Professional Documents

Culture Documents

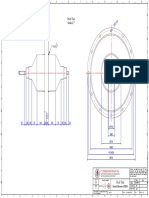

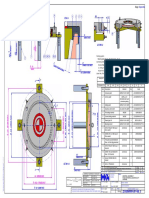

φ 311, cut thread M 35 and fit tightly with part no 1d before galvanization

Uploaded by

saubhagya majhiOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

φ 311, cut thread M 35 and fit tightly with part no 1d before galvanization

Uploaded by

saubhagya majhiCopyright:

Available Formats

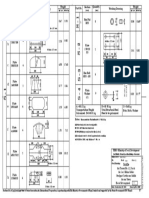

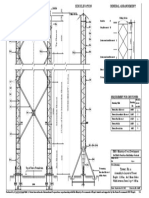

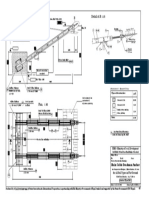

Section Quantity Working Drawing Weight Section Quantity Working Drawing Weight

Part No. Part No. [nos]

[mm] [nos] (not to scale) kg / pc total kg [mm] (not to scale) kg / pc total kg

Flat 7 holes φ 14

Angle

a 75/6

l = 90

16

45 45

1 hole φ 14 0.31 4.96g

galvanized

7 40/40/5 2

50

4.45 8.90u

l=1500 20 280 220 280 580 50 20 20 20

325 355 20

Flat

100/10 φ 46 Angle 7 holes φ 14

b 16 5.23 83.68g

8

φ17

l = 700 40/40/5 2 4.26 8.52u

galvanized

35 50 240 75 l=1435 50 50

300 gas cutting 20 150 350 150 645 20 20 20

700 prohibited

6 holes φ 17, 1 hole φ 46 Hex Bolt thread min 30mm

1 30 30 R=25 9 M12x40 72

40 or full threaded

0.049 3.53c

IS Round

Hex Bolt thread 25 mm

0.096 31.68c

c

Bar φ 75

or 3” 8 2.20 17.60g 10 M16x40

330

40

Hex Nut

l = 110

8 17 60 17 8 hole φ 10

galvanized 11 M12

72 0.015 1.08c

110 min 75 Hex Nut

9.90c

drill holeφ 311, cut thread M 35 and fit tightly with part no 1d before galvanization 12 M16

330 0.03

thread M36

d

Rod φ 36

l = 650

8 5.16 41.28g 13 Hex Nut

M36

25 0.37 9.25c

630 20 galvanized

14 Ri-Bar φ 16 2000

Rod φ 10 fix and weld to part 0.04 0.64g 8 3.16 25.28R

e l = 60

16

60 No.1c before galvanization

l = 2000

galvanized

Ri-Bars φ 20

IS Round

85 50 85 mill

down 15

15 l = ..............

........... ............. G=2.47kg/m1 ........... .........R

Bar φ 75

a 4 5.92 23.68g Stirrup φ 12

2

or 3”

l =220 35 35

2 holes φ 38

galvanized 16 l = 3550

21 800 3.15 66.15R

150

min75

b

Rod φ 6

l = 130

8

130

to be welded

to part No. 2a

0.03 0.24g

galvanized

17 open Thimble 4 Thimble to ISI 2315-1978 for Cable φ .........mm

MS forged ISI Standard hot dip galvanized

....... ........D

18 Bulldog Grip

....... Bulldog Grip to ISI 2361-1970 for Cable φ ......mm ....... ........D

Plate A = ............... kg. B = ................. kg. g = 172.08 kg.

3 350/200/6

4 175 175 5 holes φ 14 3.30 13.20u Total transportation Weight

B+C+D+R+ 2.21kg.

Total Structural

Steel = (u+g)

Structural Steel

to be galvanized

25 25 untreated C = 55.44 kg D = ............. kg. R = .................. kg

300

20 holes φ 14 Nuts, Bolts, Washers Bulldog Grips & Thimbles Reinforcement Steel

Angle

4 40/40/5 16 1.48 23.68u The following steelparts must be HMG / Ministry of Local Development

l = 500 25 50 50 50 50 50 50 50 50 50 25 20 20 hot dip galvanized acc. to IS Transportation DoLIDAR / Short SpanTrail Bridge Standard

2629 & 2633, min thickness Weights of welded Bridge Name:

16 holes φ 18 50 875 = 80 µ m Parts: No: Bank: Span:

Flat Part No. 1 & 2 Steelpart List for one Foundation:

5 100/6

l = 1800

........*

8.31 .........u

All Nuts & Bolts must conform to

IS 1363 and are galvanized

Part No. 1 = 18.78 kg

Part No. 2 = 6.05 kg Main Cable Anchorage

* obtain quantity from respective 35 50 50 1530 50 50 35 acc. to IS 1367, Part XIII for Suspension Bridges

construction drawing. 1800 Weight. (kg/pc) 4 Main Cables φ ........ mm (26 or 32mm)

Cable Total Nos. of

Angle φ mm Bulldog grips Thimble Bulldog centre to centre distance : 3.50 m

6

grip

40/40/5 2 4.75 9.50u 26 20 0.75 1.1

Nos. of Anchorages required : ........

l=1600 20 50 50 680 680 5050 20

7 holes φ 14 32 24 1.85 1.3 Date : September 30, 2002 Drawing No. 44N

Produced by Nepal Swiss Association for International Cooperation, in partnership with His Majesty’s Government of Nepal, funded and supported by the Swiss Government (SDC Nepal). 11

You might also like

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument1 pageφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationRanjit Kumar ShahNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument2 pagesφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationRanjit Kumar ShahNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- B-2 B-3 B-4 B-5: (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCDocument1 pageB-2 B-3 B-4 B-5: (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCRanjit Kumar ShahNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCRanjit Kumar ShahNo ratings yet

- Piston L705 X Dia 36 X 20.2mmDocument1 pagePiston L705 X Dia 36 X 20.2mmVishal KotiaNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- 2.0L AEG Wiring DiagramDocument10 pages2.0L AEG Wiring DiagramGilberto Martinez ANo ratings yet

- Beam Enlarge - InstructionDocument1 pageBeam Enlarge - InstructionRachel BushNo ratings yet

- Leaf Side Clamp HEX NUT M5: Parts ListDocument2 pagesLeaf Side Clamp HEX NUT M5: Parts ListPrabhat HambireNo ratings yet

- Drawing - Hub Tension Ring 67BE08Document3 pagesDrawing - Hub Tension Ring 67BE08Rizki MWNo ratings yet

- Sf6 Breaker LTB 145D1/B With Operating Mechanism Type Msd1Document2 pagesSf6 Breaker LTB 145D1/B With Operating Mechanism Type Msd1Pintea Ioan Florin100% (1)

- 1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KDocument18 pages1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KSteeven RodriguezNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- Pieza 4 Interp Circular: Dept. Technical Reference Created by Approved byDocument1 pagePieza 4 Interp Circular: Dept. Technical Reference Created by Approved byGonzalo CarnevaleNo ratings yet

- Seton PN 16Document1 pageSeton PN 16Sandeep SinghNo ratings yet

- Rebar Steel Weight CalculatorDocument2 pagesRebar Steel Weight CalculatorGohar ZamanNo ratings yet

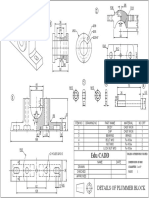

- Edu Cadd: Details of Plummer BlockDocument1 pageEdu Cadd: Details of Plummer BlockjaslinNo ratings yet

- Multi-Function Steering Wheel For Cruise Control and Radio: Wiring DiagramDocument4 pagesMulti-Function Steering Wheel For Cruise Control and Radio: Wiring DiagramAlex AlexandruNo ratings yet

- At451u-Dm 10-09Document1 pageAt451u-Dm 10-09s5548844No ratings yet

- Parts ListDocument2 pagesParts ListPrabhat HambireNo ratings yet

- 18J-1466C-Reten - Susp OPGW-APROBADODocument1 page18J-1466C-Reten - Susp OPGW-APROBADOluz dary anguloNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- 1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 110 KDocument18 pages1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 110 KSteeven RodriguezNo ratings yet

- DRILLBIT HAMMER - w50 - 210Document2 pagesDRILLBIT HAMMER - w50 - 210Ruben PradaNo ratings yet

- Axle HoldersDocument1 pageAxle HoldersjoseocsilvaNo ratings yet

- 44 9nconDocument1 page44 9nconsaubhagya majhiNo ratings yet

- Assembly 1Document21 pagesAssembly 1MOHIT PANTNo ratings yet

- 6-Armare Grinda Transeversala GT1 25X35 PDFDocument1 page6-Armare Grinda Transeversala GT1 25X35 PDFMonica BudNo ratings yet

- Spool Drum Part 4Document1 pageSpool Drum Part 4yirga shitahunNo ratings yet

- Security Posting PlanDocument1 pageSecurity Posting PlanbexcslaNo ratings yet

- Novo Curtain MotorDocument7 pagesNovo Curtain MotorehvorovNo ratings yet

- St. Francis Institute of TechnologyDocument2 pagesSt. Francis Institute of TechnologyDOLSON BUTTI204008No ratings yet

- Conventional 72,5 3-PolDocument2 pagesConventional 72,5 3-PolhansNo ratings yet

- Bull1524r0 L8543219Document76 pagesBull1524r0 L8543219Benjamin HewittNo ratings yet

- Air Conditioning (Manual Control) ,: Code AFPDocument5 pagesAir Conditioning (Manual Control) ,: Code AFPigor dvkvNo ratings yet

- Buckling Load On The Screw Shaft)Document2 pagesBuckling Load On The Screw Shaft)Ravikumar mahadevNo ratings yet

- Slider RH1Document1 pageSlider RH1Hector EstevezNo ratings yet

- Drawing 1Document3 pagesDrawing 1ridwan bismiNo ratings yet

- Cylinder Id.100 Od.115 Rod.70 Stroke 1000 10 Ton-ModelDocument1 pageCylinder Id.100 Od.115 Rod.70 Stroke 1000 10 Ton-Modelbadai_boyZNo ratings yet

- Control Unit ICU 402: EC Type Approval E5 03 0246Document2 pagesControl Unit ICU 402: EC Type Approval E5 03 0246beni :D50% (2)

- Air Conditioning (Manual Control) : Wiring DiagramDocument5 pagesAir Conditioning (Manual Control) : Wiring DiagramArmando RiveraNo ratings yet

- GF1 40x100 3 Buc: P.Th. Start Regional ProiectDocument1 pageGF1 40x100 3 Buc: P.Th. Start Regional ProiectBogdanPaiusNo ratings yet

- XL120RTFCBDocument1 pageXL120RTFCBBigPantsNo ratings yet

- Kisi-Kisi Prototype Modeling LKS 2021Document5 pagesKisi-Kisi Prototype Modeling LKS 202136. ZAKIALITSEL GEBRILIENNo ratings yet

- 02-10-6816 Hydr. Connections, Mast - h3 347 2Document1 page02-10-6816 Hydr. Connections, Mast - h3 347 2Juan Ismael Grave LolNo ratings yet

- HX-LITE - PC & EXT - BOARD ÉDocument2 pagesHX-LITE - PC & EXT - BOARD Étrung truc NguyenNo ratings yet

- AutocadDocument1 pageAutocadDima StefanNo ratings yet

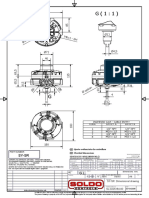

- SOLDO SY SR - Dimensional - DrawingDocument1 pageSOLDO SY SR - Dimensional - DrawingYoughorta TIRNo ratings yet

- Universal Joint 1.DwgDocument2 pagesUniversal Joint 1.DwgAldi FadlikaNo ratings yet

- Curva 32 PG 50 HP 31 KCFM 6 PG WGDocument1 pageCurva 32 PG 50 HP 31 KCFM 6 PG WGrodNo ratings yet

- R 14Document1 pageR 14darhim2017No ratings yet

- E:/hosuing - DWG, 27-07-2020 21:22:29, DWG To PDF - pc3Document1 pageE:/hosuing - DWG, 27-07-2020 21:22:29, DWG To PDF - pc3Sunil Kumar VemulaNo ratings yet

- SBRJ Evsob-1d-Rwy-20l Sid 20210520Document1 pageSBRJ Evsob-1d-Rwy-20l Sid 20210520brunogasperinNo ratings yet

- 4843-STC-0001 Platform DETAIL-signedDocument5 pages4843-STC-0001 Platform DETAIL-signedMuhammad Rizky ImaduddinNo ratings yet

- A New Robot With The Fastest Motion Speed in Its Class Is Born!Document2 pagesA New Robot With The Fastest Motion Speed in Its Class Is Born!Anonymous 0WUktHN0No ratings yet

- Spool Drum Part 2Document1 pageSpool Drum Part 2yirga shitahunNo ratings yet

- 2.8L - Engine - Motronic Multiport Fuel Injection (MFI) 130 KDocument14 pages2.8L - Engine - Motronic Multiport Fuel Injection (MFI) 130 KIbrain MoranNo ratings yet

- Industrial Robot Motoman Up50 Robotforum RuDocument2 pagesIndustrial Robot Motoman Up50 Robotforum RuTrí ChốtNo ratings yet

- MIDAS/Civil: Project TitleDocument5 pagesMIDAS/Civil: Project Titlesaubhagya majhiNo ratings yet

- Front Elevation Side Elevation General Arrangement: SaddleDocument1 pageFront Elevation Side Elevation General Arrangement: SaddleRoshan KejariwalNo ratings yet

- PileDocument1 pagePilesaubhagya majhiNo ratings yet

- 29-72 Superstructure - PagenumberDocument44 pages29-72 Superstructure - Pagenumbersaubhagya majhiNo ratings yet

- MIDAS/Civil: Project TitleDocument9 pagesMIDAS/Civil: Project Titlesaubhagya majhiNo ratings yet

- Front Elevation Side Elevation General Arrangement: SaddleDocument1 pageFront Elevation Side Elevation General Arrangement: SaddleRoshan KejariwalNo ratings yet

- RB Up WCFDocument2 pagesRB Up WCFsaubhagya majhiNo ratings yet

- LB Up WCFDocument2 pagesLB Up WCFsaubhagya majhiNo ratings yet

- WGC UpstreamDocument2 pagesWGC Upstreamsaubhagya majhiNo ratings yet

- WGC DownstreamDocument2 pagesWGC Downstreamsaubhagya majhiNo ratings yet

- RB DW WCFDocument2 pagesRB DW WCFsaubhagya majhiNo ratings yet

- Ope Type Left SoilDocument1 pageOpe Type Left Soilsaubhagya majhiNo ratings yet

- WT DW1Document3 pagesWT DW1saubhagya majhiNo ratings yet

- Open Type Right SoilDocument1 pageOpen Type Right Soilsaubhagya majhiNo ratings yet

- LB DW WCFDocument2 pagesLB DW WCFsaubhagya majhiNo ratings yet

- Section at A-A, 1:50 Section at B-B, 1:50 B: Main Cable Anchor BlockDocument1 pageSection at A-A, 1:50 Section at B-B, 1:50 B: Main Cable Anchor Blocksaubhagya majhiNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- Main HC DesignDocument3 pagesMain HC Designsaubhagya majhiNo ratings yet

- Welding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XDocument1 pageWelding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XRanjit Kumar ShahNo ratings yet

- Municipality, Jaleshwor, Province No. 2: Cost EstimateDocument2 pagesMunicipality, Jaleshwor, Province No. 2: Cost Estimatesaubhagya majhiNo ratings yet

- Chapter 3Document7 pagesChapter 3saubhagya majhiNo ratings yet

- Section at A-A, 1:50 Section at B-B, 1:50 B C: φ 20 mm, l = 2400 φ 12 mm,Document1 pageSection at A-A, 1:50 Section at B-B, 1:50 B C: φ 20 mm, l = 2400 φ 12 mm,saubhagya majhiNo ratings yet

- Section at A-A, 1:50: 40 Cable Elevation 120 40Document1 pageSection at A-A, 1:50: 40 Cable Elevation 120 40saubhagya majhiNo ratings yet

- Section at A-A, 1:50: Ri-Bars φ 20 l = 3400 16 8.40 134.40Document1 pageSection at A-A, 1:50: Ri-Bars φ 20 l = 3400 16 8.40 134.40saubhagya majhiNo ratings yet

- 44 7nconDocument1 page44 7nconsaubhagya majhiNo ratings yet

- Section at A-A, 1:75: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:75: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- 44 9nconDocument1 page44 9nconsaubhagya majhiNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Ae Powder HiDocument33 pagesAe Powder HiswoinkerNo ratings yet

- Stop-Check (Non-Return) Valves: Class 600 1480 PSI at 100°F (102.1 BAR at 38°C)Document1 pageStop-Check (Non-Return) Valves: Class 600 1480 PSI at 100°F (102.1 BAR at 38°C)harrinsonfNo ratings yet

- Selection of Materials For WeldingDocument1 pageSelection of Materials For WeldingmohammedetaNo ratings yet

- 2210306WW SF1 00 - 3Document1 page2210306WW SF1 00 - 3Victor PodlozovikNo ratings yet

- Enb 04 0553 PDFDocument4 pagesEnb 04 0553 PDFDanielLaraNo ratings yet

- Fraisa Carbide Drills Thread Cut ToolsDocument497 pagesFraisa Carbide Drills Thread Cut ToolsSobolNo ratings yet

- Witcher The Snail SchoolDocument4 pagesWitcher The Snail SchoolKirillNo ratings yet

- FIRE DOORS (120 Minutes) IS 3614: A Royal Fab Group VentureDocument11 pagesFIRE DOORS (120 Minutes) IS 3614: A Royal Fab Group VentureAlbert SekarNo ratings yet

- Abyc P1Document20 pagesAbyc P1NavalcatNo ratings yet

- Equipment - Factors Affecting SelectionDocument35 pagesEquipment - Factors Affecting SelectionAnusuya KuppuswamyNo ratings yet

- Stainless and Electrical Steels - Machinability-RatingDocument1 pageStainless and Electrical Steels - Machinability-RatinggoggerNo ratings yet

- Asmh H13 PDFDocument135 pagesAsmh H13 PDFsunsirNo ratings yet

- Enco Master Catalog 2014Document1,149 pagesEnco Master Catalog 2014gotti45No ratings yet

- Makit Hardware Christmas CatalogueDocument4 pagesMakit Hardware Christmas CatalogueBKWCoopNo ratings yet

- As 2038-1977 Methods For Detecting The Susceptibility of Austenitic Stainless Steels To Intergranular CorrosiDocument6 pagesAs 2038-1977 Methods For Detecting The Susceptibility of Austenitic Stainless Steels To Intergranular CorrosiSAI Global - APACNo ratings yet

- CLASS 151071: DEP 31.38.01.12-Gen Class 151071, Rev. K Page 1 of 12Document12 pagesCLASS 151071: DEP 31.38.01.12-Gen Class 151071, Rev. K Page 1 of 12SaguesoNo ratings yet

- GB 2585-2007 PDFDocument58 pagesGB 2585-2007 PDFJames FaizNo ratings yet

- VT-BAYARD-Automatic Control Valves-FloatDocument8 pagesVT-BAYARD-Automatic Control Valves-Floatsiva ramakrishnanNo ratings yet

- "Shaviv" Deburring ToolsDocument1 page"Shaviv" Deburring ToolsRino SutrisnoNo ratings yet

- Astm A1046-2019Document10 pagesAstm A1046-2019nagham tariq100% (1)

- ASTM B831-93 Shear Testing of Thin Aluminium Alloy ProductsDocument3 pagesASTM B831-93 Shear Testing of Thin Aluminium Alloy Productsipkm123100% (1)

- ISO 82492000 (En) Ferrite Number FNDocument3 pagesISO 82492000 (En) Ferrite Number FNMurad AlmoudiNo ratings yet

- Feuerbach 2006 Crucible Steel Production and IdentificationDocument7 pagesFeuerbach 2006 Crucible Steel Production and IdentificationNicholas ZoppaNo ratings yet

- Goodwin SLRHDocument56 pagesGoodwin SLRHCV Carlitos Maju PratamaNo ratings yet

- KAfo DCMC AdvantagesDocument14 pagesKAfo DCMC AdvantagesRajiv GandhiNo ratings yet

- Stainless Steel Welding ProcedureDocument18 pagesStainless Steel Welding Procedurealfian leoanakNo ratings yet

- ManufacturingDocument2 pagesManufacturingBarbieBarbieNo ratings yet

- GE8261-Engineering Practices Lab - MECH PDFDocument74 pagesGE8261-Engineering Practices Lab - MECH PDFMohamed BasheerNo ratings yet

- Metal Protective OilDocument2 pagesMetal Protective OilGuillermo Gonsales100% (1)

- Effect of Minor and Trace Elements in Cast IronDocument2 pagesEffect of Minor and Trace Elements in Cast IronsachinguptachdNo ratings yet