Professional Documents

Culture Documents

Maintenance of Turbochargers - Marine Engineering

Uploaded by

Hassan KhattabCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance of Turbochargers - Marine Engineering

Uploaded by

Hassan KhattabCopyright:

Available Formats

Marine Engineering Study Materials Search

Information for Marine Engineers

Home MEO Exam Safety General Motor Download Checklists Naval Electrical

Home » Motor Engineering Knowledge » Diesel Engines » Turbochargers » Maintenance of Categories

Turbochargers – Marine Engineering

Select Category

Maintenance of Turbochargers – Marine

Engineering

November 25, 2015 10:15 pm | 2 Comments | Firoz Select Your Topic

Home

Procedure for Turbocharger Overhaul

MEO Exam

Overhauling is carried out as per planned maintenance of turbochargers. The procedure for Safety

overhauling diesel engine turbocharger is explained below.

Fire Detectors

1. Lock off the engine staring mechanism. Fire Fighting

2. Remove the turbocharger air filter. Gas Freeing

3. Drain off the oil from both drain plugs.

General

4. Remove the bearing covers from both sides.

5. Remove the locking wires. Boilers

6. Unscrew the hexagon screws and remove oil suction pipes. Pum ps

7. Tighten again the hexagon screws of the bearing boxes. Com pressors

8. Check the deflection of the divergent nozzle by using pick tester and magnet stand.

Lubricating Oil

9. Remove the divergent nozzle by screw driver.

10. Measure the K value at the blower side by using depth micrometer or caliper and straight edge. Sewage Treatm ent

11. Lock the rotor with special tool. Inert Gas System

12. Extract the lubricating disc. Air Conditioning

13. Extract the both bearings by bearing extractor.

Instrum entation and Control

14. The various parts should be warped in waxed paper to protect them against dirt and moisture.

Hydraulics

Checks on Turbocharger while Overhauling Heat Exchangers

Steering Gear

1. Check the deflection of divergent nozzle.

Refrigeration

2. Measure the K value at blower side.

Corrosion

3. Change the bearing on both sides with the new one (because bearing service life is same as

turbocharger overhauling time). Welding

4. Clean blower and turbine side with chemical and inspect carefully. Purifiers

5. Check the labyrinth seal.

6. Made clear the labyrinth seal air line Motor

7. Check the casing for crack & wear Diesel Engines

8. Blade condition Vibrations

9. After reassembled, check Static Balance

Turbochargers

10. Check Impeller and Casing clearance

Tools

When will you change turbocharger bearing ? Download

Questions and Answers on Diesel

1. As per Running Hour

Engines 1

2. As per clearance

3. When damaged MEO Class 2 Question Papers

4. When vibration is heavy MEO Class 1 Question Papers

Checklists

How to check deflection of divergent nozzle ?

Naval

1. By using Pick tester &

Rudder

2. Magnet stand

Electrical

What is the main purpose of turbocharger water washing ?

To ensure efficient functioning of turbocharger.

To protect the compressor and turbine from contamination (Deposits). ***If you Like it, Share it

Disadvantages of turbocharger water washing to turbine side ?

Engine speed has to lower.

Thermal stress and corrosion usually occurred.

Longer cleaning time.

Very fine hard deposits and residues cannot be removed easily with water washing.

Recent Posts

Advantages of solid (crystal) cleaning or grit washing ?

Measuring Fuel pump Lead on Marine

Not required to reduce engine rpm, thus not affect on scheduled voyage Auxiliary Engine

No used of water, so no corrosion and thermal stress.

SIRE Inspection on Ships

Cleaning time is short.

Not wear turbine blade. Boiler Survey on Ships

Effectively remove combustion residues and hard particle.

Cargo Sampling Procedure on Ships

How will you carry out turbocharger turbine and blower side water washing ? Operation and Maintenance of Eductor

on Ships

Blower side water washing

Maintenance of Butterfly Valve on Ships

1. It can be done when M/E on full load.

2. Fill up the warm fresh water to hopper and closed the cover.

3. Open the valve and water will flow into the blower casing and mechanically attack the blower

blades and clean the deposit. Tags

4. Close the valve, open the cover and check the cleaning water must be empty.

air compressors

air conditioning

Turbine side water washing procedure boiler

boiler blow dow n

boilers

cargo

cargo

pumps

centrifugal pumps

chemical tankers

1. Turbine side water washing can be made with hot fresh water. circulation system

cooling w ater system

2. Inform to the bridge cross head bearing oil system

cylinder lube

3. Reduce the M/E rpm to recommended speed and hence turbocharger rpm. oil system

diesel engines

4. Check the water washing injection nozzle if fitted. (directly aim to the exhaust grips explosimeter

fire detectors

fire fighting

before entering to the turbocharger) fire triangle

freshwater generator

5. Open turbocharger drain valve. freshw ater generator on ships

heat

6. Open the water supply about 1 bar to turbine side. exchangers

indicator diagrams

inert gas

7. Water washing must be made until the clean water comes out.

system

invention of diesel engine

lube oil

8. Close the water supply and remove the nozzle.

system

magnetic particle testing

main bearing

9. Exhaust side drain can be closed after all water is drained out and dried.

10. Inform to the bridge and increase the M/E rpm gradually to sea speed.

marine

oil system

main engine

11. The turbine side water washing is usually at departure after manoeuvring time. engineering

marine

12. For usual practice cleaning is done at every 500 hr, running hour depending on the cleanliness engineering

of the turbocharger . study materials

marine main sw itch board

meo

class

Grit Washing or Dry Cleaning of Turbocharger exam questions

panting

pid

controller

positive displacement pumps

1. Turbine side cleaning is superseded by walnut shell, with grain size of 12 to 34 mesh pounding

proportional control

pumps

2. No speed reduction required and cleaning can be done at full speed, once every day relief valve

safeties in main sw itch board

3. Compressed air of (3 -5 bar) is used to help the grains strike the deposited Turbine Blades and sewage treatment plant

smoke detectors

Nozzles, giving effective cleaning of hard particles stp

systems of main engine

types of chemical

4. Air supply pipe is fitted to solid grain container, and grains are injected into exhaust system by air tankers

pressure, at the same point (as in water washing ) just after exhaust grids

5. Turbine casing drain kept open during cleaning time (about 2 minutes only)

What measurements are taken during auxiliary engine turbocharger overhaul ?

K value, it is a distance between the rotor shaft end and the flange of bearing cover measure at

blower side (axial clearance).

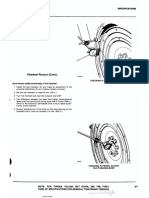

Check radial clearance (at plane bearing), by placing clock gauge on the shaft from the top and

clamp by screw driver from bottom, record the clearance.

Rotor and Casing clearance (for new casing or new rotor) (L & M values)

How to measure turbocharger axial and radial clearance ?

Axial Clearance

Push the shaft by screw jack and measure by Depth Gauge (0.2 – 0.3 mm)

Radial Clearance

Lift the shaft radially and measure by Dial Gauge (0.15 – .02 mm)

Why turbocharger exhaust outlet lower than inlet temperature ?

Some exhaust gas heat and pressure energy is transferred to mechanical rotating energy for

turbocharger, thus pressure become decrease and temperature lower.

What will occur is oil leak in turbocharger system ?

If oil is leaked into the air system the cooling surface are covered with oil which are insulated &

cooling efficiency will be reduce (ie. Scavenge temperature drop; Exhaust temperature high)

Also there will be deposits on the blower and blower efficiency will be reduced

If oil leaked into exhaust side, Carbon deposits on the nozzle & turbine blade. It cause surging,

reduces blower efficiency and fire in the exhaust piping (uptake fire)

Turbocharger Over Run

Causes

Happens in constant pressure turbo charged engine

Caused due to fire and or detonation of scavenge space

Exhaust trunk fire due to accumulation of leaked or excess lube oil and unburned fuel

Effects

Turbocharger bearings, casing damage

E/R fire

Prevention

Scavenge space regular cleaning

Exhaust gas pipe regular cleaning

Maintain complete combustion of fuel

Liner, piston and rings, fuel vales, cylinder lubrication, maintained in good order

Avoid operating M/E under reduced load for long term

Causes of Turbocharger Vibration

Unbalancing

Bearing defects

Deposits in nozzle ring

Impingement

Surging, Scavenge Fire, Overloading

Reference:

Oral Guide by – MIN ZAR TAR

Related Posts

December 17, 2015 August 28, 2015 November 16, 2015 May 7, 2014 February 25, 2015

Fuel Injector SOLAS Inspection of Dry Fouling of Main Difference

Needle Valve Requirements for Dock Jobs on Engine Lube Oil between MC and

Seizure – Marine Steering Gear Ships – Marine Cooler MC-C Engines of

Engineering Engineering MAN B&W

May 27, 2014 July 8, 2014 November 27, 2015 October 25, 2015 April 29, 2014

Parallel Operation Actions to be Monitoring CO2 Flooding Checklist for

Procedure for Taken for Slack Auxiliary Engine System – Fixed Publications to be

Marine Diesel Holding Down Performance on Fire Fighting on Held Onboard

Generators in Bolts Ships Ships

Ships

Posted in: MEO Examination Study Materials, Turbochargers | Tagged: Advantages of solid (crystal) cleaning,

Blower side water washing, Causes of Turbocharger Vibration, Checks on Turbocharger while Overhauling,

Disadvantages of turbocharger water washing to turbine side, grit washing, Grit Washing or Dry Cleaning of

Turbocharger, How to check deflection of divergent nozzle, measure turbocharger axial and radial clearance,

measurements are taken during auxiliary engine turbocharger overhaul, Procedure for Turbocharger Overhaul,

Turbine side water washing procedure, Turbocharger Over Run causes and effects, turbocharger turbine and blower

side water washing, What is the main purpose of turbocharger water washing, What will occur is oil leak in

turbocharger system, When will you change turbocharger bearing, Why turbocharger exhaust outlet lower than inlet

temperature

2 Thoughts on “Maintenance of Turbochargers – Marine Engineering”

Akif Wong

on March 14, 2020 at 11:17 am said:

Good content

Reply↓

Moe Myint Shein

on August 27, 2020 at 7:41 pm said:

Thanks Sir.

Reply↓

Leave a Reply

Your email address will not be published. Required fields are marked *

Name *

Email *

Website

Post Comment

← Previous Post Next Post →

© Copyright 2021 - Marine Engineering Online Theme by WPJournals ⋅ WordPress

You might also like

- Mooney M20 100hour PDFDocument2 pagesMooney M20 100hour PDFsplyn100% (1)

- Fluid Pump Maintenance ProcedureDocument8 pagesFluid Pump Maintenance ProcedureTrue StoryNo ratings yet

- Dart RT 2013Document541 pagesDart RT 2013nataly1993No ratings yet

- Unit 1 (Diagnosis of Vehicle)Document19 pagesUnit 1 (Diagnosis of Vehicle)kumalnimesh2No ratings yet

- Maintenance Program For HFO Diesel EngineDocument11 pagesMaintenance Program For HFO Diesel EngineUmit CengNo ratings yet

- Lesson 10 Overhaul Part 1Document2 pagesLesson 10 Overhaul Part 1Genesis SantanaNo ratings yet

- Summary of AC Motor Induction ProceduresDocument1 pageSummary of AC Motor Induction ProceduresMunazar HussainNo ratings yet

- Overseas Locomotive Shipment Preparation GuideDocument6 pagesOverseas Locomotive Shipment Preparation Guideamir barekatiNo ratings yet

- Wartsila - 18V34SG Maintenance ScheduleDocument8 pagesWartsila - 18V34SG Maintenance ScheduleironiteNo ratings yet

- Optimize 5.7L Engine DiagnosisDocument50 pagesOptimize 5.7L Engine DiagnosisJay AndrewsNo ratings yet

- Installation and Maintenance Manual For Induction MotorDocument25 pagesInstallation and Maintenance Manual For Induction Motoreko prasetyoNo ratings yet

- GEI-56128 (NEMA 140-500 HorizMotor)Document25 pagesGEI-56128 (NEMA 140-500 HorizMotor)berkahharianNo ratings yet

- (MAHINDRA) Manual de Taller Mahindra Pick Up 2.6 InglesDocument620 pages(MAHINDRA) Manual de Taller Mahindra Pick Up 2.6 InglesRodrigo Henriquez100% (1)

- Department of Aeronautical Engineering: Ae 6011 Aero Engine Maintenance & RepairDocument46 pagesDepartment of Aeronautical Engineering: Ae 6011 Aero Engine Maintenance & Repairsathesh waranNo ratings yet

- SM01 010 033.00 PDFDocument4 pagesSM01 010 033.00 PDFMohamed RashedNo ratings yet

- Service Manual SM1-10-33.0: Outrigger/Steer Pump, R & IDocument4 pagesService Manual SM1-10-33.0: Outrigger/Steer Pump, R & IMohamed RashedNo ratings yet

- Maintenance List - AK Stage V - 2020Document4 pagesMaintenance List - AK Stage V - 2020André SilvaNo ratings yet

- Light Repair and WashingDocument29 pagesLight Repair and Washingfrenz2kiranNo ratings yet

- 29 Exhaust Gas TurbochargerDocument79 pages29 Exhaust Gas TurbochargerYuri Duri50% (2)

- Vespa Service Manual 08-04-2021Document322 pagesVespa Service Manual 08-04-2021Julio Borrero100% (1)

- Maintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesDocument2 pagesMaintenance Check Sheet - DISCOVERY 3 4 ARMOURED DIESEL MODELS - MilesCristiano DellazariNo ratings yet

- 16V2000C ExportDocument5 pages16V2000C ExportteguhNo ratings yet

- Maintenance of Electrical Motors 1.5Document9 pagesMaintenance of Electrical Motors 1.5Sayed NagyNo ratings yet

- Auxiliary Blower Instruction ManualDocument35 pagesAuxiliary Blower Instruction ManualdigardbrandNo ratings yet

- Service Manual Scorpio SC DC NEF LHDDocument508 pagesService Manual Scorpio SC DC NEF LHDAlex Bravo100% (1)

- Overhauling Slipring Motors StandardDocument19 pagesOverhauling Slipring Motors StandardAhmed AshourNo ratings yet

- 200 2011 2.4LDocument265 pages200 2011 2.4LJuan Alexis Lamas OrtegaNo ratings yet

- MR - Scope - of - Work PDFDocument3 pagesMR - Scope - of - Work PDFvenkateshNo ratings yet

- Patriot 2014 2.0LDocument274 pagesPatriot 2014 2.0LsantiagoNo ratings yet

- Back Pressure Steam Turbine-Instruction Manual - R0.0Document316 pagesBack Pressure Steam Turbine-Instruction Manual - R0.0arian dwiNo ratings yet

- Recommended Actions: Transmission or Engine Accessories (If Applicable)Document3 pagesRecommended Actions: Transmission or Engine Accessories (If Applicable)sjsshipNo ratings yet

- Motor Vehicle Technician - MVTNDocument6 pagesMotor Vehicle Technician - MVTNSk Akram HossainNo ratings yet

- Engine Leak Verification Flow Chart .................................................................. 03-02-11Document37 pagesEngine Leak Verification Flow Chart .................................................................. 03-02-11Mylène RacineNo ratings yet

- Narora atomic power station Calandria Vault pump maintenance reportDocument4 pagesNarora atomic power station Calandria Vault pump maintenance reportRuchi Ragvendra BistNo ratings yet

- Manual Servicio Eaton Serie 10 PDFDocument16 pagesManual Servicio Eaton Serie 10 PDFCesar MoraNo ratings yet

- Dodge 5.7 Service InformationDocument243 pagesDodge 5.7 Service InformationNay Linn Htet100% (1)

- Avenger 2.4 2013Document263 pagesAvenger 2.4 2013Saul HernándezNo ratings yet

- Ilide - Info Meo Class 4 Oral Questions With Answerspdf PRDocument46 pagesIlide - Info Meo Class 4 Oral Questions With Answerspdf PRUpasana BhandariNo ratings yet

- Generator PM SOWsbsDocument1 pageGenerator PM SOWsbsVinay ThakurNo ratings yet

- Compass 2013 2.4LDocument292 pagesCompass 2013 2.4LCarlos MonzonNo ratings yet

- 2014 Dodge Avenger RTDocument271 pages2014 Dodge Avenger RTJose Refugio Madrigal Iglesias100% (1)

- 04 W34DF 20210809 enDocument14 pages04 W34DF 20210809 enSalman KapoorNo ratings yet

- Mercury 115 Manual 1bDocument13 pagesMercury 115 Manual 1bMomed MdNo ratings yet

- Deutx 914 Operation and Maintenance Manual AbbyDocument83 pagesDeutx 914 Operation and Maintenance Manual AbbyTASHKEEL50% (2)

- Maintenance and Repair Module2Document71 pagesMaintenance and Repair Module2Ardelean Paul100% (1)

- Manual EF494T enDocument81 pagesManual EF494T enRafaelEdisonNo ratings yet

- Manual Servicio Scorpio 2.5 L CRDe Euro IV PDFDocument585 pagesManual Servicio Scorpio 2.5 L CRDe Euro IV PDFMarco Dorigoni100% (3)

- Parte 5 Md200Document22 pagesParte 5 Md200samuelNo ratings yet

- Ehg 9340Document19 pagesEhg 9340Dherlan SukapurqNo ratings yet

- PM 4000 SeriesDocument3 pagesPM 4000 SeriesmohamedNo ratings yet

- MP Misc 255 April 10 Emd CommissioningDocument6 pagesMP Misc 255 April 10 Emd CommissioningmailbkraoNo ratings yet

- Stihl 021 023 025 Workshop Manual PDFDocument52 pagesStihl 021 023 025 Workshop Manual PDFTony Wells100% (2)

- DIESEL ENGINE ISUZU 4JG2 Service ManualDocument48 pagesDIESEL ENGINE ISUZU 4JG2 Service ManualArmando Orta90% (10)

- D4 Maintenance Check Sheet - Discovery 4 (LA) All Models - UK EU - 10-11MY - KMDocument2 pagesD4 Maintenance Check Sheet - Discovery 4 (LA) All Models - UK EU - 10-11MY - KMZM OhnNo ratings yet

- Weekly MaintenianceDocument1 pageWeekly MainteniancekhalidNo ratings yet

- 200 2013 2.4LDocument263 pages200 2013 2.4LJuan Alexis Lamas OrtegaNo ratings yet

- PT Transcoal Pacific's Safety Management ManualDocument5 pagesPT Transcoal Pacific's Safety Management ManualMusyadatNo ratings yet

- SATOH TRACTOR REPAIR MANUAL ENGINE SYSTEMDocument219 pagesSATOH TRACTOR REPAIR MANUAL ENGINE SYSTEMrepropNo ratings yet

- Engine Jeep Patriot 2.0Document296 pagesEngine Jeep Patriot 2.0Yoga Ariant100% (1)

- Mechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionFrom EverandMechanical (Turbines and Auxiliary Equipment): Second Revised and Enlarged EditionA. SherryRating: 4 out of 5 stars4/5 (5)

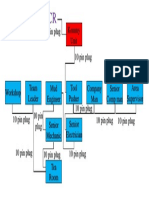

- GAI-tronics Map 1Document1 pageGAI-tronics Map 1Hassan KhattabNo ratings yet

- Osha For Rigs Oil and Gas Extraction - Hazards - Occupational Safety and Health AdministrationDocument4 pagesOsha For Rigs Oil and Gas Extraction - Hazards - Occupational Safety and Health AdministrationHassan KhattabNo ratings yet

- Flywheel ALIGNENT 2Document2 pagesFlywheel ALIGNENT 2Hassan KhattabNo ratings yet

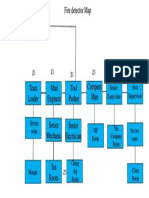

- Fire MapDocument1 pageFire MapHassan KhattabNo ratings yet

- Fire Detector Map: Senior Comp Man Area SupervisorDocument1 pageFire Detector Map: Senior Comp Man Area SupervisorHassan KhattabNo ratings yet

- Orion Rig Inspection - CheckboxL PDFDocument16 pagesOrion Rig Inspection - CheckboxL PDFdariovivaldiNo ratings yet

- Inspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairDocument2 pagesInspect Axial Play of Turbine Shaft - Toyota Hilux 1KZ TE RepairHassan KhattabNo ratings yet

- Rig 130 NOV MPDocument1 pageRig 130 NOV MPHassan KhattabNo ratings yet

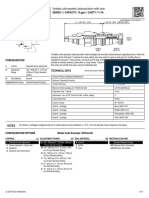

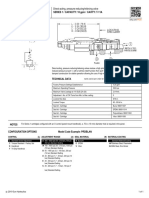

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- Vented pilot-to-open check valve specificationsDocument1 pageVented pilot-to-open check valve specificationsHassan KhattabNo ratings yet

- Bearings With Proper Play Live Longer - Machine DesignDocument3 pagesBearings With Proper Play Live Longer - Machine DesignMariam KhattabNo ratings yet

- Flywheel ALGNENT 1Document1 pageFlywheel ALGNENT 1Hassan KhattabNo ratings yet

- A Comparison Between Screw Compressor and Other Machines - AONG WebsiteDocument5 pagesA Comparison Between Screw Compressor and Other Machines - AONG WebsiteHassan KhattabNo ratings yet

- Manual de Fallas Tds 11pdfDocument68 pagesManual de Fallas Tds 11pdfHassan KhattabNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- Figure 3 - Turbulent Flow Measurements Near The Discharge Port of A Screw Compressor - SpringerLinkDocument1 pageFigure 3 - Turbulent Flow Measurements Near The Discharge Port of A Screw Compressor - SpringerLinkHassan KhattabNo ratings yet

- 06 - TDS-11 Top Drive Competency (P1PS)Document7 pages06 - TDS-11 Top Drive Competency (P1PS)Hassan KhattabNo ratings yet

- Mud Pump Bearing Life 11338 1Document12 pagesMud Pump Bearing Life 11338 1Hassan KhattabNo ratings yet

- Net2f"25N: Accumulator With Diaphragm StabilizerDocument6 pagesNet2f"25N: Accumulator With Diaphragm StabilizerHassan KhattabNo ratings yet

- Precision Hydraulics 12th Edition 2019 CTR VALVESDocument819 pagesPrecision Hydraulics 12th Edition 2019 CTR VALVESHassan KhattabNo ratings yet

- Relife Valve Low Flow Rbac - T10aDocument1 pageRelife Valve Low Flow Rbac - T10aHassan KhattabNo ratings yet

- Model Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10ADocument2 pagesModel Direct-Acting Relief Valve - Pilot Capacity: Series 1 / Capacity: .25 GPM / Cavity: T-10AHassan KhattabNo ratings yet

- Model Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11ADocument1 pageModel Direct-Acting, Pressure Reducing/relieving Valve: Series 1 / Capacity: 10 GPM / Cavity: T-11AmhasansharifiNo ratings yet

- Vented pilot-to-open check valve specificationsDocument1 pageVented pilot-to-open check valve specificationsHassan KhattabNo ratings yet

- A Comparison Between Screw Compressor and Other Machines - AONG WebsiteDocument5 pagesA Comparison Between Screw Compressor and Other Machines - AONG WebsiteHassan KhattabNo ratings yet

- Relief Valve VENTABLE RVCALAN - T11A RV1Document1 pageRelief Valve VENTABLE RVCALAN - T11A RV1Hassan KhattabNo ratings yet

- LOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterDocument2 pagesLOGIC CARTRIDGE LODCXDN - Full - en - Us - LetterHassan KhattabNo ratings yet

- Side Check Valve CXDAXAN - en - Us - LetterDocument1 pageSide Check Valve CXDAXAN - en - Us - LetterHassan KhattabNo ratings yet

- How Many Watt Solar Panel To Charge Deep Cycle Battery - EditedDocument5 pagesHow Many Watt Solar Panel To Charge Deep Cycle Battery - EditedalexNo ratings yet

- 431CSL6206T60Document2 pages431CSL6206T60Igor CanabarroNo ratings yet

- Object Oriented Programming 3Document18 pagesObject Oriented Programming 3rahul rastogiNo ratings yet

- Thermal BowingDocument8 pagesThermal BowingA. VenugopalNo ratings yet

- CA ClarityPPM Integration Guide ENUDocument553 pagesCA ClarityPPM Integration Guide ENUvictorinovilaNo ratings yet

- Model 3410: Shear Beam Load CellsDocument4 pagesModel 3410: Shear Beam Load CellsIvanMilovanovicNo ratings yet

- HES2125 10S2 Revision01Document4 pagesHES2125 10S2 Revision01Roberto RizzoNo ratings yet

- Coiled Tubing Gauge Carrier DatasheetDocument2 pagesCoiled Tubing Gauge Carrier Datasheetu2006262918No ratings yet

- Utilizacao Do Lightroom 2 - Portugues - 190 PgsDocument190 pagesUtilizacao Do Lightroom 2 - Portugues - 190 Pgsrita_poaNo ratings yet

- Is.1795.1982 Pillar TapDocument20 pagesIs.1795.1982 Pillar Tapkishor150688No ratings yet

- 5WMNT 01CDocument2 pages5WMNT 01CSaraiNo ratings yet

- Compaction Factor TestDocument3 pagesCompaction Factor TestNitisha Rathore100% (5)

- Final 2010Document8 pagesFinal 2010Hakkı ÇelimliNo ratings yet

- Why Vehicle Slip When It Is Travelling On A SlopeDocument12 pagesWhy Vehicle Slip When It Is Travelling On A SlopeRizwan Sheikh0% (1)

- Converter Faults & ProtectionDocument24 pagesConverter Faults & ProtectionrakeshNo ratings yet

- Eds 07 3102 Secondary Substation Civil DesignDocument26 pagesEds 07 3102 Secondary Substation Civil DesignUmerfarooq TawriNo ratings yet

- CUPRA TCR SEQ Technical Form - Final-1Document109 pagesCUPRA TCR SEQ Technical Form - Final-1jaime cid monzoNo ratings yet

- Macro TestDocument2 pagesMacro TestTomy GeorgeNo ratings yet

- ResumeDocument3 pagesResumedestroy0012No ratings yet

- 7-Polibrid Spray System RequirementsDocument2 pages7-Polibrid Spray System RequirementsProject NiteksindoNo ratings yet

- Hafod Arch, Brynmawr, Blaenau Gwent. Watching BriefDocument28 pagesHafod Arch, Brynmawr, Blaenau Gwent. Watching BriefAPAC LtdNo ratings yet

- AFT Software Prices (2015SWOrderForm)Document3 pagesAFT Software Prices (2015SWOrderForm)Ender ZenginobuzNo ratings yet

- PhasechangesseDocument5 pagesPhasechangesseapi-30969951177% (57)

- LED Driver Test Report IEC 61347 2 13 36CDocument11 pagesLED Driver Test Report IEC 61347 2 13 36CLingaraj Suresh LingaianNo ratings yet

- Boq ChandigarhDocument2 pagesBoq ChandigarhVinay PantNo ratings yet

- Wsc2015 Tp10 PV TW Partslist Iso A PreDocument1 pageWsc2015 Tp10 PV TW Partslist Iso A PreCristyan ReisNo ratings yet

- T Box 12-280Document4 pagesT Box 12-280Bibi DanilaNo ratings yet

- CV for Oil & Gas Control Room OperatorDocument7 pagesCV for Oil & Gas Control Room Operatormsk649No ratings yet

- Rule of Thumb: Distillation and Gas AdsorptionDocument2 pagesRule of Thumb: Distillation and Gas AdsorptionChristina Joana GuzmanNo ratings yet

- Capital BudgetingDocument30 pagesCapital BudgetingNarasimhaPrasadNo ratings yet