Professional Documents

Culture Documents

01 SOP Preventive Maintenance - Machine

Uploaded by

Pandu BirumakovelaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

01 SOP Preventive Maintenance - Machine

Uploaded by

Pandu BirumakovelaCopyright:

Available Formats

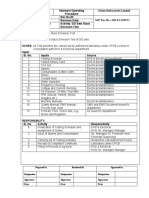

Standard Operating Orient Refractories Limited

Procedure

Issue No.01 Rev No.00

Issue date: 1st January Revision Date: Doc No.: ORL/EL/SOP/01

2016 Page 1 of 4

Department: Electrical Activity: Preventive

Maintenance Maintenance

Title : SOP for Preventive Maintenance

PURPOSE:To carry out Preventive Maintenance of Plant and Machinery

SCOPE: All Electrical Maintenance activities carried out by Electrical Department

Input :

Sl. No. Inputs Source

1. Preventive Maintenance Schedule Electrical Deapartment

2. Equipment History Card Electrical Maintenance

3. Tool Set Electrical Maintenance

4. Spares Stores and Electrical Maintenance

5. Consumables (Cotton Clothes, PVC Electrical Maintenance

Tape

6. Grease Gun Electrical Maintenance

7. PPE (Gloves, Helmet, Shoes, etc.) Electrical Maintenance

8. Machine Manuals Library/Electrical Department

9. Electrical Drawing Electrical Department

10. Formats, Files, Check lists, Log As issued to department

Books and Registers

11. Quality Manual, EMS Manual QMS and EMS Document issued to

Process flow chart department

RESPONSIBILITY:

Sl. No. Activity Responsibility

1. Planning of preventive Maintenance Shift Sr. Foreman/Asst.

Foreman/Supervisor

2. Carrying out of Maintenance Activities Charge Hand and Electrician

3. Issue of Spares and Consumables Sr. Foreman/Asst.

Foreman/Supervisor (Elect.

Maintenance)

4. Receipt of Completion Certificate Charge Hand and Electrician

5. Filling of Records & log book Shift Charge Hand/Supervisor

DESCRIPTION OF ACTIVES:

1. Preventive Maintenance

1. The Preventive maintenance schedule taken by Foreman/Supervisor.

2. Shift Sr. Foreman/Supervisor identifies the actual schedule of the preventive

maintenance and assigns the appropriate electrical person to carry out the job.

3. Shift Charge Hand/Electrician prior to starting any job, displays the board,

“Machine under Preventive Maintenance” on the operating panel and switches’

“OFF” the power of the machine.

4. Shift Charge Hand/Electrician properly cleans the working area.

5. Appropriate tools for carrying out the maintenance activities are taken by the Shift

Prepared by (HOD) Approved By(Head –Opns) Issued by (MR-QMS)

Signature Signature Signature

Standard Operating Orient Refractories Limited

Procedure

Issue No.01 Rev No.00

Issue date: 1st January Revision Date: Doc No.: ORL/EL/SOP/01

2016 Page 2 of 4

Department: Electrical Activity: Preventive

Maintenance Maintenance

Charge Hand/Electrician.

6. Sr. Foreman/Asst. Foreman/Supervisor based on the requirements identifies

appropriate spares and consumables gets it issued from the store by filling up the

indent.

7. As per the requirement machine manuals are taken on issue by the Sr.

Foreman/Supervisor from the Library.

8. As per the requirement machine electrical drawings are taken by the Sr.

Foreman/Supervisor from the electrical department.

9. For this appropriate work instruction as given of annexure to this SOP are used for

carrying out preventive maintenance activities such as Dismantling of Equipment,

(Annexure 1), Assembly of Equipment (Annexure 2).

10. Supervisor ensures that the charge hand/electrician and other personnel involved

in this activity wears required PPEs (Gloves, Helmet, Shoes, and Mouth Mask,

etc.).

11. After maintenance job completion check the machine with machine’s (M/C)

operator/Supervisor related to the M/C.

12. If the machine is running properly, removes the Board “Machine under Preventive

Maintenance” from the operating panel.

13. Collect all used items (such as used cloth, removed damage spare parts) from the

working area and dispose in the proper identified areas.

14. The waste generated from the maintenance activities is managed as per OCP on

waste management/ Hazardous waste management.

15. The signature of respective department’s HOD/supervisor is obtained on checklist

after preventive maintenance job completion.

16. Details in the check list and respective equipment’s history cards are recorded by

Sr. Foreman/Supervisor.

17. Check list properly file up for further record.

CROSS REFERENCE :

Aspect Impact-AI/EL

Output:

Sl. No. Output Location

1. Maintained Machine/Equipment Respective Departments

2. Check lists and Registers Electrical Department

3. Logs and History Cards Electrical Department

4. Machine Availability Electrical Department

Annexure 1

Work Instruction for Dismantling of Equipment

Prepared by (HOD) Approved By(Head –Opns) Issued by (MR-QMS)

Signature Signature Signature

Standard Operating Orient Refractories Limited

Procedure

Issue No.01 Rev No.00

Issue date: 1st January Revision Date: Doc No.: ORL/EL/SOP/01

2016 Page 3 of 4

Department: Electrical Activity: Preventive

Maintenance Maintenance

1. Shutdown of machine/equipment in consultation with the user department’s authorized

person.

2. Shutdown of electrical panel of the equipment.

3. Display of equipment under electrical maintenance tag.

4. Appropriate tools for carrying out the maintenance activities are taken.

5. Ensures that the supervisor/chargehand/electrician personnel involved in this activity.

6. Based on the requirements appropriate equipment/spares dismantling to be carried out.

Annexure 2

Work Instruction for Assembly of Equipment

Prepared by (HOD) Approved By(Head –Opns) Issued by (MR-QMS)

Signature Signature Signature

Standard Operating Orient Refractories Limited

Procedure

Issue No.01 Rev No.00

Issue date: 1st January Revision Date: Doc No.: ORL/EL/SOP/01

2016 Page 4 of 4

Department: Electrical Activity: Preventive

Maintenance Maintenance

1. Assembly of the Equipment.

Shutdown of machine/equipment in consultation with the user department’s authorized

person.

Shutdown of electrical panel of the equipment.

Display of equipment under electrical maintenance tag.

Appropriate tools for carrying out the maintenance activities are taken.

Ensures that the supervisor/chargehand/electrician personnel involved in this activity

wears required PPEs (Gloves, Helmet, Shoes, and Mouth Mask etc.)

Based on the requirements appropriate equipment/spares assembly to be carried out.

2. Test Run of the Equipment.

Clean the equipment which to be maintain.

Appropriate tools for carrying out the maintenance activities are taken.

Ensures that the supervisor/chargehand/electrician personnel involved in this activity

wears required PPEs (Gloves, Helmet, Shoes, and Mouth Mask etc.)

Ensure that all connections have been screwed tight again.

Check that all materials, tools, equipment, etc. that were required for maintenance and

repair work been removed from the materials testing machine's working area.

Ensure all safety devices such as MCB, Breakers, limit switches, proximity switches and

the materials testing machine's EMERGENCY OFF button in perfect working order.

Ensure all of the above work must be first correctly done free of error before the

materials testing machine is to be used by the operating personnel.

Prepared by (HOD) Approved By(Head –Opns) Issued by (MR-QMS)

Signature Signature Signature

You might also like

- SOP for GO/DO Preventive MaintenanceDocument9 pagesSOP for GO/DO Preventive MaintenancePandu BirumakovelaNo ratings yet

- SOP-04 Preventive Maintenance of DG SetsDocument11 pagesSOP-04 Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- SOP-09 Preventive Maintenance - MachineDocument10 pagesSOP-09 Preventive Maintenance - MachinePandu BirumakovelaNo ratings yet

- SOP - 06 LT - PanelDocument9 pagesSOP - 06 LT - PanelPandu Birumakovela100% (1)

- SOP-02for Breakdown MaintenanceDocument4 pagesSOP-02for Breakdown MaintenancePandu BirumakovelaNo ratings yet

- SOP Preventive Maintenance 33KVA TransformerDocument5 pagesSOP Preventive Maintenance 33KVA TransformerPandu Birumakovela100% (2)

- SOP-08 Thermocouple - DTC CalibrationDocument9 pagesSOP-08 Thermocouple - DTC CalibrationPandu BirumakovelaNo ratings yet

- SOP Noise Testing of DG SetsDocument2 pagesSOP Noise Testing of DG SetsPandu Birumakovela100% (1)

- SOP Stack Emission of DG SetsDocument2 pagesSOP Stack Emission of DG SetsPandu BirumakovelaNo ratings yet

- 02 SOP Preventive Maintenance of DG SetsDocument4 pages02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- SOP 33kVA Transformer MaintenanceDocument9 pagesSOP 33kVA Transformer MaintenancePandu BirumakovelaNo ratings yet

- SOP For Breakdown Maintenance - 1Document6 pagesSOP For Breakdown Maintenance - 1Pandu BirumakovelaNo ratings yet

- HT Panel Preventive Maintenance SOPDocument9 pagesHT Panel Preventive Maintenance SOPPandu BirumakovelaNo ratings yet

- Centurion Power Cables (P) LTD.: MaintenanceDocument3 pagesCenturion Power Cables (P) LTD.: MaintenancetriveshNo ratings yet

- CSH Maintenance SOPDocument4 pagesCSH Maintenance SOPAjlan KhanNo ratings yet

- Preventive Maintenace RecordDocument47 pagesPreventive Maintenace RecordArunPrakash JNo ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- Electrical Maintenance Standard Operative Procedure - Detailed ProceduresDocument1 pageElectrical Maintenance Standard Operative Procedure - Detailed ProceduresamlmrsscontrolNo ratings yet

- Maintenance Instruction V03Document18 pagesMaintenance Instruction V03Farooq AhmadNo ratings yet

- List of MachineDocument16 pagesList of MachineKaran MalhiNo ratings yet

- Preventive Maintenance ProcedureDocument4 pagesPreventive Maintenance ProcedureHanin BouzianeNo ratings yet

- List of MachineDocument11 pagesList of Machinemohitsharmagzb09No ratings yet

- Preventive MaintenanceDocument145 pagesPreventive Maintenancesabar nhfdiNo ratings yet

- Preventive MaintenanceDocument3 pagesPreventive MaintenanceTrilok Singh TakuliNo ratings yet

- PPM Check List: Floor: Wing: Room No: DateDocument3 pagesPPM Check List: Floor: Wing: Room No: DateMdrahaman MithuNo ratings yet

- AVTEC Limited Maintenance Staff Training RecordsDocument6 pagesAVTEC Limited Maintenance Staff Training RecordsAmiya691No ratings yet

- Quality Objectives MonitoringDocument2 pagesQuality Objectives MonitoringcholoNo ratings yet

- Title: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledDocument6 pagesTitle: Maintenance Electrical DOC. No: (ELE-P-01) : ControlledTarek FawzyNo ratings yet

- Site Maintenance ProcedureDocument13 pagesSite Maintenance ProcedureMuhammad KashifNo ratings yet

- Effective Maintenance Program DevelopmentOptimizatDocument20 pagesEffective Maintenance Program DevelopmentOptimizatAmena LNo ratings yet

- 02 Master List of Machine & EquipmentsDocument1 page02 Master List of Machine & EquipmentsVipul Panchal50% (2)

- Preventive MaintDocument23 pagesPreventive MaintRavikant PandeyNo ratings yet

- Ocp For Control of Electrical EnergyDocument3 pagesOcp For Control of Electrical EnergyNaresh Kumar100% (1)

- Guidelines For LV Motor MaintenanceDocument5 pagesGuidelines For LV Motor MaintenanceDILIPNo ratings yet

- Table of Contents Test RunDocument52 pagesTable of Contents Test RunTEMIDAYONo ratings yet

- Inspection of MCC - EEPDocument3 pagesInspection of MCC - EEPwaseemNo ratings yet

- Maintenance Management.Document34 pagesMaintenance Management.Alfan ArifNo ratings yet

- Best Maintenance Technician PracticesDocument5 pagesBest Maintenance Technician PracticesHilaire KamanaNo ratings yet

- Equipment Maintenance and UseDocument53 pagesEquipment Maintenance and UseRam Mohan SNo ratings yet

- Electrical Pump & Motor Inspection ChecklistDocument1 pageElectrical Pump & Motor Inspection ChecklistJIJESH GOKULDASNo ratings yet

- Operations Management - Maintenance Types, Objectives & AnalysisDocument7 pagesOperations Management - Maintenance Types, Objectives & AnalysisVijay Singh ThakurNo ratings yet

- 6.2 Equipment Maintenance Preventive MaintenanceDocument7 pages6.2 Equipment Maintenance Preventive MaintenanceBALAJI100% (1)

- Maintenance StrategiesDocument6 pagesMaintenance StrategiesarielsonNo ratings yet

- Metal Press Machine Preventive Maintenance RecordDocument1 pageMetal Press Machine Preventive Maintenance RecordVirendra KumarNo ratings yet

- Preventive Maintenance For High Voltage and Low Voltage SwitchgearDocument4 pagesPreventive Maintenance For High Voltage and Low Voltage Switchgearicygears21No ratings yet

- Electrical Maintenance ManualDocument2 pagesElectrical Maintenance Manualkurnia_te3769No ratings yet

- En Preventive Maintenance Plan InfraspeakDocument36 pagesEn Preventive Maintenance Plan InfraspeakMccaNo ratings yet

- Maintenance Planning SystemsDocument55 pagesMaintenance Planning SystemsGyogi MitsutaNo ratings yet

- SOP Vendor Selection EvaluationDocument1 pageSOP Vendor Selection EvaluationShahnawaz HaiderNo ratings yet

- Procedure of Maintenance For Electrical EquipmentDocument16 pagesProcedure of Maintenance For Electrical EquipmentThức Võ100% (2)

- Corrective MaintenanceDocument7 pagesCorrective Maintenancedennisjuntak100% (1)

- Preventive and Predictive Maintenance StrategiesDocument3 pagesPreventive and Predictive Maintenance StrategiesSyedNadeemAhmedNo ratings yet

- MaintenanceDocument13 pagesMaintenanceRachit KhannaNo ratings yet

- Production and Storage ProcedureDocument3 pagesProduction and Storage ProcedurePeracha EngineeringNo ratings yet

- Sermatec APP User ManualDocument50 pagesSermatec APP User ManualOleksandr ChumakNo ratings yet

- QP-72-01 Maintenance Policy & StrategiesDocument12 pagesQP-72-01 Maintenance Policy & StrategiesSamsudin Ahmad100% (2)

- Daily Maintenance SheetDocument6 pagesDaily Maintenance Sheetabhishek rathoreNo ratings yet

- RCA Copy Generator RotorDocument1 pageRCA Copy Generator RotorPraneeth ReddyNo ratings yet

- Plant Maintenance Department To Be & As IsDocument29 pagesPlant Maintenance Department To Be & As IsAmitava PalNo ratings yet

- 05 SOP Thermocouple - DTC CalibrationDocument4 pages05 SOP Thermocouple - DTC CalibrationPandu BirumakovelaNo ratings yet

- Air Leakages Up To 10.3.2024Document2 pagesAir Leakages Up To 10.3.2024Pandu BirumakovelaNo ratings yet

- 0003 mrl-rss36-rst36-1 enDocument10 pages0003 mrl-rss36-rst36-1 enPandu BirumakovelaNo ratings yet

- Calculate Size of DOL and Star-Delta Starter ComponentsDocument11 pagesCalculate Size of DOL and Star-Delta Starter ComponentsBeshoy RedaNo ratings yet

- 01 World Class EE UnitsDocument19 pages01 World Class EE UnitsPandu BirumakovelaNo ratings yet

- Electrical Installation of SINAMICS V50 JX Type 500kW Power ModuleDocument10 pagesElectrical Installation of SINAMICS V50 JX Type 500kW Power ModulePandu BirumakovelaNo ratings yet

- Commissioning Sinamics G120 AC DriveDocument10 pagesCommissioning Sinamics G120 AC DrivePandu Birumakovela0% (1)

- Getting - Started - Guide - SINAMICSV50I - 112009 With CoverDocument42 pagesGetting - Started - Guide - SINAMICSV50I - 112009 With CoverPandu BirumakovelaNo ratings yet

- SINAMICS V50 - FX Power Module Electrical Installa - 200904Document8 pagesSINAMICS V50 - FX Power Module Electrical Installa - 200904Pandu BirumakovelaNo ratings yet

- Sinamics G120 Ac DrivesDocument10 pagesSinamics G120 Ac DrivesPandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu Birumakovela0% (1)

- PID5030 M53om101 Issue14 Dt.23.10.13Document21 pagesPID5030 M53om101 Issue14 Dt.23.10.13Pandu BirumakovelaNo ratings yet

- Sinamics V20Document7 pagesSinamics V20Pandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- SINAMICS V50 - F Power Module Electrical Installat - 200904Document6 pagesSINAMICS V50 - F Power Module Electrical Installat - 200904Pandu BirumakovelaNo ratings yet

- Orient Refractories Ltd identifies environmental impacts of electrical and DG set operationsDocument40 pagesOrient Refractories Ltd identifies environmental impacts of electrical and DG set operationsPandu BirumakovelaNo ratings yet

- 02 SOP Preventive Maintenance of DG SetsDocument4 pages02 SOP Preventive Maintenance of DG SetsPandu BirumakovelaNo ratings yet

- SOP Stack Emission of DG SetsDocument2 pagesSOP Stack Emission of DG SetsPandu BirumakovelaNo ratings yet

- Objectives and Target14001Document1 pageObjectives and Target14001Pandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu BirumakovelaNo ratings yet

- RA Risk Assessment for 33kVA Transformer MaintenanceDocument4 pagesRA Risk Assessment for 33kVA Transformer MaintenancePandu BirumakovelaNo ratings yet

- Risk Assessment (RA) : Part 1: Location DetailsDocument3 pagesRisk Assessment (RA) : Part 1: Location DetailsPandu Birumakovela0% (1)

- Environmental register assessment of risks and opportunitiesDocument4 pagesEnvironmental register assessment of risks and opportunitiesPandu BirumakovelaNo ratings yet

- Operation & Maint - DG SetsDocument4 pagesOperation & Maint - DG SetsPandu BirumakovelaNo ratings yet

- Environmental Register: Process: R22 Gas Charging in Compressor/Equipment A 1Document1 pageEnvironmental Register: Process: R22 Gas Charging in Compressor/Equipment A 1Pandu BirumakovelaNo ratings yet

- Environmental register assessmentDocument4 pagesEnvironmental register assessmentPandu BirumakovelaNo ratings yet

- Orient Refractories Risk Assessment ReportDocument5 pagesOrient Refractories Risk Assessment ReportPandu BirumakovelaNo ratings yet

- Environmental Register: Process: Operation & Maintenance of DG Sets A 1Document1 pageEnvironmental Register: Process: Operation & Maintenance of DG Sets A 1Pandu BirumakovelaNo ratings yet

- Environmental Register - MasterDocument22 pagesEnvironmental Register - MasterPandu Birumakovela100% (1)

- Activitywise Hazard and RiskDocument18 pagesActivitywise Hazard and RiskPandu BirumakovelaNo ratings yet

- Imperialism of Southeast Asia DBQDocument12 pagesImperialism of Southeast Asia DBQJoshua MirandaNo ratings yet

- 19 Lake Parramatta Assessment 3 and Marking GuideDocument11 pages19 Lake Parramatta Assessment 3 and Marking GuideAlanNo ratings yet

- Sky High 3 CourseDocument7 pagesSky High 3 CourseHiginio von BachNo ratings yet

- Ancheta, Mark Honey M. CE175-3C/A73 Course Expectation Sir. Timothy Daniel FeliciaDocument2 pagesAncheta, Mark Honey M. CE175-3C/A73 Course Expectation Sir. Timothy Daniel FeliciaMark AnchetaNo ratings yet

- Mountain Man SWOT Analysis and Marketing StrategyDocument3 pagesMountain Man SWOT Analysis and Marketing StrategySebastiaan VesseurNo ratings yet

- Monochromatic.: Set 58 - Page 1 Compiled by Mr. Lelon 012-6556593Document12 pagesMonochromatic.: Set 58 - Page 1 Compiled by Mr. Lelon 012-6556593lelon81No ratings yet

- Shortcuts in P6 - 31 Using Shortcut Commands in P6Document4 pagesShortcuts in P6 - 31 Using Shortcut Commands in P6fardadirannejadi100% (1)

- Test Bank For Global Business 4th Edition by Mike Peng ISBN 130550089X 9781305500891Document36 pagesTest Bank For Global Business 4th Edition by Mike Peng ISBN 130550089X 9781305500891DebbieKeithrwok100% (24)

- CPM HandoutsDocument2 pagesCPM HandoutsPaolo LibradaNo ratings yet

- Coding DecodingDocument6 pagesCoding DecodingDeepjyoti BarmanNo ratings yet

- Reducing BiasDocument27 pagesReducing BiasMehdi BougrineNo ratings yet

- Erasmus Mundus Course ListDocument6 pagesErasmus Mundus Course Listmanin1804No ratings yet

- E7 OpSpecDocument12 pagesE7 OpSpecAlan LeeNo ratings yet

- Mary Shelley's Frankenstein: A Gothic Novel of RomanticismDocument2 pagesMary Shelley's Frankenstein: A Gothic Novel of Romanticism임키No ratings yet

- All About Data Transfer Process (DTP) - SAPDocument9 pagesAll About Data Transfer Process (DTP) - SAPsunkrish1No ratings yet

- Probability ProblemsDocument3 pagesProbability Problemsembers poggerNo ratings yet

- Install and boot macOS High SierraDocument3 pagesInstall and boot macOS High SierraDavid GatoNo ratings yet

- Hacker Monthly - Issue 3Document56 pagesHacker Monthly - Issue 3Vytautas Jakutis100% (2)

- Wish You Were Here James Moran - TARDIS PrologueDocument5 pagesWish You Were Here James Moran - TARDIS ProloguessstelNo ratings yet

- Social ConstructivismDocument2 pagesSocial Constructivismleeza dizonNo ratings yet

- Domingos Lvares African Healing and James H 11332087Document3 pagesDomingos Lvares African Healing and James H 11332087Josinaldo SousaNo ratings yet

- Pipeline Nomenclature PDFDocument18 pagesPipeline Nomenclature PDFphenkNo ratings yet

- Competency mapping project final reportDocument15 pagesCompetency mapping project final reportArthiNo ratings yet

- Assignment #2 - Case Study Part 1 InstructionsDocument5 pagesAssignment #2 - Case Study Part 1 InstructionsJordanne ChristieNo ratings yet

- History of DRAM and TypesDocument11 pagesHistory of DRAM and TypesVani SallyNo ratings yet

- Paul S. Levy's Resignation Letter To The University of Pennsylvania in Response To Amy Wax PunishmentDocument3 pagesPaul S. Levy's Resignation Letter To The University of Pennsylvania in Response To Amy Wax PunishmentThe College FixNo ratings yet

- Authentic Leadership Individual 1Document28 pagesAuthentic Leadership Individual 1Jeliteng PribadiNo ratings yet

- Automotive EngineeringDocument5 pagesAutomotive EngineeringJANNo ratings yet

- Screw Conveyor DesignDocument8 pagesScrew Conveyor DesignPavan Kumar100% (1)

- 303 - Data WarehousingDocument14 pages303 - Data WarehousingManohar AkulaNo ratings yet