Professional Documents

Culture Documents

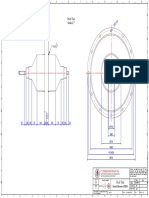

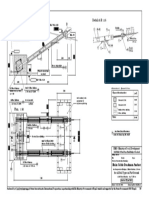

φ 311, cut thread M 35 and fit tightly with part no 1d before galvanization

Uploaded by

Ranjit Kumar ShahOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

φ 311, cut thread M 35 and fit tightly with part no 1d before galvanization

Uploaded by

Ranjit Kumar ShahCopyright:

Available Formats

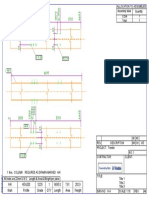

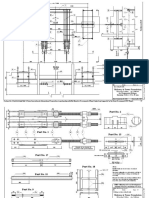

Section Quantity Working Drawing Weight Section Quantity Working Drawing Weight

Part No. (not to scale)

Part No. [nos]

[mm] [nos] kg / pc total kg [mm] (not to scale) kg / pc total kg

Flat 5 holes φ 14

75/6 Angle

a

l = 90

8

45 45

1 hole φ 14 0.31 2.48g

galvanized 7 40/40/5 2 2.23 4.46u

l=750 20 280 330 50 50 20 20 20

325 355 20

Flat

φ 46

Angle 5 holes φ 14

b 100/10 8 5.23 41.84g

8

φ17

40/40/5 2 2.03 4.06u

l = 700 galvanized

35 50 240 75 l=685

300 gas cutting 20 150 395 50 50 20 20 20

700 prohibited

6 holes φ 17, 1 hole φ 46 Hex Bolt thread min 30mm

1 30 30 R=25 9 M12x40 42

40 or full threaded

0.049 2.06c

IS Round Hex Bolt thread 25 mm

16.13c

c

Bar φ 75

or 3” 4 2.20 8.80g 10 M16x40

168

40

0.096

Hex Nut

l = 110

8 17 60 17 8 hole φ 10

galvanized 11 M12

42 0.015 0.63c

110 min 75 Hex Nut

5.04c

drill holeφ 311, cut thread M 35 and fit tightly with part no 1d before galvanization 12 M16

168 0.03

thread M36

d

Rod φ 36

l = 650

4 5.16 20.64g 13 Hex Nut

M36

13 0.37 4.81c

630 20 galvanized

Ri-Bar

14

1500

Rod φ 10 fix and weld to part 0.04 0.32g φ 16 8 2.37 18.96R

e l = 60

8

60 No.1c before galvanization l = 1500

galvanized

Ri-Bars φ 20

IS Round

85 50 85 mill

down 15

15 l=..............

2400

12 ..........

2400

G=2.47kg/m1 ....... 71.136 R

........

Bar φ 75 bend stirrup as given in

a 2 5.92 11.84g Stirrup φ 12

or 3”

16

respective construction Drawing

2 l =220 35 150

2 holes φ 38

35

galvanized 3550

l=..............

14

....... .......

80 80 for 50x50cm, l=2200mm, G=1.95kg/pc

for 80x80cm, l=3550mm, G=3.15kg/pc

....... ........

44.1 R

min75

b Rod φ 6

l = 130

4

170

to be welded

to part No. 2a

0.03 0.12g

galvanized

17 open Thimble 2 Thimble to ISI 2315-1978 for Cable φ .........mm

32

MS forged ISI Standard hot dip galvanized

.......

1.85 ........

3.7 D

18 Bulldog Grip

.......

12 Bulldog Grip to ISI 2361-1970 for Cable φ ......mm

32 .......

1.30 ........

15.6D

A = .................

919.562 kg. B = .................

649.666 kg. g = 86.04 kg.

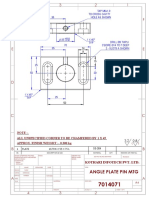

Plate

3 350/200/6

4 175 175 5 holes φ 14

3.30 13.20u Total transportation Weight

B+C+D+R+ 1.69kg.

Total Structural

Steel = (u+g) 557.626+92.04

Structural Steel

to be galvanized

25 25 untreated 19.3 kg.

300 C = 28.67 kg D =............ R = 134.196

............ kg

10 holes φ 14 Nuts, Bolts, Washers Bulldog Grips & Thimbles Reinforcement Steel

Angle

4 40/40/5

l = 500

8

25 50 50 50 50 50 50 50 50 50 25 20 20

1.48 11.84u The following steelparts must be

hot dip galvanized acc. to IS Transportation

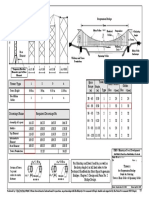

HMG / Ministry of Local Development

DoLIDAR / Short SpanTrail Bridge Standard

2629 & 2633, min thickness Weights of welded Bridge Name: Budhi Khola 1

16 holes φ 18 50 875 = 80 µ m Parts: No: Bank: Span: 52

Flat Part No. 1 & 2

Right

5

Steelpart List for one Foundation:

100/6 ...........*

40 514.566 All Nuts & Bolts must conform Part No. 1 = 18.78 kg

8.31 ...........u Part No. 2 = 6.05 kg Main Cable Anchorage

l = 1800 to IS 1363 and are galvanized

* obtain quantity from respective 35 50 50 1530 50 50 35 acc. to IS 1367, Part XIII for Suspension Bridges

construction drawing. 1800 2 Main Cablesφ 32...... mm (26 or 32mm)

Weight. (kg/pc)

Cable Bulldog grips

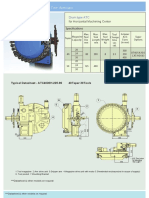

Angle φ mm for two cables Thimble Bulldog centre to centre distance : 2.50 m

6

grip

40/40/5 2 4.75 9.50u 26 10 0.75 1.1 Nos. of Anchorages required : ......

2

l=1600 20 50 50 680 680 5050 20

7 holes φ 14 32 12 1.85 1.3 Date : September 30, 2002 Drawing No. 42N

Produced by Nepal Swiss Association for International Cooperation, in partnership with His Majesty’s Government of Nepal, funded and supported by the Swiss Government (SDC Nepal). 9

You might also like

- ETM - Starter Picanto MT 2013Document1 pageETM - Starter Picanto MT 2013Hendra Gunawan100% (1)

- Translator DSM 1GDocument5 pagesTranslator DSM 1Gtcbikerguy6100% (1)

- 2.0L AEG Wiring DiagramDocument10 pages2.0L AEG Wiring DiagramGilberto Martinez ANo ratings yet

- Axle HoldersDocument1 pageAxle HoldersjoseocsilvaNo ratings yet

- Revise - Final Inception Report - PK-14 - 076-77Document59 pagesRevise - Final Inception Report - PK-14 - 076-77Ranjit Kumar ShahNo ratings yet

- L - HRF20J5001 - Hose & Pulley Block (ZM, SAE)Document5 pagesL - HRF20J5001 - Hose & Pulley Block (ZM, SAE)Gustavo RodriguezNo ratings yet

- Strategic Management PaperDocument97 pagesStrategic Management PaperElle Woods100% (3)

- Joints in Steel Construction - Simple Connections - Part 20 PDFDocument4 pagesJoints in Steel Construction - Simple Connections - Part 20 PDFkakem61No ratings yet

- Summary - Corporate Finance Beck DeMarzoDocument54 pagesSummary - Corporate Finance Beck DeMarzoAlejandra100% (2)

- V-2172-0009-0078 - 3 Status 1Document97 pagesV-2172-0009-0078 - 3 Status 1Jonathan Alexander De Los Rios OrdoñezNo ratings yet

- Dvago Brand PlanDocument46 pagesDvago Brand PlanAmeer hamzaaNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument1 pageφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationsaubhagya majhiNo ratings yet

- φ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationDocument2 pagesφ 311, cut thread M 35 and fit tightly with part no 1d before galvanizationRanjit Kumar ShahNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCRanjit Kumar ShahNo ratings yet

- Parts ListDocument2 pagesParts ListPrabhat HambireNo ratings yet

- Leaf Side Clamp HEX NUT M5: Parts ListDocument2 pagesLeaf Side Clamp HEX NUT M5: Parts ListPrabhat HambireNo ratings yet

- Bull1524r0 L8543219Document76 pagesBull1524r0 L8543219Benjamin HewittNo ratings yet

- Bull17omi L8543236R1Document80 pagesBull17omi L8543236R1aviNo ratings yet

- B-2 B-3 B-4 B-5: (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCDocument1 pageB-2 B-3 B-4 B-5: (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PCRanjit Kumar ShahNo ratings yet

- Novo Curtain MotorDocument7 pagesNovo Curtain MotorehvorovNo ratings yet

- 44 2nconDocument1 page44 2nconsaubhagya majhiNo ratings yet

- Universal Joint 1.DwgDocument2 pagesUniversal Joint 1.DwgAldi FadlikaNo ratings yet

- Drawing - Hub Tension Ring 67BE08Document3 pagesDrawing - Hub Tension Ring 67BE08Rizki MWNo ratings yet

- (MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentDocument1 page(MM) (Nos) Total KG (MM) (Nos) Total KG KG / PC KG / PC: HMG / Ministry of Local DevelopmentRanjit Kumar ShahNo ratings yet

- Plunger Pumps 1 Dan 2 - 002Document1 pagePlunger Pumps 1 Dan 2 - 002Bobby ArbianugrohoNo ratings yet

- Rebar Steel Weight CalculatorDocument2 pagesRebar Steel Weight CalculatorGohar ZamanNo ratings yet

- Drum Type HMC PDFDocument1 pageDrum Type HMC PDFSweta GajjarNo ratings yet

- Drum Type HMCDocument1 pageDrum Type HMCEliane SouzaNo ratings yet

- Assembly 1Document21 pagesAssembly 1MOHIT PANTNo ratings yet

- Model Test 1Document1 pageModel Test 1Nirlesh KothariNo ratings yet

- FCT & FCM Catalog PDFDocument2 pagesFCT & FCM Catalog PDFgiovenzana akshar salesNo ratings yet

- Section at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- 8 Ø10/15 BST500S L 6.50m 7 Ø10/15 BST500S L 4.15mDocument1 page8 Ø10/15 BST500S L 6.50m 7 Ø10/15 BST500S L 4.15mAndrei Daniel NeacsuNo ratings yet

- Data Sheet Da04 SIKODocument2 pagesData Sheet Da04 SIKONguyễnĐạtNo ratings yet

- Features: LHD TypeDocument2 pagesFeatures: LHD Typecold storageNo ratings yet

- JASJUSDocument1 pageJASJUSAzis AlfahreziiNo ratings yet

- Buckling Load On The Screw Shaft)Document2 pagesBuckling Load On The Screw Shaft)Ravikumar mahadevNo ratings yet

- Crane HookDocument1 pageCrane HookKristijan starčevićNo ratings yet

- Sharpen (8X) : 1 1 Plate T 1.5Document1 pageSharpen (8X) : 1 1 Plate T 1.5andreas endrasNo ratings yet

- MANUAL de PARTES SIST - Lubrication Oil StationDocument1 pageMANUAL de PARTES SIST - Lubrication Oil StationKasjdkasd AksdjasdjNo ratings yet

- Licad86061000008 F45Document1 pageLicad86061000008 F45Sakeel WagirkhanNo ratings yet

- Carbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesDocument1 pageCarbon Steel Pipe, Sch#40 PVC Pipe, Sch#40 at 50 C: General NotesKamrul HasanNo ratings yet

- Seton PN 16Document1 pageSeton PN 16Sandeep SinghNo ratings yet

- Sketch 1Document1 pageSketch 1Hariprasad CNo ratings yet

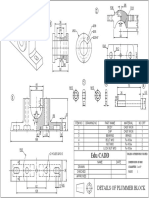

- Edu Cadd: Details of Plummer BlockDocument1 pageEdu Cadd: Details of Plummer BlockjaslinNo ratings yet

- 5 Pdfsam SingleDocument1 page5 Pdfsam Singleahmed aboyosefNo ratings yet

- Piston L705 X Dia 36 X 20.2mmDocument1 pagePiston L705 X Dia 36 X 20.2mmVishal KotiaNo ratings yet

- Manual de Partes MOLINO BUTCHER AF52Document9 pagesManual de Partes MOLINO BUTCHER AF52ivan reyes TorresNo ratings yet

- Calypso TRV-3 InstructionDocument2 pagesCalypso TRV-3 Instructionjimmy.hallberg.jhNo ratings yet

- 2948 3sie200l4 2dDocument3 pages2948 3sie200l4 2dEddo CarrionNo ratings yet

- 2948 3sie200l4 2dDocument3 pages2948 3sie200l4 2dEddo CarrionNo ratings yet

- 6-Armare Grinda Transeversala GT1 25X35 PDFDocument1 page6-Armare Grinda Transeversala GT1 25X35 PDFMonica BudNo ratings yet

- 1µm 5µm φ8 φ20 12mm 32mm 60mm: Resolution Stem StrokeDocument1 page1µm 5µm φ8 φ20 12mm 32mm 60mm: Resolution Stem StrokeFabian TorresNo ratings yet

- Piston Plate End Trailer Leveler (Ramp) : Eesta Heavy Machinery CoDocument1 pagePiston Plate End Trailer Leveler (Ramp) : Eesta Heavy Machinery CoJavadNo ratings yet

- 44 9nconDocument1 page44 9nconsaubhagya majhiNo ratings yet

- Heavy Duty CasterDocument1 pageHeavy Duty Castersamaalaa603No ratings yet

- Siemens D89 BGADocument1 pageSiemens D89 BGABobby VaganzaNo ratings yet

- Short Form CatalogueDocument41 pagesShort Form CatalogueCharlie KebasoNo ratings yet

- Frame Drawing Sample 4Document1 pageFrame Drawing Sample 4Jr Rameez RajaNo ratings yet

- P11 Practice11: Din Standard N5Document1 pageP11 Practice11: Din Standard N5ابراهيم الزهرانيNo ratings yet

- Hang Rào 3Document1 pageHang Rào 3Tre VanNo ratings yet

- 02-10-6816 Hydr. Connections, Mast - h3 347 2Document1 page02-10-6816 Hydr. Connections, Mast - h3 347 2Juan Ismael Grave LolNo ratings yet

- SX310 PTT 2000kgDocument1 pageSX310 PTT 2000kgCedric ChatonNo ratings yet

- Check Valve: RE 20378, Edition: 2017-10, Bosch Rexroth AGDocument8 pagesCheck Valve: RE 20378, Edition: 2017-10, Bosch Rexroth AGBademianNo ratings yet

- 1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KDocument18 pages1.8L - Engine - Motronic Multiport Fuel Injection (MFI) 132 KSteeven RodriguezNo ratings yet

- Syllabi Master of TechnologyDocument63 pagesSyllabi Master of TechnologyRanjit Kumar ShahNo ratings yet

- Morpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalDocument22 pagesMorpho-Hydraulic Parameters and Existing Stability Condition of Nakhu River, Southern Kathmandu, Central NepalRanjit Kumar ShahNo ratings yet

- 2.pokhariya Estimation FinalDocument152 pages2.pokhariya Estimation FinalRanjit Kumar ShahNo ratings yet

- Jhilke Khola Hydrology Aug 1 2021 20mx1Document15 pagesJhilke Khola Hydrology Aug 1 2021 20mx1Ranjit Kumar ShahNo ratings yet

- EOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNDocument12 pagesEOI Detailed Bridge Maintenance Survey and Design of The Existing Motorable Bridges On SRNRanjit Kumar ShahNo ratings yet

- Intermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituDocument8 pagesIntermediate-Lanes Traffic, Simply Supported Span, 3 Web, Cast-in-SituRanjit Kumar ShahNo ratings yet

- 48 NconDocument1 page48 NconRanjit Kumar ShahNo ratings yet

- Final Field ReportDocument37 pagesFinal Field ReportRanjit Kumar ShahNo ratings yet

- Section A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGDocument1 pageSection A-A, 1:40: Part No Section (MM) Quantity (Nos) Working Drawing Weight KG/PC Total KGRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightDocument1 pageSection at A-A, 1:50: Part No Section (MM) Quantity (Nos) Working Drawing WeightRanjit Kumar ShahNo ratings yet

- Section at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorDocument1 pageSection at A-A, 1:50 Detail at B 1:15: Main Cable Deadman AnchorRanjit Kumar ShahNo ratings yet

- Plan View: (M) Type of Construction BDocument1 pagePlan View: (M) Type of Construction BRanjit Kumar ShahNo ratings yet

- Assembly Detail Welding Details: Part No. 1Document1 pageAssembly Detail Welding Details: Part No. 1Ranjit Kumar ShahNo ratings yet

- Welding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XDocument1 pageWelding Detail of Part B-1 (A-J) : Front Elevation Side Elevation View - XRanjit Kumar ShahNo ratings yet

- Tower Type 1 2 3 4: Suspension BridgeDocument1 pageTower Type 1 2 3 4: Suspension BridgeRanjit Kumar ShahNo ratings yet

- HMG / Ministry of Local Development: Bridge Name: No: Bank: SpanDocument2 pagesHMG / Ministry of Local Development: Bridge Name: No: Bank: SpanRanjit Kumar ShahNo ratings yet

- 01-Lecture 1Document29 pages01-Lecture 1umerNo ratings yet

- Artificial Intelligence in Food Industry: Submitted To: Sir Anwar Submitted By: Gul E Kainat 15-ARID-4939Document32 pagesArtificial Intelligence in Food Industry: Submitted To: Sir Anwar Submitted By: Gul E Kainat 15-ARID-4939Lubna KhanNo ratings yet

- Introduction of The IonDocument77 pagesIntroduction of The IonLalnunsanga Pachuau LiannghawrNo ratings yet

- SCS 3142 Module #1 Rev1Document40 pagesSCS 3142 Module #1 Rev1Wahid ZakiNo ratings yet

- Brexit - Unravelling The Ties That Bind The Past, Present, and FutureDocument26 pagesBrexit - Unravelling The Ties That Bind The Past, Present, and FutureShoaib A. MalikNo ratings yet

- W3G500GN3303 EngDocument5 pagesW3G500GN3303 EngFabio VincenziNo ratings yet

- Week 1 Tutorial ProblemsDocument7 pagesWeek 1 Tutorial ProblemsWOP INVESTNo ratings yet

- RSabha QA Given by Govt On 22.07.2021Document2 pagesRSabha QA Given by Govt On 22.07.2021Project Manager IIT Kanpur CPWDNo ratings yet

- Mrunal (Misc PDFDocument10 pagesMrunal (Misc PDFPiyush GoyalNo ratings yet

- Annual Report 14 PDFDocument96 pagesAnnual Report 14 PDFgopalNo ratings yet

- Woods CAN - DMS - 141680031 - v1 - 2021 09 27 Notice of AppealDocument7 pagesWoods CAN - DMS - 141680031 - v1 - 2021 09 27 Notice of AppealHoward KnopfNo ratings yet

- Manta Aislante ThermalceramicsDocument2 pagesManta Aislante Thermalceramicsjast111No ratings yet

- HTML BackgroundsDocument5 pagesHTML Backgroundsrc.david.florendoNo ratings yet

- Worcester MT20 Wired Timer Installation and Servicing InstructionsDocument12 pagesWorcester MT20 Wired Timer Installation and Servicing InstructionspabloNo ratings yet

- Manual Secador CD 550+Document1 pageManual Secador CD 550+Paulo GarciaNo ratings yet

- Television and Video EngineeringDocument42 pagesTelevision and Video EngineeringGanesh ChandrasekaranNo ratings yet

- 00PKNDocument28 pages00PKNDjoyakim SimanungkalitNo ratings yet

- IC A25 Basic ManualDocument24 pagesIC A25 Basic ManualMiguel López AguayoNo ratings yet

- Multotec Trommel ScreensDocument6 pagesMultotec Trommel Screensalfredo_17110% (1)

- Virsa Singh Vs The State of PunjabDocument3 pagesVirsa Singh Vs The State of Punjabhimanshu charanNo ratings yet

- Ciff ADocument15 pagesCiff AjashpreetNo ratings yet

- Automation Basics - Combustible Gas Detector Sensor Drift - Catalytic VsDocument1 pageAutomation Basics - Combustible Gas Detector Sensor Drift - Catalytic VsHilder Ramirez PuellesNo ratings yet

- FM PDFDocument1 pageFM PDFnes2130No ratings yet