Professional Documents

Culture Documents

Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Development

Uploaded by

riandiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Provision of EPCI Services For EPCIC Sidayu Wellhead Platforms and Pipelines Sidayu Field Development

Uploaded by

riandiCopyright:

Available Formats

Provision of EPCI Services for

EPCIC Sidayu Wellhead Platforms and Pipelines

Sidayu Field Development

Client : Saka Indonesia Pangkah Limited

Contract No. : 4600012838

Document No. : UPD-GF-W3-SJ-PR-4009

Revision Date Description Originator Checker Approver Client

Approval

WHP-C Jacket Piles Loading to Barge Procedure

RECORD OF REVISION

Rev. Incorporated

Section Page Company Comment Contractor Response

No. (Y/N)

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 2 of 7

WHP-C Jacket Piles Loading to Barge Procedure

TABLE OF CONTENT

1. INTRODUCTION................................................................................................................................... 3

2. PURPOSE............................................................................................................................................. 4

3. REFERENCES...................................................................................................................................... 5

3.1 International Codes and Standard............................................................................................5

3.2 Project Specification.................................................................................................................5

3.3 Project Documentation............................................................................................................. 5

4. DEFINITION AND ABBREVIATION.......................................................................................................6

4.1 Definition of Terms................................................................................................................... 6

4.2 Abbreviation............................................................................................................................. 6

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 3 of 7

WHP-C Jacket Piles Loading to Barge Procedure

1. INTRODUCTION

SAKA Indonesia Pangkah Limited (here in after defined as "COMPANY") has been commissioned to

undertake the operator of Ujung Pangkah facility in East Java since January 2014 from HESS. The

Ujung Pangkah field is located offshore off the north coast of East Java approximately 35 km

north of Gresik, East Java, Indonesia; lies adjacent to the Solo river delta.

WHP-A currently producing natural gas and crude oil and then the fluid is transported to CPP near

WHP-B for separation and compression/pumping process.

WHP-B producing oil and gas, then the produced fluid are transferred to CPP for separation and

compression/pumping process. The outlet of oil and gas separation process at CPP will be

transported via 16” Export Pipeline to WHP-A, and continued with 18” Export Pipeline from WHP-

A to OPF (Onshore Processing Facilities) in Pangkah – Gresik.

COMPANY intends to exploit reservoirs located in the Sidayu Field located approximately 3.6 km

north of Ujung Pangkah Field, on offshore of Gresik, east of Java, Indonesia. The initial development

plan of Sidayu Field is to have 2 satellite wellhead platforms (WHP-C & WHP-D) with 3-4 well slots

(including existing Sidayu-3 & Sidayu-4V exploration wells and future well) for each platform to be

tied back via WHP-B to existing Ujung Pangkah CPP for export and gas lift facilities.

Production from Sidayu Wells will be commingled with Pangkah’s production at WHP-B/CPP then

delivered to Onshore Processing Facility (OPF) for final processing.

In summary, Sidayu Field is consisted of the following major components:

a) The installation of remote Wellhead Platform C (WHP-C) and remote Wellhead Platform D

(WHP-D),

b) Infield pipelines, and

c) Modify the existing facilities (WHP-B & AUP) to accommodate Sidayu’s production and

support Sidayu’s production systems

In the OPF all product will continue further process to separate oil, gas, LPG and water. The oil

product will be transferred via pipeline to Maspion Jetty ready for shipping. The further process is

liquefaction to convert heavy fraction becomes LPG and the low fraction becomes Sales Gas. The

Sales Gas will be transported to PLN at PJB via 20” Onshore Sales Gas Pipeline.

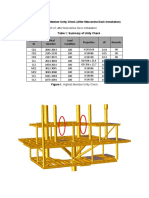

The Overall Plant layout is shown on Figure 1.1.

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 4 of 7

WHP-C Jacket Piles Loading to Barge Procedure

Figure 1-1 Sidayu Plant Layout

Consortium PT. Gunanusa Utama Fabricator and PT. Hafar Daya Konstruksi has been

commissioned to conduct an engineering, procurement, construction, installation and

commissioning (EPCIC) of this field, working towards a preferred conceptual option for the

Wellhead Platform option selection, pipeline assessment, and surface facility tie-in which is in

accordance to COMPANY’s plans for the development of the field.

2. PURPOSE

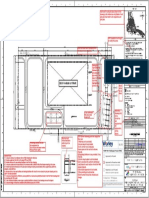

The purpose of this document is to describe the loading of piles to barge procedure. The structure will

be fabricated at PT. Gunanusa Utama Fabricators (PTG) yard. Piles will be installed on site and

process of loading to barge as shown on piles loading to barge sequences drawing.

For description WHP-C jacket piles has 3 pile. Each pile divided in 4 segment : P1, P2, P3 & P4. The

loading to barge process WHP-C jacket piles will be sailed away with the WHP-D jacket piles on one

barge.

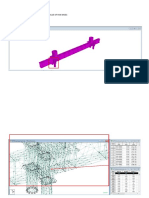

The behavior of structure when stacked shall be analyzed to ensure that there is no damage/failure on

both the structure and rigging equipment. Structural Analysis software shall be used to analyze the

deflection and unity stress ratio on the module at each stage.

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 5 of 7

WHP-C Jacket Piles Loading to Barge Procedure

3. REFERENCES

The procedures shall be in accordance with good engineering practices and in compliance with the

latest editions and revisions (unless noted otherwise) of the following Codes, Standards, Company's

Specifications and Regulations, as applicable:

3.1 International Codes and Standard

No. Description Doc Number

[A.1]

[A.2]

[A.3]

[A.4]

3.2 Project Specification

No. Description Doc Number Rev

[C.1]

3.3 Project Documentation

No. Description Doc Number Rev

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 6 of 7

WHP-C Jacket Piles Loading to Barge Procedure

4. DEFINITION AND ABBREVIATION

4.1 Definition of Terms

COMPANY Saka Indonesia Pangkah Limited

CONTRACTOR Consortium PT. Gunanusa Utama Fabricator & PT. Hafar Daya Konstruksi

SUBCONTRACTOR Party which supplies equipment/materials or services specified and

VENDOR/SUPPLIER ordered by CONTRACTOR (or COMPANY)

MANUFACTURER Party which manufactures equipment/materials specified and ordered by

CONTRACTOR (or COMPANY)

PROJECT Provision of EPCI Services for EPCIC Sidayu Wellhead Platform and Pipelines

Should Indicates a preferred course of action. Should is a non-mandatory word and is

not forbidden, but use in the body of the text should be the exception.

Shall Indicates a course of action with a mandatory status. The term “shall”shall be

used if a requirement is considered to be necessary to claim compliance with a

COMPANY document.

Approval The authorization in writing given by the COMPANY to the Contractor on a

procedure or to proceed with the performance of a specific part of the work

without releasing in any way the Contractor from any of his obligations to

conform with the technical specifications, requisitions, etc. The words

“Approve”, “Approved” and “Approval” shall be construed accordingly

4.2 Abbreviation

The following abbreviations are applied throughout this document:

AISC : American Institute of Steel Construction

API : American Petroleum Institute

AWS : American Welding Society

COG : Centre of Gravity

MT : Metric Ton

UC : Unity Check

WHP : Wellhead Platform

UPD-GF-W3-SJ-PR-4009 _Rev. B Page 7 of 7

You might also like

- Erbil Refinery Diesel Filling Pump Data SheetDocument5 pagesErbil Refinery Diesel Filling Pump Data SheetSardar PerdawoodNo ratings yet

- KPD-TAY Integrated Development Project Phase-II DatasheetDocument2 pagesKPD-TAY Integrated Development Project Phase-II Datasheetm.shehreyar.khanNo ratings yet

- Air CompressorDocument51 pagesAir CompressorInaam Ur RehmanNo ratings yet

- Pipe Stress Analysis Training Complete CourseDocument24 pagesPipe Stress Analysis Training Complete CourseFábio GamaNo ratings yet

- SP-2069 Specification For Pressure VesselsDocument68 pagesSP-2069 Specification For Pressure Vesselsarjunprasannan7No ratings yet

- Datasheet For Gate Valves: ProjectDocument3 pagesDatasheet For Gate Valves: ProjectbecpavanNo ratings yet

- Gangway Mechanical DataDocument8 pagesGangway Mechanical DatariandiNo ratings yet

- Foundation Load Table.Document1 pageFoundation Load Table.Lcm TnlNo ratings yet

- API 650 Baseplate DesignDocument3 pagesAPI 650 Baseplate DesignmjlazoNo ratings yet

- Calculo Gas Motor Tank 3000 ADocument30 pagesCalculo Gas Motor Tank 3000 AahmadhatakeNo ratings yet

- Etank Full ReportDocument108 pagesEtank Full ReportFaizal SattuNo ratings yet

- Data Sheet WB RU VDocument5 pagesData Sheet WB RU VMaharani Putri IndrianurNo ratings yet

- N2 Regulator and Gauges DatasheetDocument4 pagesN2 Regulator and Gauges DatasheetpavanNo ratings yet

- AutoPIPE QuickStart - Model Modification - WorkbookDocument63 pagesAutoPIPE QuickStart - Model Modification - WorkbookJames100% (1)

- Scope Matrix PDFDocument5 pagesScope Matrix PDFNathanNo ratings yet

- Tank Venting API 2000Document3 pagesTank Venting API 2000Gusfi CarsurinNo ratings yet

- Operation Manual for Waste Water Treatment SystemDocument21 pagesOperation Manual for Waste Water Treatment SystemVraja KisoriNo ratings yet

- Guide Document For Itemized Spring Hangers and Tie-Rod Data SheetsDocument19 pagesGuide Document For Itemized Spring Hangers and Tie-Rod Data SheetsAHMED AMIRANo ratings yet

- PSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipDocument4 pagesPSV Sizing: The Relief Load Can Be Calculated Directly, in Pounds Per Hour, From The Following RelationshipAfees OlajideNo ratings yet

- RTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVDocument15 pagesRTN - Ttu-V-2154-001-Ste-Cal-007 - 3B Capacity Calculation Sheet For PRV & VRVroronoa_zorro11No ratings yet

- Atmospheric Flash TankDocument3 pagesAtmospheric Flash TankBlitz Xyrus100% (2)

- Penawaran Pekerjaan DED 4 Unit Tanki Rev.0Document3 pagesPenawaran Pekerjaan DED 4 Unit Tanki Rev.0m khaeronNo ratings yet

- 006 - Exhibit I - Appendix I-1 & I-2Document53 pages006 - Exhibit I - Appendix I-1 & I-2Them Bui XuanNo ratings yet

- Fluid Handling Engineers: U S Agency - Taco DivDocument5 pagesFluid Handling Engineers: U S Agency - Taco DivsitehabNo ratings yet

- Storage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsDocument1 pageStorage Tanks Calculation Template: Oil & Gas Production: Company Name: Site Name: RN: Fin: Epn: Cin: Data InputsihllhmNo ratings yet

- Pig Receiver Data Sheet 91303 - 8 InchDocument4 pagesPig Receiver Data Sheet 91303 - 8 InchSinaNo ratings yet

- Design of lifting lug on spreader beamDocument2 pagesDesign of lifting lug on spreader beamSabrang LorNo ratings yet

- Calculation Relief LoadDocument4 pagesCalculation Relief LoadElias EliasNo ratings yet

- Tank FixturesDocument21 pagesTank FixturesASSSSSSSSSSSSNo ratings yet

- Compressor Drive Engine Power CalculatorDocument2 pagesCompressor Drive Engine Power CalculatorJoshi DhvanitNo ratings yet

- Data Sheet For Flare Package (PK-720)Document3 pagesData Sheet For Flare Package (PK-720)samynatha PrasathNo ratings yet

- Technodyne International Limited: Refrigerated Project ListDocument3 pagesTechnodyne International Limited: Refrigerated Project ListSir AlaaNo ratings yet

- T12026 SACM 0002 N 0 - ProposalDocument81 pagesT12026 SACM 0002 N 0 - ProposalSubrata DasNo ratings yet

- DATA SHEET FOR MFO STORAGE TANKDocument4 pagesDATA SHEET FOR MFO STORAGE TANKPascal MadhawaditomaNo ratings yet

- ES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Document23 pagesES-20.02 Quality Requirements PTT Public Co., LTD OF 23 For Pressure Vessel Engineering Standard REV: 01Nikki RobertsNo ratings yet

- Jsa For Roof Air LiftDocument2 pagesJsa For Roof Air LiftKoshy ThankachenNo ratings yet

- Valve CV Sizing Liquids GasesDocument22 pagesValve CV Sizing Liquids GasesSamuel OnyewuenyiNo ratings yet

- WRC 107 WRC 297 Co MP PDFDocument11 pagesWRC 107 WRC 297 Co MP PDFIqbal Muhammad100% (1)

- Datasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDocument4 pagesDatasheet Floating Roof Tanks Spill Prevention Level Switch SXRLTX A Series1 EnglishDylan RamasamyNo ratings yet

- Specification For Pressure TransmitterDocument15 pagesSpecification For Pressure Transmitteramini_mohiNo ratings yet

- Alpema Standerd For Brazed Aluminium Plate-Fin Heat ExchDocument78 pagesAlpema Standerd For Brazed Aluminium Plate-Fin Heat ExchBilal NazirNo ratings yet

- 7-12-0007 Rev6 (Pipe Leg Support)Document1 page7-12-0007 Rev6 (Pipe Leg Support)sumit kumar100% (1)

- Technical Evaluation HAM BAKERDocument1 pageTechnical Evaluation HAM BAKEReko123No ratings yet

- 94-QC20-J-414 - Curb Angle Check On L100X100X15Document92 pages94-QC20-J-414 - Curb Angle Check On L100X100X15Hgagselim SelimNo ratings yet

- Data Sheet Turbodisc Drier PDFDocument2 pagesData Sheet Turbodisc Drier PDFDaniel SouzaNo ratings yet

- Adequacy Report Open Vent Calcultion For Storage Tank BOT 02 & BOT 08Document6 pagesAdequacy Report Open Vent Calcultion For Storage Tank BOT 02 & BOT 08RajaramNo ratings yet

- PVVDocument10 pagesPVVJorge Arturo Rodríguez HerreraNo ratings yet

- Output Summary: SI UnitsDocument42 pagesOutput Summary: SI UnitsAkhil JoseNo ratings yet

- SVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplaceDocument8 pagesSVDN CPP I 0023 D01 0002 Rev.04 General Arrangement Drawing in Signaler ReplacejfdlksaNo ratings yet

- Valve Sizing Calculation8Document2 pagesValve Sizing Calculation8PIDNo ratings yet

- Tanky 53 KL Rev.1Document187 pagesTanky 53 KL Rev.1Priyo Jati WahyonoNo ratings yet

- 22-DS-R-001 Rev 1 API 617 GTCPsDocument25 pages22-DS-R-001 Rev 1 API 617 GTCPsChike Nwachukwu100% (1)

- LPG Amine Cooler-SummaryDocument15 pagesLPG Amine Cooler-SummaryJEEVITHANo ratings yet

- Specialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Document1 pageSpecialist Services: Heavy Oil Production Facility at Umm Niqa (15049) CONTRACT NO. 15052398Naresh KumarNo ratings yet

- Design Rule Asme Sec Viii Div 2Document2 pagesDesign Rule Asme Sec Viii Div 2Malathy RajaNo ratings yet

- Solidworks Flow Simulation Project Report: (Company Logo Here)Document13 pagesSolidworks Flow Simulation Project Report: (Company Logo Here)Michaelle Angela ArnedoNo ratings yet

- Oil Cooler - Pre Design Data SheetDocument3 pagesOil Cooler - Pre Design Data SheetSakthi VelNo ratings yet

- CPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingDocument18 pagesCPP-NA2-PM-PLN-0015 Procedure For Hydrostatic TestingAdil Ijaz100% (1)

- Calculation 950122Document36 pagesCalculation 950122fafcoNo ratings yet

- UPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BDocument42 pagesUPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BriandiNo ratings yet

- WHP-D Topside Member Unity Check (After Mezzanine Deck Installation)Document4 pagesWHP-D Topside Member Unity Check (After Mezzanine Deck Installation)riandiNo ratings yet

- Health DisordersDocument2 pagesHealth DisordersriandiNo ratings yet

- All About You and Your BusinessDocument2 pagesAll About You and Your BusinessriandiNo ratings yet

- All About PersonalityDocument2 pagesAll About PersonalityriandiNo ratings yet

- Meeting and WelcomingDocument2 pagesMeeting and WelcomingriandiNo ratings yet

- Allowable Bending Stress & Allowable Moment InputDocument2 pagesAllowable Bending Stress & Allowable Moment InputriandiNo ratings yet

- Perhitungan Pondasi TelapakDocument2 pagesPerhitungan Pondasi Telapaksaputrafrandy_95899280% (15)

- Your Workplace and ColleaguesDocument2 pagesYour Workplace and ColleaguesriandiNo ratings yet

- (Joint 1760) : PT - Technip IndonesiaDocument12 pages(Joint 1760) : PT - Technip IndonesiariandiNo ratings yet

- Material Take Off: For Construction Dept.: Engineering Section: Construction EngineeringDocument13 pagesMaterial Take Off: For Construction Dept.: Engineering Section: Construction EngineeringriandiNo ratings yet

- BASEPLT9Document27 pagesBASEPLT9Homero Silva100% (3)

- Pad Eyes DesignDocument1 pagePad Eyes DesignriandiNo ratings yet

- PT Gunanusa Utama Fabricators: Equipment Check List (WHP-D Jacket Leg Installation)Document1 pagePT Gunanusa Utama Fabricators: Equipment Check List (WHP-D Jacket Leg Installation)riandiNo ratings yet

- Saka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderDocument19 pagesSaka Indonesia Pangkah Limited Contract No. 4600012838: Piping Test Package W3-0103-01 Production HeaderriandiNo ratings yet

- Protected by PDF Anti-Copy Free: (Upgrade To Pro Version To Remove The Watermark)Document45 pagesProtected by PDF Anti-Copy Free: (Upgrade To Pro Version To Remove The Watermark)riandiNo ratings yet

- UPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BDocument42 pagesUPD-GF-G8-SJ-An-4101 - Barge Hafar 238 Stability and Longitudinal Strength Analysis During WHP-C WHP-D Pile Loadout Rev. BriandiNo ratings yet

- Data Seismic - Genap 2018-2019Document2 pagesData Seismic - Genap 2018-2019riandiNo ratings yet

- PenamaanDocument3 pagesPenamaanriandiNo ratings yet

- Location of Plates Which Have Maximum Value of Von MisesDocument4 pagesLocation of Plates Which Have Maximum Value of Von MisesriandiNo ratings yet

- 26071-203-P1-321-00011 Plot Plan Interconneting Pipe Rack (Unit 321) Sulfur Handling and StorageDocument1 page26071-203-P1-321-00011 Plot Plan Interconneting Pipe Rack (Unit 321) Sulfur Handling and StorageriandiNo ratings yet

- Area of Tension Steel Per Aci 318-02 For Singly Reinforced Flexural Members InputDocument4 pagesArea of Tension Steel Per Aci 318-02 For Singly Reinforced Flexural Members InputriandiNo ratings yet

- Allowable Bending Stress & Allowable Moment For Wide FlangesDocument4 pagesAllowable Bending Stress & Allowable Moment For Wide FlangesriandiNo ratings yet

- BoQ LogoDocument22 pagesBoQ LogoriandiNo ratings yet

- 26071-203-P1-320-00008 - 00B - Plot Plan For Sphere Area 320 D-320-03, 04 & 06 ABDocument1 page26071-203-P1-320-00008 - 00B - Plot Plan For Sphere Area 320 D-320-03, 04 & 06 ABriandiNo ratings yet

- Cone / Bending List: Topside Location Od OD THK LDocument2 pagesCone / Bending List: Topside Location Od OD THK LriandiNo ratings yet

- Confidential loading equipment documentDocument3 pagesConfidential loading equipment documentriandiNo ratings yet

- Gatic CatalogueDocument32 pagesGatic CatalogueriandiNo ratings yet

- PTGGUNUNGGARUDADocument1 pagePTGGUNUNGGARUDAHariadi Yulianto100% (4)

- Katalog Gunung Garuda NewDocument36 pagesKatalog Gunung Garuda Newabduh81No ratings yet

- Pile Load Test PDFDocument11 pagesPile Load Test PDFAjit P. SinghNo ratings yet

- AspenCapitalCostEstimatorV9 0 UserGuideDocument682 pagesAspenCapitalCostEstimatorV9 0 UserGuideRoudaina Benzeguir100% (1)

- Technical Specifications MCMSDocument223 pagesTechnical Specifications MCMSAmit100% (1)

- Omron SSG 2015 2016 EN X302E307 201503 FULL PDFDocument532 pagesOmron SSG 2015 2016 EN X302E307 201503 FULL PDFGanjar SopyanaNo ratings yet

- Process Map - Change ManagementDocument2 pagesProcess Map - Change ManagementrmdarisaNo ratings yet

- Pricing Preambles for Fifth Precinct StadiumDocument32 pagesPricing Preambles for Fifth Precinct StadiumRyan De Vera PagalNo ratings yet

- Standard Specification OCR PDFDocument408 pagesStandard Specification OCR PDFTahir Yousafzai100% (2)

- pkcs-15v1 2Document85 pagespkcs-15v1 2Pedro LopesNo ratings yet

- Change Control SOPDocument7 pagesChange Control SOPGhanta Ranjith Kumar100% (1)

- Astm A510 6 PDFDocument7 pagesAstm A510 6 PDFNafiou KamelNo ratings yet

- DM HvacDocument356 pagesDM HvacTuấn Quách100% (2)

- IVECO Daily 4x4Document110 pagesIVECO Daily 4x4Richard Thodé Jr100% (2)

- SPECIFICATIONSDocument7 pagesSPECIFICATIONSGaspar Lig-ang TolomiaNo ratings yet

- Quality QM-58 Supplier Contract Quality Requirements Specification - 0Document58 pagesQuality QM-58 Supplier Contract Quality Requirements Specification - 0Bea MokNo ratings yet

- M S SPML Infra Limited Vs NTPC Limited Anr On 16 December 2021Document10 pagesM S SPML Infra Limited Vs NTPC Limited Anr On 16 December 2021Mohammad ArishNo ratings yet

- REACH Annex XVII Status 1904Document21 pagesREACH Annex XVII Status 1904MarkChenNo ratings yet

- Sankar ResumeDocument4 pagesSankar ResumeSa RaNo ratings yet

- Practical SkillsDocument64 pagesPractical Skillsraghava12345650% (2)

- PipeFlo ProDocument3 pagesPipeFlo ProAdib HashemiNo ratings yet

- A 388 - A 388M - 03 - Qtm4oc9bmzg4tqDocument8 pagesA 388 - A 388M - 03 - Qtm4oc9bmzg4tqRod RoperNo ratings yet

- Scope.: Not Measurement SensitiveDocument45 pagesScope.: Not Measurement SensitiveMark AinsworthNo ratings yet

- UCLan Engineering Design Coursework BriefDocument9 pagesUCLan Engineering Design Coursework BriefAmin PatelNo ratings yet

- Tender Document - Piave Secondary School Borehole in Nakuru CountyDocument160 pagesTender Document - Piave Secondary School Borehole in Nakuru CountyKiplgat ChelelgoNo ratings yet

- BOLESA Residence - Architectural SpecificationDocument18 pagesBOLESA Residence - Architectural SpecificationMarilou Basallo100% (1)

- Manufacturing FlowDocument12 pagesManufacturing FlowtdeviyanNo ratings yet

- Band 2 eDocument58 pagesBand 2 eIonaş Claudia Ramona100% (1)

- A276A 276M.17 Norma Aceros Inoxidables Composicion PDFDocument8 pagesA276A 276M.17 Norma Aceros Inoxidables Composicion PDFalucard375No ratings yet

- SPP DOCS On PRE DESIGN SERVICEDocument49 pagesSPP DOCS On PRE DESIGN SERVICEDana DalayapNo ratings yet

- Engineering Mining Supplies Quality Policy ManualDocument42 pagesEngineering Mining Supplies Quality Policy ManualDanie Grobler100% (1)

- MIL-F-18240D 25 February 197? Superseding MIL-F-18240C (ASG) 17 November 1967Document19 pagesMIL-F-18240D 25 February 197? Superseding MIL-F-18240C (ASG) 17 November 1967杜文欽No ratings yet