Professional Documents

Culture Documents

Dry Particles, Wet Particles,: High Permeability Low Retentivity, Non Toxic

Uploaded by

Rajeev Kumar0 ratings0% found this document useful (0 votes)

9 views1 pageMagnetic particles are finely divided iron particles that can be used to detect surface-breaking and subsurface defects in ferromagnetic materials. They must be attracted to weak magnetic fields and not stick together outside of a field. Dry particles are larger than wet particles and come in various colors and sizes for contrast. Dry particles are better for subsurface defects due to their irregular shapes and permeability. They are applied using a blower or spray to create a particle cloud above the surface. Proper application and removal techniques are required to reveal defects while removing excess background particles.

Original Description:

Original Title

Dry part

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentMagnetic particles are finely divided iron particles that can be used to detect surface-breaking and subsurface defects in ferromagnetic materials. They must be attracted to weak magnetic fields and not stick together outside of a field. Dry particles are larger than wet particles and come in various colors and sizes for contrast. Dry particles are better for subsurface defects due to their irregular shapes and permeability. They are applied using a blower or spray to create a particle cloud above the surface. Proper application and removal techniques are required to reveal defects while removing excess background particles.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

9 views1 pageDry Particles, Wet Particles,: High Permeability Low Retentivity, Non Toxic

Uploaded by

Rajeev KumarMagnetic particles are finely divided iron particles that can be used to detect surface-breaking and subsurface defects in ferromagnetic materials. They must be attracted to weak magnetic fields and not stick together outside of a field. Dry particles are larger than wet particles and come in various colors and sizes for contrast. Dry particles are better for subsurface defects due to their irregular shapes and permeability. They are applied using a blower or spray to create a particle cloud above the surface. Proper application and removal techniques are required to reveal defects while removing excess background particles.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

Magnetic Particles:

Magnetic particles are finely divided ferromagnetic [Iron] material.

They must have,

High Permeability easily attracted to weak leakage fields.

Low retentivity, not attract each other outside magnetic field.

Non Toxic, relatively harmless to the user.

Fine particles are sensitive for surface breaking defects. Coarse

particles are superior for sub surface defects. Particles do not act as

single unit but clump together to form the indications when

magnetized. The particle size should be smaller than the width of

opening for detecting surface breaking cracks.

The two basic types of magnetic particles are,

Dry Particles, fine or course, applied as dry powder.

Wet particles, fine particles applied as suspended in a liquid.

Dry Particles : Dry particles are coarse and larger than wet

particles. The particles have a range of sizes and shapes and are

available in many colors such as yellow, gray, black, brown, red.

Fluorescent dry particles are also available, but are not in general

use mainly because of economic considerations. The color of the

particles used for testing is determined by the color of the surface

being examined and is selected for maximum contrast.

Dry particles are superior for detecting flaws lying wholly below the

surface because of its higher permeability and irregular shapes.

Large heavy particles are not likely to be arrested and held by a

weak leakage field when they are moving on the part surface.

Very fine dry particles behave like dust and easily adhere to any

damp or slightly oily surface to produce heavy dusty background.

Finer particles add mobility and sensitivity for fine surface cracks

while larger particles add sensitivity for detection of sub surface

defects and counteract the tendency of the finer ones to leave a

dusty back ground. Dry particles which are a mixture of coarse

and fine particles are mostly preferred.

Dry powder are primarily used on rough surfaces, such as un-

ground welds and castings, threaded parts and for detection of

defects below the surface. It does not have the tendency to drift

into the roughness of the surface as a wet suspension does. Dry

particles with half wave direct current and prods is the best

approach when inspecting lack of penetration in thinner welds and

hot tears and cracks in castings.

When used outdoors, breezes can cause the dry powders to blow

around. Dry particles are not affected by cold and can be used at

low temperatures. They are also heat resistant, and many powders

are usable at temperatures up to 6000 F.

Reclamation and reuse of dry particles is not recommended.

Application : Air is used to carry the particles to the examination

surface. Dry powder should be applied such that the particles Powder blower

approach the examination surface in a uniform cloud with minimum

of motion. In this way the particles reach the leakage field while

suspended in air and have three dimensional mobility. This

condition can be best achieved when the magnetized surface is

vertical or overhead. When particles are applied to a horizontal or

sloping surface, they settle directly to the surface and do not have

the same degree of mobility. Half wave rectified direct current is

recommended with dry particle inspection to impart the required

mobility. The magnetizing current must be initiated before the

application of the particles to the test surface and shall be

terminated after the excess particles have been blown off.

For Dry particle examination, the test surface must be dry, free

from grease and other adhering deposits. The particles themselves

must be free from moisture.

The relative merits of dry particles depend on the skill in

application. Dry powder can be applied by small rubber spray bulb,

squeeze bottles or specially designed powder blowers. The air

stream of these blowers is of low velocity so that a cloud of

powder is applied to the test area. These blowers can also deliver

a light stream of air for gentle removal of excess powder from the

examination surface. Excess dry particles around an indication, can

be removed by a regulated air supply, air bulb or gentle blowing

while the magnetizing field is present. The air stream should be of

sufficient force to remove the excess particles without disturbing

those particles that are evidence of indications.

Precautions shall be taken to prevent inhaling of dry particles.

Compiled by K. Chatterjee, 75643 Center for NDT P 00 Rv 03 Self study material.

You might also like

- Penetrant PresentationDocument20 pagesPenetrant PresentationJayesh100% (3)

- 10 Non Destructive Testing PDFDocument8 pages10 Non Destructive Testing PDFGosaye DesalegnNo ratings yet

- NDT Method PDFDocument31 pagesNDT Method PDFKarthikeyan MoorthyNo ratings yet

- EXPERIMENT No.: - Liquid Penetrant TestDocument6 pagesEXPERIMENT No.: - Liquid Penetrant TestVandan GundaleNo ratings yet

- Magnetic Crack DetectorDocument2 pagesMagnetic Crack DetectorMiguel Ivan Acosta MondragonNo ratings yet

- Non Destructive TestingDocument7 pagesNon Destructive Testingk_mughalNo ratings yet

- Probe Placement For Several Weld ConfigurationDocument66 pagesProbe Placement For Several Weld ConfigurationvcpNo ratings yet

- Dye Penetration TestDocument3 pagesDye Penetration Testzhuxueyun55No ratings yet

- Dye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantDocument3 pagesDye Penetration Test: Fig. 1: Surface Cleanser, Developer and PenetrantAmeenNo ratings yet

- Sample Preparation of XpsDocument5 pagesSample Preparation of XpsnajwaizzatiNo ratings yet

- NDT SDP 2CDocument54 pagesNDT SDP 2CvcpNo ratings yet

- How To Do Visible Dye Penetrant TestingDocument2 pagesHow To Do Visible Dye Penetrant TestingSrikanth Kabbal MNo ratings yet

- Dye Penetrant TestingDocument2 pagesDye Penetrant TestingshreeambhasankaranNo ratings yet

- Liquid Penetrant TestingDocument20 pagesLiquid Penetrant Testingajayghosh3140No ratings yet

- Liquid Penetrant TestingDocument20 pagesLiquid Penetrant TestingsanjibkrjanaNo ratings yet

- Unit 4 Mechanical SeparationDocument23 pagesUnit 4 Mechanical SeparationSk jahidul IslamNo ratings yet

- Liquid Penetrant Testing PDFDocument20 pagesLiquid Penetrant Testing PDFgueridiNo ratings yet

- Non Destructive DefectDocument3 pagesNon Destructive DefectHassan AliNo ratings yet

- Particulate MatterDocument26 pagesParticulate MatterDAISYLIN ANBU SUJITHA SNo ratings yet

- Dye Penetrant Inspection (DPI) - Liquid Penetrant Inspection (LPI) - Liquid Penetrant Testing (PT)Document9 pagesDye Penetrant Inspection (DPI) - Liquid Penetrant Inspection (LPI) - Liquid Penetrant Testing (PT)ISHITA ROY CHOUDHURYNo ratings yet

- 2 MT ProcedureDocument11 pages2 MT ProcedureFrancisco javierNo ratings yet

- Wet ScrubbersDocument31 pagesWet ScrubbersJoao MinhoNo ratings yet

- Air Pollution ControlDocument4 pagesAir Pollution ControlvildehusNo ratings yet

- Dye PenetrantDocument17 pagesDye Penetrantsen_subhasis_58No ratings yet

- Spheronizer and Marumerisiers and Other Special Is Ed Granulation andDocument56 pagesSpheronizer and Marumerisiers and Other Special Is Ed Granulation andNitu JhaNo ratings yet

- Nondestructive Testing (NDT)Document14 pagesNondestructive Testing (NDT)Javeed A. KhanNo ratings yet

- Module1 Testing and Flaw Detection of Materials and ComponentsDocument12 pagesModule1 Testing and Flaw Detection of Materials and ComponentsHari GovindNo ratings yet

- Air Pollution Control DeviceDocument4 pagesAir Pollution Control DeviceMica GundayNo ratings yet

- Separation and Classification of SolidsDocument3 pagesSeparation and Classification of SolidsChristopher YsitNo ratings yet

- Unit 3Document64 pagesUnit 3Sufiyan KhanNo ratings yet

- PT Theory English New 2014Document44 pagesPT Theory English New 2014CRISTIAN SILVIU IANUCNo ratings yet

- Ndte Notes Unit 2Document36 pagesNdte Notes Unit 2Kanda SamyNo ratings yet

- Kelompok 1: 1. Maulana Satya 2310100002 2. Cahyaning Lestari 2308100009 3. Gunawan Hartanto 2308100048Document13 pagesKelompok 1: 1. Maulana Satya 2310100002 2. Cahyaning Lestari 2308100009 3. Gunawan Hartanto 2308100048kradsrevolcNo ratings yet

- Dye Penetrant InspectionDocument5 pagesDye Penetrant Inspectionrashm006ranjanNo ratings yet

- Department of Mechanical Engineering: Unit-2Document65 pagesDepartment of Mechanical Engineering: Unit-2aman jainNo ratings yet

- Non Destructive TestingDocument30 pagesNon Destructive TestingRahul GajjeNo ratings yet

- NDT Module 2Document21 pagesNDT Module 2Sajeesh Saji100% (1)

- Iare NDT Lecture NotesDocument103 pagesIare NDT Lecture Notesnagarajan224100% (1)

- Dye Penetrant InspectionDocument15 pagesDye Penetrant InspectionUwaiz Qurni IINo ratings yet

- DPTDocument10 pagesDPTShabbir HassanNo ratings yet

- Often Referenced StandardsDocument18 pagesOften Referenced StandardssriramNo ratings yet

- Particulate or Dust Emission Control For IndustryDocument6 pagesParticulate or Dust Emission Control For IndustryHii Wang SingNo ratings yet

- LPT Study Material LatestDocument33 pagesLPT Study Material Latestbeltranrommel100% (2)

- LPTDocument22 pagesLPTPratik SalveNo ratings yet

- NDT Lecture Notes-1Document31 pagesNDT Lecture Notes-1ShiruNo ratings yet

- Air Pollution and ControlDocument16 pagesAir Pollution and Controlgovica0702No ratings yet

- Non Destructive TestingDocument48 pagesNon Destructive TestingRajneesh KumarNo ratings yet

- Ans ApceDocument18 pagesAns ApcekalpNo ratings yet

- NDT For TestDocument7 pagesNDT For TestGavaine MattisonNo ratings yet

- Air Pollution and Control EngineeringDocument58 pagesAir Pollution and Control EngineeringMithun Santhosh Yuvarajan100% (1)

- Types of Dev 1Document1 pageTypes of Dev 1kattabommanNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Penetrant Testing: Principles, Techniques, Applications and Interview Q&AFrom EverandPenetrant Testing: Principles, Techniques, Applications and Interview Q&ANo ratings yet

- Itp Equipment (Static)Document5 pagesItp Equipment (Static)Rajeev KumarNo ratings yet

- Itp For MechDocument5 pagesItp For MechRajeev KumarNo ratings yet

- JP For Structural WorksDocument4 pagesJP For Structural WorksRajeev KumarNo ratings yet

- Hydro TestDocument2 pagesHydro TestRajeev KumarNo ratings yet

- Hardness Ins ReportDocument2 pagesHardness Ins ReportRajeev KumarNo ratings yet

- LHS Rev-1Document29 pagesLHS Rev-1Rajeev KumarNo ratings yet

- QDR Tel-04Document2 pagesQDR Tel-04Rajeev KumarNo ratings yet

- MCF Testing of PWHTDocument21 pagesMCF Testing of PWHTRajeev KumarNo ratings yet

- Format For Manufacturer Record of Welding Operator QualificationDocument1 pageFormat For Manufacturer Record of Welding Operator QualificationRajeev KumarNo ratings yet

- Sect 11a P Welding DocumDocument31 pagesSect 11a P Welding DocumRajeev KumarNo ratings yet

- INCDEX1Document2 pagesINCDEX1Rajeev KumarNo ratings yet

- L-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteDocument4 pagesL-6699-Pins-tel-mei-0019 - Epcm QM Audit Report (Audit No. 6699-Iocl-bs-Vi-epcm-cons-006) For Bs-Vi Project at Paradip SiteRajeev KumarNo ratings yet

- Astm A217-2007Document6 pagesAstm A217-2007Rajeev KumarNo ratings yet

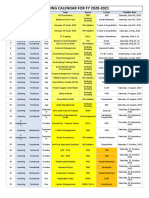

- Training Calender 2020-21Document2 pagesTraining Calender 2020-21Rajeev KumarNo ratings yet

- Acr 002Document1 pageAcr 002Rajeev KumarNo ratings yet

- BSVITEL001Document1 pageBSVITEL001Rajeev KumarNo ratings yet

- Qly Walkthrough 09-11-2022Document4 pagesQly Walkthrough 09-11-2022Rajeev KumarNo ratings yet

- Qwt-Tel-Compo-03 03 2022Document5 pagesQwt-Tel-Compo-03 03 2022Rajeev KumarNo ratings yet

- Walk Through - TEL-COMPO.22.12..2021Document3 pagesWalk Through - TEL-COMPO.22.12..2021Rajeev KumarNo ratings yet

- Acr-001 (Draft)Document2 pagesAcr-001 (Draft)Rajeev KumarNo ratings yet

- H2 Balance Month Turn Over Plan - 11.11.2022Document4 pagesH2 Balance Month Turn Over Plan - 11.11.2022Rajeev KumarNo ratings yet

- Day Wise TO Plan For The Month of DEC.22Document56 pagesDay Wise TO Plan For The Month of DEC.22Rajeev KumarNo ratings yet

- Jsa IndexDocument6 pagesJsa IndexRajeev KumarNo ratings yet

- FINAL - Audit Report - Shailesh DongareDocument7 pagesFINAL - Audit Report - Shailesh DongareRajeev KumarNo ratings yet

- Structural Steel Received DetailsDocument16 pagesStructural Steel Received DetailsRajeev KumarNo ratings yet

- U#2 W.V.Document52 pagesU#2 W.V.Rajeev KumarNo ratings yet

- HCDS Loop ListDocument20 pagesHCDS Loop ListRajeev KumarNo ratings yet

- Practice ExerciseDocument7 pagesPractice ExerciseRajeev KumarNo ratings yet

- U-2 PWHT Charts SubmissionDocument102 pagesU-2 PWHT Charts SubmissionRajeev KumarNo ratings yet

- Activity 016Document2 pagesActivity 016Rajeev KumarNo ratings yet

- Material Safety Data Sheet MSDSDocument17 pagesMaterial Safety Data Sheet MSDSRian Pratama AkbaNo ratings yet

- Silo Overpressurisation Guidance PDFDocument27 pagesSilo Overpressurisation Guidance PDFDorian StiopuNo ratings yet

- Allgaier Apt Tro Fluidizedbedtechnology en 2Document8 pagesAllgaier Apt Tro Fluidizedbedtechnology en 2Fer Lartiga VentocillaNo ratings yet

- The Next Level InstrumentationDocument102 pagesThe Next Level InstrumentationarisprakesaNo ratings yet

- Pneumatic Conveying Systems 622Document12 pagesPneumatic Conveying Systems 622sachindherange100% (1)

- CL IpkpackagingDocument15 pagesCL Ipkpackaging987_bbbNo ratings yet

- Sds ImpulsepowderDocument4 pagesSds ImpulsepowderWawan SudharsonoNo ratings yet

- English PPT PowderDocument13 pagesEnglish PPT PowderMarcello FerrelNo ratings yet

- Hand Book of Agro Chemical Industries (Insecticides & Pesticides)Document23 pagesHand Book of Agro Chemical Industries (Insecticides & Pesticides)Deepak BhanjiNo ratings yet

- Material Safety Data Sheet - SAN EARTHDocument3 pagesMaterial Safety Data Sheet - SAN EARTHPaulo CLNo ratings yet

- Powder Technology: Duy Nguyen, Anders Rasmuson, Ingela Niklasson Björn, Kyrre ThalbergDocument7 pagesPowder Technology: Duy Nguyen, Anders Rasmuson, Ingela Niklasson Björn, Kyrre ThalbergSai Santhosh ManepallyNo ratings yet

- Material Safety Data Sheet Avapolymer 5050Document4 pagesMaterial Safety Data Sheet Avapolymer 5050fs1640No ratings yet

- KB003613 - MRK1903-01 Dry Powder Method DevelopmentDocument7 pagesKB003613 - MRK1903-01 Dry Powder Method DevelopmentMiguel Zuniga MarconiNo ratings yet

- Abq Pharmaceutics Nidhi MishraDocument11 pagesAbq Pharmaceutics Nidhi MishranidhiNo ratings yet

- RST-XS.s EnglishDocument2 pagesRST-XS.s Englishbei wNo ratings yet

- United States PatentDocument7 pagesUnited States PatentThanh Linh NguyenNo ratings yet

- International Standard: Sample Preparation - Dispersing Procedures For Powders in LiquidsDocument11 pagesInternational Standard: Sample Preparation - Dispersing Procedures For Powders in LiquidsGuilherme Dias zarurNo ratings yet

- PGBSIA 2020 Conference Program 30 - 01 - 2020Document6 pagesPGBSIA 2020 Conference Program 30 - 01 - 2020Atul SharmaNo ratings yet

- Ipqc PDFDocument11 pagesIpqc PDFAshraf Farhoud100% (2)

- Lec Final Technical Reports 2022Document139 pagesLec Final Technical Reports 2022Alia AdnanNo ratings yet

- G4 Science Quiz Unit 3Document4 pagesG4 Science Quiz Unit 3Sabina E MNo ratings yet

- Business Research KalabasaMalunggay Seasoning PowderDocument13 pagesBusiness Research KalabasaMalunggay Seasoning PowderMary Lynn Dela PeñaNo ratings yet

- Single-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)Document30 pagesSingle-Fired Ceramic Wall Tile Manufacture: by Dr. Agustin Escardino Benlloch (Spain)map vitcoNo ratings yet

- Msds For Calgon PT TG en PDFDocument7 pagesMsds For Calgon PT TG en PDFdoncondomNo ratings yet

- Mixing: Andrew M. TwitchellDocument17 pagesMixing: Andrew M. Twitchellgmsanto7No ratings yet

- Husner RatioDocument11 pagesHusner RatioShania BarajaNo ratings yet

- HP Unpack - WO2020046361A1Document21 pagesHP Unpack - WO2020046361A1Pedro RosNo ratings yet

- Calcite Powder Application and Uses by RCM MineralsDocument2 pagesCalcite Powder Application and Uses by RCM Mineralsvivek vaishnavNo ratings yet

- Movacolor MC-24 Users ManualDocument69 pagesMovacolor MC-24 Users ManualZachary FedorchukNo ratings yet

- A Comprehensive Review of The Methods and Mechanisms For PowderDocument22 pagesA Comprehensive Review of The Methods and Mechanisms For PowderEduardo MendezNo ratings yet