Professional Documents

Culture Documents

Operational Excellence and Best Practices at Your Facility

Uploaded by

K T100%(1)100% found this document useful (1 vote)

9 views2 pagesOriginal Title

SSCC_FacilityChecklist

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

9 views2 pagesOperational Excellence and Best Practices at Your Facility

Uploaded by

K TCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Operational Excellence and Best Practices at Your Facility

What is your commitment to utilizing the guiding principles and tools?

These are the absolute minimum expectations…

Safety Operating Practices

❑ Active Safety Leadership Team Corrugator

❑ Daily Toolbox meetings; PIT policy ❑ Temperature monitoring equipped

❑ Required training/new hire orientation ❑ 30-inch butt roll policy

❑ Teams – maintenance, pedestrian, etc… ❑ Roll room - NO damaged rolls; orderly

❑ Clear expectations/accountabilities ❑ Speed/productivity expectations

Quality ❑ Downtime monitoring by shift

❑ Formal Annual Quality Improvement Plan (understand top 3 causes)

❑ 31 checks every order ❑ Empty roll cores

❑ Understand top three causes Converting

❑ New item process ❑ Order Readiness Program

❑ Problem-solving process for QVRs ❑ Continuous run - breaks, shift change

❑ Clear expectations/accountabilities ❑ Expectations - machine potential

Waste ❑ One-box setup, circles, rainbows

❑ Assigned Champion ❑ Downtime monitoring by shift

❑ Identification of top 3 causes of waste (understand top 3 causes)

❑ Standardized Waste Process - teams, report Finished Goods/Warehousing

❑ Identified unit dunnage ❑ All units in shippable condition

Housekeeping ❑ Load tags properly placed

❑ Assigned responsibility (routine, not reactive) ❑ Organization/lighting/cleanliness

❑ Organized machine centers ❑ Perpetual inventory process

❑ No food in plant; beverages in sealed containers ❑ Trailer Utilization Program

❑ No radios, boom boxes, cell phones in plant Asset Utilization

❑ Restrooms, building exterior, offices, paint, roof, etc… ❑ Machine hours/utilization plan

Maintenance ❑ Right number of power industrial trucks

❑ Documented preventive maintenance system ❑ Right number of tractors/trailers

❑ Capability of machines to run at their designed speeds ❑ Warehouse utilization

and deliver quality Operating Approvals

❑ Program to upgrade maintenance skills ❑ Board grade changes

❑ Zero leaks (water, air, steam, etc…) ❑ Rollstock/outside purchases

❑ Parts inventory/documentation ❑ Daily overtime

Additional Key Expectations ❑ Maintenance/clean-up schedule changes

❑ Indirect to direct ratio ❑ Warehousing agreements

❑ Headcount/BSF goal ❑ Breaking setups

❑ Plant communications board ❑ LTL/hotshot loads

❑ New hire process (selection, orientation, evaluation) ❑ Incremental tractors/trailers

Are you becoming easier to do business with?

Smurfit-Stone Container Corporation 6 City Place Creve Coeur, MO 63141 www.smurfit-stone.com

Last modified: 03/02/07

Container Division: Our Vision

As leaders of an integrated team, we will take ownership

and accountability to build profitability through revenue

growth and manufacturing excellence.

The guiding principles of this vision are:

• Functional Organization and Leadership

• Customer Alignment

• Market Discipline

• Best Practices and System Optimization

• Asset Utilization and Investment

The successful execution of this CustomerONE® driven

vision will result in one team delivering exceptional

value to our customers, employees, shareholders and

the communities in which we serve.

You might also like

- Fibo Warisan 2nd Candle New v6.0Document75 pagesFibo Warisan 2nd Candle New v6.0Muhammad ZeeharzNo ratings yet

- World Class Manufacturing - 1Document46 pagesWorld Class Manufacturing - 1Prakash VermaNo ratings yet

- Total Productive Maintenance For Organisational EffectivenessFrom EverandTotal Productive Maintenance For Organisational EffectivenessRating: 4 out of 5 stars4/5 (4)

- Unit 7Document33 pagesUnit 7Rajbir SinghNo ratings yet

- ACYMAG2 NotesDocument60 pagesACYMAG2 NotesAngel JamianaNo ratings yet

- Chapter 5Document22 pagesChapter 5alluNo ratings yet

- Chapter 7 - Operations ManagementDocument31 pagesChapter 7 - Operations ManagementMaryjanedbn DlaminiNo ratings yet

- Just in TimeDocument36 pagesJust in TimeadamNo ratings yet

- Total Productive Maintenance PDFDocument53 pagesTotal Productive Maintenance PDFpranayrulzNo ratings yet

- ExperienceExperience - Docx AnmolDocument6 pagesExperienceExperience - Docx AnmolDevendra SinghNo ratings yet

- World Class Manufacturing FinalDocument22 pagesWorld Class Manufacturing Finalshreepal19No ratings yet

- Just-In-time (Jit) Production SystemDocument21 pagesJust-In-time (Jit) Production SystemMBA...KID100% (4)

- Effective Maintenance PDFDocument59 pagesEffective Maintenance PDFEkopribadiNo ratings yet

- Maintenance Management: Group - 4Document39 pagesMaintenance Management: Group - 4vasanth_prodigyNo ratings yet

- TPM - A Zero Sum GameDocument64 pagesTPM - A Zero Sum GamemuneerppNo ratings yet

- Pulp & Paper Industry BrochureDocument8 pagesPulp & Paper Industry Brochurecarlonewmann100% (3)

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainSwapnil Jayawant100% (1)

- Topic 2-Process Analysis & ChoiceDocument8 pagesTopic 2-Process Analysis & ChoicePule JackobNo ratings yet

- External Job Posting - Condition Monitoring Supervisor PDFDocument2 pagesExternal Job Posting - Condition Monitoring Supervisor PDFAppraku StephenNo ratings yet

- JIT and Lean OperationsDocument35 pagesJIT and Lean OperationsSanjay ThakurNo ratings yet

- Maintenance Engineering Lecture Module I PDFDocument52 pagesMaintenance Engineering Lecture Module I PDFAnandaKrishnan NairNo ratings yet

- Tetrapod - PQPDocument70 pagesTetrapod - PQPGunawan IwanNo ratings yet

- Just-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainDocument52 pagesJust-in-Time Systems: Reducing Variance, Waste and Lead Time in The Supply ChainNeha Jigar PatelNo ratings yet

- Standard Work PDFDocument46 pagesStandard Work PDFpranayrulzNo ratings yet

- Total Productive MaintenanceDocument21 pagesTotal Productive Maintenancedr_tripathineerajNo ratings yet

- Capital Replacement Needs: How To Plan, Budget and Fund: October 27, 2015Document64 pagesCapital Replacement Needs: How To Plan, Budget and Fund: October 27, 2015Mismail EgypacNo ratings yet

- World Class Manufacturing FinalDocument22 pagesWorld Class Manufacturing FinalSanjog Devrukhkar100% (4)

- Maintenance Management1Document36 pagesMaintenance Management1Ankur Pathak67% (3)

- Lean Manufacturing OverviewDocument29 pagesLean Manufacturing OverviewKrunalNo ratings yet

- TPM - A Zero Sum GameDocument64 pagesTPM - A Zero Sum GameSatheesh kumarNo ratings yet

- Convertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenDocument62 pagesConvertion Cycle: Amador, Jeric Ferreras, Christine Lasalita, Kyra Danielle Panganiban, Christine Joy Tolentino, AldrenChristine Joy PanganibanNo ratings yet

- Latest CVDocument3 pagesLatest CVmohd naveeduddin musaNo ratings yet

- TPM - A Zero Sum GameDocument64 pagesTPM - A Zero Sum GameArjun100% (2)

- TPMDocument64 pagesTPMShubham Saraf100% (1)

- Why TPM?Document65 pagesWhy TPM?Gopalakrishnan100% (54)

- JD Instrumentation TTBMDocument7 pagesJD Instrumentation TTBMManoj LakshmipathyNo ratings yet

- Types of Production & Methods of ProductionDocument44 pagesTypes of Production & Methods of ProductionIsthiak Uddin Chowdhury EfthyNo ratings yet

- 2023 Hybrid Kevin PitneyDocument3 pages2023 Hybrid Kevin PitneyPragya shuklaNo ratings yet

- SQC PPT 2021 Lesson 1Document29 pagesSQC PPT 2021 Lesson 1Erica Joy EstrellaNo ratings yet

- Steering Committee Meeting: Sunflower ProjectDocument42 pagesSteering Committee Meeting: Sunflower ProjectAmitNo ratings yet

- CH 12-14 PDFDocument26 pagesCH 12-14 PDFmanarNo ratings yet

- Optimising Productivity in Foundry Optimising Productivity in FoundryDocument57 pagesOptimising Productivity in Foundry Optimising Productivity in FoundrykarthikkandaNo ratings yet

- ME3013 Chap 6Document9 pagesME3013 Chap 6pavetran raviNo ratings yet

- 2 Project RisksDocument28 pages2 Project RisksArun KumarNo ratings yet

- Tracksoftware: Optimize Outsourced Services Minimize Contract SpendDocument6 pagesTracksoftware: Optimize Outsourced Services Minimize Contract SpendhamadaabdelgawadNo ratings yet

- Lean Chapter 4Document15 pagesLean Chapter 4WinterMist11No ratings yet

- TPM BasicsDocument33 pagesTPM BasicsRajeev ChadhaNo ratings yet

- Quality PPTsDocument81 pagesQuality PPTsSahil ChaudharyNo ratings yet

- Insurance Case Study TestingDocument18 pagesInsurance Case Study Testingpaddy_workNo ratings yet

- BUSI 2301 Supply SECONDDocument6 pagesBUSI 2301 Supply SECONDJoshNo ratings yet

- Lect 5Document31 pagesLect 5shashikantppediaNo ratings yet

- Operations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiDocument43 pagesOperations Management - Session 4 and 5 Chap 3.prof. Furquan 4KtNz4YsKiNABARUN MAJUMDARNo ratings yet

- Esterline TechnologiesDocument5 pagesEsterline TechnologiesTiago Vaz Pais0% (1)

- Senior Mechanical Planning EngineerDocument7 pagesSenior Mechanical Planning EngineerIrshad AkhterNo ratings yet

- 2023 OM Aggregate-PlanningDocument49 pages2023 OM Aggregate-PlanningSuman Samal MagarNo ratings yet

- Lean and QualityDocument38 pagesLean and Qualitybharat258No ratings yet

- Operations Management: Just-in-Time SystemsDocument21 pagesOperations Management: Just-in-Time SystemsNazirul MubinNo ratings yet

- Industrial Engineering Is An Engineering Profession That Is Concerned With TheDocument145 pagesIndustrial Engineering Is An Engineering Profession That Is Concerned With TheSuresh ReddyNo ratings yet

- Audit Readiness Checklist (4754)Document4 pagesAudit Readiness Checklist (4754)Emmanuel Kwa-kofiNo ratings yet

- LinothDocument5 pagesLinothGodwin GodwinNo ratings yet

- Notes Class #1 BLDC 1020Document29 pagesNotes Class #1 BLDC 1020K TNo ratings yet

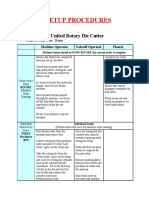

- Setup Procedures: 122 United Rotary Die CutterDocument3 pagesSetup Procedures: 122 United Rotary Die CutterK TNo ratings yet

- Townhouse Cluster Wall TakeoffDocument3 pagesTownhouse Cluster Wall TakeoffK TNo ratings yet

- Measurement of Roof Cladding ComponentsDocument10 pagesMeasurement of Roof Cladding ComponentsK TNo ratings yet

- Bungalow Roofing Takeoff - DemoDocument4 pagesBungalow Roofing Takeoff - DemoK TNo ratings yet

- 122 Setup Audit Form: InstructionsDocument2 pages122 Setup Audit Form: InstructionsK TNo ratings yet

- Environmental and Social Impacts of Marine Transport in The Great Lakes - ST Lawrence Seaway RegionDocument144 pagesEnvironmental and Social Impacts of Marine Transport in The Great Lakes - ST Lawrence Seaway RegionK TNo ratings yet

- Backyard Biodiversity: Activity Time!Document3 pagesBackyard Biodiversity: Activity Time!K TNo ratings yet

- Basic Math and Pre AlgebraDocument178 pagesBasic Math and Pre AlgebraK T100% (1)

- The Water We EatDocument6 pagesThe Water We EatK TNo ratings yet

- The Wright Brothers WorksheetsDocument24 pagesThe Wright Brothers WorksheetsK TNo ratings yet

- Worksheets: Wright BrothersDocument23 pagesWorksheets: Wright BrothersK TNo ratings yet

- Birds WorksheetsDocument25 pagesBirds WorksheetsK TNo ratings yet

- What Is Operational Excellence (Opx) ?: Era 1 Era 0 Era 2Document2 pagesWhat Is Operational Excellence (Opx) ?: Era 1 Era 0 Era 2K TNo ratings yet

- Shift Handover and Performance Log TrainingDocument24 pagesShift Handover and Performance Log TrainingK TNo ratings yet

- RVP Opx Check ListDocument2 pagesRVP Opx Check ListK TNo ratings yet

- Feel, Guess, Suppose Feel, Guess, Suppose Feel, Guess, Suppose Feel, Guess, SupposeDocument1 pageFeel, Guess, Suppose Feel, Guess, Suppose Feel, Guess, Suppose Feel, Guess, SupposeK TNo ratings yet

- Expectations of OPX Team: Smurfit-Stone Container Operational Excellence Boot CampDocument9 pagesExpectations of OPX Team: Smurfit-Stone Container Operational Excellence Boot CampK TNo ratings yet

- O e - P P - W: 1. S.A.F.EDocument2 pagesO e - P P - W: 1. S.A.F.EK TNo ratings yet

- Recap: Smurfit-Stone Container Operational Excellence Boot CampDocument85 pagesRecap: Smurfit-Stone Container Operational Excellence Boot CampK TNo ratings yet

- Recap: Smurfit-Stone Container Operational Excellence Boot CampDocument111 pagesRecap: Smurfit-Stone Container Operational Excellence Boot CampK TNo ratings yet

- Introduction To Operational ExcellenceDocument14 pagesIntroduction To Operational ExcellenceK TNo ratings yet

- 1 - Boot Camp DayDocument90 pages1 - Boot Camp DayK T100% (1)

- Welcome To Whitby: Production Manager: Wayne FlowersDocument75 pagesWelcome To Whitby: Production Manager: Wayne FlowersK T100% (1)

- Company Law - MDocument16 pagesCompany Law - MMayank SharmaNo ratings yet

- GM1738 GMTH - General - Req 2014Document42 pagesGM1738 GMTH - General - Req 2014Maryana cNo ratings yet

- The Reliability of MeasuringDocument50 pagesThe Reliability of MeasuringYury FedichkinNo ratings yet

- Reflective Essay 3 - PDIC Truth in Lending Act & Secrecy of Bank DepositDocument2 pagesReflective Essay 3 - PDIC Truth in Lending Act & Secrecy of Bank DepositCha BuenaventuraNo ratings yet

- Laporan Malam TGL 2 Mei 2020Document23 pagesLaporan Malam TGL 2 Mei 2020rafiNo ratings yet

- Act Ch02 l05 EnglishDocument3 pagesAct Ch02 l05 Englishkarolinewetzel9No ratings yet

- Assignment 1Document4 pagesAssignment 1Asm Burraq0% (2)

- Issues, Challenges and Thier Solution in An Execution of Real Estate Project at Selected Site in Addis Ababa.Document91 pagesIssues, Challenges and Thier Solution in An Execution of Real Estate Project at Selected Site in Addis Ababa.Eyob Light Worku100% (1)

- Tulungan Application Form Rev. 7Document1 pageTulungan Application Form Rev. 7joyce DtNo ratings yet

- Train Ticket 19 Feb Af - LkuDocument2 pagesTrain Ticket 19 Feb Af - LkuJitendra Singh JeetNo ratings yet

- Module 1 Practice QuestionsDocument7 pagesModule 1 Practice QuestionsEllah MaeNo ratings yet

- Final QuestionnaireDocument5 pagesFinal QuestionnaireSharlee DekateNo ratings yet

- Sonal Holland MW AAU of Wine Among SEC A Urban Indian Wine ConsumersDocument121 pagesSonal Holland MW AAU of Wine Among SEC A Urban Indian Wine ConsumersRohitAjvilkarNo ratings yet

- Mickey Proposal Final EditedDocument36 pagesMickey Proposal Final EditedMikiyas TeshomeNo ratings yet

- Basic Warehouse Inbound Processing From Supplier With QM 1701367621Document36 pagesBasic Warehouse Inbound Processing From Supplier With QM 1701367621Bijoy DuttaNo ratings yet

- Assignment 1Document4 pagesAssignment 1Janani PriyaNo ratings yet

- Name: Titian Nursaida Pratiwi NIM: 17320206Document2 pagesName: Titian Nursaida Pratiwi NIM: 17320206Titian NursaidaNo ratings yet

- Sales Key Account Manager in USA Resume Vicki WestergardDocument2 pagesSales Key Account Manager in USA Resume Vicki WestergardVickiWestergardNo ratings yet

- Final Draft Frontline Letter To BlackRockDocument3 pagesFinal Draft Frontline Letter To BlackRockComunicarSe-ArchivoNo ratings yet

- LNG Projects - Gravity Platforms Make Many Things Possible Exploration ProducDocument3 pagesLNG Projects - Gravity Platforms Make Many Things Possible Exploration ProducVijay K SinghNo ratings yet

- Annex A-PBCDocument2 pagesAnnex A-PBCVil Meyushi AlihNo ratings yet

- STR PresentationDocument49 pagesSTR PresentationApril ToweryNo ratings yet

- Corporation Law ReviewerDocument3 pagesCorporation Law ReviewerJada WilliamsNo ratings yet

- GD 001Document26 pagesGD 001Preethi Raj ThakurNo ratings yet

- Gladiolus CultivationDocument7 pagesGladiolus CultivationPraharsh ShahNo ratings yet

- Invoice - INV C 2023 2327041Document1 pageInvoice - INV C 2023 2327041Rahul Shrestha (Rahul Shrestha)No ratings yet

- Correctness by ConstructionDocument3 pagesCorrectness by ConstructionAmnaNo ratings yet

- Subject - Financial Services: Class - B.B.A./M.B.ADocument21 pagesSubject - Financial Services: Class - B.B.A./M.B.ADileep SinghNo ratings yet

- Balmer Lawrie Annual Report 2022Document210 pagesBalmer Lawrie Annual Report 2022Anjali RaiNo ratings yet