Professional Documents

Culture Documents

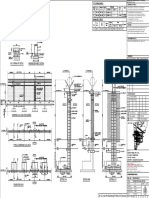

St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1

Uploaded by

MØhãmmed ØwięsCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1

Uploaded by

MØhãmmed ØwięsCopyright:

Available Formats

Important Notes:

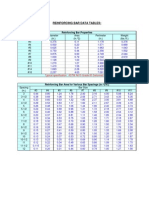

LINTEL SCHEDULE (CONCRETE C40) • Copyright by Bureau Expo Dubai 2020 (EX20). All rights reserved. This

document may not, in whole or in part, be reproduced, stored, transmitted or

distributed in any form or by any means, whether electronic, mechanical, by

REINFORCEMENT photocopy, recording or otherwise, without the prior written permission of EX20.

OPENING SIZE BREADTH DEPTH Except where otherwise expressly agreed in writing by EX20, EX20 shall have

BOTTOM TOP LINKS no responsibility or liability for any loss (direct, consequential or otherwise)

which may arise from reliance on or use of this document or the information

0000 TO 1000 100 250 1 T 10 1 T 10 T 8 - 200 contained therein.

• Where dimensions are not given, drawings must not be scaled and the matter

should be referred back to John R Harris & Partner's.

0000 TO 1000 200 250 2 T10 2 T 10 T 8 - 200 • This drawing should be read in conjunction with all other project information,

produced by John R Harris & Partner's and others. In the event of any conflict

1001 TO 2000 100 250 1 T 12 1 T 12 T 8 - 200 between the information contained on this drawing and in any other project

document, drawings, specifications, schedules etc. the matter must be referred

TOP REINFORCEMENT back to John R Harris & Partner's for clarification.

1001 TO 2000 200 250 2 T 12 2 T 12 T 8 - 200 • All dimensions and conditions are to be checked on site by the contractor prior

to preparing designs, shop drawings, calculations etc. or commencing any

work.

2001 TO 3000 200 500 2 T 16 2 T 16 T 8 - 250 • The contractor is responsible for checking that there is no conflict between site

DEPTH

10mm JOINT TO BE FILLED (WITH MORTAR) dimensions and drawn dimensions.

DURING PLASTERING. LINKS • This drawing’s should be read in conjunction with other relevant architectural,

3001 TO 4000 200 500 2 T 20 2 T 16 T 8 - 250

interior design, structural, fire safety, mechanical and electrical drawings and all

relevant sections of the project specifications.

• The contractor shall submit full shop / setting out drawing for approval (based

on site dimensions) prior to commencement of any site works, placing of

A FULL BLOCK. BOTTOM REINFORCEMENT A FULL BLOCK. orders, manufacture of fittings, fixtures and components.

(HOLLOW BLOCK FILLED WITH CONCRETE (HOLLOW BLOCK FILLED WITH CONCRETE NOTES: • Approved drawings from consultants do not relief the contractors from his

OR SOLID BLOCK) OR SOLID BLOCK) BREADTH contractual obligations or that of adhering to requirements in accordance with

1. DETAILED DESIGN OF ALL LINTELS TO BE CONTRACTORS'S RESPONSIBILITY. latest edition of Fire and Life Safety Code of practice and the International

2. LINTEL SIZE AND REINFORCEMENT PROVISIONS SHALL MEET MINIMUM REQUIREMENTS OF DETAILS SHOWN OR Codes & Standards referred to within where applicable.

• Safety, Health and Environment Information: brief details on the identified

160.0576 OPENING 160.0576 CONTRACTORS DESIGN, WHICHEVER IS GREATER. hazard symbol referencing the unusual residual hazards / risks are listed

FULL BEARING STRIP BEARING BEARING 3. LINTELS SHOWN ARE INTENDED FOR SUPPORT OF BLOCKWORK WALL CONSTRUCTION ONLY, AND NOT INTENDED above.

AS PER SPEC. (MINIMUM) (MINIMUM) - SECTION FOR SUPPORT OF FLOOR, ROOF, OR OTHER LOAD BEARING STRUCTURES.

UNDER LINTEL BEARING - ELEVATION -

4. DETAILS SHOWN ASSUME LINTELS CONSTRUCTED FROM CAST-IN-PLACE CONCRETE. PRE-CASE CONCRETE LINTELS

DO NOT SCALE THIS DRAWING.

- MAYBE PROVIDED BY CONTRACTOR IF PREFERRED.

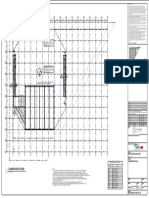

A LINTEL DETAILS CONCRETE MASONRY UNIT (CMU) NOTES

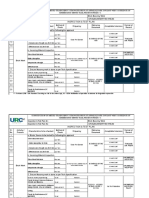

1. DETAILS CONTAINED ON THIS DRAWING ARE FOR INTERIOR, NON-LOAD BEARING WALLS AND RELATED ELEMENTS ONLY.

2. DETAILED DESIGN OF ALL MASONRY WALLS, LINTELS, SUPPORT POSTS, HEAD RESTRAINTS, AND OTHER SUPPORT SYSTEMS,

ARE CONTRACTOR'S RESPONSIBILITY. SEE ARCHITECTURAL DRAWINGS FOR LOCATION, GEOMETRY, DESIGN REQUIREMENTS,

AND OTHER RELEVANT INFORMATION. N

3. CONCRETE MASONRY SHALL HAVE A MINIMUM COMPRESSIVE STRENGTH(f'm) OF 10 MPa(1500 PS).

Makka

4. MASONRY UNITS SHALL CONFORM TO ASTM C129, NORMAL WEIGHT, HOLLOW, WITH A UNIT STRENGTH AS REQUIRED h

TO ACHIEVE COMPRESSIVE STRENGTH SPECIFIED ABOVE.

M10 STAINLESS STEEL 5. CONCRETE BUILDING BRICKS, IF USED, ARE TO CONFORM TO ASTM C55.

STAINLESS STEEL MASONRY TIE 100 THICK INSULATED BLOCKWORK MASONRY ANCHOR BOLT

6. MORTAR SHALL CONFORM TO ASTM C270, TYPE M OR S FOR ABOVE GRADE APPLICATIONS. USE TYPE M FOR BELOW

BY 'HARRIS AND EDGAR' PATTERN HEMAX 82i FIXING TO THE CONCRETE GRADE APPLICATION, IF ANY. General Notes

OR SIMILAR APPROVED AT 400 VERTICAL 7. GROUT FOR FILLED CELLS SHALL CONFORM TO ASTM C476 WITH 20 MPa(3000 PS) STRENGTH AT 28 DAYS. CELLS SHALL

TWO LAYERS OF 50mm THICK CAVITY INSULATION COMPRESSIBLE FILLER

AND 800 HORIZONTAL CENTERS AS PER SPEC. BE GROUTED IN INCREMENTS NOT EXCEEDING 1.5m(5 FEET) VERTICALLY. ALL CELLS BELOW GRADE ARE TO BE

1000 GAUGE IN ACCORDANCE WITH SECTION G : 8.3 GROUTED SOLID, IF ANY.

IN ACCORDANCE WITH SECTION G : 8.2

POLYTHENE SHEET OF STRUCTURAL SPECIFICATIONS. HEMAX SLIDING STAINLESS STEEL

OF STRUCTURAL SPECIFICATIONS. OUTSIDE FACE 8. HORIZONTAL JOINT REINFORCEMENT SHALL BE NO.9 GAGE WIRE CONFORMING TO ASTM A82 AND SHALL BE

MASONRY TIES BY 'HARRIS AND

PLACED AT EVERY OTHER COURSE, U.O.N.

EDGAR' PATTERN TYPE 35/80/E

9. ALL BLOCK SHALL BE PLACED IN RUNNING BOND.

OR SIMILAR APPROVED AT 800mm

C/C. 10. WALL DIMENSION BETWEEN VERTICAL AND HORIZONTAL RESTRAINTS SHALL NOT EXCEED SPAN/36.

80

11. WHERE MASONRY WALL ARE REQUIRED TO PROVIDE FIRE BARRIER, WALLS AND SUPPORT POSTS ETC. SYSTEMS SHALL BE

OUTSIDE FACE INSIDE FACE DESIGNED, DETAINED, AND CONSTRUCTED TO RESIST MINIMUM FIRE PERIOD SPECIFIED. REFER TO ARCHITECT'S INFORMATION

40 40

FOR WALLS TO PROVIDE FIRE BARRIER AND APPLICABLE PERIOD.

12. MASORY WALLS TO PERFORM ACOUSTIC FUNCTION TO ATTENUATE SOUND TRANSMISSION BETWEEN ADJACENT AREAS SHALL

BE DESIGNED, DETAILED, AND CONSTRUCTED ACCORDINGLY TO ENSURE SATISFACTORY PERFORMANCE.

80

REFER TO ARCHITECT'S INFORMATION FOR REQUIREMENTS.

100 THICK INSULATED 100 THICK BLOCKWORK

INSIDE FACE 120mm LONG SLEEVED STAINLESS STEEL MASONRY BLOCKWORK

SLIDING TIES BY 'HARRIS AND EDGAR' PATTERN 35/20

VOIDS TO BE FILLED WITH RC COLUMN/WALL OR SIMILAR APPROVED AT 400mm VERTICAL STAGGERED

CONCRETE (10mm AGGREGATE)

CENTERS FIXED TO CONCRETE WITH 1 NO. M6

10mm COMPRESSIBLE STAINLESS STEEL MASONRY ANCHOR BOLT.

MASTIC FILLER AS PER SPEC.

(TO ARCHITECT'S APPROVAL) (ALL TO ARCHITECT'S APPROVAL)

- PLAN - SECTION

- - RC LINTEL

B RC WALL / COLUMN TO BLOCKWORK JUNCTION

EXTERNAL CAVITY WALL

No Description

VERTICAL SIDES TO BE FILLED SAFETY, HEALTH AND ENVIRONMENT INFORMATION

WITH CONCRETE Brief details on the identified hazard symbol referencing the unusual residual

(10mm AGGREGATES) hazards / risks are listed above.

4000 MAXIMUM (EXTERNAL)

6000 MAXIMUM GENERALLY (INTERNAL)

5000 MAXIMUM (INTERNAL) 100mm THICK WALLS (FOR HEIGHT OF WALL UPTO 3250mm)

1 ISSUED FOR CONSTRUCTION AB AB 23/01/2020

(IF HEIGHT EXCEEDS 3250, PROVIDE 200mm DEEP RC LINTEL) 0 DETAIL DESIGN SUBMISSION AB AB 08/01/2020

RC FRAME Rev Description Apvr Chk'd Date

A

-

Client

DOOR

B Programme / Programme Management Consultant

G

Architectural Consultant

RC LINTEL

RC CONCRETE POST

(RESTRAINT POST) Project Title

CAST AFTER BLOCKWORK VERTICAL SIDES TO BE FILLED

RC COLUMN SOLID WALLS OR WITH CONCRETE

USA PAVILION EXPO 2020

EXTERNAL LEAF OF CAVITY WALL (10mm AGGREGATES) Enter address here

Drawing Title

C E

BLOCK WALL RESTRAINT DETAILS

- - AND LINTEL SCHEDULE SHEET-1

F

Approved Seal Date

FOR SECTION A, C, E AND DETAIL B, G, F AB

BED JOINT REINFORCEMENT

REFER DRAWING NO. S-303 EVERY SECOND COURSE WINDOW Designed Drawn Checked

IA AB

EXTERNAL WALL PANEL OF CAVITY WALL / D DOOR / WINDOW OPENING IN INTERNAL WALLS

Model File Ref: Scale A1(594x841) Revision No

C 10101-MDL-S605282-AR-900001 1 : 75 1

INTERNAL SINGLE SKIN WALL PANEL Drawing No

6324-USA-ST-DG-ST-006

You might also like

- Quotation 40sqm W JacuzziDocument3 pagesQuotation 40sqm W JacuzziZee De Vera LaderasNo ratings yet

- Mountain View Community Centre TenderDocument15 pagesMountain View Community Centre TenderDean KoortzenNo ratings yet

- Pool Overflow Stones Collection-2013Document96 pagesPool Overflow Stones Collection-2013Keri MasonNo ratings yet

- Boysen Plexibond acrylic polymer cement additiveDocument2 pagesBoysen Plexibond acrylic polymer cement additiveAtoy Liby OjeñarNo ratings yet

- ACO Floor Drains and Clean Out CatalogDocument9 pagesACO Floor Drains and Clean Out CatalogJohnny TsehayeNo ratings yet

- Site and Drainage PlanDocument1 pageSite and Drainage Planheba bassamNo ratings yet

- BOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFDocument2 pagesBOQ For Construction of Boundary Wall in QTR No. III-31 in Colony Sector at MANIT PDFVeena NageshNo ratings yet

- Technical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiesDocument12 pagesTechnical Sheet and Installation Guide for Autoclaved Aerated Concrete PropertiessubhaschandraNo ratings yet

- Wood Door Technical Data (All Sections)Document180 pagesWood Door Technical Data (All Sections)P. N. Praveen100% (2)

- Beam Column SchedulesDocument1 pageBeam Column SchedulesJason ToraldeNo ratings yet

- Civil Engineering Draftsman II: Passbooks Study GuideFrom EverandCivil Engineering Draftsman II: Passbooks Study GuideNo ratings yet

- Structural Pro™ Laminated Glass Load Resistance Report: Project Details Report DetailsDocument1 pageStructural Pro™ Laminated Glass Load Resistance Report: Project Details Report DetailsShafeeq KTNo ratings yet

- Roofing DetailsDocument1 pageRoofing DetailsJohn BarrogaNo ratings yet

- IESL EstimateDocument14 pagesIESL EstimateAnuranga SahampathNo ratings yet

- Scope of Work DocumentDocument11 pagesScope of Work DocumentJethNo ratings yet

- Gir Gai Trading Hot Rolled Steel Sections PDFDocument4 pagesGir Gai Trading Hot Rolled Steel Sections PDFtpop1707No ratings yet

- Brushbond RFX PDFDocument2 pagesBrushbond RFX PDFpiyu114No ratings yet

- Muro Wall FormworkDocument10 pagesMuro Wall FormworkDaliform GroupNo ratings yet

- Comprehensive Specs 1Document3 pagesComprehensive Specs 1Marc Dared CagaoanNo ratings yet

- Wood Truss DetailDocument1 pageWood Truss Detailseagull70No ratings yet

- White Book C04 S11 Partitions Non Loadbearing Timber StudDocument17 pagesWhite Book C04 S11 Partitions Non Loadbearing Timber StudPavaloaie Marian ConstantinNo ratings yet

- Session 3-Design Requirements of BMUsDocument37 pagesSession 3-Design Requirements of BMUsRanjit Singh100% (1)

- 14 Masonry ConstructionMethodsDocument78 pages14 Masonry ConstructionMethodsMaverick LastimosaNo ratings yet

- Sika's Support For The Design, Construction and Maintenance of HotelsDocument4 pagesSika's Support For The Design, Construction and Maintenance of HotelsCarlos ChoqueNo ratings yet

- Building Regulations NotesDocument6 pagesBuilding Regulations NotesElliot Wells100% (1)

- Construction of Public Toilet ProjectDocument5 pagesConstruction of Public Toilet ProjectAugustine Believe100% (1)

- Eaab BomceDocument22 pagesEaab BomceBert EngNo ratings yet

- Passive Block Foundation DrawingDocument1 pagePassive Block Foundation Drawingapi-426990805100% (1)

- ABC Tile Grout Technical Data Sheet 2020Document1 pageABC Tile Grout Technical Data Sheet 2020Airis Joy RojasNo ratings yet

- Aluminium SectionsDocument32 pagesAluminium SectionsAkash Singh100% (3)

- Builders Guide To CementDocument52 pagesBuilders Guide To CementSkerdi MucoNo ratings yet

- MARLEY Roofing - South AfricaDocument2 pagesMARLEY Roofing - South AfricaJoão Athayde e MeloNo ratings yet

- H003 76-10526-Detail DesignDocument1 pageH003 76-10526-Detail DesignMazen IsmailNo ratings yet

- CHP 2 Reinforcement Works BarDocument7 pagesCHP 2 Reinforcement Works Bardhevashini narayanan100% (1)

- Shs60m Can Build A 3 Bedroomed House, A Look at The Cost Breakdown - Nile PostDocument7 pagesShs60m Can Build A 3 Bedroomed House, A Look at The Cost Breakdown - Nile PostSuufu Mkhitaryan KirumiraNo ratings yet

- BPS-STR-201-R1-Foundation Plan Other Details For Compound WallDocument1 pageBPS-STR-201-R1-Foundation Plan Other Details For Compound Wallsri projectssNo ratings yet

- Page 2 - Perimeter FenceDocument1 pagePage 2 - Perimeter FenceJet ToledoNo ratings yet

- TFW-IW-01 Separating Wall/External Wall AbutmentDocument26 pagesTFW-IW-01 Separating Wall/External Wall AbutmentZoe MarinescuNo ratings yet

- Slip MembraneDocument1 pageSlip MembranescchungNo ratings yet

- Aco Drain UsaDocument81 pagesAco Drain UsaSankar CdmNo ratings yet

- Advances in Waterproofing Materials & Technology PDFDocument20 pagesAdvances in Waterproofing Materials & Technology PDFVic Charls Orbon IIINo ratings yet

- Tie Bars and Straps for Bulging BrickworkDocument2 pagesTie Bars and Straps for Bulging BrickworkStaszek WoznyNo ratings yet

- 03930-Concrete Repair-Rev.0 PDFDocument16 pages03930-Concrete Repair-Rev.0 PDFMithun UdayanarayanaNo ratings yet

- Trimdek: Design and Installation GuideDocument6 pagesTrimdek: Design and Installation GuideHarold SanaresNo ratings yet

- Tolleranze PCIDocument20 pagesTolleranze PCIkurtainNo ratings yet

- BR101Document1 pageBR101Vladimir ĐorđevićNo ratings yet

- Architectural Catalogue RenukootDocument103 pagesArchitectural Catalogue Renukootprchoudharykp100% (2)

- Construction SpecsDocument17 pagesConstruction SpecsBryan Sacramento De LeonNo ratings yet

- Building Management System (BMS) OR Building Automation System (BAS)Document23 pagesBuilding Management System (BMS) OR Building Automation System (BAS)NIRU CHAUDHARYNo ratings yet

- Qcs 2007 0117Document3 pagesQcs 2007 0117RotsapNayrbNo ratings yet

- Aco Rainwater Outlets BrochureDocument32 pagesAco Rainwater Outlets Brochurerajkumar_chinniah100% (1)

- Significant Changes to Roofing Requirements in the 7th Edition Florida Building CodeDocument6 pagesSignificant Changes to Roofing Requirements in the 7th Edition Florida Building CodeDiego Quiroga CruzNo ratings yet

- Sikadur 732Document2 pagesSikadur 732Hafidh Roiy100% (1)

- Roof Garden Spec and DetailsDocument33 pagesRoof Garden Spec and Detailsbekaen bekaen100% (1)

- National Cyber Security Center Qatar Project DetailsDocument1 pageNational Cyber Security Center Qatar Project Detailsmohamed haniNo ratings yet

- Ancoring RebarsDocument44 pagesAncoring Rebarsrvsingh17gmailcomNo ratings yet

- Reinforcing Bar Data Tables: Sizes, Areas, WeightsDocument1 pageReinforcing Bar Data Tables: Sizes, Areas, WeightsgrbucaNo ratings yet

- Satellite Structural Design MethodsDocument26 pagesSatellite Structural Design MethodsorlandoNo ratings yet

- St-102 - Foundation Plan Part-2Document1 pageSt-102 - Foundation Plan Part-2MØhãmmed ØwięsNo ratings yet

- St-502 - Foundation SectionsDocument1 pageSt-502 - Foundation SectionsMØhãmmed ØwięsNo ratings yet

- St-03 - General Notes Sheet-2Document1 pageSt-03 - General Notes Sheet-2MØhãmmed ØwięsNo ratings yet

- St-104 - Overall Ground Floor PlanDocument1 pageSt-104 - Overall Ground Floor PlanMØhãmmed ØwięsNo ratings yet

- St-112 - Lower Roof PlanDocument1 pageSt-112 - Lower Roof PlanMØhãmmed ØwięsNo ratings yet

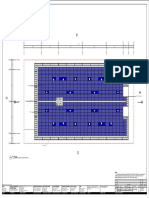

- 242 20190319 Sheet - 105 - PV Canopy PlanDocument1 page242 20190319 Sheet - 105 - PV Canopy PlanMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Table of ContentsDocument1 pageDivision 12 Furnishing - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 12494 Roller ShadesDocument5 pagesSection 12494 Roller ShadesMØhãmmed ØwięsNo ratings yet

- SGP ST RPT 0001 Rev CDocument139 pagesSGP ST RPT 0001 Rev CMØhãmmed ØwięsNo ratings yet

- Louvers and Vents SpecificationsDocument3 pagesLouvers and Vents SpecificationsMØhãmmed ØwięsNo ratings yet

- Guest Bedroom Furniture SpecsDocument5 pagesGuest Bedroom Furniture SpecsMØhãmmed ØwięsNo ratings yet

- CURTAINS AND DRAPES SPECIFICATIONSDocument4 pagesCURTAINS AND DRAPES SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsNo ratings yet

- Interior Plant SpecificationsDocument10 pagesInterior Plant SpecificationsMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Cover PageDocument1 pageDivision 12 Furnishing - Cover PageMØhãmmed ØwięsNo ratings yet

- Decorative Lamps Specification for Office Furnishing ProjectDocument3 pagesDecorative Lamps Specification for Office Furnishing ProjectMØhãmmed ØwięsNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- Interior Stone Facing SpecificationsDocument10 pagesInterior Stone Facing SpecificationsMØhãmmed ØwięsNo ratings yet

- Engineering Office Paint SpecificationDocument13 pagesEngineering Office Paint SpecificationMØhãmmed ØwięsNo ratings yet

- Section 10520 Fire Protection SpecialitiesDocument7 pagesSection 10520 Fire Protection SpecialitiesMØhãmmed ØwięsNo ratings yet

- Section 09300 TilesDocument11 pagesSection 09300 TilesMØhãmmed ØwięsNo ratings yet

- Section 10810 Toilet and Bath AccessoriesDocument7 pagesSection 10810 Toilet and Bath AccessoriesMØhãmmed ØwięsNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Section 09380 Dimension Stone TilesDocument9 pagesSection 09380 Dimension Stone TilesMØhãmmed ØwięsNo ratings yet

- WALL COVERING SPECIFICATIONSDocument4 pagesWALL COVERING SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Division 9 Finishes - Table of ContentsDocument1 pageDivision 9 Finishes - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Division9 Finishes - Cover PageDocument1 pageDivision9 Finishes - Cover PageMØhãmmed ØwięsNo ratings yet

- Architectural Building MaterialsDocument239 pagesArchitectural Building MaterialsLaurence CalpoturaNo ratings yet

- Borish 6th Sem Civil Estimate AsingmentDocument4 pagesBorish 6th Sem Civil Estimate AsingmentSawan HussainNo ratings yet

- Outline of Specs2Document10 pagesOutline of Specs2rmrv valdezNo ratings yet

- Ducting DesignDocument31 pagesDucting DesignIrwan SattuNo ratings yet

- Construction of Metro Train Depot Brick Masonry Work Inspection PlanDocument8 pagesConstruction of Metro Train Depot Brick Masonry Work Inspection PlanVipin Kumar ParasharNo ratings yet

- Construction notes and details for reinforced concrete structuresDocument14 pagesConstruction notes and details for reinforced concrete structuresBilly Joe BreakfastNo ratings yet

- Wood FrameDocument9 pagesWood FrameChristian Nathaniel Ramon PalmaNo ratings yet

- Analysis of Rates (Brick Work)Document8 pagesAnalysis of Rates (Brick Work)kyaw myo ooNo ratings yet

- Greater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeDocument12 pagesGreater London Council - 1961 - Code of Practice For Means of Escape in The.. Roof EscapeJitesh NichaniNo ratings yet

- Exposed Brickwork PDFDocument2 pagesExposed Brickwork PDFEdwardNo ratings yet

- Air System Sizing Summary For AHU-01Document29 pagesAir System Sizing Summary For AHU-01JeghiNo ratings yet

- Composite InformationDocument2 pagesComposite InformationKris Aileen CortezNo ratings yet

- Click To Find Out The Design of Cantilever Walls With: Deepex SoftwareDocument5 pagesClick To Find Out The Design of Cantilever Walls With: Deepex SoftwareRajesh KhadkaNo ratings yet

- Activity RecordDocument2 pagesActivity RecorddentuningNo ratings yet

- Strength Evaluation of Concrete Using Marble Powder and Crushed Tile Aggregates As Partial Replacement of Cement and Coarse AggregatesDocument3 pagesStrength Evaluation of Concrete Using Marble Powder and Crushed Tile Aggregates As Partial Replacement of Cement and Coarse AggregatesAndrea DeleonNo ratings yet

- Widening & Strengthening of Kathipudi - Perumallapuram Road From KM 0/000 To 14/000 in E.G.distDocument10 pagesWidening & Strengthening of Kathipudi - Perumallapuram Road From KM 0/000 To 14/000 in E.G.distPhani PitchikaNo ratings yet

- Produt Sheet Versi DrainDocument2 pagesProdut Sheet Versi DrainMuhammad Zuma Mahardhika WijayaNo ratings yet

- Time Saving Design AidsDocument86 pagesTime Saving Design AidsPurvish Joshi50% (2)

- Water Tank-Base (Flat) SlabDocument15 pagesWater Tank-Base (Flat) SlabAbhishek Gupta50% (2)

- 191008-Elmsbrook BREEAM Daylighting-Rev03Document10 pages191008-Elmsbrook BREEAM Daylighting-Rev03Neelesh RamseebaluckNo ratings yet

- Civic Center For Municipal Corporation of DelhiDocument12 pagesCivic Center For Municipal Corporation of DelhiGagan Methil100% (3)

- Structural frames and external wall requirementsDocument78 pagesStructural frames and external wall requirementsRahul RaghavNo ratings yet

- Method Statement Retaining WallDocument3 pagesMethod Statement Retaining WallPravin Pelanisamy100% (1)

- Itp - HvacDocument3 pagesItp - HvacAbdulah Asagi100% (2)

- Design of Duct For A Two Storey Retail Shop 30-1-2017Document5 pagesDesign of Duct For A Two Storey Retail Shop 30-1-2017Mir Aqueel AliNo ratings yet

- Abeysinghe, Chanaka M. Thambiratnam, David P. Perera, Nimal JDocument30 pagesAbeysinghe, Chanaka M. Thambiratnam, David P. Perera, Nimal JSäbrinä ShukrìNo ratings yet

- Issb - CollectedDocument19 pagesIssb - CollectedBrhane Gadiyon100% (1)

- Toe Wall-GantryDocument1 pageToe Wall-GantrySumant kumarNo ratings yet

- Summary of Bid Prices DPWHDocument1 pageSummary of Bid Prices DPWHInsorPiNo ratings yet

- Site Layout Rogers Drawings Final - Sheet - A107 - UnnamedDocument1 pageSite Layout Rogers Drawings Final - Sheet - A107 - Unnamedmasumba patrickNo ratings yet