Professional Documents

Culture Documents

S04 Bolting Turret ROBOL LPM

Uploaded by

rolandOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

S04 Bolting Turret ROBOL LPM

Uploaded by

rolandCopyright:

Available Formats

12-11-2003 EZ-SP-FL PAGE 1 (20)

ROBOLT LPM TURRET

MAINTENANCE MANUAL

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 2 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL BRAS B14 NV PAGE 3 (20)

CONTENT

1 PRELIMINARY REMARKS 5

1/1 SAFETY 5

1/2 ABOUT THIS BOOKLET 7

2 DESCRIPTION 8

2/1 EXPLANATION 9

3 MAINTENANCE OPERATIONS 10

3/1 FIRST ENTRY INTO SERVICE 10

3/2 OPERATIONS AT EACH SHIFT 10

3/3 50-HOURS OR WEEKLY OPERATIONS 10

3/4 200-HOURS OPERATIONS 11

3/5 600 HOURS OPERATIONS 11

3/6 1200-HOURS OR ANNUAL OPERATIONS 11

3/7 3600-HOURS OPERATIONS OVERALL INSPECTION AND RECONDITIONING 11

4 TIGHTENING TORQUES 12

5 FEED CHAINS 14

5/1 FEED CHAINS ORGANISATION CHART 14

5/2 FEED CHAINS ADJUSTMENT 15

5/3 FEED CHAINS DISMANTLING/REASSEMBLING 15

6 LUBRICATION 16

6/1 GREASING POINTS 16

6/2 GREASE NIPPLES POSITION 17

7 CHECK AND ADJUSTMENT 18

7/1 HOSE CONDITION CHECK 18

7/2 GEAR WHEELS CLEARANCE CHECK 18

7/3 CHAIN GUIDE ROLLERS CHECK 18

7/4 SKID’S AND RAILS CHECK 19

8 LIFTING - HANDLING 19

8/1 LIFTING POINTS. 19

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 4 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

9 PERIODIC MAINTENANCE TABLE - ROBOLT LPM TURRET 20

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 5 (20)

1 PRELIMINARY REMARKS

1.1 SAFETY

The informations contained in this manual must be studied and thoroughly assimilated before

undertaking any maintenance work on the equipment

Remember: SAFETY FIRST!

Always observe the warnings accompanied by the following symbols.

WARNING Operation, maintenance and adjustments are only allowed to persons with

specific training in operation and maintenance of the equipment. Read the operating

and maintenance instructions before using or servicing the equipment.

WARNING: Before starting any maintenance operation ensure that the machine is in a

!

safe location with good safety, ventilation and lighting conditions. Ensure that lifting

equipments and pedestals are compatible with elements’ weight. Follow all the safety

instructions and ware safety protections as gloves, goggle, helmet, safety boots, ear

WARNING

protectors.

WARNING: Before any operation stabilize and fix steadily all the elements on suitable

pedestals. Stop the power packs, switch the general power breaker. Place a tag or a

board to warn other members of the personnel that maintenance work on the machine

WARNING is in progress.

WARNING: Pressurized oil jets could cause severe injuries. Before any operation on

hydraulic circuit, STOP the power packs and release remaining pressure in

components by operating hydraulic control levers several times. Always release the

WARNING static pressure in cylinders before disassemble them.

NEVER WORK ON AN OPERATING CIRCUIT.

WARNING: While tests are in progress, do not allow any other member of the

personnel to stand in the area surrounding the machine. Stay at the control station to

be able to stop the movement and switch off the power pack.

WARNING

WARNING: Maintenance, adjustment and repairs are restricted to qualified personnel

with special training for the particular equipment. Always read the instructions

carefully before starting any maintenance work.

WARNING

CAUTION: Always use suitable tools and work in a clean place when dismantling and

assembling hydraulic components. After removing cylinders the hydraulic inlet/outlet

ports must be plugged to prevent dirt and air intrusion during operation.

WARNING: The operator must always wear required personal protection, such as safety

helmet, protective overall, safety boots, hearing protectors, safety goggles etc.

WARNING: Danger of high pressure oil jets.

High pressure oil jets can cause serious personal injuries.

WARNING Release the pressure in the hydraulic circuits before opening caps or connections.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 6 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

(Accumulator, Cylinder and Hydraulic circuit)

WARNING: Danger of hot surface.

Hot surface can cause serious injuries.

Components rod, shank or hydraulic component can be hot and before

starting a maintenance work, please let them cool off.

The operator must have adequate wears as gloves.

WARNING: Crushing hazard : do not stay in dangerous area, for instance:

central articulation, front chassis and rear chassis.

WARNING

SAFETY

Always follow the marked safety instructions, and

observe caution while working.

The following safety instructions are general rules.

Keep tools and drilling

equipment clean.

Do not attempt any such repairs or adjustments that you do not fully

understand.

ABOUT THE SAFETY OF REPAIRS

Certain workstages require the use of the feed mechanism during the repair.

Make sure then that:

- no danger is caused to anybody.

- the machine can be immediately stopped when necessary.

- the powerpack is stopped again before the repair-work is continued.

Before starting any repair-work move away from the area where you have just

drilled.

Use proper tools.

Always wear protective clothing, eye protection, earmuffs, safety footwear, and

other safety equipment required by the work.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 7 (20)

1.2 ABOUT THIS BOOKLET

The present manual is destined for the use of personnel in charge of carrying out, servicing

and maintenance operations on Jumbos.

It contains maintenance operations schedule and operating methods concerning the main

elements of the ROBOLT LPM TURRET.

Note that servicing and maintenance operations must be carried out by personnel with the

required qualifications, technical knowledge, and proper training on the machine.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 8 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

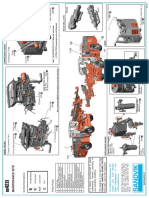

2 DESCRIPTION

Rock drill

DRILLING FEED

Rock drill cradle

Rails Feed chain

front head

Beam

Skids

Hydraulic motor

ERH (rod handler)

TURRET

Resin injection tube

Bolt magazine BOLTING FEED

Bolter wrench

Hydraulic motor

Skids

Bolter cradle

Beam Feed chain

Rails

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 9 (20)

2.1 EXPLANATION

ROBOLT LPM DRILL FEED operates in face drilling. The rock drill and the bolter wrench

must have a tramming movement in order to execut drilling and bolting. This tramming

movement is realised by a chain and a hydraulic motor, the chain is guide by two rollers and

fixed to the rock drill and bolter wrench cradles (see detail A). The paths followed by the

chains over the different gear wheels is shown in the figure above.

DETAIL A

Gear wheel

Hydraulic motor

Front gear wheel

Rollers

Feed chain

Front gear wheel

DETAIL A

Rollers Feed chain

Gear wheel

Hydraulic motor

DETAIL A

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 10 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

3 MAINTENANCE OPERATIONS

CAUTION: The safety of users and the reliability of the drill feed depend on the maintenance

operations and imply the use of genuine SANDVICK TAMROCK SECOMA spare parts.

All defective parts must be immediately replaced.

WARNING: Maintenance, adjustment and repairs are restricted to qualified personnel

with special training for the particular equipment. Always read the instructions

carefully before starting any maintenance work.

WARNING

WARNING: While tests are in progress, do not allow any other member of the personnel

to stand in the area surrounding the machine. Stay at the control station to be able to

stop the movement and switch off the power pack.

WARNING

3.1 FIRST ENTRY INTO SERVICE

• Check tightening torque after 20hours or a week.

3.2 OPERATIONS AT EACH SHIFT

Before starting up:

• Check that there is no obstruction to hinder the movement of the cradles.

• Check the overall condition of the equipment (cylinder, hoses, hydraulic unions,...).

• Check chain condition.

• Search for leakage of oil.

• Lubricate all the grease points.

CAUTION: No grease on rails (dust and grease produce an abrasive amalgam), only clean

them with water for a longer use.

After starting up:

• Operate the cradle from one end to the other end of the feed in order to be sure that it moves

freely and correctly. Movements should be steady and smooth.

3.3 50-HOURS OR WEEKLY OPERATIONS

• Check that there is no obstruction to hinder the movement of the cradles.

• Check the overall condition of the equipment (cylinder, hoses, hydraulic unions,...).

• Search for leakage of oil.

• Check chain condition.

• Lubricate all the grease points.

• Proceed drill and bolter wrench cradle verifications.

• Check tightening torque.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 11 (20)

3.4 200-HOURS OPERATIONS

• Check chain condition.

• Proceed drill and bolter wrench cradle verifications.

• Check tightening torques.

• Lubricate all the grease points.

3.5 600 HOURS OPERATIONS

• Check the overall condition of the equipment (cylinder, hoses, hydraulic unions,...).

• Search for leakage of oil.

• Check chain condition or replace.

• Control or replace rails and skids.

• Lubricate all the grease points.

• Test for correct operation.

3.6 1200-HOURS OR ANNUAL OPERATIONS

• Check the overall condition of the equipment (cylinder, hoses, hydraulic unions,...).

• Search for leakage of oil.Check condition of the hoses.

• Check chains adjust or replace

• Lubricate all the grease points.

3.7 3600-HOURS OPERATIONS OVERALL INSPECTION AND

RECONDITIONING

• Remove, dismantle and check the different parts.

• Remove all worn or defective parts.

• Change the seals, washers, bushings and bearings, and all wearing parts.

• Test for correct operation.

• Lubricate all the grease points.

NB: You can recover all these operations in the periodic maintenance table (last page of

this manual) we invite you to use this document.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 12 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

4 TIGHTENING TORQUES

For basic genuine SANDVIK TAMROCK SECOMA™ screws and nut use the following

tightening torque:

metric dimension torque in Nm torque in Nm

HEX BOLTS “SIX CUT

GRADE 8.8 HOLLOW” BOLTS

GRADE 12.9

M6 10 16

M8 25 40

M10 50 80

M12 85 140

M14 130 210

M16 200 330

M18 280 460

M20 400 650

M22 530 880

M24 670 1130

M27 1000 1650

M33 1780 2200

M36 2300 3850

M39 3000 5050

M42 3700 6250

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 13 (20)

DETAIL C DETAIL A Mount with

loctite 243

DETAIL B

DETAIL B

Mount with

loctite 243

200Nm

DETAIL D

100Nm

DETAIL A (with loctit 243)

DETAIL C 200Nm

DETAIL D

Mount with

120Nm loctite 243

120Nm

(with loctit 243)

120Nm

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 14 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

5 FEED CHAINS

5.1 FEED CHAINS ORGANISATION CHART

THE FEED CHAINS are the life of the ROBOLT LPM TURRET, you must preserve it to keep

the system in correct condition. The organisation chart above is there to help you in this way,

you just have to read it hierarchically and follow the different maintenance operations. All of the

maintenance operations are explain in the following pages.

FEED CHAIN

GOOD SHAPE BAD SHAPE

CONTROL

CLEANING DISMANTLING

OF THE OLD

ADJUSTING CHAIN

LUBRICATING

REASSEMBLING

OF THE NEW

ONE

ADJUSTING

LUBRICATING

FEED CHAIN IN

CORRECT

CONDITION

WARNING: Before starting any maintenance operation ensure that the machine is in

!

a safe location with good safety, ventilation and lighting conditions. Ensure that

lifting equipments and pedestals are compatible with elements’ weight. Follow all

WARNING

the safety instructions and ware safety protections as gloves, goggle, helmet, safety

boots, ear protectors.

WARNING: Maintenance, adjustment and repairs are restricted to qualified

personnel with special training for the particular equipment. Always read

the instructions carefully before starting any maintenance work.

WARNING

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 15 (20)

5.2 FEED CHAINS ADJUSTMENT

THE FEED CHAINS ADJUSTMENT:

The tension of the chains is realized with two tightener screws and the adjustment is fixed by

two fixing screws (see the figure above).

The feed chains must not have some deflections after the adjustment and the axis of the gear

wheels must be perpendicular to the beam.

Be careful to keep the greasing point accessible.

Detail A Tightener screws Detail A

Fixing screws

90°

5.3 FEED CHAINS DISMANTLING/REASSEMBLING

The table here above describes the unfolding you have to follow to replace the feed chains, all

of the operations are ordered.

N OPERATIONS VISUAL HELPS

°

1 Position the cradle in the middle of the feed rails

2 Remove the cradle

3 Unbend the feed chain See feed chains adjustment (page 12)

4 Take down the feed chain in front of the cradle See explanation (page 7)

5 Hook the new feed chain to the old one to find the path See explanation (page 7)

6 Put the feed chain in to the hydraulic motor gear wheel

7 Take down the old feed chain on the back of the cradle See explanation (page 7)

8 Fit the new feed chain on the back of the cradle See explanation (page 7)

9 Adjust the tension of the new feed chain See feed chains adjustment (page 12)

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 16 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

6 LUBRICATION

CAUTION: For a longer use of the feed rails, we advise you to not use grease or

oil on the rails (dust and grease produce an abrasive compund), simply clean

them once a shift with clean water.

6.1 GREASING POINTS

Grease recommandation: Based on ISO VG 100 oil

and a NLGI 2 Grade grease, containing lithium complex detergent.

Extreme pressure according to ASTM D2266: Scar diameter 0.5mm maxi.There is a grease

nipple on any rollers and gears axis.

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 17 (20)

6.2 GREASE NIPPLES POSITION

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 18 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

7 CHECK AND ADJUSTMENT

WARNING: Maintenance, adjustment and repairs are restricted to qualified personnel

with special training for the particular equipment. Always read the instructions

carefully before starting any maintenance work.

WARNING

7.1 HOSE CONDITION CHECK

Oil leakages may involve reliability and safety problems, it is imperative to replace

leaking elements immediately.

7.2 GEAR WHEELS CLEARANCE CHECK

• .HYDRAULIC MOTOR GEARS: 1 mm

Wheels fixing: the clearance value must not

exceed 1mm, replaced the kit if the

clearance value is higher.

• FRONT GEAR WHEELS:

1 mm

Check the clearance of the gear wheels and

be sure that the rotation is free.

Wheels fixing: the clearance value must not

exceed 1mm, replaced the kit if the clearance

value is higher.

7.3 CHAIN GUIDE ROLLERS

CHECK

• Chain guide rollers are fixing to an axis, if the clearance value exceeds 1mm: roller, roller

axis, screw, washer, grease nipple must be replaced.

1 mm 1 mm

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

12-11-2003 EZ-SP-FL ROBOLT LPM TURRET PAGE 19 (20)

7.4 SKID’S AND RAILS CHECK

• Skids

Use a 8 mm steel plate to check the wear limit.

8

If the wear limit exceeds 8 mm that could be cause

m

m

the skids to crack.

• Rails

Check the wear limit using a calliper.

2

m

m

8 LIFTING - HANDLING

8.1 LIFTING POINTS.

• WARNING: Check the cables you use to lift, they must

be in good condition and fit for the weight of the assembly.

• Fasten correctly the elements before starting operations.

BOLTER

Protect

YES

Protect NO

DRILL FEED

YES

NO

YES

Protect

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

PAGE 20 (20) ROBOLT LPM TURRET 12-11-2003 EZ-SP-FL

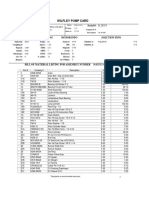

9 PERIODIC MAINTENANCE TABLE - ROBOLT LPM

TURRET

Serial number: Percussion hours (PH): Name:

Date: Signature:

S Check Adjust V Replace

O Clean P Lubricate

PERIODS DONE.

Shift 50 PH 200 600 1200 1800 2400 3600 ROBOLT LPM TURRET YES NO

PH PH PH PH PH PH

S S S S S Check freedom and condition of moving parts

S S S S S Leakage detection

S S S S S Check all equipments condition

S S S S S Check hose, unions and fitting condition

S S S SV SV Check chains

S S S S Check tightening torques

S S S S Check rock drill/bolter wrenchand cradle

assemblage.

S S S Check gear wheels

S Check weldings

S SV V Check/replace rails and skids

P P P P P P Lubricate all points

O Overall inspection and tests

V Removal and check of all assembly

Exchange all worn parts

P

SANDVIK MINING AND CONSTRUCTION LYON S.A.S.

19, av. De Lattre de Tassigny

B.P. 46 - 69881 MEYZIEU cedex, FRANCE

Tel: +33 (0)4 72 45 22 00 Fax: +33 (0)4 78 31 79 80

You might also like

- 8FBN15-30-RM Vol. 2 PDFDocument462 pages8FBN15-30-RM Vol. 2 PDFCarlos67% (3)

- Waukesha Enginator Control Panel (ECP) ECP8000/ECP8200: Control For Enginators Equipped With ESMDocument4 pagesWaukesha Enginator Control Panel (ECP) ECP8000/ECP8200: Control For Enginators Equipped With ESMJuly E. Maldonado M.100% (1)

- Manitou 78 SEC 2, 100 SEC 2, 120 SE 2 Operator's ManualDocument102 pagesManitou 78 SEC 2, 100 SEC 2, 120 SE 2 Operator's ManualMohamed Sayed50% (2)

- Technical Training Manual Tramming CircuitDocument31 pagesTechnical Training Manual Tramming CircuitALEXANDER MUGABENo ratings yet

- stk412 240 PDFDocument1 pagestk412 240 PDFluisclaudio3170% (10)

- Maintenance Manual: Robolt LPM BoomDocument26 pagesMaintenance Manual: Robolt LPM BoomrolandNo ratings yet

- S05 Boom Robolt LP - B26 XLBDocument20 pagesS05 Boom Robolt LP - B26 XLBCRACNo ratings yet

- S00 General SafetyDocument32 pagesS00 General SafetyAlvaro GuerreroNo ratings yet

- Manual Del Operador - 78493697 PDFDocument92 pagesManual Del Operador - 78493697 PDFIH MedranoNo ratings yet

- S10 Water Circuit GeneralDocument14 pagesS10 Water Circuit GeneralHENRY HUAMANNo ratings yet

- Series: Setup, Instruction-& Service ManualDocument56 pagesSeries: Setup, Instruction-& Service ManualZoje CalpulalpanNo ratings yet

- General SafetyDocument36 pagesGeneral SafetyLuis JosueNo ratings yet

- S03 Rotary Drill RHR50 - ADocument18 pagesS03 Rotary Drill RHR50 - ArolandNo ratings yet

- Manual de Entrenamiento Circuito - TransmisionDocument34 pagesManual de Entrenamiento Circuito - TransmisionNelson MezaNo ratings yet

- S03 Rotory Drill RHR50 BoltingDocument18 pagesS03 Rotory Drill RHR50 BoltingCRACNo ratings yet

- Manual Axera 5Document92 pagesManual Axera 5Sergej SchlegelNo ratings yet

- Section 1.0 - Parts ListDocument13 pagesSection 1.0 - Parts ListAnonymous 45Ile4No ratings yet

- Quasar 1FDocument76 pagesQuasar 1FDANIEL BENITES CHACALTANANo ratings yet

- 260 TJ - Operator S ManualDocument148 pages260 TJ - Operator S ManualDiego Salazar JarrínNo ratings yet

- 1.4. List of ChaptersDocument1 page1.4. List of ChaptershristoNo ratings yet

- Owner'S and Operator'S Manual: DGW400DM-380ADocument38 pagesOwner'S and Operator'S Manual: DGW400DM-380AAlejandro Hernández RojasNo ratings yet

- 'TP-800B' Overhauling of Steam TurbineDocument35 pages'TP-800B' Overhauling of Steam TurbinewasayNo ratings yet

- 8FBN15-30-RM (CE350) Toyota EletrônicaDocument462 pages8FBN15-30-RM (CE350) Toyota EletrônicaPatrick De La Garza100% (1)

- Dokumen - Tips - Manual Axera 5Document93 pagesDokumen - Tips - Manual Axera 5Hugo EstradaNo ratings yet

- s05 Boom b14nvDocument20 pagess05 Boom b14nvAnonymous iu95trpxNNo ratings yet

- Manual Transaxle: Group 22ADocument24 pagesManual Transaxle: Group 22ALuis David Leon GarciaNo ratings yet

- 2007 - Wiring Manual (VLX Rev1)Document47 pages2007 - Wiring Manual (VLX Rev1)JOSE FRANCISCONo ratings yet

- En Muvi User Handbook Rev4.2Document47 pagesEn Muvi User Handbook Rev4.2Firu Marius OvidiuNo ratings yet

- LA 434 Kubota Front Loader Operator's Manual PDFDocument44 pagesLA 434 Kubota Front Loader Operator's Manual PDFHenry Huayhua100% (1)

- Hartl Powercrusher PC1 Impact Crusher Service ManualDocument22 pagesHartl Powercrusher PC1 Impact Crusher Service ManualMax Perminov100% (1)

- 647532EN - 20-09-2017 - Web Operator Manual 160 ATJDocument142 pages647532EN - 20-09-2017 - Web Operator Manual 160 ATJTHiz OCtavvNo ratings yet

- Scorpio Crde Wiring Manual Rev3 Reduced PDFDocument51 pagesScorpio Crde Wiring Manual Rev3 Reduced PDFhelorcaNo ratings yet

- 6924 Ext 13 0Document38 pages6924 Ext 13 0thuanNo ratings yet

- IB-3006 Global Track Jaw Crusher (GT-125) 6-12Document168 pagesIB-3006 Global Track Jaw Crusher (GT-125) 6-12Manuel VenturaNo ratings yet

- MAN-00094-Bolero VLX - Wiring ManualDocument41 pagesMAN-00094-Bolero VLX - Wiring Manualjag18718No ratings yet

- s05 Boom b26f b26xlfDocument24 pagess05 Boom b26f b26xlfAnonymous iu95trpxNNo ratings yet

- OTF5000 Cryostat ManualDocument50 pagesOTF5000 Cryostat Manualallenw.tncNo ratings yet

- Manual de Taller S2-250Document201 pagesManual de Taller S2-250yisusyisusNo ratings yet

- Rotzler RW-Winde Operating Instructions EngDocument32 pagesRotzler RW-Winde Operating Instructions EngAllgeNo ratings yet

- NVF Drill Feed: Maintenance ManualDocument20 pagesNVF Drill Feed: Maintenance ManualCRACNo ratings yet

- Shindaiwa DGW400DM-ANZ-Owners-Manual-1Document40 pagesShindaiwa DGW400DM-ANZ-Owners-Manual-1Guruh SuprayitnoNo ratings yet

- 100vjr User ManualDocument92 pages100vjr User Manualruizinho 1No ratings yet

- FLUKE 77 75 73 70 23 21 Series II Service TextDocument54 pagesFLUKE 77 75 73 70 23 21 Series II Service Textmzova production100% (1)

- DGW200MS/UK: Operator'S ManualDocument36 pagesDGW200MS/UK: Operator'S ManualthuanNo ratings yet

- IB 131 Rev I 5000 7200 PN 526491Document28 pagesIB 131 Rev I 5000 7200 PN 526491ragiNo ratings yet

- Service Manual - Heraeus - Cryofuge 6000i, 8500iDocument145 pagesService Manual - Heraeus - Cryofuge 6000i, 8500iHishamudin RaisNo ratings yet

- RRP User Manual Multi LanguageDocument72 pagesRRP User Manual Multi LanguageHyeena AtNo ratings yet

- Nr01292 Iss 1 Nov 04 User Manual For 75 Tonne Telescopic Jib Rail CranesDocument110 pagesNr01292 Iss 1 Nov 04 User Manual For 75 Tonne Telescopic Jib Rail Cranesasct asct90No ratings yet

- 160 Atj E3 - Operator S ManualDocument160 pages160 Atj E3 - Operator S ManualDiego Salazar Jarrín100% (1)

- Technical Training Manual Tramming CircuitDocument22 pagesTechnical Training Manual Tramming CircuitInvenceNo ratings yet

- Upgrade Gas Duosystem Gas-Oil: Unipak LibanoDocument95 pagesUpgrade Gas Duosystem Gas-Oil: Unipak LibanoMohamed KishkNo ratings yet

- OM - HB Breaker (DICC) - Operation Manual - ENDocument57 pagesOM - HB Breaker (DICC) - Operation Manual - ENLuisa Fernanda Salazar Pulgarin100% (1)

- Electronic Torque-Controlled Tube Roller: SpecificationsDocument4 pagesElectronic Torque-Controlled Tube Roller: SpecificationsesmaeelNo ratings yet

- Barksdale Controls Valves RegulatorsDocument42 pagesBarksdale Controls Valves Regulatorsuldarico lozanoNo ratings yet

- ZF 2 WG 94 e Repair ManualDocument9 pagesZF 2 WG 94 e Repair Manualhenry100% (54)

- Capacitacoin en Hidrostatica SanvickDocument33 pagesCapacitacoin en Hidrostatica Sanvickjrgonzales24No ratings yet

- Manual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsDocument2 pagesManual Rotámetro - 0.02 - 1.2 LPM Key InstrumentsMax SdNo ratings yet

- Takeuchi TB153FR Book BJ2Z000 PM 03200Document320 pagesTakeuchi TB153FR Book BJ2Z000 PM 03200rok.feleNo ratings yet

- Anglo–American Microelectronics Data 1968–69: Manufacturers A–PFrom EverandAnglo–American Microelectronics Data 1968–69: Manufacturers A–PNo ratings yet

- Understanding Lightning and Lightning Protection: A Multimedia Teaching GuideFrom EverandUnderstanding Lightning and Lightning Protection: A Multimedia Teaching GuideNo ratings yet

- FeedbackDocument1 pageFeedbackrolandNo ratings yet

- Customer SatisfactionDocument4 pagesCustomer SatisfactionrolandNo ratings yet

- Main ContactsDocument2 pagesMain ContactsrolandNo ratings yet

- WarrantyDocument6 pagesWarrantyrolandNo ratings yet

- HelpDocument12 pagesHelpIgnacio Alejandro Jose Helo VarelaNo ratings yet

- Main ContactsDocument2 pagesMain ContactsrolandNo ratings yet

- FeedbackDocument1 pageFeedbackrolandNo ratings yet

- WarrantyDocument6 pagesWarrantyrolandNo ratings yet

- PTO NewDocument1 pagePTO NewrolandNo ratings yet

- ECM 660IV Instruction ManualDocument251 pagesECM 660IV Instruction Manualroland100% (1)

- ECD45B - HYDRAULIC CIRCUIT & ELECTRIC CIRCUIT Rev.000Document14 pagesECD45B - HYDRAULIC CIRCUIT & ELECTRIC CIRCUIT Rev.000rolandNo ratings yet

- System DescriptionDocument103 pagesSystem Descriptionroland100% (3)

- 9852 3289 01a Operators Instruction PowerROC T50 Tier 4Document112 pages9852 3289 01a Operators Instruction PowerROC T50 Tier 4fahmi rachmansutantoNo ratings yet

- Jan's Job CardsDocument4 pagesJan's Job CardsrolandNo ratings yet

- TE160HT - (9Kw - 1357Nm)Document2 pagesTE160HT - (9Kw - 1357Nm)rolandNo ratings yet

- Manual: For Diesel EngineDocument112 pagesManual: For Diesel EngineMarinel ILIE0% (1)

- Cop 1838 Me & HeDocument3 pagesCop 1838 Me & HerolandNo ratings yet

- 9852 3398 01 Settings COP 3060MEX - VerBDocument1 page9852 3398 01 Settings COP 3060MEX - VerBrolandNo ratings yet

- COP Training Student Binder 1838 GB 061114Document326 pagesCOP Training Student Binder 1838 GB 061114roland100% (1)

- 9852 0922 01d Setting The COP 1838HE-09Document1 page9852 0922 01d Setting The COP 1838HE-09rolandNo ratings yet

- DD422i - Maintenance Planner - Sheet 1Document2 pagesDD422i - Maintenance Planner - Sheet 1rolandNo ratings yet

- M 14 0005 PDFDocument5 pagesM 14 0005 PDFrolandNo ratings yet

- S10 Electric Power PackDocument12 pagesS10 Electric Power PackrolandNo ratings yet

- Safety and Environmental InstructionsDocument86 pagesSafety and Environmental InstructionsrolandNo ratings yet

- 2-1950 (RD520)Document3 pages2-1950 (RD520)rolandNo ratings yet

- S08 Diesel Power Pack PDFDocument150 pagesS08 Diesel Power Pack PDFrolandNo ratings yet

- Sandvik RD927L (Underground Drills) TS2-356 - 01Document2 pagesSandvik RD927L (Underground Drills) TS2-356 - 01rolandNo ratings yet

- Engine Fault Codes: CumminsDocument20 pagesEngine Fault Codes: CumminsCarlosNo ratings yet

- 2-1950 (RD520)Document3 pages2-1950 (RD520)rolandNo ratings yet

- Sandvik RD314B TS2-137 - 01Document2 pagesSandvik RD314B TS2-137 - 01roland100% (1)

- Guidebook of Circuits Featuring Voltage Reference Ics in Various ConfigurationsDocument32 pagesGuidebook of Circuits Featuring Voltage Reference Ics in Various ConfigurationsPatrick StivénNo ratings yet

- 2015 BMR Vhs CatalogDocument12 pages2015 BMR Vhs CatalogMouath AlraoushNo ratings yet

- MS2 IpmDocument101 pagesMS2 Ipmgionguyen0% (1)

- 2 - Calibrations in T3 Direct AC14.3 v1.0 DRAFTDocument14 pages2 - Calibrations in T3 Direct AC14.3 v1.0 DRAFTAdamNo ratings yet

- GTN 6Xx/7Xx Aml STC Installation Manual: 190-01007-A3 December 2012 Revision 4Document412 pagesGTN 6Xx/7Xx Aml STC Installation Manual: 190-01007-A3 December 2012 Revision 4Carlos Javier Silvera100% (2)

- Lista de Materiales 6KDocument3 pagesLista de Materiales 6KRoyer SanchezNo ratings yet

- 4TH SEM MECH ENGG Lab Manual TOM and MeasurementDocument36 pages4TH SEM MECH ENGG Lab Manual TOM and MeasurementWbamlak AshebrNo ratings yet

- 4054 ACtrossDocument18 pages4054 ACtrossRudi KurniawanNo ratings yet

- Catalogo de Peças - SANYDocument428 pagesCatalogo de Peças - SANYJoão MariaNo ratings yet

- GE CatalogDocument3 pagesGE CatalogBob sageNo ratings yet

- Huawei Smart PV Solution Anti-PID Module Application Guide 01 - (20151219)Document18 pagesHuawei Smart PV Solution Anti-PID Module Application Guide 01 - (20151219)Jaime Andres Herrera RestrepoNo ratings yet

- DTL & TTL Based Logic GatesDocument4 pagesDTL & TTL Based Logic Gatesubaid umarNo ratings yet

- Culligan o Ring DirectoryDocument30 pagesCulligan o Ring DirectoryCarl Schleif0% (1)

- Sewing Machine TypesDocument6 pagesSewing Machine TypesJuan Alas Ronaldo AziongNo ratings yet

- CONSILIUM Technical Bulletin For EV PP Detcetors and MCPDocument6 pagesCONSILIUM Technical Bulletin For EV PP Detcetors and MCPRomankoNo ratings yet

- ELE - Checklist For Sample DBDocument2 pagesELE - Checklist For Sample DBibrahim680% (1)

- Fuse - On: Short Circuit Protection in PV SystemsDocument8 pagesFuse - On: Short Circuit Protection in PV SystemsDiego MorenoNo ratings yet

- SIRIO - NEW Mighty Vector 4000 - ManualDocument8 pagesSIRIO - NEW Mighty Vector 4000 - ManualLeonardus Suryo SuhartoNo ratings yet

- Baxxdd0 e 208708Document24 pagesBaxxdd0 e 208708Oscar OreaNo ratings yet

- SCI1500A: Crawler Crane 150 Tons Lifting CapacityDocument34 pagesSCI1500A: Crawler Crane 150 Tons Lifting CapacityUpendra KumarNo ratings yet

- Somfy GlydeaDocument14 pagesSomfy GlydeaKarth CenaNo ratings yet

- Operator Manual Ergo SystemDocument39 pagesOperator Manual Ergo SystemOliveira eletricidadeNo ratings yet

- InteliVision 18touch - DatasheetDocument4 pagesInteliVision 18touch - DatasheetMaylen RivasNo ratings yet

- DatasheetDocument72 pagesDatasheetOscarNo ratings yet

- Mini Compressor & Cooling Units - Rigid CoolingDocument16 pagesMini Compressor & Cooling Units - Rigid CoolingronaldmarcelleNo ratings yet

- Future Scope of Dual Axis Solar Tracking SystemDocument1 pageFuture Scope of Dual Axis Solar Tracking SystemArun GuptaNo ratings yet

- 1kd Rear SealDocument4 pages1kd Rear SealMarcusNo ratings yet

- Fraunhofer HSF Report Presentation 2018Document15 pagesFraunhofer HSF Report Presentation 2018Taso GegiaNo ratings yet