Professional Documents

Culture Documents

Onstruction Raining Ualification Rogram Asphalt Plant Level II

Uploaded by

Devesh Kumar PandeyOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Onstruction Raining Ualification Rogram Asphalt Plant Level II

Uploaded by

Devesh Kumar PandeyCopyright:

Available Formats

Asphalt Plant Level II - July 2005 1 of 11

Appendix 3b

Slide 1

Construction

Training

Qualification

Program

Asphalt Plant

Level II

Appendix 3b

Batch Plants – Hot Bin

Calibration Practice Problems

This is the technique used to

Slide 2

Calibration of Hot Bins establish hot bin “pulls”, or the individual

Batch Plants bin weights, from a batching plant.

(Establishing Hot Bin Percentages and

Weights for Production Requirements)

July 2005 Appendix 3b - 2

These are the typical procedures

Slide 3

one goes through.

Batch Plant Calibration 1) Start the plant - run the cold feed, the

dryer, and the screens

• Start the plant - run the cold feed, the dryer,

and the screens

2) After stabilization - sample the

• After stabilization - sample the material from material from each hot bin

each hot bin 3) Washed gradations are preferred - but

• Washed gradation is preferred - but dry dry gradation is acceptable.

gradation is acceptable 4) Then blend the aggregates to

• Then blend the aggregates to determine the determine the percentages from each bin

percentages from each bin to meet the JMF.

to meet the JMF.

July 2005 Appendix 3b - 3

Asphalt Plant Level II - July 2005 2 of 11

Appendix 3b

Slide 4 Although the blending of

aggregates is shown here for hot bins, this

Blending of Aggregates same process is used in blending

materials for mix design as well as

• Batch Plant Hot Bins adjusting percentages on cold feeds based

• Other applications on stockpile gradations.

– Mix Design

– Cold Bins

• Methods

– Trial and Error

– Computer spread sheet

July 2005 Appendix 3b - 4

This is the formula used for the

Slide 5

procedure.

Blending of Aggregates

P = Aa + Bb + Cc + ….

– Where:

• P = % of material passing a given sieve for

the blended aggregates A, B, C, …

• A, B, C, … = % material passing a given

sieve for each aggregate A, B, C, …..

• a, b, c, …. = Proportions (decimal fractions)

of aggregates A, B, C, … to be

used in blend

July 2005 Appendix 3b - 5

Slide 6

Blending of Aggregates

P = Aa + Bb + Cc

Sieve BIN 1 a BIN 2 b BIN 3 c BIN 4 d Blend JMF

3/4 in

1/2 in

3/8 in

No. 4 A Aa B Bb C Cc D Dd P

No. 8

No. 16

No. 30

No. 50

No. 100

No. 200

July 2005 Appendix 3b - 6

Asphalt Plant Level II - July 2005 3 of 11

Appendix 3b

Slide 7 Start with the gradations of the

individual aggregates and list them based

Blending of Aggregates on the control sieves.

Sieve BIN 1 BIN 2 BIN 3 BIN 4 Blend JMF

You can determine the blend

3/4 in 100 100 100 100 100

proportions from each bin (or material)

1/2 in 100 100 100 77 96 by:

3/8 in

No. 4

100

100

100

87

98

4.1

19

3.1

87

63

1. Experience

No. 8 98 4.1 3.6 2.5 46

2. Computer program

No. 16 83 3.9 3.4 2.3 39

No. 30 65 3.0 2.5 2.0 31 3. By an empirical procedure

No. 50

No. 100

45

22

2.5

2.3

2.0

1.8

1.8

1.7

21

11

We will use the empirical

No. 200 8.0 2.0 1.0 1.1 4.4 procedure for this classroom problem.

July 2005 Appendix 3b - 7

Determine the amount to be

Slide 8

Blending of Aggregates pulled from Bin # 1 (0.45). Look for a

Bin # 1 sieve where there is a lot passing for the

Sieve BIN 1 0.45 BIN 2 BIN 3 BIN 4 Blend JMF No. 1 bin material and little passing for

3/4 in 100 100 100 100 100 the other bins. (No. 8 or No. 16 sieve)

1/2 in

3/8 in

100

100

100

100

100

98

77

19

96

87

then the equation reduces to P = Aa.

No. 4 100 87 4.1 3.1 63

No. 8 98 4.1 3.6 2.5 46

No. 16 83 3.9 3.4 2.3 39

No. 30 65 3.0 2.5 2.0 31

No. 50 45 2.5 2.0 1.8 21

No. 100 22 2.3 1.8 1.7 11

No. 200 8.0 2.0 1.0 1.1 4.4

a = JMF = ± 0.45

July 2005 A Appendix 3b - 8

Blending of Aggregates Determine the amount to be

Slide 9

pulled from Bin # 4 (0.15). This time

Bin # 4

Sieve BIN 1 (0.45) BIN 2 BIN 3 BIN 4 (0.15) Blend JMF look at the % retained = 100 – (%

3/4 in 100 45 100 100 100 100

passing), and find sieve where there is

1/2 in 100 45 100 100 77 11.6 96 some retained for Bin 4 material, and

3/8 in 100 45 100 98 19 87

No. 4 100 45 87 4.1 3.1 63

none for the other bins (1/2” sieve) then

No. 8

No. 16

98

83

44.1

37.4

4.1

3.9

3.6

3.4

2.5

2.3

46

39

the equation reduces to (100 - P) = (100 –

No. 30 65 29.3 3.0 2.5 2.0 31 D) d.

No. 50 45 20.3 2.5 2.0 1.8 21

No. 100 22 9.9 2.3 1.8 1.7 11

No. 200 8.0 3.60 2.0 1.0 1.1 4.4

d = 100 – JMF = ± 0.15

100 - D

July 2005 Appendix 3b - 9

Asphalt Plant Level II - July 2005 4 of 11

Appendix 3b

Slide 10 Blending of Aggregates Distribute the remaining amount

between bins 2 and 3 (0.20, 0.20).

Bin # 2 & # 3

Sieve BIN 1 (0.45) BIN 2 BIN 3 BIN 4 (0.15) Blend JMF

3/4 in 100 45 100 100 100 15 100

1/2 in 100 45 100 100 77 11.6 96

3/8 in 100 45 100 98 19 2.9 87

No. 4 100 45 87 4.1 3.1 0.5 63

No. 8 98 44.1 4.1 3.6 2.5 0.4 46

No. 16 83 37.4 3.9 3.4 2.3 0.3 39

No. 30 65 29.3 3.0 2.5 2.0 0.3 31

No. 50 45 20.3 2.5 2.0 1.8 0.3 21

No. 100 22 9.9 2.3 1.8 1.7 0.3 11

No. 200 8.0 3.60 2.0 1.0 1.1 0.17 4.4

July 2005 Appendix 3b - 10

Blending of Aggregates Finish all the calculations. We are

Slide 11

slightly out of spec on our target JMF.

Bin # 2 & # 3

So, we need to try the blend again.

3/4 in 100 45.0 100 20.0 100 20.0 100 15.0 100.0 100

1/2 in 100 45.0 100 20.0 100 20.0 77 11.6 96.6 96

3/8 in 100 45.0 100 20.0 98 20.0 19 2.9 87.5 87

No. 4 100 45.0 87 17.4 4.1 0.8 3.1 0.5 63.7 63

No. 8 98 44.1 4.1 0.8 3.6 0.7 2.5 0.4 46.0 46

No. 16 83 37.4 3.9 0.8 3.4 0.7 2.3 0.3 39.2 39

No. 30 65 29.3 3.0 0.6 2.5 0.5 2.0 0.3 30.7 31

No. 50 45 20.3 2.5 0.5 2.0 0.4 1.8 0.3 21.5 21

No. 100 22 9.9 2.3 0.5 1.8 0.4 1.7 0.3 11.1 11

No. 200 8.0 3.60 2.0 0.40 1.0 0.20 1.1 0.17 4.37 4.4

July 2005 Appendix 3b - 11

So we need to try the blend again.

Slide 12

Blending of Aggregates For our second trial we will use Bin # 1 –

Trial No. 2 45%; Bin # 2 – 19%; Bin # 3 – 20%; Bin

Sieve BIN 1 (0.45) BIN 2 (0.19) BIN 3 (0.20) BIN 4 (0.16) Blend JMF # 4 – 16%. We choose these percentages

3/4 in 100 100 100 100 100 based on experience and this gets us

1/2 in

3/8 in

100

100

100

100

100

98

77

19

96

87

closer to the JMF.

No. 4 100 87 4.1 3.1 63

No. 8 98 4.1 3.6 2.5 46

No. 16 83 3.9 3.4 2.3 39

No. 30 65 3.0 2.5 2.0 31

No. 50 45 2.5 2.0 1.8 21

No. 100 22 2.3 1.8 1.7 11

No. 200 8.0 2.0 1.0 1.1 4.4

July 2005 Appendix 3b - 12

Asphalt Plant Level II - July 2005 5 of 11

Appendix 3b

Slide 13 Once the individual bin

percentages are calculated, the individual

weights have to be established.

Determination of Bin

Weights or

How Much Aggregate

Should be Weighed out

from Each Bin

July 2005 Appendix 3b - 13

This slide summarizes the results

Slide 14

of the previous blend calculations. The

Example Problem mix will have 6% asphalt and will have

the aggregate proportions shown. The

• To summarize batch size will be three tons or 6000

– Batch Size 6000 lbs

pounds.

– % Asphalt 6%

– Bin # 1 45 %

– Bin # 2 19 %

– Bin # 3 20 %

– Bin # 4 16 %

July 2005 Appendix 3b - 14

The first step is to determine how

Slide 15

much aggregate will be in each batch.

Example Problem

• Calculate the amount of AC in the mix

6000 * 0.06 (6%) = 360 lb

• Total aggregate weight in the batch

6000 - 360 = 5640 lb

July 2005 Appendix 3b - 15

Asphalt Plant Level II - July 2005 6 of 11

Appendix 3b

Slide 16 After the proportions of each

aggregate have been determined – it is

Example Problem easy to calculate the weight required from

each bin.

Bin Proportion Agg wt Req. Wt.

1 45 * 5640 2538

2 19 * 5640 1072

3 20 * 5640 1128

4 16 * 5640 902

July 2005 Appendix 3b - 16

Slide 17

Hot Bin Calibration

Practice Problem

July 2005 Appendix 3b - 17

Slide 18

Practice Problem

• Given:

– Batch size = 4000 lbs

– Asphalt content = 4.5 %

– Gradations shown on next sheet

• Required

– Blend the aggregates then

– Calculate the bin weights

July 2005 Appendix 3b - 18

Asphalt Plant Level II - July 2005 7 of 11

Appendix 3b

Slide 19

Practice problem gradation

Sieve Bin # 1 Bin # 2 Bin # 3 JMF

Size

3/4 inch 100 100 100 100

1/2 inch 100 100 100 100

3/8 inch 100 100 85 96

# 4 100 78 4.2 67

# 10 92.2 2.3 1.6 47

# 40 52.6 2 1.4 27

# 80 22.7 1.8 1.4 12

# 200 3.5 1.6 1.2 2.5

July 2005 Appendix 3b - 19

Slide 20

Blending of Aggregates

P = Aa + Bb + Cc

Sieve Bin # 1 Bin # 2 Bin # 3 Blend JMF

3/4 in 100 100 100 100

1/2 in 100 100 100 100

3/8 in 100 100 85.0 96.0

No. 4 100 78.0 4.2 67.0

No. 10 92.2 2.3 1.6 47.0

No. 40 52.6 2.0 1.4 27.0

No. 80 22.7 1.8 1.4 12.0

No. 200 3.50 1.60 1.20 2.50

July 2005 Appendix 3b - 20

Slide 21

Practice Problem

• Calculate the AC content in the mix

• Total aggregate weight in the batch

July 2005 Appendix 3b - 21

Asphalt Plant Level II - July 2005 8 of 11

Appendix 3b

Slide 22

Practice Problem

• To summarize

– Batch Size 4000 lbs

– % Asphalt 5.5 %

– Bin # 1 _____ %

– Bin # 2 _____ %

– Bin # 3 _____ %

July 2005 Appendix 3b - 22

Slide 23

Practice Problem

Bin Proportion Agg wt Req. Wt.

1

July 2005 Appendix 3b - 23

Slide 24

ANSWERS

Batch Plants – Hot Bin Calibration

Practice Problem

July 2005 Appendix 3b - 24

Asphalt Plant Level II - July 2005 9 of 11

Appendix 3b

Slide 25

Hot Bin Calibration

Practice Problem

July 2005 Appendix 3b - 25

Slide 26

Practice Problem

• Given:

– Batch size = 4000 lbs

– Asphalt content = 5.5 %

– Gradations shown on next sheet

• Required

– Blend the aggregates then

– Calculate the bin weights

July 2005 Appendix 3b - 26

Slide 27

Practice problem gradation

Sieve Bin # 1 (.50) Bin # 2 (0.20) Bin # 3 (0.30) Blend JMF

3/4 in 100 50 100 20 100 30 100 100

1/2 in 100 50 100 20 100 30 100 100

3/8 in 100 50 100 20 85.0 26.0 96.0 96.0

No. 4 100 50 78.0 15.6 4.2 1.3 66.9 67.0

No. 10 92.2 46.1 2.3 0.5 1.6 0.5 47.0 47.0

No. 40 52.6 26.3 2.0 0.4 1.4 0.4 27.1 27.0

No. 80 22.7 11.4 1.8 0.4 1.4 0.4 12.1 12.0

No. 200 3.50 1.75 1.60 0.32 1.20 0.36 2.43 2.50

July 2005 Appendix 3b - 27

Asphalt Plant Level II - July 2005 10 of 11

Appendix 3b

Slide 28

Example Problem

• Calculate the AC content in the mix

4000 * 0.055 (5.5%) = 220 lb

• Total aggregate weight in the batch

4000 - 220 = 3780 lb

July 2005 Appendix 3b - 28

Slide 29

Example Problem

• To summarize

– Batch Size 4000 lbs

– % Asphalt 5.5 %

– Bin # 1 50 %

– Bin # 2 20 %

– Bin # 3 30 %

July 2005 Appendix 3b - 29

Slide 30

Example Problem

Bin Proportion Agg wt Req. Wt.

1 50 * 3780 1890

2 20 * 3780 756

3 30 * 3780 1134

July 2005 Appendix 3b - 30

Asphalt Plant Level II - July 2005 11 of 11

Appendix 3b

Slide 31

Additional Gradation

Problem

July 2005 Appendix 3b - 31

Slide 32

Gradation

Sieve BIN 1 BIN 2 BIN 3 BIN 4 Blend JMF

3/4 in 100 100 100 100 100

1/2 in 100 100 100 89.7 97

3/8 in 100 100 96.7 84.5 95

No. 4 100 82 3.4 3.6 60

No. 8 87 4.8 2.6 2.8 45

No. 16 66 4.0 2.5 1.9 34

No. 30 49 3.5 2.3 1.7 25

No. 50 34 2.1 1.9 1.5 18

No. 100 15 2.0 1.8 1.4 8

No. 200 6.0 1.8 1.6 1.3 3.7

July 2005 Appendix 3b - 32

Slide 33

Gradation Answer

Sieve BIN 1 (0.50) BIN 2 (0.10) BIN 3 (0.10) BIN 4 (0.30) Blend JMF

3/4 in 100 50 100 10 100 10 100 30 100 100

1/2 in 100 50 100 10 100 10 89.7 26.9 96.9 97

3/8 in 100 50 100 10 96.7 9.7 84.5 25.4 95.0 95

No. 4 100 50 82 8.0 3.4 0.3 3.6 1.1 59.6 60

No. 8 87 43.5 4.8 0.5 2.6 0.3 2.8 0.8 45.1 45

No. 16 66 33.0 4.0 0.4 2.5 0.3 1.9 0.6 34.2 34

No. 30 49 24.5 3.5 0.4 2.3 0.2 1.7 0.5 25.6 25

No. 50 34 17.0 2.1 0.2 1.9 0.2 1.5 0.5 17.9 18

No. 100 15 7.5 2.0 0.2 1.8 0.2 1.4 0.4 8.3 8

No. 200 6.0 3.00 1.8 0.18 1.60 0.16 1.3 0.39 3.73 3.7

July 2005 Appendix 3b - 33

You might also like

- Schaum's Outline of Principles of Accounting I, Fifth EditionFrom EverandSchaum's Outline of Principles of Accounting I, Fifth EditionRating: 5 out of 5 stars5/5 (3)

- TM-1801 AVEVA Everything3D™ (2.1) Foundations Rev 3.0Document146 pagesTM-1801 AVEVA Everything3D™ (2.1) Foundations Rev 3.0Indra Rosadi100% (3)

- Revenue Cycle To Revenue Excellence: Are You Ready To Embrace Digital Growth?Document6 pagesRevenue Cycle To Revenue Excellence: Are You Ready To Embrace Digital Growth?avinashn1984No ratings yet

- (Reaffirmed!2013) !Document28 pages(Reaffirmed!2013) !Devesh Kumar PandeyNo ratings yet

- Methods For Testing Tar and Bituminous Materials: Determination of Effect of Heat and Air by Thin Film Oven TestDocument10 pagesMethods For Testing Tar and Bituminous Materials: Determination of Effect of Heat and Air by Thin Film Oven TestDevesh Kumar PandeyNo ratings yet

- 6403 1981 AMD2 Reff2021Document19 pages6403 1981 AMD2 Reff2021Devesh Kumar PandeyNo ratings yet

- Methods For Testing Tar and Bituminous Materials - Sampling of Bituminous MaterialsDocument14 pagesMethods For Testing Tar and Bituminous Materials - Sampling of Bituminous MaterialsDevesh Kumar PandeyNo ratings yet

- Burnt Clay Building Bricks - Methods of Test: Indian StandardDocument8 pagesBurnt Clay Building Bricks - Methods of Test: Indian StandardDevesh Kumar PandeyNo ratings yet

- API RBI Tank Case Study 1Document26 pagesAPI RBI Tank Case Study 1Giang T Le100% (1)

- Anti-Termite Measures in Buildings - Code of Practice: Indian StandardDocument26 pagesAnti-Termite Measures in Buildings - Code of Practice: Indian StandardDevesh Kumar Pandey100% (2)

- DeepSea 8620 User GuideDocument40 pagesDeepSea 8620 User GuideMTU650100% (1)

- Methods For Testing Tar and Bituminous Materials - Determination of PenetrationDocument10 pagesMethods For Testing Tar and Bituminous Materials - Determination of PenetrationDevesh Kumar PandeyNo ratings yet

- CQI 9 3rd Edition Errata SheetDocument2 pagesCQI 9 3rd Edition Errata SheetANONIMONo ratings yet

- PETREL Simple SimulationDocument48 pagesPETREL Simple SimulationKuala Tambora100% (1)

- Winmostar tutorial: Gromacs Vapor Pressure・Surface TensionDocument12 pagesWinmostar tutorial: Gromacs Vapor Pressure・Surface TensionEliasSMonteiroFilhoNo ratings yet

- Method Statement SLABDocument11 pagesMethod Statement SLABdeviesrigatiNo ratings yet

- Interim Guidelines On Use of Fibre-ReinforcedDocument38 pagesInterim Guidelines On Use of Fibre-ReinforcedDevesh Kumar PandeyNo ratings yet

- Questionnaire Cement Plants-01 (1) .8.04Document9 pagesQuestionnaire Cement Plants-01 (1) .8.04Debajit BurhagohainNo ratings yet

- Lap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedDocument2 pagesLap Cement Used With Asphalt Roll Roofing, Non Fibered, Asbestos Fibered, and Non Abestos FiberedMohammad YaseenNo ratings yet

- Integral Calculus Module 2 PDFDocument14 pagesIntegral Calculus Module 2 PDFRara JaveeeNo ratings yet

- 23-8-7 ICP Baching Plant (Draft)Document23 pages23-8-7 ICP Baching Plant (Draft)rienddy fajarkusumaNo ratings yet

- Mechanical Analysis of Soils: Colorado Procedure 21-08Document2 pagesMechanical Analysis of Soils: Colorado Procedure 21-08Johannah MaligmatNo ratings yet

- New Enquiry Feasibility Review FormatDocument3 pagesNew Enquiry Feasibility Review FormatUlhas KavathekarNo ratings yet

- BAM-S05-02 Optimisation of Shaker Speed - Sep99Document12 pagesBAM-S05-02 Optimisation of Shaker Speed - Sep99RiyanNo ratings yet

- Problem: Part Hight Out of Spec Problem PhotoDocument8 pagesProblem: Part Hight Out of Spec Problem PhotoManikandanNo ratings yet

- IRC 90-2010 Hot Mix PlantDocument93 pagesIRC 90-2010 Hot Mix PlantKishor SondgeNo ratings yet

- Subject 9. Design and Scheduling of Batch ProcessessDocument27 pagesSubject 9. Design and Scheduling of Batch ProcessessEstefanía Duarte SilvaNo ratings yet

- Cantabroloss Procedure TestDocument3 pagesCantabroloss Procedure TestyasNo ratings yet

- Fertilizer 86 120 16 35 PDFDocument20 pagesFertilizer 86 120 16 35 PDFSATHISHNo ratings yet

- 'BEST' Instruction ManualDocument100 pages'BEST' Instruction ManualalbeNo ratings yet

- Cantabro Loss: Test Procedure ForDocument2 pagesCantabro Loss: Test Procedure ForMuhammad Syahid Al HaqNo ratings yet

- Cantabro Loss: Test Procedure ForDocument2 pagesCantabro Loss: Test Procedure ForMuhammad Syahid Al HaqNo ratings yet

- Astm D3625-96-R2005Document2 pagesAstm D3625-96-R2005ROBERTO MIRANDANo ratings yet

- D-5841 InglesDocument2 pagesD-5841 InglesbereniceNo ratings yet

- (IPC) Tape Test 650Document2 pages(IPC) Tape Test 650Chandra Nur KhalamNo ratings yet

- 8.11-14.11 Weekly Work Report-Nashaat Dhyaa QAQC DepartmentDocument4 pages8.11-14.11 Weekly Work Report-Nashaat Dhyaa QAQC DepartmentNashaat DhyaaNo ratings yet

- Presented By:: Saleem Ul Qamar M.Zohaib Syed.M.Ali Haris MaqsoodDocument11 pagesPresented By:: Saleem Ul Qamar M.Zohaib Syed.M.Ali Haris MaqsoodSaleem Ul QamarNo ratings yet

- QAV-2 Step-3 Audit Check Sheet PDFDocument5 pagesQAV-2 Step-3 Audit Check Sheet PDFRajNo ratings yet

- OIL Ompaction Asics: Soil CompactionDocument38 pagesOIL Ompaction Asics: Soil CompactionManny AnsariNo ratings yet

- Dynamic Modeling of ADocument251 pagesDynamic Modeling of ABayu PutraNo ratings yet

- Gross Heat in Fuel Oils and Biomass: Instrument: AC600Document3 pagesGross Heat in Fuel Oils and Biomass: Instrument: AC600Alfredo MarcanoNo ratings yet

- Unit-Ii Plant Location & LayoutDocument65 pagesUnit-Ii Plant Location & LayoutCharul AgrawalNo ratings yet

- Work Instructions (W.I.)Document18 pagesWork Instructions (W.I.)Shamsul Azhar MohdNo ratings yet

- Starch MFG Ip 03 1994Document91 pagesStarch MFG Ip 03 1994Dat TanNo ratings yet

- Remove Baking StationDocument9 pagesRemove Baking StationQuýNguyễnNo ratings yet

- Sugar Manufacturing Operations Audit ChecklistDocument21 pagesSugar Manufacturing Operations Audit ChecklistSenthil KumarNo ratings yet

- Dye and PryDocument11 pagesDye and PryeliasNo ratings yet

- Chapter 3 Marshall SpecimenDocument35 pagesChapter 3 Marshall SpecimenHanaNo ratings yet

- 3 Process AnalysisDocument35 pages3 Process Analysissuman souravNo ratings yet

- FinalDocument9 pagesFinalSonia RanaNo ratings yet

- Design of Bituminous Mixtures: Test Procedure ForDocument40 pagesDesign of Bituminous Mixtures: Test Procedure ForAlhilali ZiyadNo ratings yet

- Design of Bituminous Mixtures: Test Procedure ForDocument40 pagesDesign of Bituminous Mixtures: Test Procedure ForNor NadiaNo ratings yet

- PVT Modeling TutorialDocument7 pagesPVT Modeling Tutorialbillal_m_aslamNo ratings yet

- GP-17 BiomassDocument52 pagesGP-17 BiomasspurnawanNo ratings yet

- Aci-211Document38 pagesAci-211Dharmendraa KumarNo ratings yet

- Process Guide: TechnipDocument6 pagesProcess Guide: TechnipДмитрий ГоршковNo ratings yet

- 25 - Continous Paving Plant & ProcessDocument4 pages25 - Continous Paving Plant & Processasr.engineering2023No ratings yet

- Chapter 2 Boiler Design PDFDocument6 pagesChapter 2 Boiler Design PDFFernando Sandoval RuedaNo ratings yet

- 5 Steps Homologacion Toolings System (English) - V.28.01.2016Document10 pages5 Steps Homologacion Toolings System (English) - V.28.01.2016Aleix AdrianiNo ratings yet

- Chapter 5 - Activity Based Costing-08022021 - GLDocument55 pagesChapter 5 - Activity Based Costing-08022021 - GLStavria KalliNo ratings yet

- Ritonal: TVL-AFA Agricultural Crops Production NC Ii Eleven FourDocument4 pagesRitonal: TVL-AFA Agricultural Crops Production NC Ii Eleven FourGrace cabiliNo ratings yet

- Sampling and Testing Plan For Finished ProductsDocument7 pagesSampling and Testing Plan For Finished Productshunain zafarNo ratings yet

- Manual For Conducting Site Trials For Concrete AdmixtureDocument1 pageManual For Conducting Site Trials For Concrete AdmixtureRohanNo ratings yet

- Standard Test Procedures Manual: 1. Scope 1.1. Description of TestDocument5 pagesStandard Test Procedures Manual: 1. Scope 1.1. Description of TestTemur LomidzeNo ratings yet

- Process EvaluationDocument6 pagesProcess EvaluationJULIA REESE REYESNo ratings yet

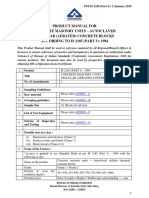

- IS 2185 PART 3 Product ManualDocument7 pagesIS 2185 PART 3 Product ManualRajat Raj VermaNo ratings yet

- Process CostingDocument108 pagesProcess CostingAnjali rajbharNo ratings yet

- BI208 M19 Lab ScheduleDocument3 pagesBI208 M19 Lab ScheduleAdv Sandeep SinghNo ratings yet

- ASRTU - Bonding GumDocument5 pagesASRTU - Bonding GumBharat Chatrath100% (1)

- BU IB2025 000A Duoble Detect Field TestDocument4 pagesBU IB2025 000A Duoble Detect Field TestimmortalNo ratings yet

- materials: SectionDocument30 pagesmaterials: SectionDaison PaulNo ratings yet

- Micellar/Polymer Flooding - An Overview: SPE-AIME, Marathon Oil CoDocument13 pagesMicellar/Polymer Flooding - An Overview: SPE-AIME, Marathon Oil Coorenji nimong crossNo ratings yet

- Exp 2 Preparation of Disturbed Soil Sample For TestDocument4 pagesExp 2 Preparation of Disturbed Soil Sample For TestMark Lester PonteNo ratings yet

- 2750 1964 Reff2021Document29 pages2750 1964 Reff2021Devesh Kumar PandeyNo ratings yet

- Stainless Steel Seamless Pipes and Tubes For General Services - SpecificationDocument26 pagesStainless Steel Seamless Pipes and Tubes For General Services - SpecificationDevesh Kumar PandeyNo ratings yet

- Glossary of Terms Relating To Industrial Screen and ScreeningDocument18 pagesGlossary of Terms Relating To Industrial Screen and ScreeningDevesh Kumar PandeyNo ratings yet

- Recycled Rubber - Vulcanized Crumb Particulate SpecificationDocument12 pagesRecycled Rubber - Vulcanized Crumb Particulate SpecificationDevesh Kumar PandeyNo ratings yet

- Specification For Steel Wheelbarrows (Single-Wheel Type) : (First Revision)Document12 pagesSpecification For Steel Wheelbarrows (Single-Wheel Type) : (First Revision)Devesh Kumar PandeyNo ratings yet

- SP2 Superpave Mix Design Asphalt InstituteDocument36 pagesSP2 Superpave Mix Design Asphalt InstituteDevesh Kumar PandeyNo ratings yet

- 1991 Reff2020Document7 pages1991 Reff2020Devesh Kumar PandeyNo ratings yet

- Amendment No. 1 MAY 1984 TO 15:6403-1981 Code of Practice For Determination of Bearing Capacity of Shallow FoundationsDocument1 pageAmendment No. 1 MAY 1984 TO 15:6403-1981 Code of Practice For Determination of Bearing Capacity of Shallow FoundationsDevesh Kumar PandeyNo ratings yet

- Microfine Ordinary Portland Cement - Specification: Indian StandardDocument18 pagesMicrofine Ordinary Portland Cement - Specification: Indian StandardDevesh Kumar PandeyNo ratings yet

- Transport and Main Roads Specifications MRTS45 Road Surface DelineationDocument20 pagesTransport and Main Roads Specifications MRTS45 Road Surface DelineationDevesh Kumar PandeyNo ratings yet

- Plastics - Polyacrylamide Materials - Designation System and SpecificationDocument20 pagesPlastics - Polyacrylamide Materials - Designation System and SpecificationDevesh Kumar PandeyNo ratings yet

- Reaffirmed 2000Document19 pagesReaffirmed 2000Devesh Kumar PandeyNo ratings yet

- %%Wirjt'Skf%Wrfim: - RF$TFKDocument11 pages%%Wirjt'Skf%Wrfim: - RF$TFKDevesh Kumar PandeyNo ratings yet

- Methods of Sampling and Test (Physical and Chemical) For Water and Waste WaterDocument10 pagesMethods of Sampling and Test (Physical and Chemical) For Water and Waste WaterDevesh Kumar PandeyNo ratings yet

- Anti-Termite Measures in Buildings - Code of Practice: Indian StandardDocument16 pagesAnti-Termite Measures in Buildings - Code of Practice: Indian StandardDevesh Kumar PandeyNo ratings yet

- (Reaffirmed!2011) !Document10 pages(Reaffirmed!2011) !Devesh Kumar PandeyNo ratings yet

- Kerosene Intermediate - Specification: Indian StandardDocument10 pagesKerosene Intermediate - Specification: Indian StandardDevesh Kumar PandeyNo ratings yet

- Road Safety Measures On Stretches of National Highways - RegardingDocument4 pagesRoad Safety Measures On Stretches of National Highways - RegardingDhiren PatelNo ratings yet

- MORTH CIRCULAR Covid 19 ReliefDocument2 pagesMORTH CIRCULAR Covid 19 ReliefDevesh Kumar PandeyNo ratings yet

- Use of Hot Mix Plant On Bituminous Construction Works On NHsDocument2 pagesUse of Hot Mix Plant On Bituminous Construction Works On NHsDevesh Kumar PandeyNo ratings yet

- Draft Guidelines On Skid Resistance On Pavement Surfacings (H-6)Document31 pagesDraft Guidelines On Skid Resistance On Pavement Surfacings (H-6)Devesh Kumar Pandey0% (1)

- NHAI Circular-Steel ApprovalDocument6 pagesNHAI Circular-Steel ApprovalDevesh Kumar Pandey0% (1)

- Transistor Amplifiers 1Document11 pagesTransistor Amplifiers 1diya shajiNo ratings yet

- 2.softwares Used in Civil EnggDocument15 pages2.softwares Used in Civil EnggSairaj NaikNo ratings yet

- SEN VA AP Circular No.: 10/2011Document2 pagesSEN VA AP Circular No.: 10/2011Le LamNo ratings yet

- Firebird 3 QuickStart PDFDocument45 pagesFirebird 3 QuickStart PDFJavier Hernandez OsorioNo ratings yet

- Logistics Course in Bangalore: E-Logistics Structure and OperationDocument6 pagesLogistics Course in Bangalore: E-Logistics Structure and OperationSindhu.. SNo ratings yet

- Essae 20.06.20Document3 pagesEssae 20.06.20Parthiban DNo ratings yet

- POWER9 Processor ArchitectureDocument12 pagesPOWER9 Processor ArchitectureGuillermo García GándaraNo ratings yet

- VLAN DOKU V10 enDocument38 pagesVLAN DOKU V10 enshimaa battahNo ratings yet

- ATIKA SALEEM SCM Assignment.Document5 pagesATIKA SALEEM SCM Assignment.Atika SaleemNo ratings yet

- PS Nvision HandbookDocument80 pagesPS Nvision HandbooknetsriNo ratings yet

- Heizka Catalogue Cat6 24awg Utp 2Document2 pagesHeizka Catalogue Cat6 24awg Utp 2votinh20687No ratings yet

- Argument realityDocument18 pagesArgument realityyunoedits324No ratings yet

- Practical C++Document30 pagesPractical C++HarmanNo ratings yet

- S7-1200 DTL Timer V10 enDocument31 pagesS7-1200 DTL Timer V10 enJes TecnosNo ratings yet

- Lecture 4 - Synthesis - Part 2 2022Document86 pagesLecture 4 - Synthesis - Part 2 2022Shay SamiaNo ratings yet

- Multimedia Information Systems (MMIS) : INSY4111Document57 pagesMultimedia Information Systems (MMIS) : INSY4111sileshi alelignNo ratings yet

- (TUTORIAL) (Noob-Friendly) NAND Dumping 2DS - 3DS - 3DS XL - N3DS - N3DS XL! - GBAtempDocument19 pages(TUTORIAL) (Noob-Friendly) NAND Dumping 2DS - 3DS - 3DS XL - N3DS - N3DS XL! - GBAtempdscjuniorNo ratings yet

- Testing and Modeling With TDLDocument88 pagesTesting and Modeling With TDLKi KiNo ratings yet

- Rancang Bangun Set Eksperimen Kalorimeter Digital Dengan Pengindera Sensor Termokopel Dan Sensor Load Cell Berbasis Arduino UnoDocument8 pagesRancang Bangun Set Eksperimen Kalorimeter Digital Dengan Pengindera Sensor Termokopel Dan Sensor Load Cell Berbasis Arduino UnoSaskia Fiestika BerlianaNo ratings yet

- Syntax - Ahmad Khodadan Azizi - 02311940000023Document3 pagesSyntax - Ahmad Khodadan Azizi - 02311940000023Dhidan AzizNo ratings yet

- Application of Reinforcement Learning To The Game of OthelloDocument20 pagesApplication of Reinforcement Learning To The Game of OthelloYumna ZNo ratings yet

- Labsheet 1 Embedded System ApplicationDocument7 pagesLabsheet 1 Embedded System Applicationaniq.aqlan45No ratings yet

- 10 Steps To Start A New Rental Service - Sharefox Rental Software E-BookDocument20 pages10 Steps To Start A New Rental Service - Sharefox Rental Software E-BookSharefoxNo ratings yet

- Test Your English 4 PDFDocument2 pagesTest Your English 4 PDFjohnymasNo ratings yet

- Functions in Python: OutputDocument4 pagesFunctions in Python: OutputPawan NaniNo ratings yet