Professional Documents

Culture Documents

Engineering Office Paint Specification

Uploaded by

MØhãmmed ØwięsOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Engineering Office Paint Specification

Uploaded by

MØhãmmed ØwięsCopyright:

Available Formats

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

SECTION 09910 - PAINTING

PART 1 - GENERAL

1.1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including conditions of contract and Division

1 Specification Sections, apply to this section.

1.2 SUMMARY

A. This Section includes surface preparation and field painting of exposed surfaces of the

following:

1. Walls and ceilings prepared with Portland cement plaster coats.

2. Steel or galvanized steel surfaces of metal fabrications specified to receive field finish

paining.

3. Wood surfaces specified to receive field-applied opaque finish painting.

B. Related Sections include the following:

1. Division 5 - Metal

2. Section 06400 - Architectural Woodwork

3. Section 09220 - Portland Cement Plaster

4. Section 09260 - Gypsum Board Assemblies

5. Section 09720 - Wall Coverings

6. Fixed Finishes Specification Sheets (Finishes Schedule)

1.3 REFERENCES

A. All reference to standards, regulations and requirements of statutory bodies shall mean the

latest published editions at the time of contract. Product manufacture, testing and installation

shall comply with the following references unless otherwise stated in the specification or

otherwise approved.

1. Green Building Regulations & Specifications by Dubai Municipality:

a. Chapter 4:404: Hazardous Materials – Paints & Coatings, for VOC content

2. American Society for Testing and Materials (ASTM):

a. ASTM D16: Standard Terminology for Paint , Related Coatings, Materials

and Applications

b. ASTM D2486: Standard Test methods for Scrub Resistance of Wall Paints

3. British Standards Institution (BSI):

a. BS 245: Specification for Mineral Solvents (White Spirit and Related

Hydrocarbon Solvents) for Paints and other Purposes

b. BS 381C: Colour Chart

c. BS 1336: Specification for Knotting

d. BS 4800: Schedule of Paint Colour

e. BS 7956: Specification for Primers for Woodwork

f. BS 6150: Painting of Buildings. Code of Practice

1.4 DEFINITIONS

A. General: Standard coating terms defined in ASTM D 16 apply to this Section.

1. Flat refers to a lustreless or matte finish with a gloss range below 15 when measured

at an 85-degree meter.

2. Eggshell refers to low-sheen finish with a gloss range between 20 and 35 when

measured at a 60-degree meter.

09910 PAINTING Page 1/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

3. Semi-gloss refers to medium-sheen finish with a gloss range between 35 and 70 when

measured at a 60-degree meter.

4. Full gloss refers to high-sheen finish with a gloss range more than 70 when measured

at a 60-degree meter.

1.5 SUBMITTALS

A. Product Data: For each paint system indicated. Include block fillers and primers.

1. Material List: An inclusive list of required coating materials. Indicate each material and

cross-reference specific coating, finish system, and application. Submit evidence that

paints proposed for use satisfy requirements for performance of paints as specified

hereafter. Identify each material by manufacturer’s catalogue number and general

classification.

2. Manufacturer’s Information: Manufacturer’s technical information, including label

analysis and instructions for handling, storing, and applying each coating material.

B. Samples for Initial Selection: For each type of finish-coat material indicated.

C. Samples for Verification: For each colour and material to be applied, with texture to simulate

actual conditions, on representative samples of the actual substrate.

1. Provide stepped Samples, defining each separate coat, including block fillers and

primers, Use representative colours when preparing samples for review. Resubmit until

required sheen, colour, and texture are achieved.

2. Provide a list of materials and applications for each coat of each sample. Label each

Sample for location and application.

3. Submit 3 samples on the following substrates for the Engineers review of colour and

texture only:

a. Painted Wood: 200mm square samples for each colour and material on

hardboard.

b. Stained or Natural Wood: 100 by 200mm samples of natural- or stained-wood

finish on representative surfaces.

c. Painted plaster board 300 x 300mm

D. Qualification Data, for the applicator:

1.6 QUALITY ASSURANCE

A. Quality System: Paints and Coatings must be accredited/certified from Dubai Central

Laboratories or any source approved by Dubai Municipality.

B. Furnish products and materials produced by manufacturer holding valid ISO 9001/9002

Quality System certificates.

C. Applicator Qualifications: A firm or individual experienced in applying paints and coatings

similar in material, design, and extent to those indicated for this Project, whose work has

resulted in applications with a record of successful in-service performance. Artisans: Only

skilled workmen shall be employed. A properly qualified foreman shall be constantly in

attendance on Site whilst the work is proceeding.

D. Source Limitations: Obtain primers for each coating system from the same manufacturer as

the finish coats.

E. Benchmark Samples (Mock-ups): Provide a full-coat benchmark finish sample for each type

of coating and substrate required. Comply with procedures specified in PDCA P5. Duplicate

finish of approved sample submittals.

1. After permanent lighting and other environmental services have been activated, the

Engineer will select room(s) or surface(s) to represent conditions for application of

each type of coating and substrate.

09910 PAINTING Page 2/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

a. After finishes are accepted, the Engineer will use the room or surface to

evaluate coating systems of a similar nature.

2. Final approval of colours will be from benchmark samples.

F. Manufacturers Qualifications: Paint materials shall be the products of paint and coating

manufacturers whose qualifications are as follows:

1. Manufacturers shall be reputable of multi-national scale in production and distribution

with capabilities to deliver paint materials quantities necessary for the project on due

time.

2. Manufacturers shall have evidence from scientific bodies that demonstrate their

participation and share in the development of paint industry generally and production of

new painting materials kinds.

3. Manufacturers shall have their own proprietary brand names that are well known

worldwide.

4. Manufacturers shall have minimum twenty-five (25) years of successful experience in

producing painting materials for use in prestigious projects worldwide of same standard

of quality as that intended for the Project.

5. Manufacturers shall be registered in the associations, councils, boards, federations or

other similar bodies of paint manufacturers in countries of origin and practice.

G. Performance of Paints: Paints shall be fit for purpose and manufactured specifically for the

applications indicated and uses intended, taking into account the type, nature, location, and

aesthetic and utility requirements of the Project.

1. Opacity: Paint shall cover or hide the substrate to the Engineers satisfaction.

2. Cleanability: Paint shall not absorb dirt and shall be capable of being washed or

scrubbed periodically, to the Engineer’s satisfaction, without adverse effect on its

attributes or appearance.

3. Scrub resistance wet and dry: Paint shall resist abrasion caused by scrubbing in

accordance with ASTM D 2486.

4. Adhesion: Paint shall adhere firmly to the substrate without peeling.

5. Exposure resistance: Paint shall resist yellowing.

6. Standards: Paints shall be manufactured BS 6150, to relevant US standards, or any

other international standard approved by the Engineer.

7. Colour Differentiation: The Contractor shall supply decorative colours to the references

that are scheduled or otherwise instructed by the Engineer and to conform to BS 4800

or BS 381C or other colour referencing systems only when specifically indicated on the

drawings or in the Specification.

1.7 DELIVERY, STORAGE, AND HANDLING

A. Deliver materials to Project site in manufacturers original, unopened packages and

containers bearing manufacturer’s name and label and the following information:

1. Manufacturer's name, initials or recognised trademark

2. Product name or title of material

3. Product description (generic classification or binder type)

4. Manufacturer’s stock number and date of manufacture

5. Contents by volume, for pigment and vehicle constituents

6. Thinning instructions

7. Application instructions

8. Colour name and number or RAL Colour reference (when specified alternatively)

9. VOC content

B. Containers not displaying the aforementioned information are not acceptable.

C. Store materials not in use in tightly covered containers in a well-ventilated area at a minimum

ambient temperature of 7°C (45°F). Maintain storage containers in a clean condition, free of

foreign materials and residue.

09910 PAINTING Page 3/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

1. Keep storage area neat and orderly. Remove oily rags and waste daily.

2. In stores within limits that may not cause change in viscosity of paint materials as

recommended in writing by manufacturers.

1.8 PROJECT CONDITIONS

A. Apply waterborne paints only when temperatures of surfaces to be painted and surrounding

air are between 10 and 32°C (50 and 90°F).

B. Apply solvent-thinned paints only when temperatures of surfaces to be painted and

surrounding air are between 7 and 35°C (45 and 95°F).

C. Do not apply paint in rain, fog, or mist; or when relative humidity exceeds 85 percent; or at

temperatures less than 3°C (37°F) above the dew point; or to damp or wet surfaces.

1.9 EXTRA MATERIALS

A. Furnish extra paint materials from the same production run as the materials applied and in

the quantities described below. Package with protective covering for storage and identify with

labels describing contents. Deliver extra materials to the Employer.

1. Quantity: Furnish the Employer with an additional 5 percent, but not less than 3.8 L or

1 case, as appropriate, of each material and colour applied.

PART 2 - PRODUCTS

2.1 PAINT MATERIALS, GENERAL

A. Material Compatibility: Provide block fillers, primers, and finish-coat materials that are

compatible with one another and with the substrates indicated under conditions of service

and application, as demonstrated by the manufacturer based on testing and field experience.

B. Material Quality: For each kind, type or application of paint material, provide best-quality and

highest-grade paint material in the full range of the approved manufacturer. For each paint

system specified or indicated, submit the written certification of the manufacturer attesting

that the proposed system is the highest quality system he produces for the application.

C. Provide painting materials that are factory formulated and recommended by the manufacturer

for application indicated.

D. Odour: Paints for repaired surfaces in occupied areas shall be odourless type paints such as

acrylic enamel paints.

E. Colours and Sheens: As selected by the Engineer from NCS full range, identified in Fixed

Finishes Specification Sheets (Finishes Schedule) and selected by the Engineer based on

submitted samples.

F. Date of Manufacture: At time of application, any paint material shall not be more than 4

months old from date of manufacture, unless shorter time period is stipulated by

manufacturer.

G. Preparatory Materials

1. Paint removers, abrasive papers and blocks, cleaning agents, etching solutions,

stopping, knotting, fillers and other commodities shall be of the types recommended by

the manufacturer of the coating to be applied.

2. White spirit shall comply with BS 245.

3. Knotting shall comply with BS 1336.

09910 PAINTING Page 4/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

4. Stopping and filler for woodwork shall be approved proprietary leadless, oil-based type

recommended for internal or external work as appropriate. Stopping for woodwork to

receive a clear finish shall be tinted to match with the surrounding woodwork.

5. Filler for plaster and rendering shall be an approved proprietary type.

Fillers and Putties: Types compatible with substrate and materials of priming and different

coatings of the coating system and recommended by the manufacture of the coating system

for the purpose.

H. Primer, Paints and Coatings

1. All brands of primers, paints and coatings shall be approved and shall comply with the

relevant BS where one exists.

2. Primers for plaster and rendering shall be alkali resistant.

3. Undercoats on wood and metal surfaces shall be of the drying-oil/alkyd resin binder

type pigmented with titanium dioxide and/or light fast coloured pigments.

4. Water thinned priming paints and undercoats shall only be used with the specific

approval of the Engineer and compliance with BS 7956 will need to be demonstrated in

order to obtain such approval.

5. Finish coats on wood and metal surfaces shall be of the drying-oil/alkyd resin binder

type pigmented with titanium dioxide and/or light fast, coloured pigments.

2.2 INTERIOR PRIMERS

A. Interior Portland Cement Plaster Primer: Factory-formulated latex-based primer for interior

application.

B. Interior Gypsum Board Primer: Factory-formulated latex-based primer for interior application.

C. Interior Wood Primer for Enamel Finishes: Factory-formulated alkyd or interior wood primer

compatible with specified finish coat.

D. Interior Ferrous-Metal Primer: Factory-formulated quick-drying rust-inhibitive lead-free,

polyurethane based metal primer.

E. Interior Zinc-Coated Metal Primer: Factory-formulated zinc-rich, lead-free galvanized metal

primer compatible with polyurethane-base-finish coat.

2.3 INTERIOR FINISH COATS

A. Acrylic Emulsion Paint: Emulsion paint for coating internal Portland cement plaster and

(gypsum) board surfaces shall be acrylic-copolymer based emulsion to produce a durable,

flexible and water-resistant coating suitable for repeated washing and scrubbing and of colour

retention and non-yellowing properties and high hiding and bonding to substrates abilities.

Percentage (%) of solids shall not be less than 35%. Only acrylic-copolymer shall be used in

solids (100% acrylic paint). The coating shall be of antimicrobial properties (shall not support

the growth of fungus and micro-organisms). The surface gloss shall be as indicated on

Finishes Schedule and as selected by the Engineer from samples submitted for different

available sheens. The coating system shall consist of two coats finish over one priming coat

as a minimum.

B. Polyurethane Based Paint: Provide the following finish system over steel and galvanized

steel:

1. Aliphatic Polyurethane Enamel, two pack acrylic resin based enamel cured with

aliphatic polyisocyanate applicable on steel primed with epoxy-based primers. Dry

enamel film shall exhibit excellent gloss and colour retention, durability, scratch and

abrasion resistance and chemical resistance. Comply with the following:

Binder: Acrylic/aliphatic polyisocyanate

Pigments: Rutile titanium dioxide and/or colour pigments and functional

extenders

09910 PAINTING Page 5/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

Appearance: Gloss, semi-gloss or matt as directed by the Engineer

Colour: As selected by the Engineer from manufacturer’s full range of

colours

% Solids: 51, by volume, minimum

Flash point: 21º C, maximum

Application: Airless spray, air spray or brush

Dry Film Thickness: 30 microns per coat, minimum

Thinners: As recommended by manufacturer

2.4 APPLICATION THICKNESS AND PAINT CHARACTERISTICS

A. General

1. All Paints and Coatings should not exceed the allowed limits of Volatile Organic

Compound (VOC) set by Dubai Green Building Regulations & Specifications.

Type A : Acrylic Copolymer Water based, alkali resistant Primer/sealer

PRIMER

(Internal)

Solids by Vol : 32±2%

Finish : Flat

Type B : Acrylic Copolymer Water based, high quality alkali resistant Primer/sealer

PRIMER(External)

Solids by Vol : 37±2%

Finish : Flat

Type C Putty Coat Water based, acrylic copolymer based putty/filler

(Internal)

Solids by Vol : 50±2%

Finish : Flat

Type D Emulsion Paint 100 % Acrylic based emulsion paint. Highly Washable Silk

(Internal) finish.

Solids by Vol 38±2%

VOC : 28-32 gms/l

Crack bridging ability Up to 1mm

Colour As instructed

Type E Textured High Build Acrylic copolymer based high-build texture paint.

(External)

Solids by Vol 62±2%

Finish As instructed

Type F Heat Reflective 100 % Acrylic based emulsion paint. Heat reflective

Washable Silk finish.

TOPCOAT

(External) Solids by Vol 39±2%

CO 2 Resistance R-Value 624 m

MV Resistance Sd Value 1.46 m

LW Resistance 99.9%

Colour As instructed

Finish : Silk

Type G Wood Primer (Internal Solvent based, Primer for wood

and External Woodwork)

Solids by Vol : 47±2%

Finish : Flat

09910 PAINTING Page 6/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

Type H Enamel Flat(Internal Alkyd based flat wood undercoat,

Woodwork)

Solids by Vol 47±2%

DFT/Coat 35 microns

Finish Matt

Colour As instructed

Type I Enamel Gloss (Internal Alkyd based gloss topcoat,

/External Woodwork)

Solids by Vol 38±2%

DFT/Coat 30 microns

Finish Gloss

Colour As instructed

Type J Acrylic Solvent Based Acrylic solvent based undercoat/topcoat

Paint (Internal/External) for

Road Marking

Solids by Vol 37±2%

DFT/Coat 60 microns

Colour As instructed

Type K Primer (Metal Work) Epoxy based Two Component Primer

Solids by Vol 50±2%

DFT/Coat 100 microns

Colour As instructed

Type L Undercoat (Metal Epoxy based Two component undercoat

Work)

Solids by Vol 82±2%

DFT/Coat 150 microns

Colour As instructed

Type M Topcoat (Metal Work) Epoxy based Two component Topcoat

Solids by Vol 50±2%

DFT/Coat 50 microns

Colour As instructed

Type N Topcoat (Metal Work) PU based Two component Topcoat

Solids by Vol 50±2%

DFT/Coat 50 microns

Colour As instructed

09910 PAINTING Page 7/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

2.5 COAT APPLICATIONS AND LOCATIONS

(i) Heat Reflective Pure Acrylic Surface Preparation as per Manufacturer’s

Masonry Paint recommendation

(Ref. Finishing Schedule) System:

st

1 Coat: Type-B

nd

2 Coat: Type-E

rd th

3 & 4 Coat: Type F

(ii) Acrylic Silk Emulsion Paint Surface Preparation as per Manufacturer’s

(Ref. Finishing Schedule) recommendation

(Internal) System:

st

1 Coat: Type-A

nd rd

2 & 3 Coat: Type-C

rd th

3 & 4 Coat: Type F

(iii) Woodwork Surface Preparation as per Manufacturer’s

(Internal) recommendation

System:

st

1 Coat: Type-G

nd

2 Coat: Type-E

rd th

3 & 4 Coat: Type-H or I

(iv) Timber Doors Surface Preparation as per Manufacturer’s

(Internal) recommendation

System:

st

1 Coat: Type-G

nd

2 Coat: Type-E

rd th

3 & 4 Coat: Type –H or I

(v) Timber Doors(External) Surface Preparation as per Manufacturer’s

recommendation

System:

st

1 Coat: Type-B

nd

2 Coat: Type-H

rd th

3 & 4 Coat: Type I

(vi) Pipework (Plastic) (Internal) Surface Preparation as per Manufacturer’s

recommendation

System:

st

1 Coat: Type-K

nd

2 Coat: Type-M

(vii) Pipework (Copper, steel) Surface Preparation as per Manufacturer’s

(Internal) recommendation

System:

st

1 Coat: Type-K

nd

2 Coat: Type-L

rd

3 Coat: Type M

(viii) Mild Steel, Aluminium, Metal Surface Preparation as per Manufacturer’s

Work recommendation

(Internal) System:

st

1 Coat: Type-K

nd

2 Coat: Type-L

rd

3 Coat: Type M

(ix) Mild Steel, Aluminium Metal Surface Preparation as per Manufacturer’s

Work(External) recommendation

System:

st

1 Coat: Type-K

nd

2 Coat: Type-L

rd

3 Coat: Type N

(x) Kerbstone Surface Preparation as per manufacturer’s

recommendation

System:

st nd

1 & 2 Coat: Type: Type-J

09910 PAINTING Page 8/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

PART 3 - EXECUTION

3.1 EXAMINATION

A. Examine substrates, areas, and conditions, with the Applicator present, for compliance with

requirements for paint application. Comply with procedures specified in referenced Standard

Specifications.

1. Proceed with paint application only after unsatisfactory conditions have been corrected

and surfaces receiving paint are thoroughly dry.

2. Start of painting will be construed as Applicators acceptance of surfaces and

conditions within a particular area.

B. Coordination of Work: Review other Sections in which primers are provided to ensure

compatibility of the total system for various substrates. On request, furnish information on

characteristics of finish materials to ensure use of compatible primers.

3.2 PREPARATION

A. General: Remove hardware and hardware accessories, plates, machined surfaces, lighting

fixtures, and similar items already installed that are not to be painted. If removal is impractical

or impossible because of size or weight of the item, provide surface-applied protection before

surface preparation and painting.

1. After completing painting operations in each space or area, reinstall items removed

using workers skilled in the trades involved.

2. Protection

a. Before painting, lacquering, varnishing or enamelling shall commence, every

possible precaution shall be taken to reduce dust to a minimum.

b. An ample supply of clean dustsheets to protect the work in progress shall be

available.

3. Equipment: All brushes, tools, pots, kettles, etc., used in carrying out the work shall be

clean and free from foreign matter, and shall be thoroughly cleaned out before being

used for a different type or class of material.

4. Dilution: No dilution of painting materials shall be allowed except strictly as detailed by

the manufacturer in directions to be supplied or by special permission of the Engineer.

The work shall be carried out strictly in accordance with BS 6150 and all relevant

British Standard specifications

B. Cleaning: Before applying paint or other surface treatments, clean substrates of substances

that could impair bond of the various coatings. Remove oil and grease before cleaning.

1. Schedule cleaning and painting so that dust and other contaminants from the cleaning

process will not fall on wet, newly painted surfaces.

C. Surface Preparation: Clean and prepare surfaces to be painted according to manufacturer’s

written instructions for each particular substrate condition and as specified.

1. Cementitious Materials: Remove efflorescence, chalk, dust, dirt, grease, oils, and

release agents. Roughen as required to remove glaze. If hardeners or sealers have

been used to improve curing, use mechanical methods of surface preparation.

a. Determine alkalinity and moisture content of surfaces by performing appropriate

tests. If surfaces are sufficiently alkaline to cause the finish paint to blister and

burn, correct this condition before application. Do not paint surfaces if moisture

content exceeds that permitted in manufacturer’s written instructions.

b. Apply two directional coats of approved compatible water-based PVA-based

filler or putty to obtain perfectly smooth uniform surface that is free of dents,

irregularities, cracks, holes or any surface imperfection. Slightly colour material

of second coat to distinguish coats. Apply material with putty knifes. Sand after

full setting of second coat and re-coat spots and locations that show signs of

09910 PAINTING Page 9/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

imperfection. For gypsum boards, use materials recommended by the gypsum

board manufacturer.

2. Gypsum Boards: Prepare surface as specified in Section 09260 GYPSUM BOARD

ASSEMBLIES.

3. Wood: Clean surfaces of dirt, oil, and other foreign substances with scrapers, mineral

spirits, and sandpaper, as required. Sand surfaces exposed to view smooth and dust

off.

a. Scrape and clean small, dry, seasoned knots, and apply a thin coat of white

shellac or other recommended knot sealer before applying primer. After priming,

fill holes and imperfections in finish surfaces with putty or plastic wood filler.

Sand smooth when dried.

b. Prime, stain, or seal wood to be painted immediately on delivery. Prime edges,

ends, faces, undersides, and back sides of wood, including cabinets, counters,

cases, and panelling.

c. Backprime panelling on interior partitions where masonry, plaster, or other wet

wall construction occurs on back side.

d. Seal tops, bottoms, and cut-outs of unprimed wood doors with a heavy coat of

varnish or sealer immediately on delivery.

4. Ferrous Metals: Clean ungalvanized ferrous-metal surfaces that have not been shop

coated; remove oil, grease, dirt, loose mill scale, and other foreign substances. Use

solvent or mechanical cleaning methods that comply with SSPC’s recommendations.

a. Blast steel surfaces clean as recommended by the paint system manufacturer

and according to SSPC-SP 6/NACE No. 3.

b. Treat bare and sandblasted or pickled clean metal with a metal treatment wash

coat before priming.

c. Touch up bare areas and shop-applied prime coats that have been damaged.

Wire-brush, clean with solvents recommended by the paint manufacturer, and

touch up with same primer as the shop coat.

5. Galvanized Surfaces: Clean galvanized surfaces with non-petroleum-based solvents

so that surface is free of oil and surface contaminants. Remove pre-treatment from

galvanized sheet metal fabricated from coil stock by mechanical methods.

D. Material Preparation: Mix and prepare paint materials according to manufacturer’s written

instructions,

1. Maintain containers used in mixing and applying paint in a clean condition, free of

foreign materials and residue.

2. Stir material before application to produce a mixture of uniform density. Stir as required

during application. Do not stir surface film into material. If necessary, remove surface

film and strain material before using.

3. Use only thinners approved by the paint manufacturer and only within recommended

limits.

E. Tinting: Tint each undercoat a lighter shade to simplify identification of each coat when

multiple coats of same material are applied. Tint undercoats to match the colour of the finish

coat, but provide sufficient differences in shade of undercoats to distinguish each separate

coat.

3.3 APPLICATION

A. General: Apply paint according to manufacturer’s written instructions. Use applicators and

techniques best suited for substrate and type of material being applied.

1. Paint colours, surface treatments, and finishes are indicated in the paint schedules

specified here under.

2. Do not paint over dirt, rust, scale, grease, moisture, scuffed surfaces, or conditions

detrimental to formation of a durable paint film.

3. Provide finish coats that are compatible with primers used.

4. The term ‘exposed surfaces’ includes areas visible when permanent or built-in fixtures,

grilles, convector covers, covers for finned-tube radiation, and similar components are

09910 PAINTING Page 10/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

in place. Extend coatings in these areas, as required, to maintain system integrity and

provide desired protection.

5. Paint surfaces behind movable equipment and furniture the same as similar exposed

surfaces. Before final installation of equipment, paint surfaces behind permanently

fixed equipment or furniture with prime coat only.

6. Paint interior surfaces of ducts with a flat, non-specular black paint where visible

through registers or grilles.

7. Paint back sides of access panels and removable or hinged covers with paint system

specified for galvanized steel surfaces of colour selected by the Engineer.

8. Sand lightly between each succeeding enamel or varnish coat.

B. Liquid Applied Façade Damp-proofing

Damp-proofing for surfaces of facades to receive cladding or curtain wall shall be carried out

by application of a solvent free SBS elastomeric bitumen gelified emulsion with an elongation

at break of at least 100 % elastic recover, having thixotropic performances

The cured membrane shall be waterproof but shall have a water vapour permeability of at

least .3g/m2/24H.

Damp-proofing shall be applied over clean, dry and smooth concrete or blockworks surface.

All pipes, details, anchors, etc., which have to penetrate the structure must be in place prior

to any Damp-proofing application.

Damp-proofing system shall be laid with brush or roller, in one coat at a rate of

650 g/sq.m minimum (on block work and concrete surfaces) and allowed to cure for at least

12 hours.

Before erection of cladding or curtain wall, precautions shall be taken to ensure the

membrane not to be damaged.

C. Scheduling Painting: The Contractor shall arrange his work so that subsequently inaccessible

surfaces are painted before the surfaces become inaccessible. Apply first coat to surfaces

that have been cleaned, pre-treated, or otherwise prepared for painting as soon as

practicable after preparation and before subsequent surface deterioration.

1. The number of coats and film thickness required are the same regardless of

application method. Do not apply succeeding coats until previous coat has cured as

recommended by the manufacturer. If sanding is required to produce a smooth, even

surface according to manufacturer’s written instructions, sand between applications.

2. Omit primer over metal surfaces that have been shop primed and touch-up painted.

3. If undercoats, stains, or other conditions show through final coat of paint, apply

additional coats until paint film is of uniform finish, colour, and appearance. Give

special attention to ensure that edges, corners, crevices, welds, and exposed fasteners

receive a dry film thickness equivalent to that of flat surfaces.

4. Allow sufficient time between successive coats to permit proper drying. Do not recoat

surfaces until paint has dried to where it feels firm, and does not deform or feel sticky

under moderate thumb pressure, and until application of another coat of paint does not

cause undercoat to lift or lose adhesion.

D. Application Procedures: Apply paints and coatings by brush, roller, spray, or other applicators

according to manufacturer’s written instructions.

1. Brushes: Use brushes best suited for type of material applied. Use brush of

appropriate size for surface or item being painted.

2. Rollers: Use rollers of carpet, velvet-back, or high-pile sheep’s wool as recommended

by the manufacturer for material and texture required.

3. Spray Equipment: Use airless spray equipment with orifice size as recommended by

the manufacturer for material and texture required.

09910 PAINTING Page 11/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

E. Minimum Coating Thickness: Apply paint materials no thinner than manufacturer’s

recommended spreading rate to achieve dry film thickness indicated. Provide total dry film

thickness of the entire system as recommended by the manufacturer, but do not exceed

spreading rates specified in this Section.

1. Measure wet film thickness by wet film gage.

2. Final approval of paint system shall be by measuring dry film thickness with

instruments designed specifically for that purpose.

F. Prime Coats: Before applying finish coats, apply a prime coat, as recommended by the

manufacturer, to material that is required to be painted or finished and that has not been

prime coated by others. Recoat primed and sealed surfaces where evidence of suction spots

or unsealed areas in first coat appears, to ensure a finish coat with no burn-through or other

defects due to insufficient sealing.

G. Pigmented (Opaque) Finishes: Completely cover surfaces as necessary to provide a smooth,

opaque surface of uniform finish, colour, appearance, and coverage, Cloudiness, spotting,

holidays, laps, brush marks, runs, sags, ropiness, or other surface imperfections will not be

acceptable.

H. Transparent (Clear) Finishes: Are specified in Division 6, Section Architectural Woodwork.

1. Provide satin finish for final coats.

I. Completed Work: Match approved samples for colour, texture, and coverage. Remove,

refinish, or repaint work not complying with requirements. Finishing coats shall be applied

evenly over the whole surface to give a solid film free from brush marks, sags, runs, orange

peeling or other defects.

3.4 FIELD QUALITY CONTROL

A. The Employer reserves the right to invoke the following test procedure at any time and as

often as the Employer deems necessary during the period when paint is being applied:

1. The Employer will engage the services of an independent testing agency to sample the

paint material being used. Samples of material delivered to the Project will be taken,

identified, sealed, and certified in the presence of the Contractor.

2. The testing agency will perform appropriate tests for the following characteristics as

required by the Employer:

a. Quantitative material analysis

b. Abrasion resistance

c. Apparent reflectivity

d. Flexibility

e. Washability

f. Absorption

g. Accelerated weathering

h. Dry opacity

i. Accelerated yellowness

j. Recoating

k. Skinning

l. Colour retention

m. Alkali and mildew resistance

3. The Employer may direct the Contractor to stop painting if test results show material

being used does not comply with specified requirements. The Contractor shall remove

non-complying paint from the site, pay for testing, and repaint surfaces previously

coated with the rejected paint. If necessary, the Contractor may be required to remove

rejected paint from previously painted surfaces if, on repainting with specified paint, the

2 coatings are incompatible.

09910 PAINTING Page 12/13 Rev.1 - 02 Aug 2015

ENGINEERING OFFICE

GENERAL SPECIFICATIONS DIVISION 9 - FINISHES

3.5 CLEANING

A. Clean-up: At the end of each workday, remove empty cans, rags, rubbish, and other

discarded paint materials from Project site.

1. After completing painting, clean glass and paint-spattered surfaces. Remove spattered

paint by washing and scraping without scratching or damaging adjacent finished

surfaces.

3.6 PROTECTION

A. Protect work of other trades, whether being painted or not, against damage from painting.

Correct damage by cleaning, repairing or replacing, and repainting, as approved by the

Engineer.

B. Provide ‘Wet Paint’ signs to protect newly painted finishes. After completing painting

operations, remove temporary protective wrappings provided by others to protect their work.

1. After work of other trades is complete, touch up and restore damaged or defaced

painted surfaces. Comply with procedures specified in PDCA P1.

3.7 INTERIOR PAINT SCHEDULE

A. Gypsum Board: Provide the following finish systems over interior gypsum board surfaces:

1. Interior Flat Acrylic Paint: Two finish coats over a primer.

a. Primer: Copolymer based primer, coverage 1 litre per 6m2. Roller applied

b. Finish Coats: Acrylic copolymer based emulsion paint, coverage 1 litre per 7m2.

Roller applied. Minimum two coats.

B. Plaster: Provide the following finish systems over new interior plaster surfaces:

a. Primer: Copolymer based primer, coverage 1 litre per 6 m2. Roller applied

b. Finish Coats: Acrylic copolymer based emulsion paint, coverage 1 litre per 7m2.

Roller applied. Minimum two coats.

C. Zinc-Coated Metal: Provide the following finish systems over zinc-coated metal:

1. Full-Gloss, polyurethane-based Enamel Finish: One finish coat over an enamel

undercoat and a primer.

a. Primer: Galvanized metal primer applied at spreading rate recommended by the

manufacturer to achieve a total dry film thickness of not less than 0.031mm.

b. Finish Coats: Two coats, full-gloss, polyurethane enamel applied at spreading

rate recommended by the manufacturer to achieve a total dry film thickness of

not less than 0.031mm.

D. Ferrous Metal: Provide the following finish systems over ferrous metal:

1. Full-Gloss, Polyurethane-based Enamel Finish: two finish coat over a primer.

a. Primer: Interior ferrous-metal primer at spreading rate recommended by the

manufacturer to achieve a total dry film thickness of not less than 0.031mm.

b. Finish Coat: Two coats, full-gloss, polyurethane enamel applied at spreading

rate recommended by the manufacturer to achieve a total dry film thickness of

not less than 0.031mm per coat.

END OF SECTION 09910

09910 PAINTING Page 13/13 Rev.1 - 02 Aug 2015

You might also like

- Laboratory Evaluation of Solid Wood For Resistance To TermitesDocument4 pagesLaboratory Evaluation of Solid Wood For Resistance To Termitesalejo-peña100% (1)

- Imus City Environment Background CheckDocument8 pagesImus City Environment Background CheckMac FelecioNo ratings yet

- ESTIMATE by Max Fajardo - Chapter 1 - ScannedDocument21 pagesESTIMATE by Max Fajardo - Chapter 1 - ScannedArnel AspeNo ratings yet

- Utilization of Banana Peel Powder in Concrete A ResultDocument4 pagesUtilization of Banana Peel Powder in Concrete A ResultEditor IJTSRDNo ratings yet

- Chapter 1 3 1Document34 pagesChapter 1 3 1Bai Fauziyah Marohomsalic100% (1)

- RRLDocument13 pagesRRLAngelineAlinsodNo ratings yet

- NSTP 2 Project Monitoring Report FormDocument6 pagesNSTP 2 Project Monitoring Report FormAlyssa RatificarNo ratings yet

- The Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilDocument21 pagesThe Effect of Saba Banana (Musa Acuminata X Balbisiana) Peel Ash and Lime On The Stability of Expansive SoilKimberly Joy TulinNo ratings yet

- Final Paper Chapter 1 3 5Document34 pagesFinal Paper Chapter 1 3 5Kane Sepida Sanchez100% (1)

- Review On Related LiteratureDocument2 pagesReview On Related LiteratureYem Verganio-Alterado100% (2)

- Building Tech Guide to Waterproofing and RoofingDocument20 pagesBuilding Tech Guide to Waterproofing and Roofing200211555100% (1)

- Thesis 1Document15 pagesThesis 1Adriane Kelly CagampanNo ratings yet

- Geotech Brgy SabangDocument100 pagesGeotech Brgy SabangKenneth AustriaNo ratings yet

- Stone&Masonry Final Text May 23Document31 pagesStone&Masonry Final Text May 23Myra Elisse M. AnitNo ratings yet

- 1999 National Plumbing Code PhilippinesDocument3 pages1999 National Plumbing Code PhilippinesSilverlandNo ratings yet

- Coconut Shell Concrete Strength ReviewDocument4 pagesCoconut Shell Concrete Strength ReviewUmange RanasingheNo ratings yet

- Reviewer - UAP DOC 201 - Pre Design ServicesDocument3 pagesReviewer - UAP DOC 201 - Pre Design Servicesar.ryanortigasNo ratings yet

- The Feasibility Study of Using Oyster Shells As Substitute in Manufacturing BricksDocument27 pagesThe Feasibility Study of Using Oyster Shells As Substitute in Manufacturing BricksDarla MamuyacNo ratings yet

- A Study On The Floating House For New Resilient LiDocument9 pagesA Study On The Floating House For New Resilient LigayathryNo ratings yet

- Strain ProblemsDocument4 pagesStrain ProblemsBianca GuevarraNo ratings yet

- E 1730 - 02 - Rte3mzaDocument4 pagesE 1730 - 02 - Rte3mzaEric GozzerNo ratings yet

- Sources of Potable WaterDocument5 pagesSources of Potable WaterIrene HugoNo ratings yet

- Visual Stability IndexDocument2 pagesVisual Stability IndexCristina OteroNo ratings yet

- Public Market: Redevelopment: (To Develop Again May or May Not Differently With DifferentDocument3 pagesPublic Market: Redevelopment: (To Develop Again May or May Not Differently With DifferentKristine NatividadNo ratings yet

- Analysis of Wood Bending PropertiesDocument11 pagesAnalysis of Wood Bending Propertiesprasanna020391100% (1)

- SwotDocument3 pagesSwotReynelyn Lyn Parcellano YoracNo ratings yet

- Cornstarch Concrete Paver Block StudyDocument66 pagesCornstarch Concrete Paver Block StudytheWICKEDspyNo ratings yet

- Compressive Strength of Hollow Blocks Made From Concrete Mixed With Bamboo StripsDocument11 pagesCompressive Strength of Hollow Blocks Made From Concrete Mixed With Bamboo StripsPaulineAnnLambitoUlan100% (1)

- Development of Medium Density Fiberboard Using Saccharum Spontaneum (Talahib) - An Alternative Material For Wall PartitionDocument17 pagesDevelopment of Medium Density Fiberboard Using Saccharum Spontaneum (Talahib) - An Alternative Material For Wall PartitionMabie Cyrill NalingNo ratings yet

- Effect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Document9 pagesEffect of Water-Cement Ratio On The Compressive Strength of Gravel - Crushed Over Burnt Bricks Concrete.Alexander DeckerNo ratings yet

- Eco-Bricks With Animal Manures For Covered WalkwaysDocument39 pagesEco-Bricks With Animal Manures For Covered WalkwaysJoeron Caezar Del Rosario (Joe)No ratings yet

- Building System Design CE-PC 328: Space PlanningDocument7 pagesBuilding System Design CE-PC 328: Space PlanningDonna MelgarNo ratings yet

- Chapter 2 RRLDocument4 pagesChapter 2 RRLJacklyn BarbieNo ratings yet

- Madre de Cacao Fibre As Hollow Block BinderDocument2 pagesMadre de Cacao Fibre As Hollow Block BinderJHON CLYDE SEPADANo ratings yet

- Appropriate Lighting Levels For A Specific OccupancyDocument1 pageAppropriate Lighting Levels For A Specific OccupancyPrincess Morales TyNo ratings yet

- New Era University: Gec Sts-18 Science Technology and SocietyDocument1 pageNew Era University: Gec Sts-18 Science Technology and SocietyRomelyn FranciscoNo ratings yet

- Medieval Gothic at RomanesqueDocument27 pagesMedieval Gothic at RomanesqueAaron BongonNo ratings yet

- Plastics Building Code RulesDocument3 pagesPlastics Building Code RulesThea AbelardoNo ratings yet

- Talahib Fiber Composites StudyDocument8 pagesTalahib Fiber Composites StudyKirsten IgnacioNo ratings yet

- Laboratory Evaluation of Wood and Other Cellulosic Materials For Resistance To TermitesDocument3 pagesLaboratory Evaluation of Wood and Other Cellulosic Materials For Resistance To TermitesAnvit GadkarNo ratings yet

- Soil Progress ReportDocument13 pagesSoil Progress ReportJohn Rhey Almojallas Benedicto100% (1)

- PNS 196 2000 Plywood - SpecificationDocument25 pagesPNS 196 2000 Plywood - SpecificationStandpro Testing Center100% (2)

- Batangas CityDocument26 pagesBatangas CityClarisse TingchuyNo ratings yet

- DIVISION 4 - Assignment Technical SpecificationsDocument4 pagesDIVISION 4 - Assignment Technical SpecificationsPatrisha SantosNo ratings yet

- b700 Boysen Clear Acrylic EmulsionDocument6 pagesb700 Boysen Clear Acrylic Emulsionraighnejames19No ratings yet

- May-23-2018-Thesis About Phorous AsphaltDocument136 pagesMay-23-2018-Thesis About Phorous AsphaltMohammed Al-abdullaNo ratings yet

- Tagburos FinalDocument46 pagesTagburos FinalZiedwrick Ayson DicarNo ratings yet

- A List of Poultry Farming Equipment and Their UsesDocument2 pagesA List of Poultry Farming Equipment and Their UsesCharles ApNo ratings yet

- Capiz Shell Use in Laurel HouseDocument11 pagesCapiz Shell Use in Laurel HouseKamille SepidozaNo ratings yet

- Resmear Chapter 1Document15 pagesResmear Chapter 1Aaron ZablanNo ratings yet

- HB 4944 - DWRWRC BillDocument47 pagesHB 4944 - DWRWRC Billpaomillan0423No ratings yet

- The Utilization of Plastic Wrappers in The Production of Non Load Bearing Hollow BlocksDocument130 pagesThe Utilization of Plastic Wrappers in The Production of Non Load Bearing Hollow Blocksvanessa JeanNo ratings yet

- Narrative ReportDocument6 pagesNarrative ReportKent XyrellNo ratings yet

- A Review of Hagakhak PlantDocument5 pagesA Review of Hagakhak Plantraphael0% (1)

- DRR 1st Pre-ActivityDocument15 pagesDRR 1st Pre-ActivityGanilyn PoncianoNo ratings yet

- Plastic & Synthetic Materials PDFDocument23 pagesPlastic & Synthetic Materials PDFMary Charisse SandroNo ratings yet

- 09 91 00 PDFDocument17 pages09 91 00 PDFSyed mohammed rasikNo ratings yet

- Painting Specification for Shamiya VillaDocument16 pagesPainting Specification for Shamiya VillaWagih NabihNo ratings yet

- Substrates.) (The Following Interior Substrates:)Document36 pagesSubstrates.) (The Following Interior Substrates:)Sean ChanNo ratings yet

- Caltrain paint specificationsDocument9 pagesCaltrain paint specificationsVincent DiepNo ratings yet

- St-104 - Overall Ground Floor PlanDocument1 pageSt-104 - Overall Ground Floor PlanMØhãmmed ØwięsNo ratings yet

- St-112 - Lower Roof PlanDocument1 pageSt-112 - Lower Roof PlanMØhãmmed ØwięsNo ratings yet

- SGP ST RPT 0001 Rev CDocument139 pagesSGP ST RPT 0001 Rev CMØhãmmed ØwięsNo ratings yet

- St-102 - Foundation Plan Part-2Document1 pageSt-102 - Foundation Plan Part-2MØhãmmed ØwięsNo ratings yet

- St-502 - Foundation SectionsDocument1 pageSt-502 - Foundation SectionsMØhãmmed ØwięsNo ratings yet

- St-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1Document1 pageSt-006 - Block Wall Restraint Details and Lintel Schedule Sheet-1MØhãmmed ØwięsNo ratings yet

- St-03 - General Notes Sheet-2Document1 pageSt-03 - General Notes Sheet-2MØhãmmed ØwięsNo ratings yet

- Guest Bedroom Furniture SpecsDocument5 pagesGuest Bedroom Furniture SpecsMØhãmmed ØwięsNo ratings yet

- Section 12090 UpholsteryDocument4 pagesSection 12090 UpholsteryMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Table of ContentsDocument1 pageDivision 12 Furnishing - Table of ContentsMØhãmmed ØwięsNo ratings yet

- Division 12 Furnishing - Cover PageDocument1 pageDivision 12 Furnishing - Cover PageMØhãmmed ØwięsNo ratings yet

- Interior Plant SpecificationsDocument10 pagesInterior Plant SpecificationsMØhãmmed ØwięsNo ratings yet

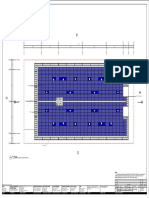

- 242 20190319 Sheet - 105 - PV Canopy PlanDocument1 page242 20190319 Sheet - 105 - PV Canopy PlanMØhãmmed ØwięsNo ratings yet

- CURTAINS AND DRAPES SPECIFICATIONSDocument4 pagesCURTAINS AND DRAPES SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 10520 Fire Protection SpecialitiesDocument7 pagesSection 10520 Fire Protection SpecialitiesMØhãmmed ØwięsNo ratings yet

- Section 12494 Roller ShadesDocument5 pagesSection 12494 Roller ShadesMØhãmmed ØwięsNo ratings yet

- Louvers and Vents SpecificationsDocument3 pagesLouvers and Vents SpecificationsMØhãmmed ØwięsNo ratings yet

- Section 10810 Toilet and Bath AccessoriesDocument7 pagesSection 10810 Toilet and Bath AccessoriesMØhãmmed ØwięsNo ratings yet

- Section 09960 Protective CoatingsDocument17 pagesSection 09960 Protective CoatingsMØhãmmed ØwięsNo ratings yet

- Decorative Lamps Specification for Office Furnishing ProjectDocument3 pagesDecorative Lamps Specification for Office Furnishing ProjectMØhãmmed ØwięsNo ratings yet

- Interior Stone Facing SpecificationsDocument10 pagesInterior Stone Facing SpecificationsMØhãmmed ØwięsNo ratings yet

- WALL COVERING SPECIFICATIONSDocument4 pagesWALL COVERING SPECIFICATIONSMØhãmmed ØwięsNo ratings yet

- Section 09380 Dimension Stone TilesDocument9 pagesSection 09380 Dimension Stone TilesMØhãmmed ØwięsNo ratings yet

- Section 09260 Gypsum Board AssembliesDocument10 pagesSection 09260 Gypsum Board AssembliesMØhãmmed ØwięsNo ratings yet

- Section 09300 TilesDocument11 pagesSection 09300 TilesMØhãmmed ØwięsNo ratings yet

- Division9 Finishes - Cover PageDocument1 pageDivision9 Finishes - Cover PageMØhãmmed ØwięsNo ratings yet

- Section 09680 CarpetDocument7 pagesSection 09680 CarpetMØhãmmed ØwięsNo ratings yet

- Section 09220 Portland Cement PlasterDocument9 pagesSection 09220 Portland Cement PlasterMØhãmmed ØwięsNo ratings yet

- Division 9 Finishes - Table of ContentsDocument1 pageDivision 9 Finishes - Table of ContentsMØhãmmed ØwięsNo ratings yet

- (Answers) 2024 - Q8 - Feb 15 +STDocument6 pages(Answers) 2024 - Q8 - Feb 15 +STThehara JayasingheNo ratings yet

- 29 Welded Joints Types and UsesDocument10 pages29 Welded Joints Types and UsesPRASAD326100% (1)

- 2020.09.24 OLV & MSV Lead Piping DiscussionDocument11 pages2020.09.24 OLV & MSV Lead Piping DiscussionAswindana Ibnu SenaNo ratings yet

- Exercise # I: Chemical BondingDocument34 pagesExercise # I: Chemical BondingIndranilNo ratings yet

- Environmental Management in The Oil, Gas and Related Energy Industries in GhanaDocument7 pagesEnvironmental Management in The Oil, Gas and Related Energy Industries in GhanaKwame D BoatengNo ratings yet

- Parofluor PTD3026 enDocument16 pagesParofluor PTD3026 enVictor Flores ResendizNo ratings yet

- Digital Profile Radiography - Practical Uses and LimitationsDocument24 pagesDigital Profile Radiography - Practical Uses and LimitationsMohan RajNo ratings yet

- CH 01Document26 pagesCH 01Sue Anne KohNo ratings yet

- COA of Sodium Ascorbyl PhosphateDocument1 pageCOA of Sodium Ascorbyl PhosphatePan EmmaNo ratings yet

- CBM 2016 1Document14 pagesCBM 2016 1SHEIKH MUHAMMAD FAHADNo ratings yet

- Msds Mepoxe MDocument5 pagesMsds Mepoxe MAhmad HidayatNo ratings yet

- 8 Engine Terms Every Marine Engineer Should Know - Part 2Document9 pages8 Engine Terms Every Marine Engineer Should Know - Part 2tomNo ratings yet

- Sample ReportDocument39 pagesSample Reportgerman esteban rodriguez baqueroNo ratings yet

- Data 568320Document1 pageData 568320Waqas AhmadNo ratings yet

- (IIT Kharagpur Research Monograph Series 6) Mitra, Rahul - Structural Intermetallics and Intermetallic Matrix Composites-CRC Press (2015)Document324 pages(IIT Kharagpur Research Monograph Series 6) Mitra, Rahul - Structural Intermetallics and Intermetallic Matrix Composites-CRC Press (2015)Joshua Amalraj100% (1)

- Physical States & Types of Food DispersionsDocument13 pagesPhysical States & Types of Food DispersionsKhaled Abu-AlruzNo ratings yet

- Natural gas pipeline capacity calculationDocument3 pagesNatural gas pipeline capacity calculationMohamed SamyNo ratings yet

- Ammonia PlantDocument10 pagesAmmonia PlantHemal Patel Sam100% (3)

- h1536731881f9789386339430 - Old PDFDocument189 pagesh1536731881f9789386339430 - Old PDFAver BatthNo ratings yet

- HTL-04 Thermal Conductivity of LiquidDocument2 pagesHTL-04 Thermal Conductivity of Liquidvindiesel9222No ratings yet

- Bronze & Brass Valves: JIS 5K/10K, ASME Class 125/150/300, KITZ Type 100/125/150/300/400/600Document52 pagesBronze & Brass Valves: JIS 5K/10K, ASME Class 125/150/300, KITZ Type 100/125/150/300/400/600roshan jaiswalNo ratings yet

- Comparative Human Salivary and Plasma Proteomes: Critical Reviews in Oral Biology & MedicineDocument8 pagesComparative Human Salivary and Plasma Proteomes: Critical Reviews in Oral Biology & MedicinerenattoNo ratings yet

- Hydrocarbon Degradation and Enzyme Activities of Aspergillus Oryzae and Mucor Irregularis Isolated From Nigerian Crude Oil-Polluted SitesDocument19 pagesHydrocarbon Degradation and Enzyme Activities of Aspergillus Oryzae and Mucor Irregularis Isolated From Nigerian Crude Oil-Polluted SitesTassioNo ratings yet

- App3Document2 pagesApp3hamidrezaee008No ratings yet

- Heat Treatment Requirement As Per ASME B31.3Document2 pagesHeat Treatment Requirement As Per ASME B31.3Siddiqui Abdul Khaliq67% (3)

- Level Management EHandbook - Chemical ProcessingDocument14 pagesLevel Management EHandbook - Chemical ProcessingAzar Deen100% (1)

- Sika Backing FillerDocument2 pagesSika Backing Fillerthepilot2No ratings yet

- Polymers: 1. Polymers 1.1 General Introduction and Its ScopeDocument7 pagesPolymers: 1. Polymers 1.1 General Introduction and Its ScopeJayvee MendozaNo ratings yet