Professional Documents

Culture Documents

SEC-VI PART-A PROJECT INFORMATION Barauni-II - 2X250 MW II-A4-0-Project Information

Uploaded by

Piyush MalviyaOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SEC-VI PART-A PROJECT INFORMATION Barauni-II - 2X250 MW II-A4-0-Project Information

Uploaded by

Piyush MalviyaCopyright:

Available Formats

CLAUSE NO.

PROJECT INFORMATION

1.00.00 BACKGROUND

Barauni Super Thermal Power Project (Coal Based) stage-II (2X250MW) is set up in

the state of Bihar, located near Barauni of Begusarai district of Bihar. The capacity of

the project in Stage-II is 500 MW comprising of 2x 250 MW units and the ultimate

capacity of the project is 720 MW (2X250 + 2X110 MW).

1.01.0 LOCATION AND APPROACH

The proposed site is located located near Barauni of Begusarai district of Bihar. It

is in between latitudes 25o 23' 36” N& longitudes 86o 1' 36” E. The site is 16.7 km

from Begusarai via National Highway (NH-31).The nearest railway station is Barauni.

The nearest airport is Patna.

1.02.00 LAND REQUIREMENT

Available land for Stage-II (2x250MW) is 336.86 Acres ( including green belt of

89.34acres.

1.03.00 WATER

The , total water commitment of 45 cusec for Barauni TPS (Stage-I & II) has been

allocated from River Ganga which includes 20 cusec for Stage-I and 25 cusec for

Stage-II. With Ganga Water supply for Barauni TPS, the existing bore wells water

supply for Stage-I will be replaced.

To meet the water requirement for Barauni TPS for both Stage-I & II, “Ganga Water

Supply Package” was awarded to M/s McNally Bharat in July 2012 at a cost of Rs.

115.59 Crores (With Rs. 31.70 Crores for Supply and Rs. 83.89 Crores execution),

which includes Intake Well Pump house, approach jetty, desilting arrangement,

Makeup Water Pump house, Raw Water Pipes, 4 Km Makeup Water Pipelines

(2x600 dia MS Pipes for Stage-I & 2x650 dia MS Pipes for Stage-II), 33kV

Switchyard and 33kV Transmission line common for Stage-I & II and PT Plant,

Clarified Water Make-up System, CW Chemical Treatment System, Potable

(Drinking water) & Filter Water for DM Plant Make-up system for Stage-I.

To meet the Stage-II water requirement a contingency pumping arrangement for

water supply from River Ganga to one unit of Stage-II by installing 4 pumps (100 HP

each) for total discharge of 1200 cubic meter/hr (4x300 cubic meter/hr) is now

provided. However, a few more additional pumps to be installed to meet the

complete Stage-II requirement.

CW blow down Water is proposed to be used for meeting the complete process

water requirement of the FGD plant.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 1 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

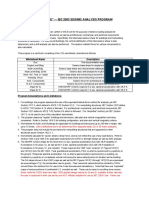

1.04.00 Coal Quality Parameters / Fuel Oil Characteristics & Plant Water details:

(i) The Coal quality parameters and Fuel Oil characteristics are indicated in Table-1

& Table-2 respectively below.

(ii) Process water:

Process water quality is CW Blowdown based on the COC indicated in Table-4.

(iii) Clarified water:

Clarified water quality is indicated in Table-4.

(iv) DM water for Equipment cooling water system.

DM water quality is indicated in Table-5.

1.05.00 Steam Generator and ESP data: refer Table-6.

2.00.00 Revised Meterological Data for Barauni

3.00.00 DETAILS OF STAGE & UNITS

Stage Stage Capacity Date of

commissioning

II 2x250 MW Under Erection &

commissioning

4.00.00 Metrological Data

The metrological data from nearest observatory is placed at Annexure-II.

5.00.00 CRITERIA FOR EARTHQUAKE RESISTANT DESIGN OF STRUCTURES AND

EQUIPMENT

All structures and equipment shall be designed for seismic forces adopting the

design parameters provided in this document and using the provisions in accordance

with IS:1893 (Part 1 to Part 4). Pending finalization of Part 5 of IS:1893, provisions of

part 1 shall be read along with the relevant clauses of IS:1893:1984, for

embankments.

The peak ground horizontal acceleration for the project site, the acceleration spectral

coefficients (in units of gravity acceleration ‘g’) in the horizontal direction for the

various damping values and the multiplying factor (to be used over the spectral

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 2 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

coefficients) for evaluating the design acceleration spectra are as given at Annexure-

I.

Vertical acceleration spectral values shall be taken as 2/3rd of the corresponding

horizontal values.

The design acceleration spectra specified at Annexure-I shall be used in place of the

response acceleration spectra, given at figure-2 in IS:1893 (Part 1) and Annex B of

IS:1893 (Part 4) is used. The acceleration spectra along with multiplying factors

specified in Annexure-I includes the effect of the seismic environment of the site, the

importance factor related to the structures and the response reduction factor.

Hence, the design spectra do not require any further consideration of the zone factor

(Z), the importance factor (I) and response reduction factor (R) as used in the

IS:1893 (Part 1 and Part 4).

Damping in Structures

The damping factor (as a percentage of critical damping) to be adopted shall not be

more than as indicated below for:

a) Steel structures : 2%

b) Reinforced Concrete structures : 5%

c) Reinforced Concrete Stacks : 3%

d) Steel stacks : 2%

Method of Analysis

Since most structures in a power plant are irregular in shape and have irregular

distribution of mass and stiffness, dynamic analysis for obtaining the design seismic

forces shall be carried out using the response spectrum method. The number of

vibration modes used in the analysis should be such that the sum total of modal

masses of all modes considered is at least 90 percent of the total seismic mass and

shall also meet requirements of IS:1893 (Part 1). Modal combination of the peak

response quantities shall be performed as per Complete Quadratic Combination

(CQC) method or by an acceptable alternative as per IS:1893 (Part 1).

In general, seismic analysis shall be performed for the three orthogonal (two

principal horizontal and one vertical) components of earthquake motion. The seismic

response from the three components shall be combined as specified in IS:1893 (Part

1).

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 3 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

The spectral acceleration coefficient shall get restricted to the peak spectral value if

the fundamental natural period of the structure falls to the left of the peak in the

spectral acceleration curve.

For buildings, if the design base shear (VB) obtained from modal combination is less

than the base shear (VB) computed using the approximate fundamental period (Ta)

given in IS:1893:Part 1 and using acceleration spectral coefficients with appropriate

multiplying factor, the response quantities (e.g. member forces, displacements,

storey forces, storey shears and base reactions) shall be enhanced in the ratio of

VB/ VB. However, no reduction is permitted if VB is less than VB.

Design/Detailing for Ductility for Structures

The design acceleration spectra is a reduced spectra and has an in-built allowance

for ductility. Structures shall be engineered and detailed in accordance with relevant

Indian/International standards to achieve ductility.

ANNEXURE – I

SEISMIC PARAMETERS FOR DESIGN OF STRUCTURES AND EQUIPMENT

The various seismic parameters for the project site shall be as follows:

1) Peak ground horizontal acceleration (MCE) : 0.24g

2) Multiplying factor to be applied to the horizontal acceleration

spectral coefficients (in units of gravity acceleration ‘g’) to

obtain the design acceleration spectra

a) for special moment resisting steel frames designed and

detailed as per IS:800 : 0.06

b) for special concentrically braced steel frames designed and : 0.045

detailed as per IS:800

c) for special moment resisting RC frames designed and

detailed as per IS:456 and IS:13920 : 0.036

d) for RCC chimney, RCC Natural Draft Cooling Tower : 0.12

e) For Liquid retaining tanks : 0.072

f) for Steel chimney, Absorber tower, Vessels : 0.09

g) for design of structures not covered under 2 (a) to 2 (f)

above and under 3 below, in general (excluding special : 0.06

structure/ configuration/materials)

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 4 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

3) Multiplying factor to be applied to the horizontal acceleration

spectral coefficients (in units of gravity acceleration ‘g’) for

design of equipment and structures where inelastic action is

not relevant or not permitted : 0.12

Note: g = Acceleration due to gravity

The horizontal seismic acceleration spectral coefficients are furnished in subsequent

pages.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 5 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

ANNEXURE – I

HORIZONTAL SEISMIC ACCELERATION SPECTRAL

COEFFICIENTS

(In units of ‘g’)

Damping Factor (as a percentage of critical damping)

Time Period

(Sec) 2% 5%

0.000 1.000 1.000

0.020 1.500 1.300

0.040 2.000 1.600

0.060 2.500 1.900

0.080 3.000 2.200

0.090 3.250 2.350

0.100 3.500 2.500

0.120 3.500 2.500

0.140 3.500 2.500

0.160 3.500 2.500

0.180 3.500 2.500

0.200 3.500 2.500

0.220 3.500 2.500

0.240 3.500 2.500

0.260 3.500 2.500

0.280 3.500 2.500

0.300 3.500 2.500

0.320 3.500 2.500

0.340 3.500 2.500

0.360 3.500 2.500

0.380 3.500 2.500

0.400 3.500 2.500

0.420 3.500 2.500

0.440 3.500 2.500

0.460 3.500 2.500

0.480 3.500 2.500

0.500 3.500 2.500

0.520 3.500 2.500

0.540 3.500 2.500

0.550 3.500 2.500

0.560 3.400 2.429

0.580 3.283 2.345

0.600 3.173 2.267

0.620 3.071 2.194

0.640 2.975 2.125

0.660 2.885 2.061

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 6 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

ANNEXURE – I

HORIZONTAL SEISMIC ACCELERATION SPECTRAL

COEFFICIENTS

(In units of ‘g’)

Damping Factor (as a percentage of critical damping)

Time Period

(Sec) 2% 5%

0.670 2.842 2.030

0.680 2.800 2.000

0.700 2.720 1.943

0.720 2.644 1.889

0.740 2.573 1.838

0.760 2.505 1.789

0.780 2.441 1.744

0.800 2.380 1.700

0.820 2.322 1.659

0.840 2.267 1.619

0.860 2.214 1.581

0.880 2.164 1.545

0.900 2.116 1.511

0.920 2.070 1.478

0.940 2.026 1.447

0.960 1.983 1.417

0.980 1.943 1.388

1.000 1.904 1.360

1.020 1.867 1.333

1.040 1.831 1.308

1.060 1.796 1.283

1.080 1.763 1.259

1.100 1.731 1.236

1.120 1.700 1.214

1.140 1.670 1.193

1.160 1.641 1.172

1.180 1.614 1.153

1.200 1.587 1.133

1.220 1.561 1.115

1.240 1.535 1.097

1.260 1.511 1.079

1.280 1.488 1.063

1.300 1.465 1.046

1.320 1.442 1.030

1.340 1.421 1.015

1.360 1.400 1.000

1.380 1.380 0.986

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 7 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

ANNEXURE – I

HORIZONTAL SEISMIC ACCELERATION SPECTRAL

COEFFICIENTS

(In units of ‘g’)

Damping Factor (as a percentage of critical damping)

Time Period

(Sec) 2% 5%

1.400 1.360 0.971

1.420 1.341 0.958

1.440 1.322 0.944

1.460 1.304 0.932

1.480 1.286 0.919

1.500 1.269 0.907

1.520 1.253 0.895

1.540 1.236 0.883

1.560 1.221 0.872

1.580 1.205 0.861

1.600 1.190 0.850

1.620 1.175 0.840

1.640 1.161 0.829

1.660 1.147 0.819

1.680 1.133 0.810

1.700 1.120 0.800

1.720 1.107 0.791

1.740 1.094 0.782

1.760 1.082 0.773

1.780 1.070 0.764

1.800 1.058 0.756

1.820 1.046 0.747

1.840 1.035 0.739

1.860 1.024 0.731

1.880 1.013 0.723

1.900 1.002 0.716

1.920 0.992 0.708

1.940 0.981 0.701

1.960 0.971 0.694

1.980 0.962 0.687

2.000 0.952 0.680

2.020 0.943 0.673

2.040 0.933 0.667

2.060 0.924 0.660

2.080 0.915 0.654

2.100 0.907 0.648

2.150 0.886 0.633

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 8 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

ANNEXURE – I

HORIZONTAL SEISMIC ACCELERATION SPECTRAL

COEFFICIENTS

(In units of ‘g’)

Damping Factor (as a percentage of critical damping)

Time Period

(Sec) 2% 5%

2.200 0.865 0.618

2.250 0.846 0.604

2.300 0.828 0.591

2.350 0.810 0.579

2.400 0.793 0.567

2.450 0.777 0.555

2.500 0.762 0.544

2.550 0.747 0.533

2.600 0.732 0.523

2.650 0.718 0.513

2.700 0.705 0.504

2.750 0.692 0.495

2.800 0.680 0.486

2.850 0.668 0.477

2.900 0.657 0.469

2.950 0.645 0.461

3.000 0.635 0.453

6.00.00 Criteria for Wind Resistant Design of Structures and Equipment

All structures shall be designed for wind forces in accordance with IS:875 (Part-3)

and as specified in this document. See Appendix – B for site specific information.

Along wind forces shall generally be computed by the Peak (i.e. 3 second gust) Wind

Speed method as defined in the standard.

Along wind forces on slender and wind sensitive structures and structural elements

shall also be computed, for dynamic effects, using the Gust Factor or Gust

Effectiveness Factor Method as defined in the standard. The structures shall be

designed for the higher of the forces obtained from Gust Factor method and the

Peak Wind Speed method.

Analysis for dynamic effects of wind must be undertaken for any structure which has

a height to minimum lateral dimension ratio greater than “5” and/or if the fundamental

frequency of the structure is less than 1 Hz.

Susceptibility of structures to across-wind forces, galloping, flutter, ovalling etc.

should be examined and designed/detailed accordingly following the

recommendations of IS:875(Part-3) and other relevant Indian standards.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 9 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

It should be estimated if size and relative position of other structures are likely to

enhance the wind loading on the structure under consideration. Enhancement factor,

if necessary, shall suitably be estimated and applied to the wind loading to account

for the interference effects.

Damping in Structures

The damping factor (as a percentage of critical damping) to be adopted shall not be

more than as indicated below for:

a) Welded steel structures : 1.0%

b) Bolted steel structures : 2.0%

c) Reinforced concrete structures : 1.6%

d) Steel stacks : As per IS:6533 & CICIND

Model Code whichever is more

critical.

APPENDIX – B

SITE SPECIFIC DESIGN PARAMETERS

The various design parameters, as defined in IS: 875 (Part-3), to be adopted for the

project site shall be as follows:

a) The basic wind speed “Vb” at ten

metres above the mean ground level : 47 metres/second

b) The risk coefficient “K1” : 1.07

c) Category of terrain : Category-2

Note: Notwithstanding the values of the above mentioned parameters, the design

wind pressure so computed at any point shall not be taken less than 1500

N/Sq. metre for all classes of structures, i.e. A, B & C, as defined in IS: 875

(Part-3).

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 10 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

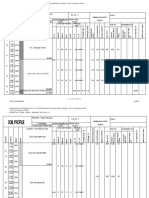

7.00.0 FOUNDATION SYSTEM AND GEOTECHNICAL DATA

7.00.01 Geotechnical data and foundation system for the FGD package at Barauni St-

II(U#8&9) site project are enclosed at annexure-I. The corresponding bore logs of

vicinity are enclosed at annexure-II.

7.00.02 Available geotech data is of vicinity of proposed structures, therefore, bidder shall

carryout his own detailed geotech investigation for facilities under this package and

shall be as per the scheme approved by owner. The scheme for geotechnical

investigation shall be as given at Clause 7.07.00 and shall be approved by owner

before execution. Geotechnical investigation work shall got executed by the

Contractor through the agencies as mentioned in Clause No. 7.06.03. However, no

time extension shall be given on account of soil investigation carried out by the

Bidder. The geotechnical investigation report shall be prepared with detailed

recommendations regarding type of foundation and allowable bearing pressure for

various structures/ facilities and other soil parameters. The report shall be submitted

for Owner’s approval prior to commencement of design of foundation.

In case, bidder feels that the available data is inadequate, he may carry out his

own geotechnical investigation before bidding.

Based upon the available soil data, soil/filled-up ash up to a depth of 13.5m

(below existing ground level) is prone to liquefaction hazard. Ground

improvement shall be carried out upto 8 m (min). For heavily loaded structures

(Silos, chimney, Crusher house, absorber and other structures), pile

foundations (with ground improvement as per clause 7.02.04) may be

considered and for lightly loaded structures including roads and drains,

ground improvement as per clause 7.02.04 may be considered.

Minimum cut off level of pile below FGL is 3m.

7.00.03 The furnished borelog details are specific to the co-ordinates where the

boreholes have been carried out and are provided for bidder’s information

only. Soil profile in the proposed area may vary with respect to the borelogs

enclosed for bidder’s information. Bidder has to consider all such variations

in his estimation, over the extent of the work to be carried out. The Bidder

should note that nothing extra whatsoever on account of variation between

soil data collected by Owner and that found by the Bidder during geotechnical

investigation by him or during execution of works, shall be Payable.

7.00.04 Tank Foundations

a) The tanks shall rest on flexible tank pad foundation, resting on sand with

concrete ring wall to retain sand. Base of the concrete ring wall shall not rest

on the expansive soil, if any.

b) Entire loose/ soft soil inside the concrete ring wall shall be removed and shall

be filled with sand. Sand for filling shall be clean and well graded conforming

to IS 383 with grading Zone I to III.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 11 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

c) Sand shall be spread in layers not exceeding 30cm compacted thickness

over the area. Each layer shall be uniformly compacted by mechanical

means like plate vibrators, small vibratory rollers, etc to achieve a relative

density of not less than 80%.

d) Other requirements of tank foundations shall be as per IS 803 and as

specified elsewhere in the specifications.

7.02.00 Foundation System

The requirements for the foundation system to be adopted are as given in

subsequent clauses. Depending upon the depth of competent strata/stratum, type of

structures, functional requirement of facility, extent of cutting / filling, suitable

foundation, open or pile shall be adopted with approval of owner.

7.02.01 General Requirements

a) All structures/equipment shall be supported either on suitable open

foundations with ground improvement (isolated, combined, raft) or pile

foundations depending on type of structures/facilities, sub-strata, topography

etc.

b) The roads, ground floor slabs, trenches, pipe pedestals, channels/drains and

staircase foundation with foundation loading intensity less than 4 T / M2 may

be supported on open / shallow foundations resting on virgin / controlled

compacted filled up soil. For ground improvement below roads, drains and

pipe pedestals, refer respective clause.

c) No other foundation (other than as mentioned in (b) above and (j) below)

shall rest on the filled up ground / soil.

d) No foundation shall rest on the black cotton soil.

e) Before execution of work the bidder shall ensure that there is no obstruction

to underground/overground facilities like sewer lines, pipe lines etc. Any such

damage and remedial/ rectification measures shall be at the contractors cost.

For underground facilities survey, Ground Penetration Radar (GPR)

may be used.

f) Bidder shall also ensure that there is no damage to existing nearby

foundations and the foundations pertaining to this package are not placed at

shallower depth than the nearby foundations. If required depth of foundation

is deeper than the existing foundations, proper protection shall be provided to

existing foundations.

g) All foundations shall be designed in accordance with relevant parts of the

latest revisions of Indian Standards.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 12 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

h) The water table for design purpose shall be considered at Finished Ground

Level.

i) A combination of open and pile foundations shall not be permitted under the

same equipment / structure / building.

j) Foundation for miscellaneous equipment’s on ground floor.

For equipments of static weight upto 1.5 T, the equipment may be supported

on the ground floor slab by locally thickening the slab. Thickening of the

ground floor slab shall be done upto an extent of about 0.6 m beyond the plan

area of the equipment on all the sides. Further, the load intensity below the

equipment shall be limited to 4T/m2. Other requirements of floor slab and

compaction below the floor slab shall be adhered, as specified elsewhere in

the specifications.

For equipment’s of static weight between 1.5 T and 20 T, the equipment may

be supported on compacted sand filling with the load intensity below the

equipment limited to 4T/m2. The minimum depth of foundation is 1.0m below

FFL. Other requirements of sand compaction below the foundation shall be

adhered, as specified elsewhere in the specifications.

For equipment of static weight more than 20 T, the equipment foundation shall

be taken to the founding level or shall be built up with PCC from the level as

mentioned in the Table 2. The pedestal of equipment foundation or the

foundation Block shall be isolated from the adjoining floor slab by providing

bitumen impregnated fiber board of minimum 50 mm thick, conforming to IS:

1838 all around the equipment pedestal for the full depth of the floor slab.

7.02.02 Open Foundations

In case open foundations are adopted, following shall be adhered to.

a) The minimum width of foundation shall be 1.0 m.

b) Minimum depth of foundation shall be 1.0m below Ground Level.

c) It shall be ensured that all foundations of a particular structure/ buildings/

facility shall rest on one bearing stratum.

d) Wherever the intended bearing sub-strata is virgin soil stratum but the actual

stratum encountered during foundation excavation consists of filled up soil at

founding level, under such cases either the foundation shall be lowered

completely into the virgin stratum or the filled up soil upto the virgin layers

shall be removed and built up through PCC (1:4:8) up to designed foundation

level.

7.02.03 Pile Foundations –

Following structures are to be placed on pile foundation:

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 13 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Heavily loaded structures like Silos, Chimney, Crusher house, absorber and

other structures.

In case piles are adopted, following shall be adhered to :

i) The pile foundation shall be of RCC, Cast-in-situ bored piles as per

IS:2911. Pile boring shall be done using Self erecting Crawler

mounted Rotary Hydraulic Rigs. However, conventional tripod rig may

be allowed in inaccessible areas subject to site specific conditions.

Two stage flushing of pile bore shall be ensured by airlift technique

duly approved by the Employer.

Based upon the geotechnical investigation report, filled-up fly ash

followed by fine sand is met upto 13.5m depth. In view of this,

temporary/permanent MS liner may be provided for piling.

ii) The allowable load capacity of the pile in different modes (vertical

compression, lateral and pullout) shall be as per approved

geotechnical report & as enclosed in annexure-I.

iii) Only straight shaft piles shall be used. Minimum cast length of pile

above cutoff level shall be 1.0 m.

iv) The contractor shall furnish design of piles (in terms of rated capacity,

length, diameter, termination criteria to locate the founding level for

construction of pile in terms of measurable parameter, reinforcement

for job as well as test piles, pile load test arrangement, locations of

initial test piles etc.) for Engineer’s approval.

v) The piling work shall be carried out in accordance with IS:2911

(Relevant part) and accepted construction methodology. The

construction methodology shall be submitted by the Contractor for

Engineer's approval.

vi) Number of initial load tests to be performed for each diameter and

rated capacity of pile shall be subject to minimum as under.

Vertical

Lateral Minimum of 2 Nos. in each mode.

Uplift

vii) The initial pile load test shall be conducted with test load three times

the pile capacity as mentioned at Annexure-I. In case of vertical

compression test (initial test) the method of loading shall be cyclic as

per IS:2911 (relevant part).

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 14 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

viii) Load test shall be conducted at pile Cut-off Level (COL). If the water

table is above the COL the test pit shall be kept dry throughout the

test period by suitable dewatering methods. Alternatively the vertical

load test may be conducted at a level higher than COL. In such a

case, an annular space shall be created to remove the effect of skin

friction above COL by providing an outer casing of suitable diameter

larger than the pile diameter.

ix) Number of routine pile load tests to be performed for each

diameter/allowable capacity of pile shall be as under :

i) Vertical : 0.5% of the total number of piles provided.

ii) Lateral : 0.5% of the total number of piles provided.

x) The routine tests on piles shall be conducted upto test load of one and

half times the allowable pile capacity. Piles for routine load tests shall

be approved by the Employer.

xi) In case, routine pile load test shows that the pile has not achieved the

desired capacity or pile(s) have been rejected due to any other

reason, then the Contractor shall install additional pile(s) as required

and the pile cap design shall accordingly be reviewed and modified, if

required.

xii) Testing of piles and interpretation of pile load test results shall be

carried out as per IS:2911 (Part-4). Contractor shall ensure that all the

measuring equipment and instruments are properly calibrated at a

reputed laboratory / institute prior to their use. Settlement / movement

of the pile top shall be made by Linear Variable Differential

Transducers (LVDT) having a least count of 0.01mm.

xiii) The test load on initial test piles shall be applied by means of reaction

from reaction piles alone or combination of reaction piles and

kentledge with concrete blocks.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 15 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

xiv) Low Strain Pile Integrity test shall be conducted on all test piles and

job piles. This test shall be used to identify the routine load test and

not intended to replace the use of static load test. This test is limited

to assess the imperfection of the pile shaft and shall be undertaken by

an independent specialist agency to be approved by Engineering

department of Owner. The test equipment shall be of TNO or PDI

make or equivalent. The process shall confirm to ASTM.

xv) Routine pile load tests to be performed on 0.5% of the total number of

piles provided for each diameter/allowable capacity. High Strain

dynamic load test may be carried out for routine load testing of

working piles. However, at least two numbers of static routine vertical

load tests shall be carried out on pile on which high strain dynamic

load test has already been carried out for establishing the correlation

between the two tests. In case of discrepancy if any between dynamic

and static vertical load tests, then additional static routine vertical load

tests shall be conducted as decided by the Engineer and the results of

static routine vertical load shall prevail. Number of routine vertical pile

load tests as per clause 7.02.03 (ix) shall be total of static routine

vertical load test and high strain dynamic load tests.

In case agency wish to carry out only static routine vertical load test on

0.5% of total number of piles, he may adopt the same.

The procedure to carry out the test shall be submitted to the Engineer.

The test and equipment shall conform to ASTM D4945-00. The test

shall be conducted by an experienced independent test agency

approved by the owner. Field data shall be submitted to the site

engineer and shall include force velocity curves, pile capacity,

simulated static load test curve, net and total pile displacement, pile

integrity. A (Case pile wave analysis) CAPWAP or equivalent software

analysis shall be conducted on the field data for correct capacity

estimation and to evaluate end bearing and skin friction components

of the pile.

xvi) From load considerations, single pile may be used under a

column/tower. In that case, pile shall be connected with tie beams at

pile cut off level in both directions.

xvii) Contribution of frictional resistance of filled up soil if any, shall not be

considered for computation of frictional resistance of piles.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 16 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

xviii) Reinforcement for job piles shall be designed as following:

(a) Compression + bending piles: For these piles, the allowable

safe pile capacities in compression and bending shall be

considered.

(b) Tension + bending piles: For these piles, the actual pile forces

to be considered. However, maximum 3 types of combinations

for varying percentage of tension capacity + bending case may

be designed & adopted by contractor for the entire scope of

work under this package.

7.02.04 Ground Improvement below structures/facilities using stone columns:

i) The work broadly involves installation of stone columns for mitigation of

liquefaction hazard, improvement in bearing capacity of the soil and to bring

down the residual settlements so that the facilities that may be constructed

over the stone column area shall stand safely and perform satisfactorily

throughout their lifetime.

The stone columns shall be installed using bottom/top feed Vibroflotation

techniques without water jetting i.e. dry method (displacement method) in

accordance with these specifications. Installation of stone column by

rammed/driven technique without water jetting may also be permitted/used

subject to conforming to the specification and meeting to the construction

schedule.

In case of vibro replacement method, the bidder shall submit the construction

methodology giving information regarding details of equipment, type and

energy rating of vibratory probe, details of power output, compaction criteria

etc.

In case of rammed stone column methodology, the bidder shall submit the

construction methodology giving information regarding type of equipment,

weight of rammer, height of fall, compaction criteria, stages of casing

withdrawal etc. Use of bentonite slurry for formation of stone columns shall not

be permitted. A casing pipe shall be provided by the bidder upto to full depth of

stone column.

In either of the above techniques adopted, the parameters shall be so chosen

to give stone column of specified diameter and load carrying capacity.

In either of the above techniques adopted, the quantity of stones shall be

placed in such that the column is filled in stages of height not exceeding 1m.

Each stage shall be compacted to ensure uniform consumption of stones

throughout the depth.

The method of placement of stone shall be such that it is possible to measure

the total consumption of stones in a column.

Stone column installation procedure submitted by the bidder shall be approved

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 17 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

by the Engineer.

ii) All materials and workmanship shall be in accordance with this specification and

IS: 15284: Part 1: 2003.“Design and Construction for Ground Improvement –

Guidelines, Part 1 Stone Columns”.

iii) Case:1 Ground improvement without piling provision after it

Dia of column (d) = 900mm

Spacing = 2.5d to 3d (Triangular pattern)

Depth of ground improvement (d) = 8m to 13.5m

Depth of stone column shall be finalized based upon geotechnical

investigation report.

Case:2 Ground improvement with piling provision after it

Dia of column (d) =600mm/760mm

Spacing = 2.5d to 3d (Triangular pattern)

Depth of ground improvement (d) = 8m to 13.5m

Depth of stone column shall be finalized based upon geotechnical

investigation report.

iv) Ground improvement with stone column shall be carried out minimum d/2

distance beyond the footprint of buildings (minimum 2 rows beyond the building

footprint), where d is the depth of improvement. The ground improvement shall be

carried out below the entire building/structure rather than restricting it to just below

the foundations.

v) Initial load tests shall be performed at the trial site as identified by Engineer to

evaluate load settlement behaviour of the stone columns. These tests shall be

conducted on a single as well as on a group of three columns. Load testing

procedure, equipment and interpretation shall confirm to IS 15284 (Part-I).

vi) Fill material for stone columns shall comprise of stones. The individual particles

should be clean, chemically inert, hard and resistant to breakage. Well graded

stones of size from 75mm down to 12mm with not more than 5% fines passing

12mm sieve shall be used. The uniformity coefficient shall be greater than 5.

vii) Boreholes shall be drilled prior and after the installation of stone columns and

frequency shall be minimum 1 borehole under each structure/facility or 2000 Sqm

whichever is less. The performance of the stone column(s) shall be considered

acceptable and approved by the Engineer based on the SPT ‘N’ values of the

improved ground.

The installation of stone column is considered acceptable if it achieved SPT ‘N’

value more than 15 and 25 for depth less than 5m and more than 10m respectively

below ground level. For values of depth between 5m and 10m, linear interpolation

shall be done. The minimum load intensity after ground improvement shall be as

mentioned in table-2 in Annexure-I.

Ground Improvement below roads, drains and pipe pedestals using stone

columns:

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 18 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Minimum 1000mm thick compacted moorum/Non-Expansive Soil shall be provided

replacing existing ash/soil below and 1000mm from the outer edges of the roads &

drains.

7.03.00 Special Requirements

7.03.01 Details of treatment for foundations / underground structures required to counteract

soil / water chemical environment shall be as per detailed geotechnical investigation

to be carried out by contractor. Contractor shall carry out chemical analysis during

detailed geotechnical investigation and required treatment shall be provided

accordingly.

7.04.00 Excavation, Filling and Dewatering

7.04.01 For excavation works, comprehensive dewatering with well point or deep wells

arrangement, if required, shall be adopted. Scheme for dewatering and design with

all computations and back up data for dewatering shall be submitted for the owner’s

information. The water table shall be maintained at 0.5m below the founding depth.

7.04.02 Excavation for shallow foundations shall be covered with PCC immediately after

reaching the founding level. In case of any local loosening of soil or any loose

pockets are encountered at founding level during excavation the same shall be

removed and compensated by PCC M7.5. The final layer of about 300 mm

thickness above the founding level shall be excavated by suitable means, so as to

avoid disturbance to founding stratum.

7.04.03 Backfilling around foundations, pipes, trenches, sumps, pits, plinths, etc. shall be

carried out with approved material in layers not exceeding 300 mm compacted

thickness (higher thickness of layers upto 500mm with heavy mechanical

compacting equipment) and each layer shall be compacted to 90% of standard

proctor density for cohesive soils and to 80% of relative density for non-cohesive

soils

7.04.04 Founding level for trenches/channels shall be decided as per functional requirement.

The bottom of excavation shall be properly compacted prior to casting of bottom slab

of trenches / channels.

7.04.05 CBR tests for pavement/road design shall be carried out by the Contractor after

earth filling (if applicable) has been completed upto the formation level.

7.04.06 The contractor shall take all necessary measures during excavation to prevent

the hazards of falling or sliding of material or article from any bank or side of

such excavation which is more than one and a half meter above the footing by

providing adequate sheet piling, shoring, bracing etc. against such bank or

sides.

Adequate and suitable warning signs shall be put up at conspicuous places at the

excavation work to prevent any persons or vehicles falling into the excavation trench.

No worker should be allowed to work where he may be stuck or endangered by

excavation machinery or collapse of excavations or trenches.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 19 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

7.05.00 Sheeting & Shoring

The contractor shall ascertain for himself the nature of materials to be excavated

and difficulties, if any, likely to be encountered in excavation while executing the

work. Sheet piling, sheeting and shoring, bracing and maintaining suitable slopes,

drainage, etc. shall be provided and installed by the Contractor, to the satisfaction of

the Engineer.

7.06.00 Geotechnical Investigation

The Contractor shall carry out detailed geotechnical investigation in the areas under

his scope for establishing the sub-surface conditions and to decide type of

foundations for the structures envisaged, construction methods, any special

requirements/treatment called for remedial measures for sub-soil/ foundations etc. in

view of soft sub-soils, aggressive sub-soils and water, expansive/swelling soils etc.

prior to commencement of detailed design/drawings. The Contractor shall obtain the

approval for the field testing scheme proposed by him from the Owner before

undertaking the geotechnical investigation work.

7.06.01.00 Scheme of geotechnical Investigation

7.06.02.01 Field test shall include but not be limited to the following:

Boreholes, Standard Penetration Test (SPT), Dynamic Cone Penetration Test

(DCPT), collection of disturbed samples (DS) and undisturbed soil samples (UDS),

Trial Pits (TP), Plate Load Tests (PLT), Electrical Resistivity Test (ERT), In situ field

permeability tests, collection of water samples, etc.

7.06.02.02 The diameter of borehole shall be minimum 150 mm in soil and 76 mm in rock. The

diameter of UDS sampler shall be 100 mm minimum. Core drilling in rock shall be

done by using hydraulically feed rotary drill & double tube core barrel with diamond

bit.

7.06.02.03 The minimum tests are indicated in Clause No. 7.07.00. Adequate number of tests

shall be conducted up to sufficient depth for complete determination of subsoil

conditions. The depth of boreholes shall be as specified in Appendix A. SPT shall

be carried out in all types of soil deposits and in all rock formations with core

recovery up to 20%, met within a borehole. This test shall be conducted at every

3.0 m interval or at change of strata, up to the final depth. SPT ‘N’ of 100 and

above shall be referred as refusal. UDS shall be collected at every 3.0 m interval or

at change of strata up to depth of borehole. UDS may be replaced by additional

SPT, if SPT’N’ value in the strata is above 50.

7.06.02.04 Laboratory tests shall be done as per relevant IS codes. The laboratory tests, not

be limited to the following shall be conducted on disturbed and undisturbed soil

samples, rock samples & water samples collected during field investigations in

sufficient numbers.

Laboratory Tests on Soil Samples

Laboratory tests shall be carried out on disturbed and undisturbed soil samples for

Grain Size Analysis, Hydrometer Analysis, Atterberg Limits, Triaxial Shear Tests

(UU), Natural Moisture Content, Specific Gravity and Bulk Unit Weight, Consolidation

Tests, Unconfined Compression Test, Free swell Index, Shrinkage Limit, Swell

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 20 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Pressure Test, Chemical Analysis test on soil and water samples to determine the

carbonates, sulphates, chlorides, nitrates, pH, organic matter and any other

chemicals harmful to concrete and reinforcement/ steel.

Laboratory Tests on Rock Samples

Moisture content, porosity & density, Specific Gravity, Hardness, Soundness, Slake

durability index, Unconfined compression test (Both at saturated and in-situ water

content), Point load strength index and deformability test (Both at saturated and in-

situ water content) shall be carried out on rock samples.

7.06.02.05 Geotechnical investigation (field & laboratory) shall be carried out in accordance

with the provisions of relevant Indian Standards.

On completion of all field & laboratory work, geotechnical investigation report shall

be submitted for Owner’s review/approval. The Geotechnical investigation report

shall contain geological information of the region, procedure adopted for

investigation, field & laboratory observations/ data/ records, analysis of results &

recommendations on type of foundation for different type of structures envisaged

for all areas of work with supporting calculations. Recommendations on treatment

for soil, foundation, based on subsoil characteristics, soft soils, aggressive

chemicals, expansive soils, etc.

Recommendations on foundation system and the net allowable bearing pressures

and pile capacity shall be based on the conservative values of geotechnical

investigation data.

7.06.03.00 Geotechnical investigation work shall be got executed by the Contractor through

the following agencies.

1. C.E.TESTING COMPANY Pvt. Ltd, Kolkata

2. Cengrs Geotechnica Pvt. Ltd, New Delhi

3. KCT Consultancy Services, Ahemdabad

4. M.K. Soil Testing Laboratory, Ahemdabad

7.07.00 Geotechnical Investigation Scheme

a) Boreholes (Minimum)

S.N Structure Spacing/Number of Depth of Remarks

o borehole borehole

1 FGD Minimum 14 Nos. Depth of

boreholes

Depth of

shall be

borehole

35m to

s shall be

40m.

as

2 Crusher House Minimum 2 Nos. Depth of mentione

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 21 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

boreholes

d in

shall

column be

35m to

“Depth of

40m.

Borehole

” or 5m

3 Gypsum and Lime Minimum 10 Nos. Depth of continuo

storage area boreholes us in

shall be rock with

25m to RQD >

35m

25%

whicheve

4 Other Structure/Facility Minimum 2 Nos. 25 to 35 m

boreholes under r is

each area / facility earlier.

5 Chimney Minimum 2 Nos. 40 to 45m

under each chimne

b) Other Field Tests (Minimum)

1 Cyclic Plate Load Test 3 nos Test Depth from 2 to 4

(CPLT) m

2 2 Nos. Depths covering from

CROSS-HOLE TEST

1.0 m to 15.0 m

3 TRIAL PIT (TP) 5 Nos. Depth - 3 m

4 IN SITU In minimum 3 Nos. Tests shall be

PERMEABILITY TEST of boreholes conducted at depths

IN BOREHOLES of 1.0m, 3.0m, 5.0m,

8.0m and 12.0m.

5 Minimum 10 Nos.

ERT

• Depth and location of Boreholes and other field tests (PLT, ERT, field

permeability tests etc.) shall be approved by Owner before execution of

geotechnical investigation work.

• Investigation in any other building / structure / facilities / trestles which are

not mentioned above shall also be carried out, if required, by the bidder for

the facilities under his scope.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 22 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Annexure-I (Barauni St-II)

GEOTECHNICAL DATA AND FOUNDATION SYSTEM

Employer has carried out geotechnical investigation in vicinity to the proposed area.

Logs of representative boreholes solely for bidder’s information in the vicinity of

proposed area are enclosed at Annexure-II.

The bidder is required to carry out geotechnical investigation as per Clause No

7.06.00 & 7.07.00 and ascertain the pile capacity and bearing capacity. The onus of

correct assessment / interpretation and understanding of the existing subsoil

condition / data is on the Bidder.

a) The foundation system to be adopted for different structures shall be as given in

Table – 1 below

Table – 1: Net Allowable Bearing Pressure

STRUCTURE TYPE OF FOUNDATION TO

BE ADOPTED

FGD and related structures Open(with ground

improvement)/Piles (with

ground improvement)

b) Bidder is required to carry out geotechnical investigation in this area. During detailed

engineering, the Allowable Bearing Pressure shall be adopted after approval of

geotechnical investigation report. However, the maximum allowable bearing

pressure shall be lower of the two values i.e. as per approved geotechnical report

and as per the values furnished in Table-2. The ground improvement scheme shall

be approved by owner before execution.

Table – 2: Net Allowable Bearing Pressure

Founding Depth/ Stratum Net Allowable Bearing Pressure

T/m2

Isolated and combined Rafts

footings (width >

6m)

Width upto Width >

3.0m 3.0m upto

6m

1.0m to 5.0m below FGL (After 10 10 10

ground improvement using

stone columns)

FGL Corresponds to RL(+)45.0

In case any loose/soft pockets is encountered at founding level, the same shall be

removed completely upto the hard strata and filled up with PCC (1:4:8).

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 23 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

The net allowable bearing pressure higher than above mentioned values shall not be

permitted. At intermediate levels the bearing capacity shall be same as the net

allowable bearing pressure corresponding to the immediate shallower level

mentioned above.

c) Permissible Settlement of Foundations:

For open foundations, the total permissible settlement and differential settlement

shall be governed by IS: 1904 and from functional requirements whichever is more

stringent. However, total settlement shall be restricted to the following:

Isolated, Strip & Raft (machine foundation) 25 mm

Isolated & Strip (Other than machine foundation) 40 mm

Raft (widths greater than 6 m) (Other than machine 75 mm

foundation)

In case the total permissible settlement is to be restricted to less than as above

specified from functional requirements, then the net allowable bearing pressure shall

be reduced after review in consultation with Engineer.

d) The allowable load capacity of the pile in different modes (vertical compression,

lateral and pullout) shall be least of the three values i.e. as per approved geotechnical

report, as per the values furnished in following table and pile capacity achieved in pile

load tests.

Area/ Pile Minimum Safe Load Capacity in

length of

Location Diameter

pile Vertical Pullout Lateral

(mm) below

Comp. (MT) (MT)

cut-off

level (m) (MT)

FGD and related 600 27.0 140.0 45.0 7.0

structures

760 28.0 225.0 75.0 12.0

- Cut off Level (COL) is assumed at 3.0 m below FGL.

e) The criteria for Pile Termination (founding level) shall be as given below:

i) Minimum length of the pile below COL (cut off level) shall be as specified

above in Clause (d) above.

ii) The minimum pile length for each group of piles shall be determined based

on the nearest borelog. Pile shall be terminated into strata with SPT ‘N’

greater than 40 for 600mm dia pile & 760mm dia pile, while deciding the

minimum length of pile. For pile termination, SPT ‘N’ values shall be used

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 24 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

from the nearby borelog data. The boreholes are in the bidder’s scope and

shall be conducted as per the approved scheme.

iii) However, in no case the length of pile shall be less than the minimum length

determined as in (i) or (ii) above whichever is longer, for that pile group.

f) Pattern of stone columns (Typ)

Outer edge of footing

2.5 d to 3d in

triangular pattern

NOTES

• Finished dia of stone column shall be 600/760/900 mm and depth of stone

column and the stone column shall be terminated in silty sand/ sand layer.

Minimum embedment of stone column into this layer shall be 500mm.The

installation of stone column is considered acceptable if it achieved SPT ‘N’ value

more than 15 and 25 for depth less than 5m and more than 10m respectively

below ground level. For values of depth between 5m and 10m, linear

interpolation shall be done.

• Stone columns shall be installed in triangular pattern at 2.5 d to 3d (d= dia of

stone columns) centre to centre and installation of stone columns shall be as per

technical specifications.

Two row of stone columns beyond the outer edge of footing shall be ensured.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 25 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

TABLE – 1

COAL CHARACTERISTICS

Worst Coal

Parameter Unit Design Coal for mill

selection

High Heating Value kcal/kg 3,300 3,100

Total Moisture % 8.0 10.0

Volatile Matter % 17.7 20.6

Proximate Analysis

Fixed Carbon % 29.7 29.4

Ash % 44.6 40.0

Carbon % 29.43 39.66

Hydrogen % 4.47 4.68

Nitrogen % 1.89 1.85

Ultimate Analysis Oxygen % 11.31 3.81

Sulfur % 0.3 -

Ash % 44.6 40.00

Moisture % 8.00 10.00

TABLE – 2

FUEL OIL CHARACTERISTICS

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 26 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

---------------------------------------------------------------------------------------------------------------------------

Sl. Characteristics Heavy Furnace

No. Oil grade HV

(HVFO)

IS-1593(Latest Revision)

----------------------------------------------------------------------------------------------------------------------------

1. Total sulphur content 4.5% Max.

2. Gross calorific value of the order

(KCal/kg) of 10,000

3. Flash Point (Min) 66 deg C

4. Water content by 1.0%

volume (Max)

5. Sediment by weight 0.25%

(Max)

6. Asphaltene content by 2.5%

weight (Max.)

7. Kinematic viscosity 370(max)

in Centistokes

8. Ash Content by 0.1%

weight (Max.)

9. Acidity (inorganic) Nil

10. Pour Point (Max.) 50deg C

11. Sodium+Potasium content 40

12. Vanadium content 70 ppm

13. Specific heat below 0.48

pour point (KCal/Kg °C)

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 27 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

TABLE – 2

LIGHT DIESEL OIL CHARACTERISTICS

AS PER IS 1460-2000

Characteristics LDO

1. Pour Point (max) 18 deg.C & 12°C for Summer

and Winter respectively

2. Kinematic viscosity in 2.5 to 15.7

centistokes at 40 deg.C

3. Sediment percent by mass (max) 0.10

4. Total sulphur percent by 1.8

mass (max)

5. Ash percentage by mass (max) 0.02

6. Carbon residue (Rans bottom) 1.50

percent by pass (max.)

7. Acidity in organic Nil

8. Flash point(Min.) - Pensky Martens 66 deg.C

9. Specific gravity at 15°C 0.85

10. Water content, % by volume(max) 0.25

11. GCV (Kcal/kg) 10,000

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 28 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

TABLE – 3

(Not used)

Table-4

B) DESIGNED CLARIFIED WATER ANALYSIS

-------------------------------------------------------------------------------------------------------

Sl. Constituent unit mg per litre

No.

------------------------------------------------------------------------------------------------------

1. Calcium as CaCO3 ppm 87.5

2. Magnesium as CaCO3 ppm 70.9

3. Sodium as CaCO3 ppm 60.9

4. Potassium as CaCO3 ppm 0.0

5. Fe as CaCO3 ppm 0.5

6. Total hardness as CaCO3 mg/l 158.33

7. Total Cations as CaCO3 mg/l 219.72

1. M-Alkanity as CaCO3 mg/l 47.14

2. Bicarbonates as CaCO3 mg/l 47.14

3. Carbonates as CaCO3 mg/l 0

4. Nitrate as CaCO3 ppm 0.65

5. Chloride as CaCO3 ppm 84.51

6. Sulphate as CaCO3 ppm 75.22

7. Nitrites as CaCO3 9.662

8. Phosphate as CaCO3 ppm 0.14

9. Amonia 0.582

10. Fluride as CaCO3 ppm 1.82

11. EMA as CaCO3 mg/l 172.58

12. Total Anions as CaCO3 mg/l 219.72

13. pH Value - 10

14. Turbidity(max.) NTU 10

15. Total Dissolved solids mg/l 237

.

Note: At the outlet of clarifier of PT Plant

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 29 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Table-4

PROCESS WATER / CW BLOW DOWN WATER ANALYSIS

-------------------------------------------------------------------------------------------------------

Sl. Constituent unit mg per litre

No.

------------------------------------------------------------------------------------------------------

1. Calcium as CaCO3 ppm 525

2. Magnesium as CaCO3 ppm 425.4

3. Sodium as CaCO3 ppm 365.4

4. Potassium as CaCO3 ppm 0.0

5. Fe as CaCO3 ppm 3

6. Total hardness as CaCO3 mg/l 949.98

7. Total Cations as CaCO3 mg/l 1318.32

1. M-Alkanity as CaCO3 mg/l 282.84

2. Bicarbonates as CaCO3 mg/l 282.84

3. Carbonates as CaCO3 mg/l 0

4. Nitrate as CaCO3 ppm 3.9

5. Chloride as CaCO3 ppm 507.06

6. Sulphate as CaCO3 ppm 451.32

7. Nitrites as CaCO3 57.972

8. Phosphate as CaCO3 ppm 0.84

9. Amonia 3.492

10. Fluride as CaCO3 ppm 10.92

11. EMA as CaCO3 mg/l 1035.48

12. Total Anions as CaCO3 mg/l 1318.32

13. pH Value - 10

14. Turbidity (max.) NTU 60

15. Total Dissolved solids mg/l 1422

Note : The C.W system is expected to operate at about 6 Cycles of

Concentration.

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 30 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Table-5

DM WATER ANALYSIS

Sl. Constituent as mg per litre

No.

------------------------------------------------------------------------------------------------------

1. Silica (Max.) - 0.02 ppm as SiO2

2. Iron as Fe - Nil

3. Total hardness - Nil

4. pH value - 6.8 to 7.2

5. Conductivity - Not more than 0.1

excluding the effects of

free CO2

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 31 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

Table-6

STEAM GENERATOR DATA

A. BARAUNI – II

1. Location Outdoor

2. Operation Base load

3. Type Pulverised coal fired

4. Maximum Continuous Rating 810 Tonns/hr.

5. Steam pressure at SH outlet 156 Kg/cm²(a)

6. Steam temperature at SH outlet 540°C

7. Oil for start up and flame LDO + LSHS/HPS

stabilisation

8. Fuel oil system sizing 3x100% HFO pumping and heating

unit unit each with firing capacity of 30%

, MCR, common for two boilers.

. 2x100% LDO pumping unit each with

firing capacity of 10% MCR common

for two boilers

9. Pulverised coal size Minimum 70% through 200 Mesh

10. Type of pulveriser TUBE MILLS

11. Type of oil burners Air atomised for LDO

Steam atomised for LSHS/HPS

12. No. of air heaters Two (2) for the secondary air side and

Two (2) for the primary air side.

13. No. of ID Fans Two (both working)

ESP DATA Stage II (Per Unit basis)

1. Location: Downstream side of Air preheaters

2. Operation: Base load

3. Type: Rigid Discharge frame

4. Rapping: Intermittent

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 32 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

CLAUSE NO. PROJECT INFORMATION

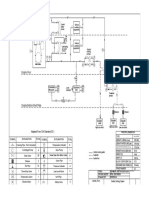

Table-7

List of Drawings placed below in this sub section:

Sl.No. Drawing Description Drawing No.

1. General Layout Plan Enclosed

2. Layout of ID system(plan) Enclosed

3. Layout of ID system(elevation) Enclosed

4. Layout of ducting Enclosed

5. Key plan of boilers Enclosed

LOT-6 PROJECTS PAGE

TECHNICAL SPECIFICATION SUB SECTION-II-A4 33 OF 33

FLUE GAS DESULPHURISATION (FGD) SECTION-VI, PART-A PROJECT INFORMATION

SYSTEM PACKAGE BID DOC. NO. : CS-0011-109(6)-9 BARAUNI-II (2X250 MW)

You might also like

- Tech Spec For Plate Heat ExchangersDocument37 pagesTech Spec For Plate Heat ExchangersSHIVAJI CHOUDHURY50% (2)

- DEA ReportDocument24 pagesDEA ReportMd Sohag100% (1)

- Pressure Vessles PPT 25.02.2020Document110 pagesPressure Vessles PPT 25.02.2020Piyush MalviyaNo ratings yet

- Index: Technical Manual Technical ManualDocument22 pagesIndex: Technical Manual Technical ManualBruno MarianoNo ratings yet

- Problem Set Number 1Document4 pagesProblem Set Number 1Johnlloyd BarretoNo ratings yet

- Project Information - FGD System Package for Meja TPP Stage IDocument37 pagesProject Information - FGD System Package for Meja TPP Stage IAbhijeet OundhakarNo ratings yet

- Coal Transportation: Project InformationDocument9 pagesCoal Transportation: Project InformationVenkatesh HebbarNo ratings yet

- Obcc Samalei 2022 STR Pi Urc Design ReportDocument47 pagesObcc Samalei 2022 STR Pi Urc Design ReportSangramkeshari BejaNo ratings yet

- 1762-112-Cal-7102-0c Calculation Report For WarehouseDocument46 pages1762-112-Cal-7102-0c Calculation Report For WarehouseWasimullah KhanNo ratings yet

- Bili of Qunatity Cum Price Schedule (Annexure-I) : A-I) Soil Investigation Alongwith Soil Resistivity MeasurementDocument5 pagesBili of Qunatity Cum Price Schedule (Annexure-I) : A-I) Soil Investigation Alongwith Soil Resistivity MeasurementSushant MallickNo ratings yet

- Security Cabin DBRDocument31 pagesSecurity Cabin DBRKOTADIA KISHANNo ratings yet

- 4247 - 3-Surface Powerhouse PDFDocument7 pages4247 - 3-Surface Powerhouse PDFBishowkumar Shrestha0% (1)

- Part 2 - Sec 1.6.4 - 11 2010 K G RPT 2210 - FinalDocument26 pagesPart 2 - Sec 1.6.4 - 11 2010 K G RPT 2210 - FinalHung NguyenNo ratings yet

- 17th EOM Letter N AgendaDocument63 pages17th EOM Letter N AgendaSiddharth MohantyNo ratings yet

- Volume 3 of 3Document232 pagesVolume 3 of 3Pranoy BaruaNo ratings yet

- Design InformationDocument3 pagesDesign Informationsoumi bhattacharyaNo ratings yet

- JUTE shed-DEADocument39 pagesJUTE shed-DEAMd SohagNo ratings yet

- Container Foundation Design Calculation ReportDocument38 pagesContainer Foundation Design Calculation ReportCivil StructureNo ratings yet

- Addendum 2Document2 pagesAddendum 2Pranoy BaruaNo ratings yet

- Tender Document For Construction of Ghorasal 300-450 MW ... - BPDBDocument315 pagesTender Document For Construction of Ghorasal 300-450 MW ... - BPDBhumayan kabir100% (1)

- "Ibc2003E" - Ibc 2003 Seismic Analysis ProgramDocument30 pages"Ibc2003E" - Ibc 2003 Seismic Analysis ProgramFranklyn GenoveNo ratings yet

- IBC 2003 Code Seismic AnalysisDocument30 pagesIBC 2003 Code Seismic Analysishakan tasdemirNo ratings yet

- 3177Document62 pages3177krishnan_88No ratings yet

- CE-402 Question - Paper - CE - 402 - 2012-13Document16 pagesCE-402 Question - Paper - CE - 402 - 2012-13rajeshtak05No ratings yet

- Tower Crane Raft Design ReportDocument22 pagesTower Crane Raft Design ReportFranklyn Genove100% (4)

- Design Report Rev 02Document92 pagesDesign Report Rev 02Khurram ShahzadNo ratings yet

- FW Pipe Rack DocumentDocument38 pagesFW Pipe Rack DocumentSumanthNo ratings yet

- Ibc2003e - Ibc 2003 Seismic Analysis ProgramDocument30 pagesIbc2003e - Ibc 2003 Seismic Analysis Programtham leoNo ratings yet

- Is 3177 1977Document66 pagesIs 3177 1977Avijit Dey100% (1)

- 2023-BRL-05-XX-SP-C-1006 Geotextile SpecificationDocument13 pages2023-BRL-05-XX-SP-C-1006 Geotextile SpecificationFrançois Le RouxNo ratings yet

- DCCOL ISG 1eDocument15 pagesDCCOL ISG 1eJr-Gon HouNo ratings yet

- BC Building Code amended to regulate energy efficiencyDocument21 pagesBC Building Code amended to regulate energy efficiencyehlverixNo ratings yet

- 20RIT-122 - DC003 - 35m GFT13.5F - 3L - 280kmph - 30sqm - EndorsedDocument37 pages20RIT-122 - DC003 - 35m GFT13.5F - 3L - 280kmph - 30sqm - EndorsedJay ar TenorioNo ratings yet

- Design Report ALH 250Document18 pagesDesign Report ALH 250Sanjeev VermaNo ratings yet

- Design Report ALH 250 PDFDocument18 pagesDesign Report ALH 250 PDFSanjeev VermaNo ratings yet

- O & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Document465 pagesO & M Estimate KC-29 (531+000 To 785+000) 10.2.2022Muhammad TufailNo ratings yet

- Att#1 - QT1-0-Z-050!62!01017 - STB - Method of Concrete Work For Steam Turbine Buidling (IFA, Rev. B)Document85 pagesAtt#1 - QT1-0-Z-050!62!01017 - STB - Method of Concrete Work For Steam Turbine Buidling (IFA, Rev. B)Thi Châu VănNo ratings yet

- WMS-002 Pile Driving by Pile-Driving Barge REV.ADocument136 pagesWMS-002 Pile Driving by Pile-Driving Barge REV.AVan Cuong PhamNo ratings yet

- Base Report Bridge Roads Toll Plaza RevDocument26 pagesBase Report Bridge Roads Toll Plaza RevSandeep Singh100% (1)

- DJP80 QFNdocumnetof EIAReportDocument285 pagesDJP80 QFNdocumnetof EIAReportvivek1280No ratings yet

- 2009-12-17-Structural Analysis Tunnel T77B&CDocument35 pages2009-12-17-Structural Analysis Tunnel T77B&CRayees AhmadNo ratings yet

- Double Wall Storage Tank1Document33 pagesDouble Wall Storage Tank1INFO SAGANo ratings yet

- Iso 3010Document8 pagesIso 3010asvenk3090% (1)

- Structural - Analysis - Skid A4401 PDFDocument94 pagesStructural - Analysis - Skid A4401 PDFMohammed Saleem Syed Khader100% (1)

- 48 BD 08Document34 pages48 BD 08Mayur UrkudeNo ratings yet

- Matara-Kataragama Railway Extension Project Phase 1 Water Cooling System Mock Up AmendmentDocument3 pagesMatara-Kataragama Railway Extension Project Phase 1 Water Cooling System Mock Up AmendmentAmila Priyadarshana DissanayakeNo ratings yet

- Structural Design of Underground Powerhouse Runway BeamsDocument10 pagesStructural Design of Underground Powerhouse Runway BeamsRam Krishna AdhikariNo ratings yet

- FA00010S-T0101 GENERAL ARCHITECTURE DESCRIPTION (Rev.1)Document26 pagesFA00010S-T0101 GENERAL ARCHITECTURE DESCRIPTION (Rev.1)arief fardy yuskaNo ratings yet

- HFY-3800-1600-CIV-RPT-0021 - A - Foundation Design Calculation Depropaniser (C-923010)Document30 pagesHFY-3800-1600-CIV-RPT-0021 - A - Foundation Design Calculation Depropaniser (C-923010)prasadcspNo ratings yet

- Seismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2Document35 pagesSeismic Design For Petrochemical Facilities As Per NBCC 2005 Rev1.2jakeer7100% (2)

- SBU-2 FlyAsh System Scope of Work - R1 - Final - 03.04.2020Document22 pagesSBU-2 FlyAsh System Scope of Work - R1 - Final - 03.04.2020Rashid patelNo ratings yet

- The OBE Elimination in Piping Design: Hee-Cheol Cho, In-Yeung Kim, Soon-Chul Yun, Koo-Woun ParkDocument6 pagesThe OBE Elimination in Piping Design: Hee-Cheol Cho, In-Yeung Kim, Soon-Chul Yun, Koo-Woun Parkravichandiran_a2001No ratings yet

- Technical Clarification-Seoul Machinery-1910-0318 OfferDocument4 pagesTechnical Clarification-Seoul Machinery-1910-0318 OfferAnaNo ratings yet

- Vol2 TL-S1-6 3626 PGCBDocument124 pagesVol2 TL-S1-6 3626 PGCBabhi120783No ratings yet

- Information Required For ESIA - Gie - 2018!01!18Document11 pagesInformation Required For ESIA - Gie - 2018!01!18hassan zakwanNo ratings yet

- Bridge Technical Note 2023 - 023 AS5100 Part 3 v20 July 2023Document11 pagesBridge Technical Note 2023 - 023 AS5100 Part 3 v20 July 2023roshansm1978No ratings yet

- Sail Eot Technical 2-02-004-18Document21 pagesSail Eot Technical 2-02-004-18SumitBhaumikNo ratings yet

- Foundation DesignDocument19 pagesFoundation DesignBolarinwa100% (1)

- Shoring Calculation Report 20211118Document37 pagesShoring Calculation Report 20211118Oshin RajapakshaNo ratings yet

- Sustainable Steel Buildings: A Practical Guide for Structures and EnvelopesFrom EverandSustainable Steel Buildings: A Practical Guide for Structures and EnvelopesBernhard HaukeNo ratings yet

- Flow Measurement: By Square-Edged Orifice Plate Using Corner TappingsFrom EverandFlow Measurement: By Square-Edged Orifice Plate Using Corner TappingsRating: 5 out of 5 stars5/5 (1)

- NTPC FGD System Technical SpecificationDocument100 pagesNTPC FGD System Technical SpecificationPiyush MalviyaNo ratings yet

- Project Barauni Stg-II U#8&9 (2X250MW) Electrical Items Indicative Vendor ListDocument31 pagesProject Barauni Stg-II U#8&9 (2X250MW) Electrical Items Indicative Vendor ListPiyush MalviyaNo ratings yet

- Part ADocument226 pagesPart APiyush MalviyaNo ratings yet

- Geotechnical Investigation for 2 x 250 MW Barauni Thermal Power StationDocument16 pagesGeotechnical Investigation for 2 x 250 MW Barauni Thermal Power StationPiyush MalviyaNo ratings yet

- Thermax - NTPC PresentationDocument57 pagesThermax - NTPC PresentationPiyush MalviyaNo ratings yet

- Absorber Nozzle Allowable LoadDocument6 pagesAbsorber Nozzle Allowable LoadPiyush MalviyaNo ratings yet

- TM B DCT 001 - Technology Manual of DuctingDocument70 pagesTM B DCT 001 - Technology Manual of DuctingPiyush MalviyaNo ratings yet

- FGD Project at 2X 525 MW MPL: Document Title: Design Calculations of Naoh TankDocument1 pageFGD Project at 2X 525 MW MPL: Document Title: Design Calculations of Naoh TankPiyush MalviyaNo ratings yet

- Design and Simulation of A PV System With Battery Storage Using Bidirectional DC DC Converter Using Matlab SimulinkDocument9 pagesDesign and Simulation of A PV System With Battery Storage Using Bidirectional DC DC Converter Using Matlab SimulinkMohd Mohsin SohailNo ratings yet

- NBTS-08_Document23 pagesNBTS-08_ShrutiNo ratings yet

- Ametek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetDocument2 pagesAmetek Windjammer 117637 117643 117636 117642 117635 117641 Spec SheetGonzalo Jesus Ccahuin FernandezNo ratings yet

- Mexico DisasterDocument5 pagesMexico DisasterVaibhav GuliaNo ratings yet

- ALDAR Projects Health and Safety Alert Electrical SafetyDocument1 pageALDAR Projects Health and Safety Alert Electrical SafetyerwinNo ratings yet

- NPCIL Personal - Details - FormatDocument2 pagesNPCIL Personal - Details - FormatpraveenNo ratings yet

- Wall Mount RO Installation ManualDocument37 pagesWall Mount RO Installation ManualBIOMED HCCNo ratings yet

- Models HRSB & HRSD: Model FeaturesDocument9 pagesModels HRSB & HRSD: Model FeaturesAlejandro DuranNo ratings yet

- E-Books+Guide Manuals ListDocument11 pagesE-Books+Guide Manuals ListObd Bytes0% (1)

- FTNV-B FINAL - CatalogueDocument8 pagesFTNV-B FINAL - CatalogueAmodu Usman AdeyinkaNo ratings yet

- Aero Thermodynamics Analysis and Design of A Rolling Piston EngineDocument59 pagesAero Thermodynamics Analysis and Design of A Rolling Piston EngineraviNo ratings yet

- DRRR - Week 5-8Document48 pagesDRRR - Week 5-8Willy Albert BrazaNo ratings yet

- Rotc FinalsDocument215 pagesRotc FinalsAyaseNo ratings yet

- Alternating Voltage and Current Grob's Basic Electronics-11ed-15Document10 pagesAlternating Voltage and Current Grob's Basic Electronics-11ed-15Taufiq Fahlifi YfzerobrrNo ratings yet

- Paper Battery: Name-Omprakash Tanty Branch-Electrical Sem-6th Sem Jharsuguda Engineering School Regdno-F18005001051Document18 pagesPaper Battery: Name-Omprakash Tanty Branch-Electrical Sem-6th Sem Jharsuguda Engineering School Regdno-F18005001051Bulu PatraNo ratings yet

- Empanelment FormDocument5 pagesEmpanelment FormBalaji RNo ratings yet

- Wrong answer summary analysisDocument7 pagesWrong answer summary analysisGennadi JermilovNo ratings yet

- Boiler Pressure PartsDocument32 pagesBoiler Pressure PartsavtarsinghsandhuNo ratings yet

- Kenyas Seven Deadliest CartelsDocument8 pagesKenyas Seven Deadliest CartelsKeerthikaNo ratings yet

- Miftah Dhia Falah - Cooling System PnIDDocument1 pageMiftah Dhia Falah - Cooling System PnIDRaja Fatah Satrio AbimanyuNo ratings yet

- CHE10705, Steam Generation andDocument34 pagesCHE10705, Steam Generation andNacer KisyNo ratings yet

- Em-Vam - Gvju (Edus711116b) 01-04-2020Document32 pagesEm-Vam - Gvju (Edus711116b) 01-04-2020CharbelNo ratings yet

- Important Instructions For The School Principal: (Not To Be Printed With The Question Paper)Document15 pagesImportant Instructions For The School Principal: (Not To Be Printed With The Question Paper)Laksh RameshNo ratings yet

- Hiranandani Foundation School, Powai Std. X Subject: Geography (H.C.G. Paper 2) Semester II Worksheet - 1Document2 pagesHiranandani Foundation School, Powai Std. X Subject: Geography (H.C.G. Paper 2) Semester II Worksheet - 1richman77No ratings yet

- Sci 8 L5 - Kinetic EnergyDocument12 pagesSci 8 L5 - Kinetic EnergyTorres Jhon Chriz GabrielNo ratings yet