Professional Documents

Culture Documents

For Approval: Design Calculation Penstock Straight Ferrules (Material Astm 537 CL 1) 0) 9

Uploaded by

Ashim LamichhaneOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

For Approval: Design Calculation Penstock Straight Ferrules (Material Astm 537 CL 1) 0) 9

Uploaded by

Ashim LamichhaneCopyright:

Available Formats

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

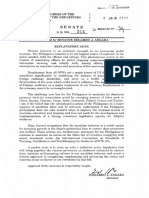

FOR APPROVAL

Date Representative

OWNER/CLIENT: OWNER’S ENGINEER:

NUMBUR HIMALAYA HYDROPOWER PVT. LTD. ENTURA

PROJECT :

LIKHU A

Rev Modifications Date Prepared By Checked By Approved BY

TITLE:

DESIGN CALCULATION

PENSTOCK STRAIGHT FERRULES

(MATERIAL ASTM 537 CL 1)

0)

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD 9 by

Prepared R.D. 11.04.2019 File name

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL Checked by W.S. 19.04.2019

Contract Nº N/CA/HM/TP/01 Approved by A.K. 22.04.2019 File date 22-04-2019

=FU PLN

Internal No. C-90-834972-058-030-DC-PS-010

+LO

Page 1

Document No. LKA-030-DC-010-A Rev 0 of 27

A4

#

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Table of Contents

1. GENERAL .....................................................................................................................3

2. CODES TO BE FOLLOWED/ DRAWINGS/ DESIGN CRITERIA .................................................3

3. TECHNICAL PARAMETER................................................................................................4

4. ALLOWABLE STRESSES .................................................................................................5

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

5. ROCK PARTICIPATION ....................................................................................................5

6. MINIMUM HANDLING THICKNESS .....................................................................................5

7. DESIGN FOR HORIZONTAL SHAFT...................................................................................6

This document is the INTELLECTUAL PROPERTY of

8. DESIGN FROM VERTICAL BEND TO EL 1383.340 .............................................................7

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

9. DESIGN FROM EL 1383.340 TO EL 1310.82 ..................................................................8

10. CALCULATION SUMMARY SHEET UPTO EL 1310.82 ......................................................12

11. DESIGN FROM EL 1310.820 TO VERTICAL BEND 2 .......................................................12

12. DESIGN OF PENSTOCK AFTER BIFURCATION I FOR 1500 MM DIA ....................................13

13. DESIGN OF PENSTOCK AFTER BIFURCATION II FOR DIA 1100 MM ...................................14

14. DESIGN OF PENSTOCK AFTER BIFURCATION II FOR 1900 MM DIA ...................................16

15. DESIGN FOR EXTERNAL PRESSURE FOR UNSTIFFENED SHELL ......................................17

15.1 UPPER HORIZONTAL PORTION ....................................................................................17

15.2 AT EL 1310.82 .........................................................................................................19

15.3 NEAR BIFURCATION I .................................................................................................20

16. DESIGN FOR EXTERNAL PRESSURE FOR STIFFENED SHELL ..........................................22

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 2

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

1. General

Design of penstock has been carried out as per the civil drawing layout is provided.

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

2. Codes to be followed/ drawings/ Design criteria

IS 11693 (Part I)

IS 11693 (Part II)

This document is the INTELLECTUAL PROPERTY of

IS 11693 (Part III)

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

ASCE manual No. 79 (2012)

IS 2825

EHTLKA-DD-C-GA-004, sheet 1/2 Rev. 02

received via mail dated 28th March 2019

EHTLKA-DD-C-GA-005, sheet 2/2 Rev. 01

received via mail dated 28th March 2019

EHTLKA-DD-C-GA-003, Rev. 01

received via mail dated 2019

Approved design memorandum dated 21st March 2019 and subsequent clarifica-

tion from the customer on 26th March 2019.

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 3

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

3. Technical Parameter

FRL EL 1450.20 m

Max Surge Level EL 1457.00 m

C/l of machine EL 1297.70 m

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Internal Dia of Pipe 2.5 m

No. of Branches 3 Nos.

This document is the INTELLECTUAL PROPERTY of

Internal Dia. of branches 1500 mm & 1100 mm

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

% of pressure rise due to 35 %

water hammer

Seismic Coff. Hor. = 0.24g & Ver.= 0.16 g

Corrosion Allowance (CA) 1. 5 mm

Weld Joint Eff. 0.9

Max. Temperature of Water 33 degree

Min. Temperature of Water 3 degree

Material ASTM 537 Cl I

Yp of Material 345 Mpa

UTS of Material 480 Mpa

Rock type Calcareous Quartzite with interbedded Phyllite

Modulus of Elasticity of Rock 900000 kg/cm2

Modulus of Elasticity of Concrete 193650 kg/cm2

Modulus of Elasticity of Steel 2100000 kg/cm2

Thickness of concrete over liner 500 mm

Poisson ratio of steel 0.303

Poisson ratio of rock 0.2

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 4

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

4. Allowable Stresses

Steel Liner

As per IS 11693 Part (II) clause No. 4.2

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

In Normal Condition

Minimum of

This document is the INTELLECTUAL PROPERTY of

60 % of Yp = 0.6 x 345 = 207 Mpa

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

1/3 of UTS = 1/3 x 480 = 160 Mpa

Hence Adopted Allowable Stress for Steel Liner = 160 Mpa

5. Rock participation

No rock participation for portion between surge shaft and PPV.

No rock participation 30 m d/s from the penstock protection valve.

15 % rock participation for inclined pressure shaft.

No rock participation 30 m u/s from the tunnel outlet portal.

No rock participation for the portion d/s of tunnel outlet portal.

Rock participation for the balance length of horizontal shaft.

Hence, In the design calculation no rock participation is considered from surge shaft to first bend as

minimum handling is governing in that reach. Same thickness is extended upto certain level d/s of

bend.

Similarly, 30 m u/s from outlet portal near bifurcation I, no rock participation is considered. From bi-

furcation to power house no rock participation has been considered.

However, rock participation depends upon the load shared by the liner for expanding up to gap, and

rest of the stresses pass to rock. The calculated stresses getting transferred to rock should be veri-

fied by Engineer/geologist after rock testing. Please note that the formula used considering penstock

embedded in fissured concrete and rock.

6. Minimum handling thickness

As per clause no. 7 of IS 11693 Part (II), regardless of pressure, a minimum thickness of liner shall be

provided.

Minimum Handling thickness = R+.25/200

Where D is Diameter of shell in cm

For 2500 mm dia.

tmin = .0075 m say 8 mm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 5

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

For 1500 mm dia.

tmin = 0.005 m say 5 mm

For 1100 mm dia.

tmin = 0.004 m say 4 mm

7. Design for Horizontal Shaft

From Surge Shaft to Vertical Bend 1

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Rock participation = 0

Design Pressure as per Water Hammer Drg = 34.895 m

Head considered pressure =(34.895 X 1000 X 9.82)/1000000

This document is the INTELLECTUAL PROPERTY of

=0.342N/mm2

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 2500mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=2.98 mm

Hence, adopted ta = 6.50 mm, Minimum Handling Governing

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =73.21 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

ap = 0.303 c

=0.303 × 73.21

ap =22.18 N/mm2

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Tm= Average temperature of water = 20 °C

α= Thermal coefficient = 0.000012/°C

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

T2 =-17°C

Thermal stress due to temperature variation

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 6

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

= T E

Thermal stresses due to (T1):

=13 × .000012 × 210000

aT1 =32.76 N/mm2

Thermal stresses due to (T2):

=–17 × 0.000012 × 210000

aT2 =–42.84 N/mm2

Equivalent Stress

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

This document is the INTELLECTUAL PROPERTY of

Substituting values

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

=66 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 86 N/mm2

Allowable stress =160 N/mm2

Hence adopted thickness = 6.5 + 1.5(CA) = 8 mm.

8. Design from Vertical Bend -1 to EL 1383.340 m

Rock participation = 0

Design Pressure as per Water Hammer Drg = 75 m (Approx)

Head considered pressure =(75 X 1000 X 9.82)/1000000

=0.7365 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 2500mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=6.40 mm

Hence, Adopted ta = 6.50 mm

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =157.3718 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 7

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

ap = 0.303 c

=0.303 × 157.3718

ap =47.68365 N/mm2

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Tm= Average temperature of water = 20 °C

α= Thermal coefficient = 0.000012/°C

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

This document is the INTELLECTUAL PROPERTY of

T2 =-17°C

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Thermal stress due to temperature variation

= T E

Thermal stresses due to (T1):

=13 × .000012 × 210000

aT1 =32.76 N/mm2

Thermal stresses due to (T2) :

=–17 × 0.000012 × 210000

aT2 =–42.84 N/mm2

Equivalent Stress

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

Substituting values

=137 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 156 N/mm2

Allowable stress =160 N/mm2

Hence adopted thickness = 6.5 + 1.5(CA) = 8 mm.

9. Design from EL 1383.340 m up to EL 1310.82 m

Considering that steel liner will interact with Surrounding Rock:-

Equation as per IS 11693 part (II) clause no. 6.1.3.

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 8

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 9

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Design for Self - sustaining pipe

Design Pressure as per Water Hammer Drg = 130 m (Approx)

Head considered pressure =(130 X 1000 X 9.82)/1000000

=1.27 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 2500mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=11.08 mm

Hence, Adopted ta = 12.50 mm

Considering Participation of rock:-

Values known to us for Equation provided above

R = Radius of penstock = 125 cm

Yo = 0.0003 x R

= 0.0003 x 125 = 0.0375 cm say 0.04 cm

t = thickness assumed = 0.85 cm

C = Outside radius of concrete = 0.85 + 50 + 125 = 175.85 cm

d = radius to the end of radial fissure = 2 x 125 + 175.85 = 425.85 cm

Es = 2100000 kg/cm2

Er = 90000 kg/cm2

Ec= 193650 kg/cm2

µs = 0.303

µr = 0.2

Substituting the values in equations:-

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 10

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

2

Po = 4.72 kg/cm

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

M = 1.895

2

Ps = 7.07 kg/cm

2

‘fst = 1040.01 kg/cm

2

‘frt = 1.74 kg/cm

As per Clause no. 6.1.4 of IS 11639 part (II),” The maximum hoop tensile stress in steel

liner fSt should not exceed the product of joint efficiency and the allowable stress.

2 2

Allowable stress x joint eff. = 160 x10.2 x 0.9 = 1469 kg/cm > 1041 kg/cm , HENCE SAFE.

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 11

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

10. Calculation summary sheet up to EL 1310.82 m

Sr Internal Radius of Self Thk. of Thickness of Outer radius Outer Mus Mur gap joint Allowable P0 M PS FST allow str* FRT ROCK

No. Pressure Penstock Sustaining Steel Concrete of concrete radius of (cm) eff stresses (Kg/cm^ (Kg/cm^2) (Kg/cm^2) Joint eff PRT

Kg/cm^2 (cm) liner thk liner (cm) (cm) (cm) cracked (Kg/cm^2) 2)

cm rock (cm)

P R T Tc C D

1 13.00 125.00 1.11 0.85 50.00 175.85 425.85 0.30 0.20 0.04 0.90 1632 4.72 1.895 7.07 1040.01 1469 1.74 0.46

2 14.00 125.00 1.19 1.05 50.00 176.05 426.05 0.30 0.20 0.04 0.90 1632 5.83 1.895 8.52 1013.95 1469 1.61 0.39

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

3 16.50 125.00 1.40 1.25 50.00 176.25 426.25 0.30 0.20 0.04 0.90 1632 6.94 1.894 10.46 1046.28 1469 1.77 0.37

4 18.30 125.00 1.56 1.45 50.00 176.45 426.45 0.30 0.20 0.04 0.90 1632 8.05 1.894 12.19 1050.63 1469 1.79 0.33

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

11. Design from EL 1310.820 to Vertical bend 4

Rock participation = 0

Design Pressure as per Water Hammer Drg = 202.12 m

Head considered pressure =(202.12X 1000 X 9.82)/1000000

=1.985 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 2500mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=17.23 mm

Hence, adopted ta = 18.5 mm

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =149.01 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

ap = 0.303 c

=0.303 × 149.01

ap =45.15 N/mm2

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 12

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Tm= Average temperature of water = 20°C

α= Thermal coefficient = 0.000012/°C

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

T2 =-17°C

Thermal stress due to temperature variation

= T E

Thermal stresses due to (T1):

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

=13 × .000012 × 210000

aT1 =32.76 N/mm2

This document is the INTELLECTUAL PROPERTY of

Thermal stresses due to (T2):

=–17 × 0.000012 × 2100000

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

aT2 =–42.84 N/mm2

Equivalent Stress

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

Substituting values

=130 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 14855 N/mm2

Allowable stress =160 N/mm2

Hence adopted thickness = 18.5 + 1.5(CA) = 20 mm

12. Design of penstock after bifurcation I and II for 1500 mm diameter

Rock participation = 0

Design Pressure as per Water Hammer Drg = 192 m (Approx.)

Head considered pressure =(192 X 1000 X 9.82)/1000000

=1.88 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 1500mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=9.82 mm

Hence, Adopted ta = 10.50 mm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 13

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =149.6381 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

ap = 0.303 c

=0.303 × 149.6381

This document is the INTELLECTUAL PROPERTY of

ap =45.34 N/mm2

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Tm= Average temperature of water = 20°C

α= Thermal coefficient = 0.000012/°C

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

T2 =-17°C

Thermal stress due to temperature variation

= T E

Thermal stresses due to (T1):

=13 × .000012 × 210000

aT1 =32.76 N/mm2

Thermal stresses due to (T2):

=–17 × 0.000012 × 2100000

aT2 =–42.84 N/mm2

Equivalent Stress

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

Substituting values

=130 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 149 N/mm2

Allowable stress =160 N/mm2

Hence adopted thickness = 10.5 + 1.5(CA) = 12 mm.

13. Design of penstock after bifurcation I for dia. 1100 mm

Rock participation = 0

Design Pressure as per Water Hammer Drg = 205.875 m (Approx.)

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 14

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Head considered pressure =(205.875X 1000 X 9.82)/1000000

=2.021 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 1100mm

S =Allowable stress, 160 N/mm2

t =Thickness of liner, mm

v =Joint efficiency. 0.9

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Pw d

t =

2 S v

This document is the INTELLECTUAL PROPERTY of

Substituting values,

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

t=

=7.72 mm

Hence, Adopted ta = 8.50 mm

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =145.35 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

ap = 0.303 c

=0.303 × 145.35

ap =44.04 N/mm2

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Tm= Average temperature of water = 20 °C

α= Thermal coefficient = 0.000012/°C

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

T2 =-17°C

Thermal stress due to temperature variation

= T E

Thermal stresses due to (T1):

=13 × .000012 × 210000

aT1 =32.76 N/mm2

Thermal stresses due to (T2) :

=–17 × 0.000012 × 2100000

aT2 =–42.84 N/mm2

Equivalent Stress

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 15

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

Substituting values

=126 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 145 N/mm2

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Allowable stress =160 N/mm2

Hence adopted thickness = 8.5 + 1.5(CA) = 10 mm.

This document is the INTELLECTUAL PROPERTY of

14. Design of penstock after bifurcation II for 1900 mm diameter:

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Rock participation = 0

Design Pressure as per Water Hammer Drg = 205.875 m (Approx.)

Head considered pressure =(205.875X 1000 X 9.82)/1000000

=2.021 N/mm2

Calculation of Thickness of Liner

Pw =Water pressure acting, N/mm2

d =Diameter of penstock, 1900mm

S =Allowable stress, 160 N/mm

t =Thickness of liner, mm

v =Joint efficiency. 0.9

Pw d

t =

2 S v

Substituting values,

t=

=13.34 mm

Hence, Adopted ta = 14.50 mm

Circumferential stresses due to internal pressure

P d

c = w

2 ta v

Substituting values,

c =147.173 N/mm2

Poisson ratio of steel =0.303

Axial stress due to Poisson effect

ap = 0.303 c

=0.303 × 147.173

ap =44.59 N/mm2

Axial Stress due to Temperature

T1 = Maximum temperature of water = 33°C

T2 =Minimum temperature of water = 3°C

Tm= Average temperature of water = 20 °C

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 16

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

α= Thermal coefficient = 0.000012/°C

E = Modulus of elasticity = 210000 N/mm2

T1 =13°C

T2 =-17°C

Thermal stress due to temperature variation

= T E

Thermal stresses due to (T1):

=13 × .000012 × 210000

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

aT1 =32.76 N/mm2

Thermal stresses due to (T2) :

This document is the INTELLECTUAL PROPERTY of

=–17 × 0.000012 × 210000

aT2 =–42.84 N/mm2

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Equivalent Stress

As per Huber Hencky Equation

Stress due to T1 = c2 (ap aT1 )2 c (ap aT1 )

Substituting values

=128 N/mm2

Stress due to T2 = c2 (ap aT2 )2 c (ap aT2 )

Substituting values,

= 147 N/mm2

Allowable stress =160 N/mm2

Hence adopted thickness = 14.5 + 1.5(CA) = 16 mm.

15. Design for External Pressure for Unstiffened shell

Calculations pertaining to minimum thickness (8mm) and maximum thickness (16mm) is carried out be-

low to check whether the thickness if remain unstiffened, is capable of taking external pressure acting on

it or not respectively.

15.1 Upper horizontal portion

As per clause no. 6.2.1 of IS 11639 part (II) , Minimum value of critical external pressure shall be adopted from

the Vaughan & Amstutz formula:-

(a) Vaughan formula ( as per IS 11639 part II)

13 K 2 2 3K Yo Fy K 4 Fy F 2 y

P cr 2 Pcr 1

'

' 0

4E ' R 2 E K E

Where,

K= Ratio of pipe diameter to plate thickness

K= 2.500/0.008= 312.50

Es

E'

1 2s

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 17

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

Yo= Initial gap between steel lining concrete in m,0.0003x R= 0.0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

2 2

Fy= Yield point stress in steel in N/m , = 345000000 N/m

2

Substituting respective values and assuming value of Pcr in above equation as 1332238.093 N/m

L.H.S = R.H.S

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

2

Hence, Pcr= 1332238.093 /100000= 13.32 kg/cm

2

Safe Pcr = 13.32/1.5 = 8.88 kg/cm

This document is the INTELLECTUAL PROPERTY of

Hence, 8 mm thick plate having 2500 dia. can take 88 m head as per Vaughan formula.

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

(b) Amstutz Formula

3

1 f n Yo 3K f n 2

2

f ' y f n K f ' y f n

' 1 1.68 K 1

E R E' ' '

E 4 E

2 Pcr

2 fn

1 0.175

K f ' y fn

K E'

fy

3 f 'y

1 s s

2

2 2

fy= Yield point stress in steel in N/m , = 345000000 N/m

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

Yo= Initial gap between steel lining & concrete in m,0.0003x R= .0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

t= thickness of penstock

2

fn= allowable stress in steel in N/m

Substituting values in equation 3

2

f’y = 388155325.80 N/m

2

Substituting values in equation 1 and assuming value of f n as 67869885.50 N/m

L.H.S= R.H.S

Substituting values in equation 2

2

Pcr = 460298.9604 N/m

2

Hence , Pcr= 4602989604 /100000= 4.60 kg/cm

2

Safe Pcr = 4.60/1.5 =3.066 kg/cm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 18

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Hence, 8 mm thick plate having 2500 dia. can take 30 m head as per Vaughan formula.

Adopting, lower values from both equations, i.e. 30 m

As evident from the above calculations that 8 mm thick plate for 2500 mm diameter if remain unstiffened can

take external pressure head up to 30 m In our case maximum external pressure head acting FRL (1450.20) –

C/l of penstock(1422.105) = 28.095 m. Hence stiffeners are not required in upper horizontal line. However,

stiffeners are being provided as the values are close.

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

15.2 AT EL 1310.82

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

As per clause no. 6.2.1 of IS 11639 part(II) , Minimum value of critical external pressure shall be adopted from

the Vaughan & Amstutz formula:-

(a) Vaughan formula ( as per IS 11639 part II)

13 K 2 2 3K Yo Fy K 4 Fy F 2 y

4E '

P cr 2 P 1 R 2 E ' K E ' 0

cr

Where,

K= Ratio of pipe diameter to plate thickness

K= 2.500/0.016= 156.25

Es

E'

1 2s

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

Yo= Intial gap between steel lining concrete in m,0.0003x R= 0.0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

2 2

Fy= Yield point stress in steel in N/m , = 345000000 N/m

2

Substituting respective values and assuming value of Pcr in above equation as 3625088.085 N/m

L.H.S = R.H.S

2

Hence , Pcr= 3625088.085 /100000= 36.25 kg/cm

2

Safe Pcr = 36.25/1.5 = 24.16 kg/cm

Hence, 16 mm thick plate having 2500 dia. can take 241 m head as per Vaughan formula.

(b) Amstutz Formula

3

1 f n Yo 3K f n 2

2

f ' y f n K f ' y f n

' 1 1.68 K 1

E R E' ' '

E 4 E

2 Pcr

2 fn

1 0.175

K f ' y fn

K E'

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 19

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

fy

3 f 'y

1 s s

2

2 2

fy= Yield point stress in steel in N/m , = 345000000 N/m

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Yo= Intial gap between steel lining & concrete in m,0.0003x R= .0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

This document is the INTELLECTUAL PROPERTY of

t= thickness of penstock

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

2

fn= allowable stress in steel in N/m

Substituting values in equation 3

2

f’y = 388155325.80 N/m

2

Substituting values in equation 1 and assuming value of f n as 129230560.60 N/m

L.H.S= R.H.S

Substituting values in equation 2

2

Pcr = 1721646.262 N/m

2

Hence , Pcr= 1721646.262 /100000= 17.21 kg/cm

2

Safe Pcr = 17.21/1.5 =11.478 kg/cm

Hence, 16 mm thick plate having 2500 dia. can take 114 m head as per Vaughan formula.

Adopting, lower values from both equations, i.e. 114 m

As evident from the above calculations that 16 mm thick plate for 2500 mm diameter if remain unstiffened can

take external pressure head upto 121 m In our case maximum external pressure head acting FRL (1450.20) –

C/l of penstock near bifurcation(1308.975) = 141.225 m. Hence stiffeners are required in this reach.

15.3 Near Bifurcation - I

As per clause no. 6.2.1 of IS 11639 part (II), Minimum value of critical external pressure shall be adopted from

the Vaughan & Amstutz formula:-

(a) Vaughan formula (as per IS 11639 part II)

13 K 2 2 3K Yo Fy K 4 Fy F 2 y

P cr 2 Pcr 1

'

' 0

4E ' R 2 E K E

Where,

K= Ratio of pipe diameter to plate thickness

K= 2.500/0.018= 138.89

Es

E'

1 2s

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 20

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

Yo= Initial gap between steel lining concrete in m,0.0003x R= 0.0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

2 2

Fy= Yield point stress in steel in N/m , = 345000000 N/m

2

Substituting respective values and assuming value of Pcr in above equation as 4274764.08205 N/m

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

L.H.S = R.H.S

2

Hence, Pcr= 4274764.08205/100000= 42.74 kg/cm

This document is the INTELLECTUAL PROPERTY of

2

Safe Pcr = 42.74/1.5 = 28.49 kg/cm

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Hence, 16 mm thick plate having 2500 dia. can take 284 m head as per Vaughan formula.

(b) Amstutz Formula

3

1 f n Yo 3K f n 2

2

f ' y f n K f ' y f n

' 1 1.68 K 1

E R E' ' '

E 4 E

2 Pcr

2 fn

1 0.175

K f ' y fn

K E'

fy

3 f 'y

1 s s

2

2 2

fy= Yield point stress in steel in N/m , = 345000000 N/m

2 2

Es = Modulus of elasticity of steel in N/m , =210000000000 N/m

μs = Poisson ratio of steel , 0.303

2

Pcr= critical external pressure at buckling, N/m

Yo= Intial gap between steel lining & concrete in m,0.0003x R= .0003x1.25= .0004 m

R = radius of steel liner in m, =1.25 m

t= thickness of penstock

2

fn= allowable stress in steel in N/m

Substituting values in equation 3

2

f’y = 388155325.80 N/m

2

Substituting values in equation 1 and assuming value of f n as 151021991.30 N/m

L.H.S= R.H.S

Substituting values in equation 2

2

Pcr = 2120401.279 N/m

2

Hence , Pcr= 2120401.279 /100000= 21.20 kg/cm

2

Safe Pcr = 21.20/1.5 =14.13 kg/cm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 21

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Hence, 16 mm thick plate having 2500 dia. can take 141.33 m head as per Vaughan formula.

Adopting, lower values from both equations, i.e. 141.33m

As evident from the above calculations that 16 mm thick plate for 2500 mm diameter if remain unstiffened can

take external pressure head up to 141.33 m In our case maximum external pressure head acting FRL

(1450.20) – C/l of penstock near bifurcation(1308.975) = 141.225 m. Hence stiffeners are not required in this

reach.

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

16. Design for External Pressure for Stiffened shell

This document is the INTELLECTUAL PROPERTY of

As per clause no. 6.2.3 of IS 11639 Part (II)

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Critical external pressure for steel liner with stiffening rings should be computed by Timoshenko equation.

The critical external pressure should not be less than l-5 times the

maximum external pressure.

For determining Spacing of Stiffeners Timoshenko formula is used:-

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 22

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

TIMOSHENKO CALCULATION FOR 8 mm thk. liner having stiffener spacing 1250 m .

Elevation up to which 8 mm is proposed = EL 1404.064

External Pressure acting = FRL (1450.20) – 1404.064 = 46.136 m

Thk. of 8 mm with stiffener spacing 1250 mm can take head up to 45.96 m

Marginally upwards, HENCE ADOPTED.

R Radius of penstock m 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25

L Spacing of stifferner rings m 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25 1.25

t Thickness of liner plate m 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008 0.008

n No. of full waves 2.00 3.00 4.00 5.00 6.00 7.00 8.00 9.00 10.00 11.00 12.00 13.00 14.00 15.00 16.00 17.00 18.00

Es Modulus of elasticity for steel kn/m2 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08 2.10E+08

μ Poisson's ratio of steel 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30 0.30

E

S2

E' 1 kn/m2 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08 2.31E+08

2R

K t 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50 312.50

L

λ t 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25 156.25

Pcr Critical external pressure kn/m2 226895 46045 13176 4677 2031 1111 784 689 699 760 852 965 1093 1235 1388 1553 1728

Minimum critical external pressure kn/m2 689.47

Allowable critical external pressure kn/m2 459.65 = 4.60 kg/cm2 = 45.96 m of head

Summary for allowable head of various thicknesses with spacing 1250 mm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 23

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Allowable

head as per

S.NO Thk Dia Timoshenko

1 8 2500 45.96

2 10 2500 80.49

3 12 2500 128.74

4 14 2500 188.4

5 16 2500 265.68

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

Hence a spacing of 1250 mm is adopted for whole penstock wherever stiffeners are required to resist external

This document is the INTELLECTUAL PROPERTY of

pressure.

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

For determining Size/ section of Stiffeners rings of Stiffeners Vaughan formula is used:-

The size of stiffener rings may be worked out using Vaughan’s formulae by trial and error

method so that the ~external critical pressure is not less than 1.5 times the maximum external pressure.

a) For Minimum Thickness i.e. 8 mm

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 24

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Size of stiffener rings by Vaughan's formula (IS 11639 Part 2)

Radius of penstock R m 1.25

Modulus of elasticity of steel Es Kn/m 2 2.10E+08

Poisson ratio of steel µ 0.30

Thickness of liner plate t m 0.008

Thickness of stiffner ring ts m 0.008

depth of stiffner ring d m 0.150

Permissible yield stress of liner σy N/m 2 3.45E+08

Es

E '

E' 2.31E+08

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

1 s

2

Contact zone width of stiffner on ferrule b m 0.008

Associated width L b 1.56 Rt L m 0.16

This document is the INTELLECTUAL PROPERTY of

m2

Observe the protection notice ISO 16016

Sectional area of stiffner ring Ar 0.00120

ANDRITZ HYDRO Pvt. Ltd.

Ar

Equivalent thickness t' t t' m 0.02

l

Total area of composite section A m2 0.00

Initial freedom of shell to become distorted Yo m 0.0004

Distance between the neutral axis of the combined section

and the outer extreme edge of the stiffner V m 0.12

Moment of inertia of the combined section about neutral

axis I m4 6.168554E-06

4

R

K1 K1 6.906951E-07

E' t'

Y I K2 0.03

K2 R3 o

R R A V

I y t' I

K3 R K3 141876.73

A V A V

I 2 y t2

2

K4 K4 679683037.73

4 A V 2 R

2

K1 Pcr K 2 Pcr K 3 Pcr K 4 0

3 2

Goal seek by changing Pcr 0

Critical pressure P cr Kn/m 2 4796.64

Critical pressure P cr Kg/cm 2 47.97

Maximum allowable external pressure m 31.98

Allowable head of water m 319.78

b) For Maximum thickness (16 mm)

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 25

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

This document is the INTELLECTUAL PROPERTY of

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

Hence size of stiffeners provided as 8 mm (thk.) x 150 mm (Height)

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 26

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

DESIGN CALCULATION

Li-A/PENSTOCK STRAIGHT FERRULES/ASTM 537 CL 1

Likhu - A HEP, Weight of penstock straight ferrules with Material ASTM 537 Cl I

Spacing Fin-

Thickness Thickness Height of No. of

S. Diameter Length between ished

Reach EL of Ferrule of stiffen- stiffener Stiffen-

No. (mm) (m) stiffeners weight

(mm) er (mm) (mm) ers

(mm) (MT)

1 Up to El 1383.340 2500 82.6 8 8 150 1250 66 46

2 Up to El 1336.711 2500 60.0 10 8 150 1250 48 42

49/5, Mathura Road, Village Prithla, District Palwal - 121102 (Haryana) INDIA

3 Up to El 1326.997 2500 12.5 12 8 150 1250 10 10

This document is the INTELLECTUAL PROPERTY of

4 Up to EL 1316.944 2500 143.5 14 8 150 1250 115 134

Observe the protection notice ISO 16016

ANDRITZ HYDRO Pvt. Ltd.

5 Up to El 1310.820 2500 115.0 16 8 150 1250 92 122

6 Up to El 1297.700 2500 58.1 20 73

BF 1 to

PH and

7 1500 25.5 12 12

BF 2 to

PH

BF 2 to

8 1100 16.7 10 5

PH

Between

BF 1

9 1900 9.4 16 7

and BF

2

10 Seepage rings and Backing Strips 7

Total 458

Client NUMBUR HIMALAYA HYDROPOWER PVT LTD Internal No. =

Plant LIKHU A HYDRO ELECTRIC PROJECT, NEPAL C-90-834972-058-030-DC-PS-010 +

Contract Nº N/CA/HM/TP/01 Document No.

Page 27

File date 22-04-2019 LKA-030-DC-010-A Rev 0 of 27

A4

You might also like

- BBP PreceduresDocument6 pagesBBP PreceduresSachin SinghNo ratings yet

- Trading Rules Strategies William F EngDocument290 pagesTrading Rules Strategies William F EngDheeraj Suntha100% (10)

- Electromechanical and Hydro MechanicalComponentsDocument42 pagesElectromechanical and Hydro MechanicalComponentsMOHD SALMANNo ratings yet

- Design of Hydraulic WorksDocument23 pagesDesign of Hydraulic WorksHowell Danner Peña Chaquila100% (1)

- Kutehr-IE Phase1 ReportDocument96 pagesKutehr-IE Phase1 ReportL.C. GOYALNo ratings yet

- Final Report Upper RaghughatDocument251 pagesFinal Report Upper Raghughatसुबास अधिकारी0% (1)

- Hydraulic transient analysis report for Nyamagasani 1 HEPP in UgandaDocument92 pagesHydraulic transient analysis report for Nyamagasani 1 HEPP in UgandaRavindu JayalathNo ratings yet

- Hydroelectric Performance EvaluationDocument72 pagesHydroelectric Performance EvaluationDaniel Yoworld100% (1)

- Project Report - THDCILDocument36 pagesProject Report - THDCILMukesh VermaNo ratings yet

- Key Elevation (Not To Scale) Detail A Scale - A: Units Engineering Consultancy Pvt. Ltd. Padam Khola Small Hydro ProjectDocument2 pagesKey Elevation (Not To Scale) Detail A Scale - A: Units Engineering Consultancy Pvt. Ltd. Padam Khola Small Hydro ProjectManjil PuriNo ratings yet

- Khudi BOQ HMDocument37 pagesKhudi BOQ HMBishal PokharelNo ratings yet

- Hydro Turbine Manual 2009.2Document44 pagesHydro Turbine Manual 2009.2Archil Kokhtashvili100% (1)

- Keyal Khwar DamDocument160 pagesKeyal Khwar DamSaad YounusNo ratings yet

- Francis TurbineDocument8 pagesFrancis TurbineVikram Shah100% (1)

- Hydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Document30 pagesHydrodynamic Calculation Butterfly Valve Lenticular Disc $S - D 0.26$Eng-CalculationsNo ratings yet

- HYDG20749Document108 pagesHYDG20749NARENDER KUMARNo ratings yet

- Preliminary Design Hydroelectric Station Problem Without Prime UnitsDocument13 pagesPreliminary Design Hydroelectric Station Problem Without Prime UnitsadnanNo ratings yet

- Surge Shaft - Design ConceptDocument65 pagesSurge Shaft - Design Conceptpankaj100% (2)

- PowerHouse Design Guidelines 2018 PDFDocument357 pagesPowerHouse Design Guidelines 2018 PDFRakesh Sapkota100% (1)

- Pulichintala ProjectDocument5 pagesPulichintala Projectrn_nadhamNo ratings yet

- Chanju-I Model Test ReportDocument26 pagesChanju-I Model Test ReportBalwant SinghNo ratings yet

- Protecting Run-of-River Hydropower from WaterhammerDocument14 pagesProtecting Run-of-River Hydropower from Waterhammeryouknows50% (2)

- PB Hydro en PDFDocument86 pagesPB Hydro en PDFWahyu Tirta NugrahaNo ratings yet

- Optimum Design of Penstock For Hydro Projects PDFDocument12 pagesOptimum Design of Penstock For Hydro Projects PDFTharindu Nuwan JayakodyNo ratings yet

- Draft Tube CFD Validation with FLINDT DataDocument26 pagesDraft Tube CFD Validation with FLINDT DataKhairy ElsayedNo ratings yet

- LOWER ALEO HEP PROJECT: OPERATION & MAINTENANCE MANUAL TURBINEDocument52 pagesLOWER ALEO HEP PROJECT: OPERATION & MAINTENANCE MANUAL TURBINEMohan ThakurNo ratings yet

- Ensuring dam safety through regular monitoring, inspections and rehabilitationDocument256 pagesEnsuring dam safety through regular monitoring, inspections and rehabilitationSANDIP ROYNo ratings yet

- 2 x 60 MW Nafra HE Project Spherical Valve Technical DescriptionDocument12 pages2 x 60 MW Nafra HE Project Spherical Valve Technical DescriptionHrshiya SharmaNo ratings yet

- EvaPower For HydropowerDocument15 pagesEvaPower For HydropowerTamboli EnergiNo ratings yet

- Kaigah HPP - Executive SummaryDocument27 pagesKaigah HPP - Executive SummaryAli Nawaz Khan100% (1)

- Khani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalDocument10 pagesKhani Khola - 1 HPP: Design Calculation of Bifurcation Block HorizontalAsmita Koirala100% (1)

- Forebay Tank - Design and Construction: Asanka Kumarasiri PG Diploma in Structural Engineering 2014Document17 pagesForebay Tank - Design and Construction: Asanka Kumarasiri PG Diploma in Structural Engineering 2014Anonymous pmwNrPum1CNo ratings yet

- Project Report Everest Power Pvt. LTD: (100 MW) Hydro-Electric Power Project Malana-2 Kullu, Himachal PradeshDocument44 pagesProject Report Everest Power Pvt. LTD: (100 MW) Hydro-Electric Power Project Malana-2 Kullu, Himachal PradeshmohitbiuNo ratings yet

- Alak Description Pelton TurbineDocument12 pagesAlak Description Pelton Turbinepavankumar001No ratings yet

- Spherical Valve Foundation ForceDocument1 pageSpherical Valve Foundation ForceRakesh SapkotaNo ratings yet

- The Gate Shall Be Operated by Rope Drum Hoist: Key PlanDocument1 pageThe Gate Shall Be Operated by Rope Drum Hoist: Key Planbalwant_negi7520No ratings yet

- Kameng Hep: 1 Penstock Loss in PS 2Document2 pagesKameng Hep: 1 Penstock Loss in PS 2vkarayanadathNo ratings yet

- Vol 2 Khep Rmu e MDocument144 pagesVol 2 Khep Rmu e MMuhammed AnasNo ratings yet

- Andritz Hydro Indonesia Presentation 2014Document24 pagesAndritz Hydro Indonesia Presentation 2014Dmz FreakzNo ratings yet

- Silt Gravel Removal GateDocument16 pagesSilt Gravel Removal GateRaja SinghNo ratings yet

- Design Parameters Report: Vishnugad Pipalkoti Hydro Electric Project (4 X 111 MW), THDC, Rishikesh, IndiaDocument58 pagesDesign Parameters Report: Vishnugad Pipalkoti Hydro Electric Project (4 X 111 MW), THDC, Rishikesh, IndiaShivendra KumarNo ratings yet

- Design of Hydraulics Structures 89Document6 pagesDesign of Hydraulics Structures 89Jhon Sebastian BolañosNo ratings yet

- 8 Penstock BFV and AccessoriesDocument6 pages8 Penstock BFV and Accessoriespavankumar001No ratings yet

- Optimization Report-Upper Piluwa10!4!018Document20 pagesOptimization Report-Upper Piluwa10!4!018Manoj BaralNo ratings yet

- 4MW Thak Chillas Hydropower ProjectDocument9 pages4MW Thak Chillas Hydropower Projectliu_jonesNo ratings yet

- Voulume III - Technical AnnexDocument140 pagesVoulume III - Technical AnnexyeyenNo ratings yet

- KERALA STATE ELECTRICITY BOARD LTD. TECHNICAL SPECIFICATIONS (E&M WORKSDocument640 pagesKERALA STATE ELECTRICITY BOARD LTD. TECHNICAL SPECIFICATIONS (E&M WORKSMuhammed AnasNo ratings yet

- Expression of Interest (EOI) : Title of Consulting Service: BHP/CS/ICB-1/2077/78Document47 pagesExpression of Interest (EOI) : Title of Consulting Service: BHP/CS/ICB-1/2077/78Jyan DeuriNo ratings yet

- Bifurcation Design PDFDocument51 pagesBifurcation Design PDFMadhav BaralNo ratings yet

- Radial GateDocument47 pagesRadial Gatenidhisasidharan100% (2)

- Check List - Water FillingDocument1 pageCheck List - Water Fillingsumit1975No ratings yet

- HYDRO Power Plant PresentationDocument71 pagesHYDRO Power Plant Presentationfiraol temesgenNo ratings yet

- Volume 3B PTSDocument625 pagesVolume 3B PTSpavankumar001No ratings yet

- VSHP090041 Pelton T3341e 72dpiDocument8 pagesVSHP090041 Pelton T3341e 72dpiJose Fuentes MendezNo ratings yet

- Of The Hydel Project: Layout PlanDocument75 pagesOf The Hydel Project: Layout PlanDishantNo ratings yet

- Expantion Joint (2) : Section 1Document1 pageExpantion Joint (2) : Section 1Made Agus BudiarthaNo ratings yet

- Calculation of DischargeDocument2 pagesCalculation of DischargeCristina OrmenisanNo ratings yet

- Surge TanksDocument3 pagesSurge TanksPrithwish2014No ratings yet

- Analysis of Hydraulic Pressure Transients in The Waterways of Hydropower StationsDocument77 pagesAnalysis of Hydraulic Pressure Transients in The Waterways of Hydropower Stationskamran1340No ratings yet

- Bend Loss in PenstockDocument22 pagesBend Loss in PenstockAan ShresthaNo ratings yet

- GEL-IN-HMEL-POLY-LTP-V-DOC-001 (2) (1)Document25 pagesGEL-IN-HMEL-POLY-LTP-V-DOC-001 (2) (1)rinkukachhelaNo ratings yet

- LPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetDocument4 pagesLPP-30-W4-DS-202-R Rev.4 Instrument Air Dryer Package Unit Data SheetNyssaMaurillaNo ratings yet

- Startup BusinessDocument43 pagesStartup BusinessAshim LamichhaneNo ratings yet

- Gaming Hub: Business PlanDocument45 pagesGaming Hub: Business PlanAshim LamichhaneNo ratings yet

- Hello Freelancer!: Welcome To Boostmybusiness - Solutions!Document1 pageHello Freelancer!: Welcome To Boostmybusiness - Solutions!Ashim LamichhaneNo ratings yet

- Business PlanDocument30 pagesBusiness PlanAshim LamichhaneNo ratings yet

- Flow Analysis and Structural Design of Penstock Bifurcation of Kulekhani III HEPDocument7 pagesFlow Analysis and Structural Design of Penstock Bifurcation of Kulekhani III HEPSuhasNo ratings yet

- Figure 1.1 Photovoltaic Solar Energy UnitDocument7 pagesFigure 1.1 Photovoltaic Solar Energy UnitAshim LamichhaneNo ratings yet

- Internship Report on Practicum at District Health Office KathmanduDocument27 pagesInternship Report on Practicum at District Health Office KathmanduAshim LamichhaneNo ratings yet

- Globalization's Impact on Public HealthDocument27 pagesGlobalization's Impact on Public HealthAshim LamichhaneNo ratings yet

- Final Year ReportDocument65 pagesFinal Year ReportAshim LamichhaneNo ratings yet

- MEPP 557-Chapter 02-Renewable Energy PerspectivesDocument42 pagesMEPP 557-Chapter 02-Renewable Energy PerspectivesAshim LamichhaneNo ratings yet

- Internship Report AsthaDocument24 pagesInternship Report AsthaAshim LamichhaneNo ratings yet

- Kathmandu University: Department of Mechanical EngineeringDocument36 pagesKathmandu University: Department of Mechanical EngineeringAshim LamichhaneNo ratings yet

- For PBL PresentationDocument2 pagesFor PBL PresentationAshim LamichhaneNo ratings yet

- Internship Report on Practicum at District Health Office KathmanduDocument27 pagesInternship Report on Practicum at District Health Office KathmanduAshim LamichhaneNo ratings yet

- Globalization's Impact on Public HealthDocument27 pagesGlobalization's Impact on Public HealthAshim LamichhaneNo ratings yet

- MEPP 557-Chapter 01-Introduction and OverviewDocument52 pagesMEPP 557-Chapter 01-Introduction and OverviewAshim LamichhaneNo ratings yet

- Globalization's Impact on Public HealthDocument27 pagesGlobalization's Impact on Public HealthAshim LamichhaneNo ratings yet

- Vapour Absorption Refrigreration SystemDocument28 pagesVapour Absorption Refrigreration SystemAshim LamichhaneNo ratings yet

- Ashim Lamichhane and Manish Devkota PBL ReportDocument12 pagesAshim Lamichhane and Manish Devkota PBL ReportAshim LamichhaneNo ratings yet

- LPG Is The Most Used Measure of Cooking in Nepal TodayDocument1 pageLPG Is The Most Used Measure of Cooking in Nepal TodayAshim LamichhaneNo ratings yet

- MEPP 457 Hydrogen TechnologiesDocument88 pagesMEPP 457 Hydrogen TechnologiesAshim LamichhaneNo ratings yet

- HVAC Systems and EquipmentDocument41 pagesHVAC Systems and EquipmentDHADKAN K.C.No ratings yet

- Replacement Scenarios in Conventional Cooking Methods To UseDocument10 pagesReplacement Scenarios in Conventional Cooking Methods To UseAshim LamichhaneNo ratings yet

- Vapour Absorption Refrigreration SystemDocument28 pagesVapour Absorption Refrigreration SystemAshim LamichhaneNo ratings yet

- Psychrometric Processes NumericalsDocument16 pagesPsychrometric Processes NumericalsDHADKAN K.C.No ratings yet

- Refrigeration and Air Conditioning Components GuideDocument43 pagesRefrigeration and Air Conditioning Components GuideAshim Lamichhane100% (1)

- HVAC Systems and EquipmentDocument41 pagesHVAC Systems and EquipmentDHADKAN K.C.No ratings yet

- Refrigeration & AC: Cooling Load Estimation NumericsDocument11 pagesRefrigeration & AC: Cooling Load Estimation NumericsDHADKAN K.C.No ratings yet

- Cooling-Heating Load EstimationDocument20 pagesCooling-Heating Load EstimationDHADKAN K.C.No ratings yet

- Nucor at A Crossroads: Group-2, Section - BDocument8 pagesNucor at A Crossroads: Group-2, Section - BHimanshiNo ratings yet

- 05 Handout 1Document5 pages05 Handout 1Jeanette Pavo TrinidadNo ratings yet

- Terms of Reference: Mataasnakahoy Senior High SchoolDocument13 pagesTerms of Reference: Mataasnakahoy Senior High SchoolAngelica LindogNo ratings yet

- Intention To SubmitDocument12 pagesIntention To SubmitJoseph SalazarNo ratings yet

- 6 1 Reducing Rational Expressions To Lowest TermsDocument21 pages6 1 Reducing Rational Expressions To Lowest Termsapi-233527181No ratings yet

- GW - Energy Storage Solutions - Brochure-ENDocument24 pagesGW - Energy Storage Solutions - Brochure-ENjhtdtNo ratings yet

- Spark Plug ReadingDocument7 pagesSpark Plug ReadingCostas GeorgatosNo ratings yet

- Incremental Analysis Decision MakingDocument4 pagesIncremental Analysis Decision MakingMa Teresa B. CerezoNo ratings yet

- Job DescriptionDocument4 pagesJob Descriptionnafis hasnayenNo ratings yet

- Chord MethodDocument17 pagesChord MethodJedielson GirardiNo ratings yet

- Revista Mexicana de Ciencias Forestales Vol. 9 (49Document32 pagesRevista Mexicana de Ciencias Forestales Vol. 9 (49dacsilNo ratings yet

- Macquarie Capital Cover LetterDocument1 pageMacquarie Capital Cover LetterDylan AdrianNo ratings yet

- Trade Register 2017 2022Document9 pagesTrade Register 2017 2022CatherineNo ratings yet

- HP Compaq Notebook Pricelist: Intel Core I3 380 (2.4Ghz) 3Gb 320 GB W7Hb WLBT 15.6" 512 MB GraphicsDocument14 pagesHP Compaq Notebook Pricelist: Intel Core I3 380 (2.4Ghz) 3Gb 320 GB W7Hb WLBT 15.6" 512 MB GraphicsXris Loidz GanadoNo ratings yet

- Student ProfileDocument2 pagesStudent Profileapi-571568290No ratings yet

- SEAFARERSDocument29 pagesSEAFARERSJohanna Arnaez100% (1)

- Economic and Eco-Friendly Analysis of Solar Power Refrigeration SystemDocument5 pagesEconomic and Eco-Friendly Analysis of Solar Power Refrigeration SystemSiddh BhattNo ratings yet

- GSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundDocument192 pagesGSAA HET 2005-15, Tranche M2 - JPMorgan Investment Funds / Income Oppt'y FundTim BryantNo ratings yet

- Quotes About Homework Being BannedDocument7 pagesQuotes About Homework Being Bannedafeuhyxst100% (1)

- CollegeMathText F2016Document204 pagesCollegeMathText F2016PauloMtzNo ratings yet

- ARIA JumpChainDocument52 pagesARIA JumpChainDorothy FeelyNo ratings yet

- Satelec X Mind DC Brochure enDocument133 pagesSatelec X Mind DC Brochure enAndres Alberto Sanchez LaraNo ratings yet

- Vinamilk - Group 5Document13 pagesVinamilk - Group 5trinhhai09062003No ratings yet

- Guide To Low Voltage Busbar Trunking Systems-BeamaDocument20 pagesGuide To Low Voltage Busbar Trunking Systems-BeamaGhayath Omer100% (1)

- リエイまもかーるDemand Letter Tokutei Ginou Format2022.07.26Document1 pageリエイまもかーるDemand Letter Tokutei Ginou Format2022.07.26Cthu HtunNo ratings yet

- Abortion Guide: Types, Causes and TreatmentDocument46 pagesAbortion Guide: Types, Causes and TreatmentNikhil TyagiNo ratings yet

- Induction Motor StarterDocument5 pagesInduction Motor StarterAnikendu MaitraNo ratings yet

- SATR-W-2007 Rev 7Document4 pagesSATR-W-2007 Rev 7QA QCNo ratings yet