Professional Documents

Culture Documents

Chapter-1 Introduction

Uploaded by

الأردني Jordanian0 ratings0% found this document useful (0 votes)

15 views18 pagesCopyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views18 pagesChapter-1 Introduction

Uploaded by

الأردني JordanianCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

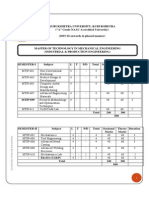

Design of Mechanisms

MEEN :3391

Dr. Muhammad Asad

Room- S029

Ph: 849-9378, Email: masad@pmu.edu.sa

Department of Mechanical Engineering

Prince Mohammed Bin Fahd University

Topics to be Covered

Introduction to design and the design concept

Review of concepts of mechanics, dimensions and unit systems

Introduction to kinematics and mechanisms

Determination of position, velocity, and acceleration in

mechanisms (Graphical & Analytical approaches)

Force analysis of mechanisms

Linkage analysis and design

Cam design

Gears and gear trains

Books

Course Assessment

• 2 Midterm Exams: 40%

• Quizzes(4 to 5): 10%

• Class participation/Assignments/Hw: 10%

• Project: 10%

• Final Exam: 30%

Total 100%

For further details on Course Please go through “Course Syllabus

and General Information” file

Design

• To formulate a plan for the satisfaction of a specified need

• Process requires innovation, iteration, and decision-

making

• Products should be

– Functional

– Safe

– Reliable

– Competitive

– Usable

– Manufactureable

– Marketable

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Mechanical Engineering Design

• Mechanical engineering design involves all the

disciplines of mechanical engineering.

• Example

– Bearing: fluid flow, heat transfer, friction, energy

transport, material selection, thermo-mechanical

treatments, statistical descriptions, etc.

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Mechanical Engineering Design Process

In designing a mechanical component, there

is no rigid rule. The problem may be

attempted in several ways. However, the

general procedure to solve a design problem

is as follows

1. Recognition of need. First of all, make a

complete statement of the problem,

indicating the need, aim or purpose for

which the product is to be designed.

2. Synthesis . Select the possible

components or group of components

(mechanisms) which will give the desired

motion.

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Mechanical Engineering Design Process

3. Analysis of forces. Find the forces acting

on each member of the product and the

energy transmitted by each member.

4. Material selection. Select the material

best suited for each member of the machine.

5. Design of elements (Size and Stresses).

Find the size of each member of the product

by considering the force acting on the

member and the permissible stresses for the

material used. It should be kept in mind that

each member should not deflect or deform

than the permissible limit.

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Mechanical Engineering Design Process

6. Modification. Modify the size of the

member to agree with the past experience and

judgment to facilitate manufacture. The

modification may also be necessary by

consideration of manufacturing to reduce

overall cost.

7. Detailed drawing. Draw the detailed

drawing of each component and the assembly

of the product with complete specification for

the manufacturing processes suggested.

8. Production. The component (Product), as

per the drawing, is manufactured in the

workshop/factory.

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Design Considerations

• Some characteristics that influence the design

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Standards and Codes

• Standard

– A set of specifications for parts, materials, or processes

– Intended to achieve uniformity, efficiency, and a specified quality

– Limits the multitude of variations

– For example: Conformité Européenne CE marking is a certification

mark that indicates conformity with health, safety, and

environmental protection standards for products sold within

the European Economic Area (EEA).

– Various organizations establish and publish standards for common

and/or critical industries

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Standards and Codes

• Code

– A set of specifications /rules for the analysis, design, manufacture,

and construction of something

– To achieve a specified degree of safety, efficiency, and

performance or quality

– For example: International Building Codes (IBC) obligates the

incorporation of Fire Protection and Prevention system into

building construction.

• Various organizations establish and publish standards and codes for

common and/or critical industries

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Standards and Codes

https://www.amerpi

pe.com/steel-pipe-

products/carbon-

pipe/a106/a106-

specifications/

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Economics

• Cost is almost always an important factor in

engineering design.

• Use of standard sizes is a first principle of cost

reduction.

• Certain common components may be less

expensive in stocked sizes.

• Efficient use of Materials and Processes.

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Dimensions & Unit Systems

Fundamental Units

The measurement of physical quantities is one of the most important

operations in engineering. Every quantity is measured in terms of some

arbitrary, but internationally accepted units, called fundamental units.

Derived Units

Some units are expressed in terms of other units, which are derived from

fundamental units, are known as derived units

System of Units

There are four systems of units, which are commonly used and

universally recognized.

These are known as :

1. C.G.S. units, 2. F.P.S. units, 3. M.K.S. units, and 4. S.I. units.

*In the present course S.I. system of units, shall be normally followed

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Dimensions & Unit Systems

Fundamental Units

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Dimensions & Unit Systems

Derived Units

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

Please have it ASAP

Drafting Equipment Calculator

Dr. Sathyan Krishnan

Dept. of Mechanical Engineering MANUFACTURING METHODS IN DESIGN

College of Engineering, PMU

You might also like

- MDM References Exam MDM References Exam: Machine Design & Materials Machine Design & MaterialsDocument39 pagesMDM References Exam MDM References Exam: Machine Design & Materials Machine Design & MaterialsH VNo ratings yet

- Final Process Engineering Course Material-8Document229 pagesFinal Process Engineering Course Material-8Sathish Rajan100% (3)

- Durco Mark 3 71569102 English 03-17Document72 pagesDurco Mark 3 71569102 English 03-17Triod jackson0% (1)

- Jamesbury Ball Valves PDFDocument20 pagesJamesbury Ball Valves PDFGabriel Andrés Barcha Angulo100% (1)

- Finite Element Analysis Using ANSYSDocument77 pagesFinite Element Analysis Using ANSYSMed ElyoubiNo ratings yet

- ConsDocument340 pagesConsgendadeyu552625No ratings yet

- Reverse Engineering ReportDocument15 pagesReverse Engineering Reportdhanalakshmi k s100% (2)

- Vehicle Design Lecture1Document31 pagesVehicle Design Lecture1noubyluxorNo ratings yet

- An Introduction To Machine DesignDocument23 pagesAn Introduction To Machine DesignFauiqe Yousaf100% (1)

- Asme b31.3 Process Piping Code SimplifiedDocument1 pageAsme b31.3 Process Piping Code SimplifiedAdnan Rana0% (1)

- Intro Engineering Design Chapter NotesDocument0 pagesIntro Engineering Design Chapter NoteswanpudinNo ratings yet

- Engineering Design FundamentalsDocument27 pagesEngineering Design Fundamentalschoon yong lohNo ratings yet

- Training Manual (GET Process) 1Document34 pagesTraining Manual (GET Process) 1Steve Wan100% (2)

- Material Selection 1-5Document45 pagesMaterial Selection 1-5Abdallah Hashem100% (11)

- Machine DesignDocument128 pagesMachine Designshivani joshi100% (1)

- Hazard Check List P.E.D - Asme b31.3Document8 pagesHazard Check List P.E.D - Asme b31.3akisdassasNo ratings yet

- Gas Turbine CyclesDocument60 pagesGas Turbine Cyclesالأردني JordanianNo ratings yet

- Numerical DifferentiationDocument14 pagesNumerical Differentiationالأردني JordanianNo ratings yet

- Precast Concrete Structures: A Concise GuideDocument267 pagesPrecast Concrete Structures: A Concise GuidepelinNo ratings yet

- 2327 enDocument52 pages2327 enMario ArmelaoNo ratings yet

- Chapter 1Document39 pagesChapter 1الأردني JordanianNo ratings yet

- Product Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesFrom EverandProduct Manufacturing and Cost Estimating using CAD/CAE: The Computer Aided Engineering Design SeriesRating: 4 out of 5 stars4/5 (4)

- Mindray PM 9000 User ID10240 PDFDocument378 pagesMindray PM 9000 User ID10240 PDFJuan FernandoNo ratings yet

- Ipebs 31 CourseDocument9 pagesIpebs 31 Coursevenky2hemaNo ratings yet

- Power Plant EngineeringDocument5 pagesPower Plant EngineeringSyedNadeemAhmedNo ratings yet

- Manual Compresor VTMDocument84 pagesManual Compresor VTMSINAGUS80% (5)

- Resume Supplier Quality Engineer 3 Yrs Exp Auto OEM Vinoth KumarDocument2 pagesResume Supplier Quality Engineer 3 Yrs Exp Auto OEM Vinoth KumarVinothKumarDhananjayanNo ratings yet

- Design of Machine ElementsDocument12 pagesDesign of Machine ElementsArghya ModakNo ratings yet

- 1st Lecture (Introduction) ADocument40 pages1st Lecture (Introduction) AAlaa100% (1)

- MCE 417 Course CompactDocument7 pagesMCE 417 Course CompactKEHINDE BABALOLANo ratings yet

- 475 Using Asme Performance Test Codes in TheDocument18 pages475 Using Asme Performance Test Codes in Theaaa206No ratings yet

- Machine Design Course OutlineDocument19 pagesMachine Design Course Outlinenauman khanNo ratings yet

- M.tech Mechanical Engg. (I &P)Document44 pagesM.tech Mechanical Engg. (I &P)Upender DhullNo ratings yet

- Engineering Design Featuring The Life Cycle Approach For Reconfigurable Machine Tool ReportDocument19 pagesEngineering Design Featuring The Life Cycle Approach For Reconfigurable Machine Tool ReportBasilNo ratings yet

- Chapter 1 IntroDocument40 pagesChapter 1 IntroMoustafa SabeaNo ratings yet

- Msme BE Mechanical Engineering 2019 Course Structure An 220719 101123-1Document5 pagesMsme BE Mechanical Engineering 2019 Course Structure An 220719 101123-1sonawanepmsNo ratings yet

- University Technology Mara Faculty of Mechanical EngineeringDocument3 pagesUniversity Technology Mara Faculty of Mechanical Engineeringarina azharyNo ratings yet

- DKOM Lab ManualDocument24 pagesDKOM Lab Manualaakash chakrabortyNo ratings yet

- 4.32 & 4.33 TE & BE - Mech EnggDocument13 pages4.32 & 4.33 TE & BE - Mech EnggganeshNo ratings yet

- Syllabus Vjti Structural EnggDocument276 pagesSyllabus Vjti Structural EnggPravin AwalkondeNo ratings yet

- Machine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDocument16 pagesMachine Design-I: Mechanical Engineering Department Madan Mohan Malaviya University of Technology GorakhpurDeekshaomarNo ratings yet

- Lecture 3 Process PlanningDocument35 pagesLecture 3 Process Planningविशाल पुडासैनीNo ratings yet

- Resume SampleDocument2 pagesResume Sample18TUEC119 Kiran SeshiNo ratings yet

- YogaDocument93 pagesYogaGopi KaramananNo ratings yet

- Mechanical EngineeringDocument6 pagesMechanical EngineeringAyush ParateNo ratings yet

- V G Barani: E-MailDocument4 pagesV G Barani: E-MailMagesh ChanderNo ratings yet

- ES2C6-15 Electromechanical System DesignDocument6 pagesES2C6-15 Electromechanical System DesignMesafint kassieNo ratings yet

- A Design Methodology For Automotive Component Manufacturing SystemsDocument94 pagesA Design Methodology For Automotive Component Manufacturing SystemsKAMAL BEHLNo ratings yet

- Rationalization of Exhaust System Mounting BracketsDocument94 pagesRationalization of Exhaust System Mounting BracketsGopi KaramananNo ratings yet

- Aalborg Universitet: Andersen, Torben Ole Pedersen, Henrik Clemmensen Hansen, Michael RygaardDocument10 pagesAalborg Universitet: Andersen, Torben Ole Pedersen, Henrik Clemmensen Hansen, Michael RygaardMohab AhmedNo ratings yet

- Dme Question Bank by Syam Prasad AmmineniDocument22 pagesDme Question Bank by Syam Prasad AmmineniDharmendra SharmaNo ratings yet

- Syllabus DFM 2014Document29 pagesSyllabus DFM 2014sudheer920% (1)

- Choi Nicholas ResumeDocument1 pageChoi Nicholas Resumeapi-376444733No ratings yet

- Ch.E-403 Chemical Engineering Plant Design: Dr. Umair AslamDocument55 pagesCh.E-403 Chemical Engineering Plant Design: Dr. Umair AslamimtiazNo ratings yet

- R 2017 Syllabus BookDocument184 pagesR 2017 Syllabus BookNagarjun J0% (1)

- Honours CurriculumDocument13 pagesHonours CurriculumJOIJODENo ratings yet

- 6th Sem - 7 - Mechanical Engineering - 2 PDFDocument39 pages6th Sem - 7 - Mechanical Engineering - 2 PDFfotickNo ratings yet

- Requested FileDocument42 pagesRequested Fileedinson rojas ramosNo ratings yet

- Additive Manufacturing-Achal DubeyDocument25 pagesAdditive Manufacturing-Achal DubeyAchal Kumar DubeyNo ratings yet

- CHE3166 - Process Design UnitDocument2 pagesCHE3166 - Process Design UnitLim LeongNo ratings yet

- Mechanical Engineering Design Presentation on Scope and Objectives (CA1Document13 pagesMechanical Engineering Design Presentation on Scope and Objectives (CA1jahir khanNo ratings yet

- Kumarfme@iitr - Ernet.in: Course 12. Industrial Engineering (Video Course) Faculty Coordinator(s) : 1Document5 pagesKumarfme@iitr - Ernet.in: Course 12. Industrial Engineering (Video Course) Faculty Coordinator(s) : 1vupputuriNo ratings yet

- Engineering ProfessionDocument45 pagesEngineering ProfessionUpender DhullNo ratings yet

- Win13 Aspen PlusDocument2 pagesWin13 Aspen Plusalireza198No ratings yet

- ME 4103 - IE-1. IntroductionDocument31 pagesME 4103 - IE-1. IntroductionasanNo ratings yet

- Unit 37: Virtual EngineeringDocument29 pagesUnit 37: Virtual Engineeringamdan srlNo ratings yet

- Presentation MDDocument15 pagesPresentation MDChadNo ratings yet

- Spce WebDocument13 pagesSpce Webapi-184316840No ratings yet

- 1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringDocument37 pages1.3 Specialized Sub-Disciplines in Mechanical Engineering - Production, Automobile, Energy EngineeringMr. K.S. Raghul Asst Prof MECHNo ratings yet

- Prinsip dan Metode Analisis dan Desain TeknikDocument47 pagesPrinsip dan Metode Analisis dan Desain TeknikRay SragaNo ratings yet

- 10 - Vibration - F22-An Introduction To Modal AnalysisDocument20 pages10 - Vibration - F22-An Introduction To Modal Analysisالأردني JordanianNo ratings yet

- 2DOF Vibration Lecture NotesDocument29 pages2DOF Vibration Lecture Notesالأردني JordanianNo ratings yet

- Automatic Plant Trimming System DJTDocument45 pagesAutomatic Plant Trimming System DJTالأردني JordanianNo ratings yet

- 9 - Vibration - F22-An Introduction To Vibration MeasurementsDocument17 pages9 - Vibration - F22-An Introduction To Vibration Measurementsالأردني JordanianNo ratings yet

- 8 - Vibration - F22-Vibration Isolation and AbsorptionDocument26 pages8 - Vibration - F22-Vibration Isolation and Absorptionالأردني JordanianNo ratings yet

- 4 - Vibration - F22-Damped VibrationsDocument19 pages4 - Vibration - F22-Damped Vibrationsالأردني JordanianNo ratings yet

- CamScanner Scanned Document PagesDocument24 pagesCamScanner Scanned Document Pagesالأردني JordanianNo ratings yet

- Lec-1 IntroductionDocument14 pagesLec-1 Introductionالأردني JordanianNo ratings yet

- Chapter1 6Document13 pagesChapter1 6الأردني JordanianNo ratings yet

- Chapter1 7Document21 pagesChapter1 7الأردني JordanianNo ratings yet

- EEE118 Problem SheetsDocument6 pagesEEE118 Problem Sheetsالأردني JordanianNo ratings yet

- Chapter1 4Document16 pagesChapter1 4الأردني JordanianNo ratings yet

- Design and Experimental Evaluation of A Form TrimmDocument13 pagesDesign and Experimental Evaluation of A Form Trimmالأردني JordanianNo ratings yet

- MEEN-3432 Computational Methods: Approximations, Errors & Taylor SeriesDocument35 pagesMEEN-3432 Computational Methods: Approximations, Errors & Taylor Seriesالأردني JordanianNo ratings yet

- Ordinary Differential Equations (ODEs)Document33 pagesOrdinary Differential Equations (ODEs)الأردني JordanianNo ratings yet

- Chapter1 5Document18 pagesChapter1 5الأردني JordanianNo ratings yet

- Truncation Errors and The Taylor SeriesDocument18 pagesTruncation Errors and The Taylor Seriesالأردني JordanianNo ratings yet

- Linear Algebraic EquationsDocument21 pagesLinear Algebraic Equationsالأردني JordanianNo ratings yet

- Approximations and Round-Off ErrorsDocument16 pagesApproximations and Round-Off Errorsالأردني JordanianNo ratings yet

- Application of MATLAB To Numerical Solutions: Online Tutorial With Dr. ZazoumDocument2 pagesApplication of MATLAB To Numerical Solutions: Online Tutorial With Dr. Zazoumالأردني JordanianNo ratings yet

- Chapter 2-Moist Air and Its PropertiesDocument27 pagesChapter 2-Moist Air and Its Propertiesالأردني JordanianNo ratings yet

- In Previous Lectures, We Defined StabilityDocument36 pagesIn Previous Lectures, We Defined Stabilityالأردني JordanianNo ratings yet

- Chapter-2 Introduction To Kinematics and MechanismsDocument43 pagesChapter-2 Introduction To Kinematics and Mechanismsالأردني JordanianNo ratings yet

- Numerical IntegrationDocument24 pagesNumerical Integrationالأردني JordanianNo ratings yet

- Chapter 3 - Position-Velocity-Acceleration Analysis (Graphical Method) - 1Document47 pagesChapter 3 - Position-Velocity-Acceleration Analysis (Graphical Method) - 1الأردني JordanianNo ratings yet

- Homework 1-Solution: MEEN 3391: Mechanical Engineering Design 1Document3 pagesHomework 1-Solution: MEEN 3391: Mechanical Engineering Design 1الأردني JordanianNo ratings yet

- 2.7 Developments in Standards For Noise Barriers P MorganDocument17 pages2.7 Developments in Standards For Noise Barriers P MorganVarunn VelNo ratings yet

- Bsi en 124Document4 pagesBsi en 124Karthikeyan SankarrajanNo ratings yet

- General Catalogue: Technical Features DocumentationDocument1 pageGeneral Catalogue: Technical Features DocumentationAmarK90No ratings yet

- WEG Declaration of Conformity 20140930 - 20140930114427Document1 pageWEG Declaration of Conformity 20140930 - 20140930114427JULIO EFRAIN DIAZ CABRERANo ratings yet

- Highpowered and Programmable Switching Power Supply: Series IT6500 User's ManualDocument49 pagesHighpowered and Programmable Switching Power Supply: Series IT6500 User's ManualPrimandi BaskoroNo ratings yet

- MAFI Product Catalogue 2016Document108 pagesMAFI Product Catalogue 2016Mindaugas Pepper100% (1)

- Elbi Expansion TankDocument26 pagesElbi Expansion TankAhamed KyanaNo ratings yet

- KM301 CeDocument1 pageKM301 CeemarkotNo ratings yet

- Solis - Certificate - EN&IEC 61000-6-1 (-2) (-3) (-4) &EN 55011&EN 301489&EN 300328&EN 50663&EN 62109-1 (-2) - S6-EH1P (3-8) K-L-PRO - RED - V01Document4 pagesSolis - Certificate - EN&IEC 61000-6-1 (-2) (-3) (-4) &EN 55011&EN 301489&EN 300328&EN 50663&EN 62109-1 (-2) - S6-EH1P (3-8) K-L-PRO - RED - V01carrei JohnNo ratings yet

- Masonry Support Systems and LintelsDocument36 pagesMasonry Support Systems and LintelsariyarathneNo ratings yet

- Power Supply Safety Standards Agencies and MarksDocument23 pagesPower Supply Safety Standards Agencies and MarksMohamed HafrathNo ratings yet

- PQS E08-E013 Manufacturer Guide1.4Document23 pagesPQS E08-E013 Manufacturer Guide1.4saberNo ratings yet

- COMPUTERISED MACHINES AND SYSTEMSS OPERATING GUIDEDocument22 pagesCOMPUTERISED MACHINES AND SYSTEMSS OPERATING GUIDEgad lunaNo ratings yet

- Internal Audit Checklist SampleDocument25 pagesInternal Audit Checklist SampleLimNo ratings yet

- Salisbury - Industrial CatalogDocument108 pagesSalisbury - Industrial CatalogththeeNo ratings yet

- CMMO ST EA SY - 2015 06b - 8039016g1Document172 pagesCMMO ST EA SY - 2015 06b - 8039016g1pravinNo ratings yet

- Katalog 2020 enDocument148 pagesKatalog 2020 enAlejandro BoccoNo ratings yet

- ETAG 026 - Part-1 - 2013Document20 pagesETAG 026 - Part-1 - 2013StefanBelibouNo ratings yet

- IC GrejaciDocument353 pagesIC GrejaciAleksandarNo ratings yet

- User Guide: Gps Pathfinder Proxrt ReceiverDocument131 pagesUser Guide: Gps Pathfinder Proxrt ReceiverJuan CarlosNo ratings yet

- Forever 808 CE CertificateDocument1 pageForever 808 CE CertificatevalentynapanfilenkoNo ratings yet

- Ze Gcp01a15 EngDocument300 pagesZe Gcp01a15 EnggeorgeNo ratings yet