Professional Documents

Culture Documents

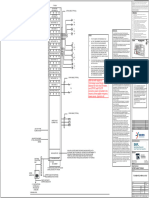

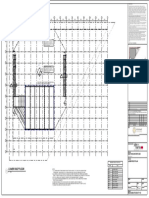

St-03 - General Notes Sheet-2

Uploaded by

MØhãmmed ØwięsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

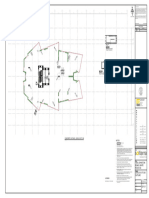

St-03 - General Notes Sheet-2

Uploaded by

MØhãmmed ØwięsCopyright:

Available Formats

Important Notes:

• Copyright by Bureau Expo Dubai 2020 (EX20). All rights reserved. This

document may not, in whole or in part, be reproduced, stored, transmitted or

distributed in any form or by any means, whether electronic, mechanical, by

photocopy, recording or otherwise, without the prior written permission of EX20.

Except where otherwise expressly agreed in writing by EX20, EX20 shall have

no responsibility or liability for any loss (direct, consequential or otherwise)

which may arise from reliance on or use of this document or the information

contained therein.

• Where dimensions are not given, drawings must not be scaled and the matter

STEEL STRUCTURE NOTES. 5.0 FLOORING STANDARD SYMBOLS

should be referred back to John R Harris & Partner's.

• This drawing should be read in conjunction with all other project information,

produced by John R Harris & Partner's and others. In the event of any conflict

1.0 GENERAL.

between the information contained on this drawing and in any other project

document, drawings, specifications, schedules etc. the matter must be referred

5.1 ALL FLOORING SHALL BE AS PER ARCH DRAWINGS. back to John R Harris & Partner's for clarification.

+26.500 SSL LEVELS IN m ON SECTIONS OR ELEVATIONS • All dimensions and conditions are to be checked on site by the contractor prior

1.1 READ THIS DRAWING ALONG WITH ALL RELEVANT ARCHITECTURAL, STRUCTURAL AND MEP DRAWINGS. to preparing designs, shop drawings, calculations etc. or commencing any

work.

1.1 ALL WORKS SHALL BE CARRIED OUT IN ACCORDANCE WITH CONTRACT SPECIFICATIONS. +26.500 SSL • The contractor is responsible for checking that there is no conflict between site

LEVELS IN m ON PLANS OR GA'S dimensions and drawn dimensions.

1.2 ALL DIMENSIONS ARE IN MILLIMETERS. • This drawing’s should be read in conjunction with other relevant architectural,

6.0 CONNECTIONS, GUSSET PLATES AND STIFFNERPLATES

interior design, structural, fire safety, mechanical and electrical drawings and all

1.3 ALL ELEVATIONS ARE IN METERS AND RELATED TO DATUM ELEVATION, UNLESS OTHERWISE STATED. 200 relevant sections of the project specifications.

THICKNESS OF SLAB IN mm SHOWN ON PLANS OR GA'S • The contractor shall submit full shop / setting out drawing for approval (based

on site dimensions) prior to commencement of any site works, placing of

1.4 DO NOT SCALE THE DRAWING. ONLY WRITTEN DIMENSION SHALL BE FOLLOWED. ALL CONNECTIONS STEEL TO STEEL AND STEEL TO CONCRETE SHALL BE DESIGNED BY THE SPECIALIST STEEL orders, manufacture of fittings, fixtures and components.

• Approved drawings from consultants do not relief the contractors from his

1.5 BEFORE STARTING THE FABRICATION,THE FABRICATOR SHOULD CHECK THE DIMENSIONS CONTRACTOR/FABRICATOR. CONNECTION FORCES SHALL BE PROVIDED BY THE CONSULTANT. PERMANENT OPENING IN FLOOR OR WALL contractual obligations or that of adhering to requirements in accordance with

latest edition of Fire and Life Safety Code of practice and the International

GIVEN IN THE DRAWING WITH THE ACTUAL SITE CONDITION (CORRECTNESS OF POSITIONS, Codes & Standards referred to within where applicable.

LEVELS & ALIGNMENT OF ALL PARTS OF ALL THE WORKS) IN COORDINATION WITH SITE - ALL GUSSET PLATES ARE MINIMUM 16 mm THICK.(U.N.O.) • Safety, Health and Environment Information: brief details on the identified

CONSTRUCTION OPENING (BOX OUT) IN hazard symbol referencing the unusual residual hazards / risks are listed

EXECUTION TEAM. IN ANY DISCREPANIES OBSERVED IT SHOULD BE BROUGHT TO THE NOTICE - ALL STIFFENER PLATES ARE MINIMUM 10 mm THICK.(U.N.O.) above.

OF ENGINEER AND IT SHOULD BE RECTIFIED BEFORE STARTING THE FABRICATION. FLOOR OR WALL

- ALL CAP PLATES ARE MINIMUM 6 mm THICK.(U.N.O.) DO NOT SCALE THIS DRAWING.

1.6 ALL THE STRUCTURES AFTER FABRICATION SHALL BE CONTROL ASSEMBELED IN SHOP - ALL BASE PLATES ARE MINIMUM 40 mm THICK.(U.N.O.) DENOTES SETDOWN TO TOP OF SLAB

TO MATCH THE MATCHING DIMENSIONS AND CONNECTIONS OF DIFFERENT ERECTION - ALL INSERTE PLATES ARE MINIMUM 20 mm THICK.(U.N.O.)

MARKS BEFORE DESPATCH TO SITE.

3 REVISION MARK

1.7 ALL ASTERIKED DIMENSIONS (INDICATED THUS : *) ARE TO BE CONFIRMED ON SITE AND

REPORTED TO THE CONSULTANT FOR CONSIDERATION. 7.0 ERECTION N

7.1 ALL SAFETY PROCEDURE SHALL BE FOLLOWED DURING ERECTION OF STEEL MEMBERS. TBA TO BE AGREED Makka

2.0 STRUCTURAL STEEL MATERIAL h

7.2 THE CONTRACTOR SHALL PROPERLY ALIGN EACH PART OF THE STRUCTURE BEFORE MAKING

2.1 STEEL STRUCTURES SHALL BE FABRICATED IN ACCORDANCE WITH GOOD WORKING THE FIELD CONNECTIONS. E1

PRACTICE. MATERIALS, WORKMANSHIP, AND TESTING GENERALLY SHALL COMPLY WITH ELEVATION MARK

DWG General Notes

AISC AMERICAN INSTITUTE OF STEEL CONSTRUCTION. 7.3 THE CONTRACTOR SHALL ENTIRELY BE RESPONSIBLE FOR THE STABILITY OF THE STEEL

WORK DURIG ERECTION AND HE SHALL ARRANGE ALL TEMPORARY GUYING. BRACING AND

S1

SUPPORT TOGETHER WITH ANY ADDITIONAL TACK BOLTS NECESSARY FOR THE STABILITY OF SECTION MARK

2.2 STRUCTURAL STEEL SHALL COMPLY WITH THE FOLLOWING MATERIAL REQUIRMENT. DWG

THE STEEL WORK UNTIL FINAL BOLTING UP.

GRADE FYLD= 275 AS/BS EN 10025.

7.4 THE STEEL WORK SHALL BE ACCURATELY ERECTED WITH IN THE FOLLOWING TOLERANCE. DETAIL MARK

2.3 STRUCTURAL STEEL SHALL COMPLY WITH THE REQUIREMENT OF AISC AMERICAN INSTITUTE OF

STEEL CONSTRUCTION. SETTING CUT-PLAN DIMENSIONS :- ±10mm OVERALL BUILDING BUT NOT MORE

2.4 ALL METSEC C-SECTION PRODUCT IS MANUFACTURED FROM PRE HOT DIPPED GALVANISED STEEL THAN ±5mm IN ANY ONE 5 METER BAY ±5

mm 0.1% OF HEIGHT, BUT NOT MORE D1

TO BS EN 100346:2015, Z275 COATING AND WITH A MINIMUM YIELD STRENGTH OF 450 N/mm.2 DWG

LEVELS-FOR STANCHIONS, AND THAN 5mm OVERALL NOT MORE THAN THE SUBTITLES

COLUMN BASE PLATES. PLUMB ROLLING

OF STANCHIONS, POSTS, ETC- TOLERANCES AS GIVEN IN THE APPROPRIATE E1 ELEVATION SUBTITLE FOR

3.0 BOLTING STRAIGHTNESS OR BOW OR AMERICAN STANDARD. 302 ELEVATION DRAWING

OUT OF SQUARENESS OF

SECTIONS AFTER ERECTION. DWG. No. WHERE ELEVATION

3.1 BOLTS AND NUTS HAVE ISO-METRIC COARSE THREAD.

MARK IS CALLED UP

3.2 HIGH TENSILE BOLTS GRADE 8.8 OR OF HIGHER GRADE, NUTS AND WASHERS SHALL COMPLY

WITH THE REQUIREMENTS OF ASTM A325,DESIGN OF BOLT SHALL BE DONE WITH GRADE 8.8. S1 SECTION SUBTITLE FOR

302 SECTION DRAWING

3.3 WASHERSARE TO BE PROVIDED UNDER ALL NUTS ON BEVELLED SURFACES. SQUARE TAPER

WASHERS 8.0 HOT-DIP GALVANIZING / PAINTINGS DWG. No. WHERE SECTION

MARK IS CALLED UP

- ALL BOLTS SHALL BE FULLY TORQUED FOR BOTH FRICTION AND BEARING TYPE CONNECTIONS. 8.1 THE SURFACE OF STRUCTURAL STEEL BEFORE PAINTING SHALL BE CLEANED PFF RUST, SCALE, SUBTITLE FOR

No Description

- THE MINIMUM NUMBER OF BOLTS PER CONNECTION SHALL BE TWO (4) - DIRT AND OTHER FOREIGN MATTER BLASTING TO SA 2-1/2" OF SWEDISH SPECIFICATIONS. D1 DETAIL DETAIL DRAWING

SAFETY, HEALTH AND ENVIRONMENT INFORMATION

302 Brief details on the identified hazard symbol referencing the unusual residual

M16 DIAMETER, A490 BOLTS. hazards / risks are listed above.

DWG. No. WHERE DETAIL

9.0 CORROSION PROTECTION NOTES: MARK IS CALLED UP

4.0 WELDING / FABRICATION 9.1 CORROSION PROTECTION FOR STRUCTURAL STEEL SHALL BE AS PER SPECIFICATION.

1. SECTIONS ARE DENOTED BY NUMBERS. ALL OTHER DETAILS ARE DENOTED BY LETTER.

4.1 WELDING USED IN THE FABRICATION WORK IS TO BE BY THE METALIC ARC PROCESS USING 2. IF A DETAIL DRAWING ETC., IS SHOWN ON THE SAME DRAWING AS THE DETAIL 1 ISSUED FOR CONSTRUCTION AB AB 23/01/2020

ELECTRODES COMPLYING WITH THE REQUIRMENTS OF AWS (AMERICAN WELDING SOCIETY). 10.0 FIRE RATING MARK THEN "-" IS USED INSTEAD OF DRAWING No.

0 DETAIL DESIGN SUBMISSION AB AB 08/01/2020

Rev Description Apvr Chk'd Date

10.1 FIRE RATING AS PER STRUCTURAL SPECIFICATION. Client

4.2 THE ENDS OF ALL STANCHIONS AND POSTS TOGETHER WITH GUSSETS WHERE PRESENT AND 3. IF A DETAIL ETC., CALLED UP ON MORE THAN ONE THEN THOSE DRAWING Nos.

ALREADY WELDED ON, SHALL BE MACHINED SO THAT THE WHOLE AREA IS IN DIRECT ARE ADDED TO THE DETAIL SUB-TITLE AS SHOWN BELOW:

CONTACT WITH THE BASE, BEARING OR CAP PLATE. SUCH PLATES BEING TRULY AT RIGHT

ANGLES TO THE STANCHION AXIS OR AS OTHERWISE SPECIFIED ON THE DRAWING. TANKING D1 DETAIL

SHOULD BE CARRIED OUT AS PER THE SPECIFICATIONS AND INSTRUCTIONS OF THE Programme / Programme Management Consultant

302 303

MANUFACTURER 304

4. IF A DETAIL APPLIES TO MANY DRAWINGS OR IF IT IS A GENERIC DETAIL

4.3 IN GENERAL, WELDS SHALL BE FULL STRENGTH BUTT WELDS. RADIO GRAPHIC AND THEN A STANDARD DETAIL SYMBOL IS USED.

ULTRASONIC TESTS SHALL BE DONE ON ALL FULL STRENGTH BULL WELDS. ALL

Architectural Consultant

TESTS AND REQUIREMENTS SHALL BE IN ACCORDANCE WITH THE STRUCTURAL

SPECIFICATIONS. WELD SYMBOLS ARE TO "AWS". ALL WELDS SHALL BE FULL

PROFILE, UNLESS NOTED OTHERWISE.

Project Title

4.4 PLATE FOR CONSTRUCTIONS AND BASE PLATE, HIGHER THICKNESS PLATES SHALL BE

ACCEPTABLE, IF PLATES OF REQUIRED THICKNESS ARE NOT AVAILABLE. USA PAVILION EXPO 2020

Enter address here

4.5 JOINT SEALANT IS TO BE MULTI COMPONENT, LOW MODULUS, HIGH PERFORMANCE SEALANT, Drawing Title

FORMULATED FROM EXPOXY TREATED POLYURETHENE. JOINT FILLET TO BE COMPATIBLE

WITH THE SELECTED JOINT SEALANT. ALL MATERIALS SHALL BE SUBJECT TO THE APPROVAL GENERAL NOTES SHEET-2

OF THE ENGINEER. ALL APPLICATIONS ARE TO BE CARRIED OUT STRICTLY IN ACCORDANCE

WITH THE MANUFACTURERS INSTRUCTIONS.

4.6 ALL STRUCTURAL HOLLOW SECTIONS SHALL, UNLESS NOTED OTHERWISE,

BE SEALED AT EACH EACH END WITH A 6mm CAP PLATE CONNECTED BY FILLET

WELD. WHERE HOLLOW MEMBERS ARE TO BE GALVANISED, VENT HOLES SHALL

BE PROVIDED IN ACCORDANCE WITH THE SPECIFICATION.

4.7 PRE-CAMBER VALUES SHOWN ON THE DRAWINGS REFER TO THE FABRICATED SHAPE BEFORE

LOADS ARE APPLIED.

Approved Seal Date

4.8 PRE-CAMBER SHALL BE PROVIDED AS

AB

SPAN/500,UNLESS NOTED OTHERWISE.

Designed Drawn Checked

IA AB

Model File Ref: Scale A1(594x841) Revision No

10101-MDL-S605282-AR-900001 1 : 100 1

Drawing No

6324-USA-ST-DG-ST-03

You might also like

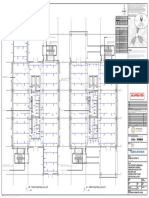

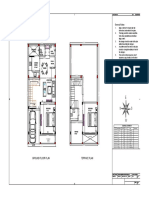

- St-104 - Overall Ground Floor PlanDocument1 pageSt-104 - Overall Ground Floor PlanMØhãmmed ØwięsNo ratings yet

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 pageSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsNo ratings yet

- Elevation 01 - Legacy 1: All Levels On Plans, Sections & Elevations Are DMD LevelsDocument1 pageElevation 01 - Legacy 1: All Levels On Plans, Sections & Elevations Are DMD LevelsAbdul BasithNo ratings yet

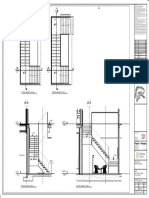

- Staircase Section B-B BB Staircase Section A-A AADocument1 pageStaircase Section B-B BB Staircase Section A-A AAAbdul BasithNo ratings yet

- Key Plan: Table of Isolation Valve Chambers Reinforcement DetailsDocument1 pageKey Plan: Table of Isolation Valve Chambers Reinforcement DetailsLeon Golden RatioNo ratings yet

- Material SumittalDocument73 pagesMaterial Sumittalsubash0% (1)

- 4MAKA08-TNEC-FC-720-TE-DWG-60402-A-IT & SECURITY SCHEMATIC DIAGRAM LAYOUT-AAADocument1 page4MAKA08-TNEC-FC-720-TE-DWG-60402-A-IT & SECURITY SCHEMATIC DIAGRAM LAYOUT-AAAShaaban HassanNo ratings yet

- As-Built: Al Wakrah Stadium and Precinct, QatarDocument1 pageAs-Built: Al Wakrah Stadium and Precinct, QatargenricNo ratings yet

- As Approved: GF - Fire Fighting Layout 1 01 - Fire Fighting Layout 2Document1 pageAs Approved: GF - Fire Fighting Layout 1 01 - Fire Fighting Layout 2Edgar Lenard GumapasNo ratings yet

- 4maka08 Tnec Fc 722 Te Dwg 60402 a It Schematic Diagram Layout AaaDocument1 page4maka08 Tnec Fc 722 Te Dwg 60402 a It Schematic Diagram Layout AaaShaaban HassanNo ratings yet

- Oppo Mobiles India Pvt. LTD.: Key PlanDocument2 pagesOppo Mobiles India Pvt. LTD.: Key PlanKarma NorbuNo ratings yet

- Oppo Mobiles India Pvt. LTD.: Key PlanDocument1 pageOppo Mobiles India Pvt. LTD.: Key PlanKarma NorbuNo ratings yet

- 1 Subject: Marking The Date of ManufactureDocument6 pages1 Subject: Marking The Date of ManufacturegustavoNo ratings yet

- 1025 K.IN Studio & HANAMORI's Office - 210507Document11 pages1025 K.IN Studio & HANAMORI's Office - 210507KinoNo ratings yet

- Tolerance Clarification 720029483 PDFDocument1 pageTolerance Clarification 720029483 PDFQualitysm MicrotechprecisionengineeringNo ratings yet

- Notes:: 0 0.2M 0.4M 0.6M 0.8M 1M 1:20Document1 pageNotes:: 0 0.2M 0.4M 0.6M 0.8M 1M 1:20mandeep gautamNo ratings yet

- Port Folio: Denise Mejia Selected Works 2017 - 2019Document26 pagesPort Folio: Denise Mejia Selected Works 2017 - 2019Denise MejiaNo ratings yet

- Basement Floor Plan: Revisions NodatedescriptionDocument1 pageBasement Floor Plan: Revisions NodatedescriptionEugeneNo ratings yet

- Portfoli O: Practi CAL Trai NI NGDocument52 pagesPortfoli O: Practi CAL Trai NI NGDhruvi KananiNo ratings yet

- Fire Alarm ShopdrawingDocument6 pagesFire Alarm Shopdrawingkamil arnousNo ratings yet

- Fran Eth Z1 B1 DR e CT20Document1 pageFran Eth Z1 B1 DR e CT20Lucian KrsNo ratings yet

- C09-AEB-D-STA-B-ST-04-04-1106: Refer To Upper Tier Drawings For Steel Framing LayoutDocument1 pageC09-AEB-D-STA-B-ST-04-04-1106: Refer To Upper Tier Drawings For Steel Framing LayoutRyan De Vera PagalNo ratings yet

- Civil Works Guide Line For SMC: Braskem-Idesa CodeDocument92 pagesCivil Works Guide Line For SMC: Braskem-Idesa CodeDaniel EsparzaNo ratings yet

- Airtel provides certificate from debenture trustee on financial resultsDocument2 pagesAirtel provides certificate from debenture trustee on financial resultspratik567No ratings yet

- Owner's Manual: Thank You, and Congratulations On Your Choice of The BOSS GT-10Document156 pagesOwner's Manual: Thank You, and Congratulations On Your Choice of The BOSS GT-10bcstefan022No ratings yet

- Timboon Housing Estate PlansDocument17 pagesTimboon Housing Estate PlansKyra GillespieNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31156-Pdf (T00) - GRC Fins-Retail Frontage-LocationsDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31156-Pdf (T00) - GRC Fins-Retail Frontage-LocationsZaido Al HalabiNo ratings yet

- TECH-7 Work Schedule SampleDocument1 pageTECH-7 Work Schedule SamplemarkNo ratings yet

- Pvi Usb RS232 - 485Document2 pagesPvi Usb RS232 - 485Lucas CostaNo ratings yet

- Harold Pupkewitz Graduate School of Business 2023Document37 pagesHarold Pupkewitz Graduate School of Business 2023Ditend TeshNo ratings yet

- DEP BoilerDocument45 pagesDEP Boilerbalaji krishnanNo ratings yet

- Oppo Mobiles India Pvt. LTD.: Key PlanDocument1 pageOppo Mobiles India Pvt. LTD.: Key PlanKarma NorbuNo ratings yet

- Issued For BP - Structural - 19Document1 pageIssued For BP - Structural - 19Tran DtrungNo ratings yet

- Final Craft Center Schedule(Modified)Document7 pagesFinal Craft Center Schedule(Modified)AndebetNo ratings yet

- 210-03-03 Roof Floor PlanDocument1 page210-03-03 Roof Floor PlanAnish MohanNo ratings yet

- Lift machine room levelsDocument1 pageLift machine room levelsmathivananNo ratings yet

- General Notes:-: Toilet 4'0"x4'4" Bath 4'0"x4'4" Wash Area 7'10"x4'4"Document1 pageGeneral Notes:-: Toilet 4'0"x4'4" Bath 4'0"x4'4" Wash Area 7'10"x4'4"Chaturbhuj Ikat FabricsNo ratings yet

- International Standard: Iso/Iec/ Ieee 42020Document126 pagesInternational Standard: Iso/Iec/ Ieee 42020Sam100% (1)

- SC-C06-CAG-HBK-CAL-ST-00061-Appendix 3-DrawingDocument1 pageSC-C06-CAG-HBK-CAL-ST-00061-Appendix 3-DrawingLe Phuoc NghiaNo ratings yet

- Carbonite Black Hardware QS (4804DR 200 09)Document2 pagesCarbonite Black Hardware QS (4804DR 200 09)Jorge MirandaNo ratings yet

- Pdch14-Gaj-Dwg-000-Xxx-Arc-31155-Pdf (T00) - GRC Fins-Retail Frontage-TypesDocument1 pagePdch14-Gaj-Dwg-000-Xxx-Arc-31155-Pdf (T00) - GRC Fins-Retail Frontage-TypesZaido Al HalabiNo ratings yet

- 2 PDFsam A1716-00002-2019-ST06 SE1820 20210111Document1 page2 PDFsam A1716-00002-2019-ST06 SE1820 20210111fade2black11No ratings yet

- Electrical Codes PDFDocument16 pagesElectrical Codes PDFcosmin1991No ratings yet

- SXCDVFBG NDocument1 pageSXCDVFBG NSachin AgarwalNo ratings yet

- Revised Construction Schedule/S Curve and Catch-Up Plan: DescriptionDocument2 pagesRevised Construction Schedule/S Curve and Catch-Up Plan: Descriptionandreu colomaNo ratings yet

- 2021 Business PerformanceDocument22 pages2021 Business PerformanceSebastian SinclairNo ratings yet

- Birla Alokya IsometricDocument16 pagesBirla Alokya IsometricDave LooNo ratings yet

- Schaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Document249 pagesSchaltplan JGS420 - SO#36824 JY108 - 7458609 - 258Muhammad Mujtaba TariqNo ratings yet

- Schaltplan JGS420 - SO#36824 JY108 - 7458609 - 258 PDFDocument249 pagesSchaltplan JGS420 - SO#36824 JY108 - 7458609 - 258 PDFMuhammad Mujtaba Tariq100% (1)

- 2021 09 20 Garden Mall-A10.02-Typical Details-Sections Wall-Acoustic CeilingDocument1 page2021 09 20 Garden Mall-A10.02-Typical Details-Sections Wall-Acoustic CeilingDan SarmientoNo ratings yet

- DSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedDocument10 pagesDSGN DRWN CHKD Appd AG CB CCS CB: GMR Goa International Airport LimitedAditya KNo ratings yet

- Inf JPNDocument67 pagesInf JPNFlor Terrera HamadaNo ratings yet

- 2018jlssbroc PDFDocument2 pages2018jlssbroc PDFJohn Ray ClarinNo ratings yet

- E104 - FF - Interior LightingDocument1 pageE104 - FF - Interior Lightingdavid abbreyNo ratings yet

- E102 - FF - Small PowerDocument1 pageE102 - FF - Small Powerdavid abbreyNo ratings yet

- L02-R02D01-FOS-00-XX-DWG-AR-52004Document1 pageL02-R02D01-FOS-00-XX-DWG-AR-52004Osama KheadryNo ratings yet

- Toilets-Parent's Bathroom 28-05-2019Document1 pageToilets-Parent's Bathroom 28-05-2019Ankit GuptaNo ratings yet

- 4maka08 MBL SD 100 PL SHD 10011 1Document1 page4maka08 MBL SD 100 PL SHD 10011 1jvfcvNo ratings yet

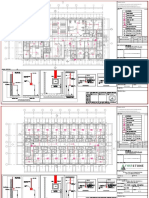

- St-102 - Foundation Plan Part-2Document1 pageSt-102 - Foundation Plan Part-2MØhãmmed ØwięsNo ratings yet

- St-502 - Foundation SectionsDocument1 pageSt-502 - Foundation SectionsMØhãmmed ØwięsNo ratings yet

- St-112 - Lower Roof PlanDocument1 pageSt-112 - Lower Roof PlanMØhãmmed ØwięsNo ratings yet

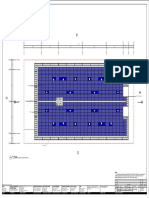

- 242 20190319 Sheet - 105 - PV Canopy PlanDocument1 page242 20190319 Sheet - 105 - PV Canopy PlanMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Table of ContentsDocument1 pageDivision 12 Furnishing - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 12494 Roller ShadesDocument5 pagesSection 12494 Roller ShadesMØhãmmed ØwięsNo ratings yet

- SGP ST RPT 0001 Rev CDocument139 pagesSGP ST RPT 0001 Rev CMØhãmmed ØwięsNo ratings yet

- Louvers and Vents SpecificationsDocument3 pagesLouvers and Vents SpecificationsMØhãmmed ØwięsNo ratings yet

- Guest Bedroom Furniture SpecsDocument5 pagesGuest Bedroom Furniture SpecsMØhãmmed ØwięsNo ratings yet

- CURTAINS AND DRAPES SPECIFICATIONSDocument4 pagesCURTAINS AND DRAPES SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsNo ratings yet

- Interior Plant SpecificationsDocument10 pagesInterior Plant SpecificationsMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Cover PageDocument1 pageDivision 12 Furnishing - Cover PageMØhãmmed ØwięsNo ratings yet

- Decorative Lamps Specification for Office Furnishing ProjectDocument3 pagesDecorative Lamps Specification for Office Furnishing ProjectMØhãmmed ØwięsNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- Interior Stone Facing SpecificationsDocument10 pagesInterior Stone Facing SpecificationsMØhãmmed ØwięsNo ratings yet

- Engineering Office Paint SpecificationDocument13 pagesEngineering Office Paint SpecificationMØhãmmed ØwięsNo ratings yet

- Section 10520 Fire Protection SpecialitiesDocument7 pagesSection 10520 Fire Protection SpecialitiesMØhãmmed ØwięsNo ratings yet

- Section 09300 TilesDocument11 pagesSection 09300 TilesMØhãmmed ØwięsNo ratings yet

- Section 10810 Toilet and Bath AccessoriesDocument7 pagesSection 10810 Toilet and Bath AccessoriesMØhãmmed ØwięsNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Section 09380 Dimension Stone TilesDocument9 pagesSection 09380 Dimension Stone TilesMØhãmmed ØwięsNo ratings yet

- WALL COVERING SPECIFICATIONSDocument4 pagesWALL COVERING SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Division 9 Finishes - Table of ContentsDocument1 pageDivision 9 Finishes - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Division9 Finishes - Cover PageDocument1 pageDivision9 Finishes - Cover PageMØhãmmed ØwięsNo ratings yet