIONS MUST PROVIDE ADEQUATE SUPPORT FOR THE SKID BASE FRAME

INFORMATION AND PROVIDE RELEVANT INSTALLATION AT DESIGNATED LOCATION. THE FOUNDATION SUPPORT MUST BE ADEQUATE FOR

INFORMATION ONLY. ALL OTHER COMPONENTS SHOWN ARE ALL LOAD CASES FOR DEAD, ROOF, SEISMIC, WIND, SNOW ETC WHICH ARE DEFINED FG196

INDICATIVE OF TYPICAL HARDWARE ARRANGEMENTS. DIMENSIONS IN THE APPLICABLE LOCAL AND NATIONAL REGULATIONS FOR STRUCTURES. REFER

NOT IDENTIFIED FOR THE HARDWARE ARRANGEMENT SHOWN ON TO MLI 323B DRAWING (PROVIDED WITH EG23 PACKAGE) FOR SITE DATA AS A

THIS DRAWING SHALL BE PER THE RESPECTIVE SUPPLIER'S DESIGN. MINIMUM LIST.

6. THE MODULE TO BE MOUNTED ON PLANT DESIGNER AND/OR 22. THE FOUNDATION DESIGNER SHALL CONSIDER THE SIZE OF THE STRUCTURE

PLANT INSTALLER FOUNDATION AND ANCHORED AT FOURTEEN (14) DIMENSIONED ON THIS DRAWING AND THE CENTER OF GRAVITY LOCATIONS

LOCATIONS. THE PLANT DESIGNER AND/OR PLANT INSTALLER SHALL PROVIDED ON THE ELEVATION VIEW. THE FOUNDATION DESIGN MAY TREAT

PROVIDE ALL NUTS, WASHERS AND FOUNDATION BOLTS REQUIRED THE SKID AS A RIGID BASE FOR THEIR DETERMINATION OF THE INDIVIDUAL FG188

TO ANCHOR THE SKID AS SHOWN ON THE DRAWING. RECOMMENDED DESIGN REACTIONS TO FOUNDATION INTERFACE PROVIDED ON THE DRAWING0.

ANCHOR BOLTS ARE 1.00 - 8 UNC [25,4] ASTM F1554 GR36 (OR EQUIVALENT) FOR ALL DESIGN LOAD CASES, THE DIFFERENTIAL DISPLACEMENTS (VERTICALLY)

A

AND HAVE A MINIMUM PROJECTION 0F 4.50 [114,3]. SEE LOAD TABLE FOR BETWEEN ANY 2 SUPPORT PLATES (WHERE USED) UNDER THE SERVICE LOADS

ADDITIONAL DETAILS. SHALL BE EQUAL OR LESS THAN 0.25 INCH [6.4 MM].

7. THE TOTAL RESULTANT FORCE AND TOTAL RESULTANT MOMENT IMPOSED 23. THE BASE FRAME SHALL ONLY BE IN CONTACT WITH THE FOUNDATION AT

ON ANY CONNECTION MUST NOT EXCEED THE FOLLOWING: THE 14 DESIGNATED MOUNTING PLATE/PAD POSITIONS. ALL THE 14 PLATES AT

BASE OF SUPPORT FRAME SHALL BE IN FULL CONTACT WITH FOUNDATION BEARING

ENGLISH UNITS SURFACE. ANY GAPS MUST BE SHIMMED WITH STEEL PLATE. FINAL SUPPORT BASE

SHALL BE INSTALLED LEVEL IN BOTH X AND Y DIRECTIONS.

F = (300) X (D)

H2)

M = (600) X (D) 24. IF NECESSARY, PARTS/PIPING EXCEEDING MAXIMUM SHIPPING OF 13' 6" HEIGHT (S

TO BE SHIPPED IN SEPARATE CONTAINER WITH THE SKID.

A

WHERE F = RESULTANT FORCE IN POUNDS

FG184

M = RESULTANT MOMENT IN LBS-FT,

D = PIPE SIZE OF CONNECTION (I.P.S.) IN INCHES

UP TO 8.00 IN DIAMETER FOR SIZES GREATER THAN

8.00 IN DIAMETER USE A VALUE OF (D) EQUAL

ISOMETRIC VIEW

R

TO (16 + I.P.S.) / 3.

FUEL GAS CONDITIONING MODULE

G010-ARRANGEMENT

METRIC UNITS

F = (53.38) x (D)

M = (32.54) x (D)

WHERE F = RESULTANT FORCE IN NEWTONS,

M = RESULTANT MOMENT IN N-M,

D = NOMINAL DIA. UP TO 200 DN IN DIAMETER,

FOR SIZES GREATER THAN 200 DN IN DIAMETER,

USE A VALUE OF (D) EQUAL TO (400+DN)/3. CUSTOMER CONNECTION LIST

8. EQUIPMENT ACCESS WALKWAYS AND LADDERS FOR SERVICING TO BE CONN. DESCRIPTION RATING MATERIAL

SUPPLIED BY PLANT DESIGNER AND/OR PLANT INSTALLER. WALKWAYS FG184 FUEL GAS CONDITIONING SKID INLET 8" 600 CL ANSI RF 304/304L SS

AND LADDERS SHALL MEET ALL OSHA AND LOCAL SAFETY STANDARDS.

FG185 FUEL GAS CONDITIONING SKID OUTLET 8" 600 CL ANSI RF 304/304L SS

D

9. ISOLATION VALVES ARE NOT PERMITTED IN THE HEATER RELIEF VALVE OR FG195 HP FEED WATER INLET 4" SCHXXS BW A106 Gr C CS

WATER RELIEF VALVE OUTLET PIPES. GAS SIDE RELIEF VALVE AND VENT TO BE FG188 IP FEED WATER INLET 3" 2500 CL ANSI RF A106 Gr B CS

VENTED TO SAFE AREA (PIPING BY PLANT DESIGNER AND/OR PLANT INSTALLER).

FG189 FEED WATER OUTLET 4" 1500 CL ANSI RF A106 Gr B CS

10. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL TEST VESSEL(S) FG274 FUEL GAS VENT 1" 600 CL ANSI RF 304/304L SS

PRESSURE RELIEF VALVE(S) PRIOR TO INITIAL OPERATION. FG190A HP FEED WATER DRAIN 1" 2500 CL ANSI RF A106 Gr C CS

11. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL PERFORM LEAK TESTS FG190B IP FEED WATER DRAIN 1" 2500 CL ANSI RF A106 Gr B CS

OF VESSEL(S) AND INTERCONNECT PIPING PRIOR TO INITIAL OPERATION. FG187 FUEL GAS SIDE RELIEF VALVE 3" 600 CL ANSI RF 304/304L SS

FG193 HP FEED WATER SIDE RELIEF VALVE 3" 300 CL ANSI RF A106 Gr B CS

12. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL ENFORCE PROPER AND SAFE

LIQUID CONDENSATE (INCLUDING LIQUID HYDROCARBON) REMOVAL AND FG196 IP/HP FEED WATER TEE RELIEF VALVE 3" 300 CL ANSI RF A106 Gr B CS

DRAIN PROCEDURES FROM THE VESSEL(S)AND DRAIN SYSTEM. FG191 IP FEED WATER SIDE RELIEF VALVE 3" 300 CL ANSI RF A106 Gr B CS

13. PLANT DESIGNER AND/OR PLANT INSTALLER SHALL PROHIBIT THE USE OF ALL FG192 G010 INSTRUMENT AIR SUPPLY 2" NPTF 316/316L SS

SOURCES OF IGNITION AND OPEN FLAMES WITHIN THE HAZARDOUS AREA

SURROUNDING THE EQUIPMENT.

135T5412 S. ZAVALA G010

(Jun 01 2021 11:16 AM CDT)

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED 1080188 J.VERDIN NONE

2021

THIRD ANGLE PROJECTION ARRANGEMENT

GAS FUEL PERFORMANCE HEATER

2021-06-01 139T6950 - 1of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

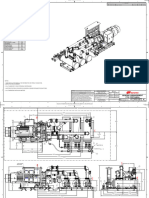

DWG Number 139T6950 Rev - Page 2 of 6

FG274 D (SH3)

FG187

℄ SKID

T

FG-PH-1

163.02

4140,8

E (SH4) G (SH4)

159.00 GROUND LUG

4038,6

FG185

F

FG192

65.88

2.50 9.84

1673,4

63,5 BASE PLATE

250,0

37.16

943,8

C

DETAIL (H4)

.00 TYP 2 PLACES

0,0

A

C

85.36

2168,0

100.40

2550,1 FG193

F (SH5)

334.65

8500,0

.00 FG191

0,0 VIEW A (H14, SH1)

FG-PH-1

R

FG184

124.56

FG185 3163,9

FG196 110.66

2810,8

FG195

FG192

65.88 FG188

1673,4 52.43

1331,7

D

25.11 24.94

637,8 16.79 633,5

426,4

.00

0,0

FG190A FG189 123.88

FG190B

3146,5

134.86

3425,4

236.81

6014,9

263.53

6693,8

300.59

7635,0

306.48

7784,7

322.24

8185,0 .00

VIEW B (D19, SH1) 0,0

(Jun 01 2021 11:16 AM CDT)

ARRANGEMENT

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED

GAS FUEL PERFORMANCE HEATER

2021

2021-06-01 139T6950 - 2of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

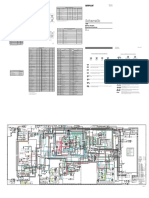

DWG Number 139T6950 Rev - Page 3 of 6

�322.38�

�8188,4�

T

�306.48�

�7784,7�

�263.52�

�6693,5�

�236.81�

�6014,9�

�134.86�

�3425,4�

F

�123.88�

�3146,5� FG196

FG193 FG189 FG190A FG190B

A1 A2 A3 A4 A5 A6

VA41-9

VA41-91

.00

156.00

3962,4

FG185

69.28

1759,7

JB310

16.86

428,1

C1

R A C2

℄ SKID

D

0,0 B1 B2 B3 B4 B5 B6

8.23 FG274

FG187 VA41-61

209,0 VA41-6

85.36

FG184

2168,0

℄ SKID

100.40

2550,1

�334.65�

�8500,0�

.00

0,0

VIEW D (A9, SH2)

(Jun 01 2021 11:16 AM CDT)

ARRANGEMENT

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED

GAS FUEL PERFORMANCE HEATER

2021

2021-06-01 139T6950 - 3of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number 139T6950 Rev - Page 4 of 6

FG193

FG191

F T FG274

FG187 FG187

FG193

FG191

A

FG185 �163.02�

�4140,8�

162.01

4115,1

�159.00�

154.71

�4038,6� FG184

MAX. SHIPPING LENGTH FG184 3929,7 �110.66�

SEE NOTE 24

�2810,8�

�124.56�

FG196 �3163,9�

FG196

FG189 FG188

�65.88� �65.88�

�52.43� �1673,4� FG190B �1673,4�

R

�1331,7� FG190B �37.16�

�24.94� �943,8� �25.11�

�633,5� �637,8�

.00 .00

0,0 0,0

�16.79� FG192 68.69

�426,4� 1744,6

�156.00�

�69.28� �3962,4�

.00

�1759,7� 0,0

.00

VIEW E (D2, SH2) 0,0 VIEW G (D16, SH2)

D

(Jun 01 2021 11:16 AM CDT)

ARRANGEMENT

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED

GAS FUEL PERFORMANCE HEATER

2021

2021-06-01 139T6950 - 4of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

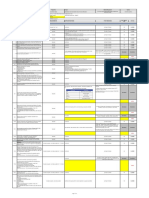

DWG Number 139T6950 Rev - Page 5 of 6

-Z IS OUT

T

OF PAGE +X

1.00

25,4

TYP .00

0,0

+Y B2 B3 B4 B5 B6

B1 MOUNTING PAD

F

.00

1.00 0,0

25,4

TYP

78.00

1981,2

TYP

A

158.00

4013,2 ℄ SKID

MAX. SHIPPING LENGTH

C1 C2

9.00

228,6

2.25

57,2

1.25

31,8

4.50

114,3

R

9.00

228,6

DETAIL D

3.50

88,9

D

3.25

82,6

3.00

76,2

A1

.75 -10 UNC TYPICAL

JACKING PROVISION

65.53

1664,4

TYP

A2

R

D

A3

℄ SKID

334.65

8500,0

MAX. SHIPPING LENGTH

F

VIEW (K9, SH2)

PLATFORM AND BEAM SUPPORTS NOT SHOWN FOR CLARITY

BASE PLATES (A1, A2, A3), (A4, A5, A6)

A4

(B1, B2, B3), (B4, B5, B6) ARE ORIENTED AT SAME.

A5 A6

(Jun 01 2021 11:16 AM CDT)

TYPICAL ALL MOUNTING PLATES

PLATE THICKNESS = 1.00 [25,4]

ARRANGEMENT

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED

GAS FUEL PERFORMANCE HEATER

2021

2021-06-01 139T6950 - 5of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

DWG Number 139T6950 Rev - Page 6 of 6

163

414

.02

0,8

F T C.O.G.

A

68.9

0±3.

175 00

0,0±7 C.O.G.

6,2

.00

0,0

+Z

R

+Y �51.1

�8

�130

0,�0

+X

171

.41±6

435 .00

.00 3,8±1 C.O.

52,4 G.

0,0

.O.G.

334 C

.65 �51.1 5 ±3 .00

�8 69.7 6,2

D

850

0,0 �130 7 1 ,6±7

0,�0 17

. 00

156

9 6 2,4

3

ISOMETRIC VIEW

LIFTING ARRANGEMENT

SEE NOTE 20

(Jun 01 2021 11:16 AM CDT)

ARRANGEMENT

GE CLASS II (NON-CRITICAL) / NOT EXPORT CONTROLLED

GAS FUEL PERFORMANCE HEATER

2021

2021-06-01 139T6950 - 6of6

GE Proprietary Information - Class II (Internal) US EAR - NLR

You might also like

- Shell - Process Safeguarding Flow SchemesDocument37 pagesShell - Process Safeguarding Flow SchemesIgnatios Staboulis100% (1)

- WS - QHSE - S05 - Wellsite Operations PDFDocument74 pagesWS - QHSE - S05 - Wellsite Operations PDFDAMASO MARTINEZ RODRIGUEZNo ratings yet

- d6n Hydraulic Ds PilotDocument2 pagesd6n Hydraulic Ds PilotEmmanuel solomonNo ratings yet

- Hidraulico 563eDocument2 pagesHidraulico 563eTeofilo Paredes CosmeNo ratings yet

- Basic Hydraulics: Pressure Control Circuits Pressure Control CircuitsDocument50 pagesBasic Hydraulics: Pressure Control Circuits Pressure Control CircuitsJose Manuel Barroso PantojaNo ratings yet

- Diag, Schem Pp-Fire Protection 121T1290Document3 pagesDiag, Schem Pp-Fire Protection 121T1290Bounezra OussamaNo ratings yet

- 9 13 Notes:: Construction IssueDocument1 page9 13 Notes:: Construction IssueХөгжилтэй ЗугаатайNo ratings yet

- Engine Flywheel: Power Take-Off Sae Type 1Document6 pagesEngine Flywheel: Power Take-Off Sae Type 1GdadbhhNo ratings yet

- Gas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001Document5 pagesGas Fuel Conditionning Skid 1021776 2g0 Ek PFB 0001faisalnadimNo ratings yet

- CatDocument2 pagesCatNicole SmithNo ratings yet

- V754749001XC (241 242) PDFDocument5 pagesV754749001XC (241 242) PDFErin JohnsonNo ratings yet

- Plano HidraulicoDocument2 pagesPlano HidraulicoklausNo ratings yet

- Elect SpecsDocument74 pagesElect SpecsNaveedNo ratings yet

- Section D-D: NEST, LGA, 7X7,0.5X48, G3Document2 pagesSection D-D: NEST, LGA, 7X7,0.5X48, G3Ericson. TatlongmariaNo ratings yet

- V9616-7 - EN051 - General Arrangement Drawing - ADocument3 pagesV9616-7 - EN051 - General Arrangement Drawing - Asunnudwi10No ratings yet

- StrucDocument3 pagesStrucAlvin DeliroNo ratings yet

- 0962燃气管道布置qme 00 g 141b 000 Ei 172 en d Piping Arrangement Gas Turbine(121t7058)0962Document10 pages0962燃气管道布置qme 00 g 141b 000 Ei 172 en d Piping Arrangement Gas Turbine(121t7058)0962ALAMGIR HOSSAINNo ratings yet

- Instruction Manual Thermo-Chiller HRR012/018/024/030 Series: Original InstructionsDocument4 pagesInstruction Manual Thermo-Chiller HRR012/018/024/030 Series: Original Instructionsyucca palmuNo ratings yet

- CONSTRUCTION OF (Name of Project and Location) : DPWH Standard Project BillboardDocument1 pageCONSTRUCTION OF (Name of Project and Location) : DPWH Standard Project Billboardcristian gonzalesNo ratings yet

- Trasmittal Nr. HFY-3800-CPECC-PEGVR-T-0205 - HFY-3800-1501-VED-182-MEC-DWG-0001 - 0 - GA DWG For Lean Ami Air Cooler - Code-ADocument4 pagesTrasmittal Nr. HFY-3800-CPECC-PEGVR-T-0205 - HFY-3800-1501-VED-182-MEC-DWG-0001 - 0 - GA DWG For Lean Ami Air Cooler - Code-Ajuuzousama1No ratings yet

- Diagramas Caterpillar RENR1428 - 01Document2 pagesDiagramas Caterpillar RENR1428 - 01jorge antonio guillenNo ratings yet

- Product Manual - R 3EL 125 - PO 8584Document71 pagesProduct Manual - R 3EL 125 - PO 8584Ravi RamdeoNo ratings yet

- Reference Designator Symbol Legend: NotesDocument106 pagesReference Designator Symbol Legend: NotesVU ingenieriaNo ratings yet

- Attachment-1 - Scope & Technical DatasheetDocument2 pagesAttachment-1 - Scope & Technical DatasheetAshwini KasarlaNo ratings yet

- HFY-3800-0000-VED-197-STR-DWG-0021 - B - Ere GA Dra of Mis Ste STR SRU Code ADocument19 pagesHFY-3800-0000-VED-197-STR-DWG-0021 - B - Ere GA Dra of Mis Ste STR SRU Code Ajuuzousama1No ratings yet

- MECHANICALDocument3 pagesMECHANICALAbigail SalazarNo ratings yet

- 2-18-2020 - GAC MSC - Acworth - Add2 Full SetDocument21 pages2-18-2020 - GAC MSC - Acworth - Add2 Full SetRicardo Mayorga ParedesNo ratings yet

- 4124 Ai Du 21110S006S01 Is01 - CheckprintDocument1 page4124 Ai Du 21110S006S01 Is01 - CheckprintamitNo ratings yet

- Bernabe-Imus StructuralDocument3 pagesBernabe-Imus StructuralAlvin DeliroNo ratings yet

- TH GS1 Pro 19030 00 Eor03 Mec TCS 1002 - BH - 20210420Document8 pagesTH GS1 Pro 19030 00 Eor03 Mec TCS 1002 - BH - 20210420Nat WutthivongthanakornNo ratings yet

- At575 43Document1 pageAt575 43Juan BalderasNo ratings yet

- (Encloser 2) KAR1904-PPL-DS-0000-GEN-0004 - Rev 0 - Data Sheet For Pig Launcher Receiver 1Document10 pages(Encloser 2) KAR1904-PPL-DS-0000-GEN-0004 - Rev 0 - Data Sheet For Pig Launcher Receiver 1DarshAwadNo ratings yet

- DG-030-12251-0006 - 5th CAD inDocument1 pageDG-030-12251-0006 - 5th CAD inyohanes153No ratings yet

- PB Waste Crane - PB Bunker Runway Beam - Waste Crane Mark UpDocument4 pagesPB Waste Crane - PB Bunker Runway Beam - Waste Crane Mark Upyip konglungNo ratings yet

- Outline, Genset: A055J590 ArrowDocument2 pagesOutline, Genset: A055J590 ArrowmahranNo ratings yet

- Butadiene Unit 101 - ModelDocument5 pagesButadiene Unit 101 - ModelWaleed EL-sheshtawyNo ratings yet

- Section A-A: See Detail CDocument2 pagesSection A-A: See Detail CGalva decoNo ratings yet

- 6 SS Direct Fired Air HeaterDocument1 page6 SS Direct Fired Air HeaterYhony Gamarra VargasNo ratings yet

- RA612003001P0A1Document1 pageRA612003001P0A1Muhammad AbrarNo ratings yet

- 772 Hest 0401Document2 pages772 Hest 0401yifei.zhuNo ratings yet

- KOLER ARCHITECTURAL DrawingsDocument15 pagesKOLER ARCHITECTURAL DrawingsDanny NguyenNo ratings yet

- Me-2001b (3) - 231004-Basement 2 Layout Plan Sheet BDocument1 pageMe-2001b (3) - 231004-Basement 2 Layout Plan Sheet BhumcanopNo ratings yet

- Mega-Lntiel-Stn-Ns-Sbrs-Str-Dd-S199-R0-Pms-Numeration Detail of Steel Staircase From Concourse Level To Platform Level-Sh 2 of 2Document1 pageMega-Lntiel-Stn-Ns-Sbrs-Str-Dd-S199-R0-Pms-Numeration Detail of Steel Staircase From Concourse Level To Platform Level-Sh 2 of 2Suresh BabuNo ratings yet

- Ds05 Test Train D&D Installation Facility ProjectDocument7 pagesDs05 Test Train D&D Installation Facility ProjectHARDIK PATELNo ratings yet

- Angloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Document1 pageAngloamerican: 0 Ec Emitido para Construccion JGM 06-Sep-19Pedro ChaucaNo ratings yet

- Sds 091 (Granite Laying For Ramp Area) Rev.01 - BackupDocument5 pagesSds 091 (Granite Laying For Ramp Area) Rev.01 - BackupSIDHARTH SNo ratings yet

- MR150K GA Drawing 45980208 - FDocument2 pagesMR150K GA Drawing 45980208 - Flymn linNo ratings yet

- Asbuilt Drawing Sbux MSCDocument41 pagesAsbuilt Drawing Sbux MSCbetawi digital printingNo ratings yet

- CRN Steam Tracing SpecDocument13 pagesCRN Steam Tracing SpecKarl CaudalNo ratings yet

- SMH RBG TD ST 03B 00 DT S521Document1 pageSMH RBG TD ST 03B 00 DT S521hemanthsridharaNo ratings yet

- Structcon Designs Pvt. LTD.: For ApprovalDocument1 pageStructcon Designs Pvt. LTD.: For ApprovalBilling EngineersNo ratings yet

- CpuDocument2 pagesCpujp mishraNo ratings yet

- Water Injection System - MODDocument2 pagesWater Injection System - MODmustafa1989ocNo ratings yet

- 9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Document15 pages9192-B000-A00000-0009-0903-0001 - 02 (Existing Cable Schedule)Pottem VanithareddyNo ratings yet

- IP1-02-002-00-11-SW-AGP-SD-000002 (01) - SD For Dome Plot Access Storm Water Network Layout Plan Sheet - 15-SignedDocument3 pagesIP1-02-002-00-11-SW-AGP-SD-000002 (01) - SD For Dome Plot Access Storm Water Network Layout Plan Sheet - 15-Signedmuhammed ali kandakciNo ratings yet

- Jumeirah 6-49Document19 pagesJumeirah 6-49Lê Quý ĐạiNo ratings yet

- 4124 Ai Du 21130i046s01 Is01 - Checkprint - DineshDocument1 page4124 Ai Du 21130i046s01 Is01 - Checkprint - Dineshamit bagchiNo ratings yet

- Hmc1031ms8e Eval PCB SchematicDocument3 pagesHmc1031ms8e Eval PCB SchematicbaymanNo ratings yet

- B437048001P01Document1 pageB437048001P01Mohammad ShayanNo ratings yet

- PS-B11 - BeamDocument1 pagePS-B11 - Beamanjas_tsNo ratings yet

- 48KW LPG Generator 48RCLBDocument2 pages48KW LPG Generator 48RCLBCarlos LízcanoNo ratings yet

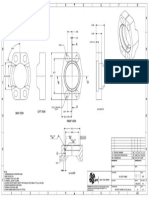

- Sae Split Flange s1fs-32 - DWG - 1Document1 pageSae Split Flange s1fs-32 - DWG - 1kaliya12No ratings yet

- Sae Split Flange s1fs-16 - DWG - 1Document1 pageSae Split Flange s1fs-16 - DWG - 1kaliya12No ratings yet

- Sae Split Flange s1fs-32 - DWG - 1Document1 pageSae Split Flange s1fs-32 - DWG - 1kaliya12No ratings yet

- Sae Insert S1yt1616 DWG 0Document1 pageSae Insert S1yt1616 DWG 0kaliya12No ratings yet

- Sae Insert S1yt3232 DWG 0Document1 pageSae Insert S1yt3232 DWG 0kaliya12No ratings yet

- Application Form For PCC PDFDocument3 pagesApplication Form For PCC PDFkaliya12No ratings yet

- Ms CatalogueDocument40 pagesMs Cataloguekaliya12No ratings yet

- SkillSelect Ceilings 02-01-17Document13 pagesSkillSelect Ceilings 02-01-17kaliya12No ratings yet

- Police Clearance Certificate (PCC) Checklist: Section A: Documents Required You StaffDocument3 pagesPolice Clearance Certificate (PCC) Checklist: Section A: Documents Required You Staffkaliya12No ratings yet

- Pipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, IncDocument10 pagesPipe Stress Analysis Case Study - Pump Discharge - Piping Technology & Products, Inckaliya12100% (1)

- MSA CDR Outcome Letter For 5415336Document1 pageMSA CDR Outcome Letter For 5415336kaliya12No ratings yet

- API 580 Questionnaires Bank - 1Document64 pagesAPI 580 Questionnaires Bank - 1AnasNo ratings yet

- 31369093Document2 pages31369093mohammed8051No ratings yet

- Evo Duo Manual Us Lit91127us 05.2018Document67 pagesEvo Duo Manual Us Lit91127us 05.2018Ronal SolisNo ratings yet

- Valvula Bypass b166Document4 pagesValvula Bypass b166burckhardt83No ratings yet

- Good Industry Practice - LPG Road Tanker ManagementDocument64 pagesGood Industry Practice - LPG Road Tanker ManagementSubhradeb PramanikNo ratings yet

- Manual PRV 3, Spring Loaded ERV PDFDocument42 pagesManual PRV 3, Spring Loaded ERV PDFAnonymous ZvPZcetr5No ratings yet

- Repair Pa Rts Sheet P - 3 9 1, 1004 / P-392, 1 0 0 5Document2 pagesRepair Pa Rts Sheet P - 3 9 1, 1004 / P-392, 1 0 0 5JPJFNo ratings yet

- Aib Motor Booster 4505 - AngDocument7 pagesAib Motor Booster 4505 - AngBruno LeãoNo ratings yet

- N 50B 4KG1 PDFDocument2 pagesN 50B 4KG1 PDFdocrafiNo ratings yet

- 810586Document11 pages810586John MaldonadoNo ratings yet

- Bosch Rexroth HaggludsDocument20 pagesBosch Rexroth HaggludsLubricants ServerNo ratings yet

- Pressure Relief Smith BurgessDocument12 pagesPressure Relief Smith Burgesssammar_10No ratings yet

- NFPA-20-fire Pump ReliefDocument3 pagesNFPA-20-fire Pump ReliefhossameldeenNo ratings yet

- Types 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsDocument8 pagesTypes 1808 and 1808A Pilot-Operated Relief Valves or Backpressure RegulatorsAlberto CastellanosNo ratings yet

- LNG Tanker MannualDocument49 pagesLNG Tanker MannualJohn CabiativaNo ratings yet

- FMDS1202Document31 pagesFMDS1202yunying21No ratings yet

- Thermal Relief Valve Instructions & Operations ManualDocument12 pagesThermal Relief Valve Instructions & Operations ManualHiren Panchal100% (1)

- Hot Water Generator: Installation and Operation ManualDocument24 pagesHot Water Generator: Installation and Operation Manualmangal deo pathakNo ratings yet

- Controlling Positive Displacement PumpsDocument10 pagesControlling Positive Displacement PumpsDan AngheleaNo ratings yet

- SPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationDocument6 pagesSPE/IADC-194547-MS MPD Deployment For Deepwater Drilling Operations - HSE & Risk Considerations and Mitigation, Rig Configuration Challenges and MPD Equipment Selection and StandardizationnabiNo ratings yet

- Safeguarding Memorandum - EnggcyclopediaDocument2 pagesSafeguarding Memorandum - EnggcyclopediaSarfraz AliNo ratings yet

- Toyo 56-87Document123 pagesToyo 56-87Yuda SatriaNo ratings yet

- Operating Manual BM BE 55-56-2U 1115Document18 pagesOperating Manual BM BE 55-56-2U 1115Lit Phen TuNo ratings yet

- Failure Analysis - Case StudyDocument43 pagesFailure Analysis - Case StudySyed HaiderNo ratings yet

- Es-Lf53 LF530CDocument1 pageEs-Lf53 LF530CWattsNo ratings yet

- P Erv L 092011 GBDocument2 pagesP Erv L 092011 GBialankar4u6336No ratings yet

- Bobma Jedco - Omega F1000 W2250Document71 pagesBobma Jedco - Omega F1000 W2250numonveNo ratings yet