Professional Documents

Culture Documents

Chapter Six, Beam-Coulmn

Uploaded by

abdulkadir debaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Chapter Six, Beam-Coulmn

Uploaded by

abdulkadir debaleCopyright:

Available Formats

Chapter Six: Combined Bending and Axial Load Members 1

Chapter Six: Combined Bending and Axial Load Members

6.1 Introduction

Nearly all members in a structure are subjected to both bending moment and axial force-either

tension or compression. When the magnitude of one or the other is relatively small, its effect is

usually neglected and the member is designed either as a beam, or as an axially loaded column.

For many situations neither effect can properly be neglected and the behaviour under combined

loading must be considered in design. A special class of such members that are subjected to

both axial compression force and bending moment are called beam-columns. They represent the

general load case of an element in a structural frame.

There are a number of factors that affect the performance of a member under combined axial

force and bending moment. A number of categories of combined bending and axial load along with

the likely mode of failure may be summarized as follows:

a. Axial tension and bending: failure usually by yielding.

b. Axial compression and bending about one axis: failure by instability in the plane of

bending, without twisting.

c. Axial compression and bending about the strong axis: failure by lateral-torsion buckling.

d. Axial compression and biaxial bending-torsionally stiff sections: failure by instability in

one of the principal directions. (W shapes are usually in this category.)

e. Axial compression and biaxial bending thin-walled open sections: failure by combined

twisting and bending on these torsionally weak sections.

f. Axial compression, biaxial bending, and torsion: failure by combined twisting and bending

when plane of bending does not contain the shear center.

It may be apparent from this summary that no single design procedure is likely to properly

account for such varied behavior. Current design procedures generally follow empirical

interaction procedures to design structural members under combined stresses. Through such

interaction equations the true behavior is accounted for more accurately for most of the

stability situations.

In addition to mode of moment application as noted above, the behavior of a beam-column also

depends on its length on its lateral support conditions. In this later context, and with special

reference to beam-columns, the behavior can be classified into the following five cases:

Case 1: A short column subjected to axial load and uniaxial bending about either axis or

biaxial bending.

Failure generally occurs when the plastic capacity of the section is reached. Note

limitations set in Case (2) below.

Case 2: A slender column subjected to axial load and uniaxial bending about the major

axis y-y.

If the column is supported laterally against buckling about the minor axis z-z out

of the plane of bending, the column fails by buckling about the x-x axis. This is

not a common case (see fig. 6.1a) at low axial loads or if the column is not very

slender a plastic hinge forms at the end or point of maximum moment.

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 2

Case 3: A slender column subjected to axial load and uniaxial bending about the minor

axis z-z.

The column does not require lateral support and there is no buckling out of the

plane of bending. The column fails by buckling about the z-z axis. At very low

axial loads it will reach the bending capacity for z-z axis .

Case 4: A slender column subjected to axial load and uniaxial bending about the major

axis y-y.

This time the column has no lateral support. The column fails due to a

combination of column buckling about the z-z axis and lateral torsional buckling

where the column section twists about x-axis as well as deflecting in the yx and

yz planes (see fig. 6.1b).

Case 5: A lender column subjected to axial load and biaxial bending.

The column has no lateral support. The failure is the same as in Case 4 above but

minor axis buckling will have the greatest effect. This is the general loading case

(see fig. 6.1c).

Column deflects in zx plane, then Column deflects in zx and yx planes

Column deflects in zx plane only buckles by deflecting and twists about x-axis

in yx plane and twisting about x-axis

Fig. 6.1a In-plane behavior Fig. 6.1c Bi-axial bending

Fig. 6.1b Flexural-torsional behavior

6.2 Overall Stability

In a beam column the treatment of cross-sectional behavior take account of the way in which

the moment M at the particular cross-section under consideration was generated. Figure 6.2

shows a beam-column undergoing lateral deflection as a result of the combination of compression

and equal and opposite moments applied at the ends.

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 3

(a) Equal and opposite moment case (b) Non-uniform moment case

Fig. 6.2 Primary and secondary moments

The moment at any point within the length may conveniently be regarded as being composed of

two parts:

primary moment M

secondary moment Nv

Effect of Pattern of Primary Moment

Figure 6.2a showed how, for the particular case of equal and opposite end moments, the primary

moments are amplified due to the effect of the axial load N acting through the lateral

displacements v. When the pattern of primary moment is different the two effects will not be

so directly additive since maximum primary and secondary moments will not necessarily occur at

the same location. Figure 6.2b illustrates the situation for end moments M and M, where can

adopt values between +1 (uniform single curvature) and -1 (double curvature). The particular case

shown corresponds to a value -0,5.

For the case illustrated the maximum moment still occurs within the member length but the

situation is clearly less severe than that of Figure 6.2a assuming all conditions to be identical

apart from the value of . It is customary to recognize this in design by reducing the

contribution of the moment term to the interaction relationship.

Since the case of uniform single curvature moment is the most severe, it follows that a safe

simplification is always to use the procedure for = 1.0.

Returning to Figure 6.2b, it is possible for the point of maximum moment to be at the end at

which the larger primary moment is applied. This would usually occur if the axial load was small

and/or slenderness was low so that secondary bending effects were relatively slight. In such

cases design will be controlled by the need to ensure adequate cross-sectional resistance at this

end.

6.3 Limit State Design, EBCS 3 1995

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 4

Resistance of Cross Section

According to the EBCS 3 Specification, members designed to resist factored bending moments

My.sd and Mz.sd, calculated using appropriate load combinations, must satisfy the following

condition:

a. When Vsd 0.50Vbs, rd

N Sd M y .Sd N Sd e Ny M z .Sd N Sd e Nz (6.1)

1 .0

N Rd M c. y . Rd M c. z . Rd

Where:

NSd, My.Sd, Mz.Sd are the design forces acting at the cross-section

NRd is the resistance to axial force as discussed earlier

Mc.y.Rd,Mc.z.Rd are the resistances to uniaxial moment respectively

eNy, eNz are the shifts in the neutral axis when the cross-section is subjected to uniform

compression. Note that for class 1, 2 and 3 cross-sections and for doubly symmetric Class 4

cross-section, both eNy and eNz are both zero. For single-symmetric Class 4 sections, either eNy

or eNz is zero.

Note that for angles, the y and z axes in the above should be taken as the u and v axes

respectively.

When Nsd is tensile, both eNy and eNz are to be taken as zero and Nsd is to be taken as positive.

b. When Vsd 0.50Vbs, rd

The design resistance of the cross-section to the combination of moment and axial force should

be calculated using a reduced yield strength (1-) fy for the shear area where = (2VSd/VRd – 1)2

Buckling Resistance

a. Axial tension and bending

Members subject to combined axial tension and bending should be checked to the requirements

of flexural members presented in Chapter Four, but advantage may be taken of the stabilizing

effect of the tension when considering lateral-torsional buckling as follows:

When the axial tension and bending moment can vary independently, the design value of the axial

tension should be multiplied by a reduction factor, for vectorial effects, of 0.8.

The check should be carried out using an effective design internal moment M Sd obtained from:

MSd = Wc c (6.2)

Where

c = the net stress in the extreme fiber due to the vectorial effects of factored loads.

Wc = the elastic section modulus for the extreme fiber.

b. Axial Compression and Bending

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 5

In addition to satisfying the requirements of cross-sectional resistance presented above, at

every point along the length of the member and the general requirements for flexural as

presented in Chapter Four, interaction effects should be considered between compressive loads

and bending moments. The following interaction criteria are suitable:

1. Axial compression and uni-axial major axis moment:

i. To avoid buckling about the major axis:

Nsd k y M y Sd N Sd eN y

1 (6.3a)

Nb. y.Rd wyWpl. y f y Ml

y N sd

In which ky 1 but k y 1.5

X y Af y

Wpl. y Wel . y

y y (2 my 4) but y 0.9

W el . y

Conservatively:

Nsd 1.5M y Sd N Sd eN y

1 (6.3b)

N b. y.Rd wy W pl. y f y Ml

ii. To avoid buckling about the minor axis (for members subject to lateral-torsional

buckling):

N Sd k M N Sd eNy

lT y.Sd 1.0 (6.3c)

Nb. z.Rd M b.Rd

LT N sd

In which k LT 1 but kLT 1

X z Af y

LT 0.15z M .LT 0.15 but LT 0.9

Conservatively:

N Sd M y.Sd N Sd e Ny

1.0 (6.3d)

N b. z.Rd M b.Rd

2. Axial compression and uni-axial minor axis moment:

To avoid buckling about the minor axis:

N Sd k M N Sd eNz

z z .Sd 1.0 (6.4a)

Nb. z .Rd w. yWpl. z f y Ml

Conservatively:

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 6

N Sd 1.5M z.Sd N Sd eNz

1.0 (6.4b)

Nb. z.Rd w. yWpl. z f y Ml

3. Axial compression and biaxial moments:

i. All members should satisfy:

N Sd k y M y.Sd N Sd eNy k z M z .Sd N Sd eNz

1.0 (6.5a)

Nb. z.Rd min w. yWpl. z f y Ml w. zWpl. z f y Ml

z N sd

In which kz 1 but kz 1.5

X z Af y

Wpl. z Wel . z

z z (2 mz 4) but z 0.9

W el . z

Conservatively:

N Sd 1.5M y.Sd N Sd e Ny 1.5M z .Sd N Sd e Nz

1.0 (6.5b)

N b. z.Rd min w. yW pl. z f y Ml w. zW pl. z f y Ml

ii. Members potentially subject to lateral-torsional buckling should also satisfy:

N Sd k M N Sd eNy k z M z .Sd N Sd eNz

LT y.Sd 1.0 (6.5c)

Nb. z .Rd M b.Rd w. zWpl. z f y Ml

Conservatively:

N Sd M N Sd eNy 1.5M z .Sd N Sd eNz

y.Sd 1.0 (6.5d)

Nb. z .Rd M b.Rd w. zWpl. z f y Ml

In the above equations:

NSd,eNy and eNz are defined in above under “Resistance of Cross-section”

MySd and MzSd are the maximum design moments, each considered separately, occurring

in the member.

Nb.yRd and Nb.zRd are the flexural buckling resistances for the y and z axes respectively

(see under “Flexural buckling”, Chapter two - Compression Members).

(Nb.Rd)min is the lesser of Nb.yRd and Nb.zRd (all buckling modes considered)

Xy and Xz are reduction factors (see chapter 3 or 4) for the y-y and z-z axes

respectively.

my and mz are equivalent uniform moment factors for flexural buckling (see Figure)

M.LT is an equivalent uniform moment factor for lateral-torsional buckling (see

Figure 6.3)

wy and w.z are the values of w determined for the y and z axes respectively in

which

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 7

w = 1 for class 1 or 2 cross sections

= Wel/Wpl for class 3 cross-sections

= Wel/Wpl for class 4 cross-sections

Wpl.y and Wpl.z are the plastic moduli for the y and z axes respectively

Mb.Rd is the lateral-torsional buckling moment (see Chapter Four-Flexural

Members)

Note that for angles, the y and z axes in the above should be taken as the u and v axes

respectively.

c. Biaxial Bending

The cross-sectional resistance should be checked as provided earlier as well as the general

requirements for beam members (see Chapter Four-Flexural Members).

The following interaction criteria are suggested for verification of buckling resistance for

biaxial bending in the absence of axial compression:

k y M y.Sd k z M z .Sd

1.0 (6.6a)

w. yWpl. y f y Ml w. zWpl. z f y Ml

And, where lateral-torsional buckling is a possible buckling mode:

k LT M y.Sd k z M z.Sd

1.0 (6.6b)

M b.Rd w. zWpl. z f y Ml

Where all quantities are defined under “axial compression and bending” earlier.

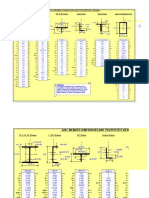

Note: the equivalent uniform moment factors m.y, m.z and m.LT shall be obtained from the

foolwing figure according to the shape of the bending moment diagram between the relevant

braced points as follows:

Factor Moment about axis Points braced in direction

m.y y-y z-z

m.z z-z y-y

m.LT y-y y-y

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 8

Figure 6. 3 Equivalent uniform moment factors

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 9

6.4 Limit State Design, AISC-LRFD SPECIFICATION

According to the AISC-LRFD Specification, doubly or singly symmetric structural members

designed to resist a factored axial load N Sd bending moment Mu, calculated using the appropriate

load combinations, must satisfy the condition:

1. For Pu/Pn 0.2:

Pu 8 M ux M uy

1.0

(6.7a)

Pn 9 b M nx b M ny

2. For Pu/Pn 0.2:

Pu 8 M ux M uy

1.0 (6.7b)

2Pn 9 b M nx b M ny

Where:

a. If P is tensile,

Pu = factored tensile axial force

Pn = design tensile strength (see Chapter Two-Tension Members)

Mu = factored moment

Mn = design flexural strength (see Chapter Four-Flexural Members)

= t = resistance factor for tension = 0.9

= resistance factor for flexure = 0.9

b. If P is compressive,

Pu = factored compressive axial force

Pn = design compressive strength (see Chapter Three-Compression Members)

Mu = factored moment to be determined as per subsequent discussion

Mn = design flexural strength (see Chapter Four-Flexural Members)

= c = resistance factor for compression = 0.85

b = resistance factor for flexure = 0.90

The factored moment Mu should be determined from a second-order elastic analysis. In lieu of

such an analysis, the following equation may be used:

Mu = B1Mnt + B2Mlt (6.8)

Where

Mnt = factored moment in member, assuming the frame does not undergo lateral

translation (provision of artificial restraint at the joints)

Mlt = factored moment in member as a result of lateral translation (equal and opposite

forces at the same joint)

B1 = Cm/(1-Pu/Pc) 1.0

Pe = 2El/(KL)2, with K1.0 in the plane of bending

Cm = a coefficient to be determined from the following discussion

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 10

B2 =

1 1 Pu oh HL

or B2 1 1 Pu P

e

p u

= sum of all factored loads acting on and above the story under consideration

oh = first-order inter-story translation

H = sum of all lateral loads acting on and above the story under consideration

L = story height

For end-restrained members that do not undergo relative joint translation and are not subject

to transverse loading between their supports in the plane of bending, C m is given by:

M

C m 0.6 0.4 1 (6.9a)

M2

Where: M1/M2 is the ratio of the smaller to larger member end moments. The ratio is positive if

the member bends in reverse curvature and negative if the member bends in single curvature.

For end restrained members that do not undergo relative joint translation and are subject to

transverse loading between their supports in the plane of bending,

Cm = 0.85 (6.9b)

For unrestrained members that do not undergo relative joint translation and are subject to

transverse loading between their supports in the plane of bending,

Cm = 1.00 (6.9c)

The selection of trial sections for use as beam-columns is facilitated by rewriting the

interaction equations, Eq.(6.7a) and Eq.(6.7b) into the so-called equivalent axial load form.

For Pu/cPn > 0.2:

Pu + mxMux + myUMuy cPn (6.10a)

For Pu/cPn 0.2:

Pu 9 9

m x m yUM uy c Pn (6.10b)

2 8 8

Where

mx

8

c Pn b M nx

9

m yU c Pn b M ny

8

9

Numerical values for m and U are provided in the AISC Manual of Steel Construction. The

advantage of using Eqs. (6.10) for preliminary design is that the terms on the left-hand side of

the inequality can be regarded as an equivalent axial load, (P u)eff. The similarity in form between

the two equations and Eq.(3.7a), Chapter Three, allows the designer to take advantage of the

column tables provided in the manual for selecting trial sections.

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 11

Biaxial Bending

Members subjected to bending about both principal axes (e.g., purlins on an inclined roof) should

be designed for biaxial bending. Since both the moment about the major axis, Mux and the

moment about the minor axis, Muy, create flexural stress over the cross section of the member,

to avoid yielding at the most severely stressed point the following equation for the yielding limit

state must be satisfied:

fun bfy (6.11)

where

fun = Mux/Sx + Muy/Sy = the flexural stress under factored loads

Sx, Sy = elastic section moduli about the major and minor axes, respectively

b = 0.90

fy = specified minimum yield stress

In addition, the limit state for lateral torsional buckling about the major axis should also be

checked, i.e.,

bMnx Mux (6.12)

Where bMnx the design flexural strength about the major axis (see Chapter Four-Flexural

Members). Note that lateral torsional buckling will not occur about the minor axis.

Equation (6.11) can be rearranged to give:

M ux M uy Sx M ux M ux d

Sx 3.5 (6.13)

b f y b f y S f b f y df

y b y

The use of Eq. (6.13) greatly facilitates the selection of trial sections for use in biaxial bending

problems.

Combined Bending, Torsion, and Axial Force

Members subjected to the combined effect of bending, torsion, and axial force should be

designed to satisfy the following limit states:

Yielding Under Normal Stress

fy fm (6.14)

Where

= 0.90

fy = specified minimum yield stress

fun = maximum shear stress determined from an eleastic analysis under factored loads

Yielding Under Shear Stress

(0.6fy) fun (6.15)

Where

= 0.90

fy = specified minimum yield stress

Design of steel and timber structures (CE 519) Yibeltal Temesgen

Chapter Six: Combined Bending and Axial Load Members 12

fvu = maximum shear stress determined from an elastic analysis under factored

loads.

Buckling

cfcr fun or fuv, which ever is applicable. (6.16)

Where

cfcr = cPn/Ag, in which cPn is the design compressive strength of the member

(see Chapter Three-Compression Members)

fun,fvn = normal and shear stresses as defined in Eq. (6.14) and (6.15).

______________________________

ADDITIONAL READING

E.H. Gayloard and J.E. Stalmeyer

Chapter 6

Charles G. Salmon and Johne E. Johnson

Chapter 12

Robert Englekirk

Chapter 3

EBSC 3 and EC 3

Design of steel and timber structures (CE 519) Yibeltal Temesgen

You might also like

- ISUZU Forward Service ManualDocument53 pagesISUZU Forward Service ManualLeonardo Araque100% (1)

- Rectangular Tank CalculationDocument28 pagesRectangular Tank CalculationHiếu Nguyên78% (32)

- Manual of Steel DesignDocument158 pagesManual of Steel DesignSajoyan Haque100% (1)

- Torsional Buckling of I Beam PDFDocument5 pagesTorsional Buckling of I Beam PDFparamarthasom1974No ratings yet

- Shear and Bending Moment DiagramDocument21 pagesShear and Bending Moment DiagramFahim Faisal RaunaqNo ratings yet

- Chapter-4 Shear & Moment in BeamsDocument22 pagesChapter-4 Shear & Moment in BeamsNaimur Asif BornoNo ratings yet

- Eurocode 3 Lecture NotesDocument30 pagesEurocode 3 Lecture Noteskhx2No ratings yet

- Chapter 6 Applied StabilityDocument59 pagesChapter 6 Applied StabilitytimsykiNo ratings yet

- CBD Aisc 360 16Document98 pagesCBD Aisc 360 16Angel Vargas100% (1)

- Section Modulus 012004Document2 pagesSection Modulus 012004dakidofdaboomNo ratings yet

- Tedds Engineering Library (AU)Document79 pagesTedds Engineering Library (AU)CSEC Uganda Ltd.No ratings yet

- GT Strudl: Steel Design Code User ManualDocument278 pagesGT Strudl: Steel Design Code User ManualCarlos Abascal MendozaNo ratings yet

- Slenderness Effects in ColumnsDocument11 pagesSlenderness Effects in ColumnsDaniyal AhmadNo ratings yet

- Introduction To Elastic StabilityDocument20 pagesIntroduction To Elastic Stabilitygirma kebede0% (1)

- Chapter 3 Column and Compression MembersDocument60 pagesChapter 3 Column and Compression Membersbihanba100% (1)

- Design of Steel BeamsDocument25 pagesDesign of Steel Beamsronaldnyirenda2230No ratings yet

- CE 5001 Structural Steel Design Lecture 05Document56 pagesCE 5001 Structural Steel Design Lecture 05Oshada Attygalle100% (1)

- Stress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionFrom EverandStress Analysis Problems in S.I. Units: The Commonwealth and International Library: Mechanical Engineering DivisionRating: 2.5 out of 5 stars2.5/5 (4)

- R6 - Design of RC Columns and Walls p.13Document47 pagesR6 - Design of RC Columns and Walls p.13kongl100% (3)

- Beams and Framed Structures: Structures and Solid Body MechanicsFrom EverandBeams and Framed Structures: Structures and Solid Body MechanicsRating: 3 out of 5 stars3/5 (2)

- Self-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)Document23 pagesSelf-Supported Cone Roof Design Data: Design of Steel Storage Tanks As Per Api-650 (Diameter 3M)hgagselim2012No ratings yet

- SCF and Cantiliver Strenth AnalysisDocument68 pagesSCF and Cantiliver Strenth Analysisvikasrajput1989No ratings yet

- Chapter 6 Special Structure: Special Structural Elements Deep Beams and CorbelsDocument14 pagesChapter 6 Special Structure: Special Structural Elements Deep Beams and Corbelsomar100% (1)

- Hot Rolled Steel - Composite Beam DesignDocument7 pagesHot Rolled Steel - Composite Beam Designsrikanth.iitkgpNo ratings yet

- Chapter Six: Combined Bending and Axial Load MembersDocument12 pagesChapter Six: Combined Bending and Axial Load MembersOumer MohammedNo ratings yet

- Unit 6Document32 pagesUnit 6Prosenjit DasNo ratings yet

- Module - 1Document45 pagesModule - 1naveenNo ratings yet

- Chapter 6 Lateral Torsional Buckling: 6.2 Elastic Beams 6.2.1 Buckling of Elastic BeamsDocument51 pagesChapter 6 Lateral Torsional Buckling: 6.2 Elastic Beams 6.2.1 Buckling of Elastic BeamsabadittadesseNo ratings yet

- Chapter 5 Beam ColumnDocument42 pagesChapter 5 Beam ColumnMohammed KedirNo ratings yet

- Chapter 5Document61 pagesChapter 5abdu yimerNo ratings yet

- Unrestrained Beam Design-IiDocument21 pagesUnrestrained Beam Design-Iihemant_durgawaleNo ratings yet

- Lecture 3 Column BucklingDocument31 pagesLecture 3 Column BucklingTor GrimlundNo ratings yet

- Design of Laterally Restrained Beams: Theoretical BackgroundDocument13 pagesDesign of Laterally Restrained Beams: Theoretical BackgroundZeyad Tareq Al SaroriNo ratings yet

- CIVL2007 Introduction To Structural Engineering: Module 12 Lecture - Steel in Bending: Flexural MembersDocument48 pagesCIVL2007 Introduction To Structural Engineering: Module 12 Lecture - Steel in Bending: Flexural MembershvyvuyvNo ratings yet

- Pure BendingDocument38 pagesPure BendingMalik Rehan SyedNo ratings yet

- Jima Unversity Steel StructureDocument27 pagesJima Unversity Steel StructureAkli Ale ManNo ratings yet

- Chapter 11Document36 pagesChapter 11sharathr22No ratings yet

- Flexural Members-IiDocument29 pagesFlexural Members-IiDhinesh KalaimaranNo ratings yet

- Pure BendingDocument22 pagesPure BendingTarik Hassan ElsonniNo ratings yet

- Basic Lectures ON Structural Steel FOR Fourth Stage in Civil Engineering College Asst. Prof. Dr. Saad Khalaf MohaisenDocument46 pagesBasic Lectures ON Structural Steel FOR Fourth Stage in Civil Engineering College Asst. Prof. Dr. Saad Khalaf MohaisenMalik SharjeelNo ratings yet

- 0-Design of Mono-Symmetric and Asymmetric Sections in CompressionDocument2 pages0-Design of Mono-Symmetric and Asymmetric Sections in CompressiontavialimNo ratings yet

- JL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Document20 pagesJL-89-January-February Lateral Stability of Long Prestressed Concrete Beams-Part 1Dong-Yong KimNo ratings yet

- Chapter13 PDFDocument60 pagesChapter13 PDFRemitesh JosephNo ratings yet

- Buckling AnalysisDocument10 pagesBuckling AnalysisAmit JainNo ratings yet

- Chapter Six, Deep Beams and CorbelsDocument8 pagesChapter Six, Deep Beams and CorbelsHaftom Gebreegziabiher50% (2)

- Section 4 - Determinate Beam and Frame Analysis Annotated Oct20Document35 pagesSection 4 - Determinate Beam and Frame Analysis Annotated Oct20Colin MacDougallNo ratings yet

- Web Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodDocument14 pagesWeb Buckling in Castellated Beams: A. A. Aglan, R. G. RedwoodmokhtazulNo ratings yet

- Chapter One ColumnsDocument26 pagesChapter One Columnsmintesinot sisayNo ratings yet

- 07-04-2020 ADSS ClassDocument20 pages07-04-2020 ADSS ClassmonikaNo ratings yet

- Lecturenote - 1714126640chapter Six, Deep Beams and CorbelsDocument8 pagesLecturenote - 1714126640chapter Six, Deep Beams and CorbelsTmiky GateNo ratings yet

- Analysis and Design of Compression MembersDocument21 pagesAnalysis and Design of Compression MembersSilendrina Misha100% (1)

- Chapter Four: Columns: Chapter Three: Flat SlabsDocument26 pagesChapter Four: Columns: Chapter Three: Flat SlabsTsegaw FikaduNo ratings yet

- 6-6 Beams - Moment of Resistance Part 1Document10 pages6-6 Beams - Moment of Resistance Part 1Brendon GovaNo ratings yet

- AdinaDocument13 pagesAdinaGaneshNo ratings yet

- Compression Members in Rigid FramesDocument74 pagesCompression Members in Rigid Framesjuan jr lucenaNo ratings yet

- Deflection of Beams PDFDocument28 pagesDeflection of Beams PDFBrave Hlulani MabasoNo ratings yet

- 6 BeamsDocument116 pages6 BeamsIrish TambisNo ratings yet

- Shear Center Lab PDFDocument9 pagesShear Center Lab PDFAndras ZajNo ratings yet

- Elastic Instability ModesDocument13 pagesElastic Instability ModesMihajloDjurdjevicNo ratings yet

- MODULO 5 Compression MembersDocument23 pagesMODULO 5 Compression Memberscarlomonsalve1No ratings yet

- 6chapter PDFDocument35 pages6chapter PDFRamu Neel Nishanth DevaraNo ratings yet

- Chapter 4 PDFDocument10 pagesChapter 4 PDFWendimu TolessaNo ratings yet

- Chapter 6 Shear and Moments in Beams Updting 2020Document19 pagesChapter 6 Shear and Moments in Beams Updting 2020k.ghanemNo ratings yet

- Deflection of Beam - 2sDocument19 pagesDeflection of Beam - 2sDave Harrison FloresNo ratings yet

- Theory of Shells: © 2003 by CRC Press LLCDocument37 pagesTheory of Shells: © 2003 by CRC Press LLCAnonymous LFgO4WbIDNo ratings yet

- Strength of Materials 2 Stage (2021-2022) Civil Engineering Department Dr. Ali Hassan AliDocument26 pagesStrength of Materials 2 Stage (2021-2022) Civil Engineering Department Dr. Ali Hassan AliEggrollmanNo ratings yet

- Class NotesDocument149 pagesClass NotespfsfosnecaNo ratings yet

- Design of Compression Members: As Per IS 800: 2007Document119 pagesDesign of Compression Members: As Per IS 800: 2007umeshapkNo ratings yet

- Strength I Chapter SixDocument16 pagesStrength I Chapter SixAbel ErmiasNo ratings yet

- CV410 - Steel Structures - Lec09 - UpdatedDocument54 pagesCV410 - Steel Structures - Lec09 - UpdatedSharjeel GillNo ratings yet

- Institute of Engineering Thapathali Campus: A Lab Report On Deflection of BeamsDocument17 pagesInstitute of Engineering Thapathali Campus: A Lab Report On Deflection of BeamsBarun ShresthaNo ratings yet

- Lateral Load ExampleDocument24 pagesLateral Load Exampleabdulkadir debaleNo ratings yet

- Hawassa University Institute of Technology School of Civil and Environmental Engineering Ce 6505 - Structural Dynamics Assignment 1Document3 pagesHawassa University Institute of Technology School of Civil and Environmental Engineering Ce 6505 - Structural Dynamics Assignment 1abdulkadir debaleNo ratings yet

- Bridge Desig ProjectDocument31 pagesBridge Desig Projectabdulkadir debaleNo ratings yet

- Deap Beam PDFDocument136 pagesDeap Beam PDFabdulkadir debaleNo ratings yet

- Dsi Underground at Pipe Umbrella en CaDocument24 pagesDsi Underground at Pipe Umbrella en CabrodieNo ratings yet

- Chapter 10 (6) - ADocument63 pagesChapter 10 (6) - AMahfuzur RahmanNo ratings yet

- Quiz 1 - Simple Stress Analysis - No AnalysisDocument1 pageQuiz 1 - Simple Stress Analysis - No AnalysisMahusay Neil DominicNo ratings yet

- Report On Techniques For Bridge Strengthening: Design Example - Plate Girder Shear and Flexural StrengtheningDocument49 pagesReport On Techniques For Bridge Strengthening: Design Example - Plate Girder Shear and Flexural StrengtheningEngr Zin Myo MinNo ratings yet

- Module - 1 Theory DsseDocument16 pagesModule - 1 Theory DsseRøãrîñg GîrîshNo ratings yet

- Diseño Vigas H Ó WDocument109 pagesDiseño Vigas H Ó WJohan Benazir Aliaga EscurraNo ratings yet

- Principle of PTDocument30 pagesPrinciple of PTJimmy ChungNo ratings yet

- Design Calculation For Hexadecagonal Pole: L W W T FDocument3 pagesDesign Calculation For Hexadecagonal Pole: L W W T FsaravqwertyNo ratings yet

- Sectional Properties R0Document15 pagesSectional Properties R0skilmagNo ratings yet

- Protastructure Design Guide Design of Formworks and Formwork ScaffoldsDocument39 pagesProtastructure Design Guide Design of Formworks and Formwork ScaffoldsRJSQNo ratings yet

- AISC - Check Slender+Underhung CraneDocument39 pagesAISC - Check Slender+Underhung CraneMinh HoangNo ratings yet

- Deflection of Beam - 2sDocument19 pagesDeflection of Beam - 2sDave Harrison FloresNo ratings yet

- Exam Set 01Document1 pageExam Set 01allovidNo ratings yet

- API 4F Paper - Issue StudyDocument9 pagesAPI 4F Paper - Issue StudyJorge SilvaNo ratings yet

- Chapter 8 Part II STDDocument35 pagesChapter 8 Part II STDBelkacem AchourNo ratings yet

- AISC Properties MM GPP 2017Document87 pagesAISC Properties MM GPP 2017Pablo García PeñaNo ratings yet

- Bending and Shear Stresses in BeamDocument20 pagesBending and Shear Stresses in BeamJiya ShindeNo ratings yet

- CSICOL Manual PDFDocument118 pagesCSICOL Manual PDFHongVuthyNo ratings yet