Professional Documents

Culture Documents

06) - Fmea For 11190722 - D

Uploaded by

MONISHRAJOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

06) - Fmea For 11190722 - D

Uploaded by

MONISHRAJCopyright:

Available Formats

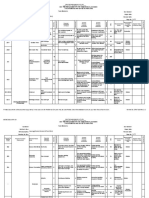

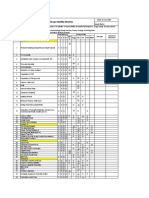

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

1). Work instruction (ISC-II-MS-WI- 022) displayed

Next Operation 1) Parts not stacking properly 1)Inward /Receiving inspection

at shop floor

Part rejected 2) Dedicated bins not available 2). Training Provided for material handling Inward /Receiving inspection

Subsequent Operation

3) Severity of the problem not explained to the 100% Visually checked wheather it is covered

Un known of seriousness On the job training

operators properly

PARTS DAMAGED 4 3 7 84

Assembly

No Effect

End user

No Effect

CASTING WITHOUT VISUAL

DEFECTS

Next Operation

Parts need to be rework 1). Parts stored in open place 1). Dedicated layout provided

Subsequent Operation 2). Parts not dipped in oil 2). Oil dipping process included in process flow

10. Problem in semifinish operation 3). Parts are transferred by roofless vechile 3). Covered vechile or Tarpaulin used

RUST 100 % Visual inspection carried out at inward

TRANSPORTATION NA 2 3 8 48

APPEARANCE inspection

& STORAGE Assembly

No Effect

End user

No Effect

Next Operation

Quantity excess or shortage while machining 1). Quantity excess or shortage while machining Proper counting with trained persons

Subsequent Operation

No Effect

QUANTITY AS PER MENTIONED IN IMPROPER

3 3 100% Visual inspection with delivery chalan 8 72

DELIVERY CHALAN COUNTING

Assembly

No Effect

End user

No Effect

OPERATION NO :- 20 RAW MATERIAL INSPECTION

Next Operation

Causes poor machining

Subsequent Operation

20. PARAMETERS Causes poor

CASTING WITHOUT DEFECTS & machining in further process 1). Improper inspection, 1). Proper inspection, Inspection as per SSIP level 1 with appropriate

RAW MATERIAL NA OUT OF 4 3 7 84

PRODUCT SPECIFICATIONS 2). Ineffecient training to the inspector. 2). Effective training to the operator. measuring instruments Incoming inspectiopn

INSPECTION SPECIFICATIONS Assembly

No Effect

End user

No Effect

OPERATION NO :- 30 RAW MATERIAL STORAGE

Next Operation

Part rejected

Subsequent Operation

30. Problem in next operation

1)OPL /Work instruction displayed at shop floor (

RAW MATERIAL NA PARTS WITHOUT DAMAGE PARTS DAMAGED 4 1) Improper stacking 3 100% Visual inspection 7 84

ISC-MS-SRDAN-02-PM )

STORAGE Assembly

No Effect

End user

No Effect

PAGE NO- 1 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 Next Operation

RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Time delayed due to sorting of 100%

Subsequent Operation

30. Time delayed due to sorting of 100%

RAW MATERIAL NA PARTS WITHOUT MIXUP PARTS MIXED UP 4 zig-zag material flow dedicted layout 3 Inward inspection 7 84

STORAGE Assembly

No Effect

End user

No Effect

OPERATION NO :- 40 RAW MATERIAL TRANSPORTATION FROM STORAGE AREA TO MACHINE SHOP

1). Work instruction (ISC-II-MS-WI- 022) displayed

Next Operation 1) Parts not stacking properly 1)Inward /Receiving inspection

at shop floor

Part rejected 2) Dedicated bins not available 2). Training Provided for material handling Inward /Receiving inspection

Subsequent Operation

3) Severity of the problem not explained to the 100% Visually checked wheather it is covered

PARTS DAMAGED Un known of seriousness 4 operators

On the job training 3 properly 7 84

Assembly

No Effect

40.

RAW MATERIAL End user

TRANSPORTATION CASTING WITHOUT VISUAL No Effect

NA

FROM STORAGE DEFECTS

AREA TO MACHINE Next Operation

SHOP Parts need to be rework 1). Parts stored in open place 1). Dedicated layout provided

Subsequent Operation 2). Parts not dipped in oil 2). Oil dipping process included in process flow

RUST Problem in semifinish operation 3). Parts are transferred by roofless vechile 3). Covered vechile or Tarpaulin used 100 % Visual inspection carried out at inward

3 3 8 72

APPEARANCE Assembly inspection

No Effect

End user

No Effect

OPERATION NO :- 50 PRE MACHINING - 1 ( DATUM "E" OPPOSITE SIDE )

Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide

Master program verification, job set up and As per

Stock minimized at next operation / Unwash Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR

observed at face

periodic inspection with 2D Height Gauge

Subsequent Operation 3). Tool built up edge 3). Alarm & lock in machine for tool life excess

4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

DISTANCE UNDER No Effect 4). Play in cross slide

5 ( ISCII-TS-MTC-PMP/C-R04 ) 3 PMP-R05) with CMK study 5 75

SIZE

Assembly

No Effect

End User

CORE HOLE DISTANCE FOR No Effect

--- 32.00±0.50 STOCK

( 32.20(-0.00 to +0.10)mm ) Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide

Master program verification, job set up and As per

Load for the next process will be high and it may Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR

lead to lower the tool life periodic inspection with 2D Height Gauge

Subsequent Operation 3). Tool wear 3). Alarm & lock in machine for tool life excess

DISTANCE OVER 4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

No Effect 4 4). Play in cross slide 3 6 72

SIZE ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

Assembly

No Effect

End User

50.

PRE MACHINING - 1 No Effect

( DATUM "E"

OPPOSITE SIDE ) Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide Master program verification, job set up and As per

Stock minimized at next operation / Unwash Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR periodic inspection with 2D Height Gauge (or)

observed at face

Digital Vernier Caliper

Subsequent Operation 3). Tool built up edge 3). Alarm & lock in machine for tool life excess

THICKNESS 4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

No Effect 5 4). Play in cross slide 3 5 75

UNDER SIZE ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

Assembly

No Effect

End User

TOTAL THICKNESS FOR No Effect

--- 67.00±0.50 STOCK

( 69.20(-0.00 to +0.10)mm ) Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide Master program verification, job set up and As per

Load for the next process will be high and it may Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR periodic inspection with 2D Height Gauge (or)

lead to lower the tool life

Digital Vernier Caliper

Subsequent Operation 3). Tool wear 3). Alarm & lock in machine for tool life excess

THICKNESS 4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

No Effect 4 4). Play in cross slide 3 6 72

OVER SIZE ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

Assembly

No Effect

End User

No Effect

PAGE NO- 2 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

10 PRE

OPERATION NO :- 60 RAWMACHINING

MATERIAL FROM FOUNDRY

- 2 ( DATUM TO MACHINE

"E" SIDE ) SHOP

Next Operation 1). Tool worn out 1) tool freq. mentioned TMC

Master program verification, job set up and As per

Taper of drills , coordinates erros, 2). Improper M/C Setup 2). Proper checked JSIR Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

periodic inspection with Height Gauge with dial

Subsequent Operation 3). Tool built up edge / wear 3). Alarm & lock in machine for tool life excess

PARALLELISM ON DATUM 'E'

4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

OPPOSITE FACE No Effect 4). Play in cross slide

OUT OF ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

--- 6 3 5 90

SPECIFICATION

Assembly

( f | 0.30 | E )

No Effect

End User

No Effect

Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide

Master program verification, job set up and As per

Stock minimized at next operation / Unwash Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR

observed at face periodic inspection with 2D Height Gauge (or)

Digital Vernier Caliper

Subsequent Operation 3). Tool built up edge 3). Alarm & lock in machine for tool life excess

60. 4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

THICKNESS No Effect 4). Play in cross slide

PRE MACHINING - 2 5 ( ISCII-TS-MTC-PMP/C-R04 ) 3 PMP-R05) with CMK study 5 75

UNDER SIZE

( DATUM "E" SIDE ) Assembly

No Effect

End User

TOTAL THICKNESS FOR No Effect

--- 67.00±0.50 STOCK

( 67.40(-0.00 to +0.10)mm ) Next Operation 1). Wrong Tool Offset 1). Dead stopper on lathe machine slide

Master program verification, job set up and As per

Load for the next process will be high and it may Sampling Plan (ISC-II-TS-QCD-SSIP-D02)

2). Improper M/C Setup 2). Proper checked JSIR

lead to lower the tool life periodic inspection with 2D Height Gauge (or)

Digital Vernier Caliper

Subsequent Operation 3). Tool wear 3). Alarm & lock in machine for tool life excess

4). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

THICKNESS OVER No Effect 4). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

4 3 6 72

SIZE

Assembly

No Effect

End User

No Effect

OPERATION NO :- 70 RAW MATERIAL INSPECTION

Next Operation

Causes poor machining

Subsequent Operation

70.

PARAMETERS Causes poor machining in further process

PRE MACHINING CASTING WITHOUT DEFECTS & 1). Improper inspection, 1). Proper inspection, Inspection as per SSIP level 1 with appropriate

NA OUT OF 4 3 7 84

INWARD PRODUCT SPECIFICATIONS 2). Ineffecient training to the inspector. 2). Effective training to the operator. measuring instruments Incoming inspectiopn

SPECIFICATIONS Assembly

INSPECTION

No Effect

End user

No Effect

OPERATION NO :- 80 SURFACE GRINDING-1 ( DATUM "E" OPPOSITE SIDE )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with Surface

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Roughness Tester

SURFACE FINISH ON DATUM 'E' 3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness Preventive maintainance Record (ISCII-TS-MTC-

OPPOSITE FACE ( ISCII-TS-MTC-PMP/C-R04 )

OUT OF 4). Preventive maintainance Plan PMP-R05) with CMK study

75 Part get rejected at final inspection 8 4). Play in cross slide 2 6 96

SPECIFICATION ( ISCII-TS-MTC-PMP/C-R04 )

Ra 2.50

( 2X Rz 16 ) Assembly

Performance failure

80. End User

SURFACE Reduced Performance

GRINDING-1

( DATUM "E" Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

OPPOSITE SIDE ) jobs once periodic inspection with Surface

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Roughness Tester

SURFACE FINISH ON DATUM 'E' 3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

OPPOSITE FACE ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

OUT OF PMP-R05) with CMK study

79 8 4). Preventive maintainance Plan 2 6 96

SPECIFICATION Part get rejected at final inspection 4). Play in cross slide

Ra 2.50 ( ISCII-TS-MTC-PMP/C-R04 )

( 2X Rz 16 ) Assembly

Performance failure

End User

Reduced Performance

PAGE NO- 3 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with CMM & 4 No"s

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Per Shift Cpu Chart Inspection with CMM

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

FLATNESS ON DATUM 'E' ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

OPPOSITE FACE 4). Preventive maintainance Plan PMP-R05) with CMK study

OUT OF Part get rejected at final inspection 4). Play in cross slide

77 8 ( ISCII-TS-MTC-PMP/C-R04 ) 2 6 96

SPECIFICATION

(2X c | 0.035 ) Assembly

Performance failure

End User

Reduced Performance

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with CMM & 5 No"s

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Per Shift Cpu Chart Inspection with CMM

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

FLATNESS ON DATUM 'E' ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

OPPOSITE FACE 4). Preventive maintainance Plan PMP-R05) with CMK study

OUT OF Part get rejected at final inspection 4). Play in cross slide

81 8 ( ISCII-TS-MTC-PMP/C-R04 ) 2 6 96

SPECIFICATION

(2X c | 0.035 ) Assembly

Performance failure

End User

80.

SURFACE Reduced Performance

GRINDING-1 1). Key lock for un autorised access & program

( DATUM "E" Next Operation 1). Wrong offset

control for parameters

OPPOSITE SIDE ) Master program verification at Job set up and 5

Stock minimized at next operation / Unwash jobs once periodic inspection with 2D Height

2). Improper M/C Setup 2). Proper checked JSIR

observed at face Gauge

Subsequent Operation 2). Grinding wheel wear out 3). Alarm & lock in machine for tool life excess

THICKNESS 4). Preventive maintainance Plan

No Effect 5 4). M/C Bed Flatness More Poor awarness 3 5 75

( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

UNDER SIZE

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

No Effect

End User

TOTAL THICKNESS FOR

--- 67.00±0.50 STOCK No Effect

( 4 X 67.15±0.06mm ) 1). Key lock for un autorised access & program

Next Operation 1). Wrong offset

control for parameters

Master program verification at Job set up and 5

Load for the next process will be high and it may jobs once periodic inspection with 2D Height

2). Improper M/C Setup 2). Proper checked JSIR

lead to lower the tool life Gauge

Subsequent Operation 3). Grinding wheel worn out 3). Alarm & lock in machine for tool life excess

THICKNESS OVER 4). Preventive maintainance Plan

No Effect 4 4). M/C Bed Flatness More Poor awarness 3 6 72

SIZE ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

No Effect

End User

No Effect

OPERATION NO :- 90 SURFACE GRINDING-2 ( DATUM "E" -SIDE )

1). Key lock for un autorised access & program

Next Operation 1). Wrong offset

control for parameters Master program verification at Job set up and 5

jobs once periodic inspection with 2D Height

No Effect 2). Improper M/C Setup 2). Proper checked JSIR

Gauge

Subsequent Operation 2). Grinding wheel wear out 3). Alarm & lock in machine for tool life excess

DISTANCE UNDER Part get rejected at final inspection 4). Preventive maintainance Plan

7 4). M/C Bed Flatness More Poor awarness 3 Preventive maintainance Record (ISCII-TS-MTC- 4 84

SIZE ( ISCII-TS-MTC-PMP/C-R04 )

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

Fitment problem

End User

90.

SURFACE No Effect

TOTAL THICKNESS

GRINDING-2 102 A 1). Key lock for un autorised access & program

( 67.00±0.50mm ) Next Operation 1). Wrong offset

( DATUM "E" -SIDE control for parameters Master program verification at Job set up and 5

) jobs once periodic inspection with 2D Height

No Effect 2). Improper M/C Setup 2). Proper checked JSIR

Gauge

Subsequent Operation 3). Grinding wheel worn out 3). Alarm & lock in machine for tool life excess

4). Preventive maintainance Plan

DISTANCE OVER Part get reject/rework at final inspection 4). M/C Bed Flatness More Poor awarness

6 ( ISCII-TS-MTC-PMP/C-R04 ) 3 Preventive maintainance Record (ISCII-TS-MTC- 5 90

SIZE

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

Fitment problem

End User

No Effect

PAGE NO- 4 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP 1). Key lock for un autorised access & program

Next Operation 1). Wrong offset

control for parameters

Master program verification at Job set up and 5

No Effect 2). Improper M/C Setup 2). Proper checked JSIR jobs once periodic inspection with CMM (or) 2D

Height Gauge

Subsequent Operation 2). Grinding wheel wear out 3). Alarm & lock in machine for tool life excess

DISTANCE UNDER 4). Preventive maintainance Plan

Part get rejected at final inspection 8 4). M/C Bed Flatness More Poor awarness 3 5 120

SIZE ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

Fitment problem

End User

CORE HOLE DISTANCE No Effect

57

( 32.00±0.50mm )

1). Key lock for un autorised access & program

Next Operation 1). Wrong offset

control for parameters Master program verification at Job set up and 5

No Effect 2). Improper M/C Setup 2). Proper checked JSIR jobs once periodic inspection with CMM (or) 2D

Height Gauge

Subsequent Operation 2). Grinding wheel worn out 3). Alarm & lock in machine for tool life excess

4). Preventive maintainance Plan

Part get reject/rework at final inspection 4). M/C Bed Flatness More Poor awarness

DISTANCE OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

8 3 6 144

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Play in cross slide

( ISCII-TS-MTC-PMP/C-R04 )

Fitment problem

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with Surface

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Roughness Tester

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

SURFACE FINISH ON DATUM 'E' ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

FACE OUT OF 4). Preventive maintainance Plan PMP-R05) with CMK study

14 Part get rejected at final inspection 8 4). Play in cross slide 2 6 96

SPECIFICATION ( ISCII-TS-MTC-PMP/C-R04 )

Ra 2.50

( Rz 16 ) Assembly

Performance failure

90.

SURFACE End User

GRINDING-2

( DATUM "E" -SIDE Reduced Performance

) Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with CMM & 5 No"s

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Per Shift Cpu Chart Inspection with CMM

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

FLATNESS ON DATUM 'E' FACE

OUT OF 4). Preventive maintainance Plan PMP-R05) with CMK study

13 Part get rejected at final inspection 8 4). Play in cross slide 2 6 96

SPECIFICATION ( ISCII-TS-MTC-PMP/C-R04 )

( c | 0.035 )

Assembly

Performance failure

End User

Reduced Performance

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with 2D Height

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Gauge

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

PARALLELISM ON DATUM 'E'

4). Preventive maintainance Plan PMP-R05) with CMK study

OPPOSITE FACE Part get rejected at final inspection 4). Play in cross slide

OUT OF ( ISCII-TS-MTC-PMP/C-R04 )

76 6 3 5 90

SPECIFICATION

(2X |

f | 0.50 E ) Assembly

Performance failure

End User

Reduced Performance

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR Master program verification at Job set up and 25

jobs once periodic inspection with 2D Height

No Effect 2). Grinding wheel worn out 2). Alarm & lock in machine for tool life excess Gauge

3). Preventive maintainance Plan

Subsequent Operation 3). M/C Bed Flatness More Poor awarness

( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

PARALLELISM ON DATUM 'E'

4). Preventive maintainance Plan PMP-R05) with CMK study

OPPOSITE FACE Part get rejected at final inspection 4). Play in cross slide

OUT OF ( ISCII-TS-MTC-PMP/C-R04 )

80 6 3 5 90

SPECIFICATION

(2X |

f | 0.50 E ) Assembly

Performance failure

End User

Reduced Performance

PAGE NO- 5 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10

100 -RAW MATERIAL

( DATUM FROM FOUNDRY

"E" OPPOSITE TO MACHINE

SIDE ) SPOT SHOP FORMING, DRILLING, TAPPING & CHAMFERING

FACING, PORT

1). Product placed in wrong position while 1). Proper training provided for clamping

Next Operation 100% Visual Inspection with Fixture set up

clamping Operation standard ( OP/08/DFS-08 ).

1). Lead to tool breakage in current operation

2). Proper training provided for clamping

2). Can not achive the product specification in 2). Clamping tight variation 100% proper tighted (15 to 25 Nm ) with allen Key

Operation standard ( OP/08/DFS-08 ).

current operation

100.(01) Subsequent Operation

IMPROPER

CLAMP THE JOB IN --- PROPER CLAMPING Part get rejected at final inspection 7 2 6 84

CLAMPING

FIXTURE

Assembly

No Effect

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Can not achive the dimension Ø11.00(+0.001 to

+0.011)mm in 100.4th process and get rejected 2). Tool built up edge 2). Alarm & lock in machine for tool life excess Tool verification as per tool package sheet before

at 100.4th process part setting

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection

control for parameter

DIAMETER OVER 4). Preventive maintainance Plan

Part get rejected at final inspection 5 4). Tool worn out 2 5 50

SIZE ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

No Effect

HOLE DIAMETER ON Ø11.00(+0.001

End User

to +0.011) STOCK

---

No Effect

( Ø10.70±0.10mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Load for the 100.4th process will be high and it

2). Tool wear out 2). Alarm & lock in machine for tool life excess

may lead to lower the tool life Tool verification as per tool package sheet before

3). Key lock for un authorised access & Program part setting

Subsequent Operation 3). Wrong Tool selection

control for parameter

DIAMETER

Possibility for subsequent tool broken 6 2 4 48

UNDER SIZE

Assembly

No Effect

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Can not achive the dimension 35.00±0.20 mm in

100.4th process and get rejected at 100.4th 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

process

3). Key lock for un authorised access & Program Master program verification

100.(02) Subsequent Operation 3). Wrong Tool selection

control for parameter

Ø10.70MM DRILLING 4). Key lock for un authorised access & Program

FOR Ø11.00 DEPTH OVER Part get rejected at final inspection 4). Wrong Tool offset

6 control for parameter 3 4 72

ROUGHING - 1 SIZE

5). Key lock for un authorised access & Program

PLACE Assembly 5). Wrong work offset

control for parameter

( DATUM "E"

OPPOSITE SIDE ) Fitment problem not mating with mating part

End User

HOLE DEPTH ON Ø10.70 No Effect

---

( 35.00±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Load for the 100.4th process will be high and it

2). Tool wear out 2). Alarm & lock in machine for tool life excess

may lead to lower the tool life

3). Key lock for un authorised access & Program Master program verification

Subsequent Operation 3). Wrong Tool selection

control for parameter

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DEPTH UNDER control for parameter

7 3 4 84

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

No Effect

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification

2). Key lock for un authorised access & Program

Possibility for combination reamer broken 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

POSITION ON Ø10.70 ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

OUT OF

--- Part get rejected at final inspection 5 2 5 50

SPECIFICATION

( j | Ø0.30 | E | F-G | G )

Assembly

Fitment problem not mating with mating part

End User

No Effect

PAGE NO- 6 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

1). Key lock for un authorised access & Program

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Program change

control for parameter Master program verification

2). Key lock for un authorised access & Program

100.(02) Possibility for combination reamer broken 2). Wrong work offset

control for parameter

Ø10.70MM DRILLING 3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

CENTER DISTANCE ON Ø10.70 Subsequent Operation 3). Machine axis variation (machine wear)

FOR Ø11.00 ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

OUT OF

ROUGHING - 1 --- Part get rejected at final inspection 5 2 4 40

( 15.40±0.15mm ), SPECIFICATION

PLACE

( 11.00±0.15mm ). Assembly

( DATUM "E"

OPPOSITE SIDE ) Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess Nos once periodic inspection with Groove vernier

3). Key lock for un authorised access & Program caliper (or) CMM

Subsequent Operation 3). Wrong Tool selection

control for parameter

DIAMETER OVER 4). Preventive maintainance Plan

Part get rejected at final inspection 6 4). Tool worn out 3 5 90

SIZE ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

part

End User

HOLE DIAMETER

183 Q No Effect

( Ø12.20±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess Master program verification at Job set up and 5

Nos once periodic inspection with Groove vernier

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection caliper (or) CMM

control for parameter

DIAMETER

Part get rejected at final inspection 7 3 4 84

UNDER SIZE

Assembly

Tight Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

DEPTH OVER 4). Key lock for un authorised access & Program

Part get rejected at final inspection 6 4). Wrong Tool offset 3 4 72

SIZE control for parameter

5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

100.(03) End User

Ø12.20MM DRILLING

HOLE DEPTH ON Ø12.20 No Effect

- 1 PLACE 183 D

( DATUM "E" ( 13.00±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

OPPOSITE SIDE )

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

DEPTH UNDER 4). Key lock for un authorised access & Program

Part get rejected at final inspection 7 4). Wrong Tool offset 3 4 84

SIZE control for parameter

5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up and

2). Key lock for un authorised access & Program Shift once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

POSITION ON Ø12.20 Subsequent Operation 3). Machine axis variation (machine wear)

OUT OF ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

184 Part get rejected at final inspection 7 2 6 84

SPECIFICATION

( j | Ø0.30 | E | F | G )

Assembly

Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up

2). Key lock for un authorised access & Program inspection with CMM

No Effect 2). Wrong work offset

control for parameter

CENTER DISTANCE ON Ø12.20 3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

OUT OF ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

Part get rejected at final inspection 7 2 6 84

91, ( 15.40±0.15mm ), SPECIFICATION

89. ( 11.00±0.15mm ). Assembly

Fitment problem not mating with mating part

End User

No Effect

PAGE NO- 7 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

Master program verification at Job set up and 5

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Nos once periodic inspection & 100% process

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess inspection with Bore Dial Gauge (or) Air Plug

3). Key lock for un authorised access & Program Gauge & 4 Nos per Shift Xbar R Chart Inspected

Subsequent Operation 3). Wrong Tool selection with Air Plug Gauge.

control for parameter

4). Preventive maintainance Plan

Part get rejected at final inspection 4). Tool worn out

DIAMETER OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

8 2 5 80

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

part

End User

HOLE DIAMETER No Effect

178

( Ø11.00(+0.001 to +0.011)mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess Nos once periodic inspection & 100% process

3). Key lock for un authorised access & Program inspection with Bore Dial Gauge (or) Air Plug

Subsequent Operation 3). Wrong Tool selection Gauge & 4 Nos per Shift Xbar R Chart Inspected

control for parameter

with Air Plug Gauge.

DIAMETER Part get rejected at final inspection

8 3 4 96

UNDER SIZE Assembly

Tight Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital vernier

control for parameter

caliper

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DEPTH OVER control for parameter

6 3 4 72

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

No Effect

End User

100.(04) No Effect

HOLE DEPTH ON Ø11.00

Ø11.00MM REAMER - ---

( 35.00±0.20mm )

1 PLACE Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

( DATUM "E"

OPPOSITE SIDE ) No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital vernier

control for parameter

caliper

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DEPTH UNDER control for parameter

7 3 4 84

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program Master program verification at Job set up

Next Operation 1). Program change

control for parameter inspection & Shift once periodic inspection with

2). Key lock for un authorised access & Program CMM & 4 Nos per day Cpu Chart inspect with

No Effect 2). Wrong work offset

control for parameter CMM

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

CIRCULARITY ON Ø11.00 Part get rejected at final inspection

OUT OF

183 B 8 2 6 96

SPECIFICATION

( e | 0.007 ) Assembly

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program inspection & Shift once periodic inspection with

No Effect 2). Wrong Tool selection

control for parameter Surface Roughness tester & 4 Nos per day Cpu

3). Key lock for un authorised access & Program Chart inspect with Surface Roughness tester

SURFACE FINISH ON Ø11.00 Subsequent Operation 3). Wrong offset

control for parameter

OUT OF 4). Preventive maintainance Plan

183 C Part get rejected at final inspection 8 4). Machine axis variation (machine wear) 2 4 64

SPECIFICATION ( ISCII-TS-MTC-PMP/C-R04 )

( Ra 3.20

Rz 25 ) Assembly

Customer dissatisfaction at assembly

End User

Performance Low

PAGE NO- 8 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

1). Key lock for un authorised access & Program

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Program change

control for parameter Master program verification at Job set up and

2). Key lock for un authorised access & Program Shift once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

POSITION ON Ø11.00 Part get rejected at final inspection

OUT OF

184 7 2 6 84

SPECIFICATION

( j | Ø0.30 | E | F-G | G ) Assembly

Fitment problem not mating with mating part

100.(04) End User

Ø11.00MM REAMER -

1 PLACE No Effect

( DATUM "E" 1). Key lock for un authorised access & Program

OPPOSITE SIDE ) Next Operation 1). Program change

control for parameter Master program verification at Job set up

2). Key lock for un authorised access & Program inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

CENTER DISTANCE ON Ø11.00 ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

OUT OF Part get rejected at final inspection

7 2 6 84

91, ( 15.40±0.15mm ), SPECIFICATION

89. ( 11.00±0.15mm ). Assembly

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess Nos once periodic inspection with Digital vernier

3). Key lock for un authorised access & Program caliper (or) Plug Gauge

Subsequent Operation 3). Wrong Tool selection

control for parameter

4). Preventive maintainance Plan

Part get rejected at final inspection 4). Tool worn out

DIAMETER OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

6 3 5 90

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

part

End User

SPOT FACE DIAMETER

183 J No Effect

( Ø16.50±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess Master program verification at Job set up and 5

3). Key lock for un authorised access & Program Nos once periodic inspection with Digital vernier

Subsequent Operation 3). Wrong Tool selection caliper (or) Plug Gauge

control for parameter

DIAMETER Part get rejected at final inspection

7 3 4 84

UNDER SIZE

Assembly

Tight Fitment problem not mating with mating part

End User

No Effect

100. (05)

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

ES. 1352 (G 1/4)

PORT FORM TOOL

Ø16.50 & 11.80 - 1 No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

PLACE Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

( DATUM "E" Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Vernier

control for parameter

OPPOSITE SIDE ) Caliper

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DEPTH OVER control for parameter

6 3 4 72

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

SPOT FACE DEPTH ON Ø16.50

183 S

( 4.90±0.10mm ) Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Vernier

control for parameter

Caliper

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

control for parameter

DEPTH UNDER

7 5). Key lock for un authorised access & Program 3 4 84

SIZE Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

PAGE NO- 9 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up

3). Key lock for un authorised access & Program inspection & Periodic inspection with CMM (or) 2D

Subsequent Operation 3). Wrong Tool selection

control for parameter

Height Gauge

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DISTANCE UNDER control for parameter

8 3 4 96

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

SPOT FACE DEPTH DISTANCE ON No Effect

289 Ø16.50

( 62.10±0.13mm ) Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection inspection & Periodic inspection with CMM (or) 2D

control for parameter

Height Gauge

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

DISTANCE OVER control for parameter

8 5). Key lock for un authorised access & Program 3 4 96

SIZE Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

2). Key lock for un authorised access & Program Master program verification at Job set up

No Effect 2). Wrong Tool selection

control for parameter inspection with Surface Roughness tester

3). Key lock for un authorised access & Program

SURFACE FINISH ON Ø16.50 Subsequent Operation 3). Wrong offset

control for parameter

OUT OF 4). Preventive maintainance Plan

183 F Part get rejected at final inspection 6 4). Machine axis variation (machine wear) 2 4 48

SPECIFICATION ( ISCII-TS-MTC-PMP/C-R04 )

( Ra 3.20

Rz 25 ) Assembly

100. (05) Customer dissatisfaction at assembly

ES. 1352 (G 1/4)

End User

PORT FORM TOOL

Ø16.50 & 11.80 - 1 Performance Low

PLACE

( DATUM "E" 1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up & Day

OPPOSITE SIDE )

2). Key lock for un authorised access & Program once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

CONCENTRICITY ON Ø16.50

OUT OF Part get rejected at final inspection

183 N 7 2 6 84

SPECIFICATION

( r | Ø0.40 | D ) Assembly

Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up & Day

2). Key lock for un authorised access & Program once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

PERPENDICULARITY ON Ø16.50 ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

FACE OUT OF Part get rejected at final inspection

183 T 7 2 6 84

SPECIFICATION

( b | 0.10 | D ) Assembly

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with CMM (or) Profile Projector with

control for parameter

moulded paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

PORT 'C' BORE DIAMETER OUT OF Part get rejected at final inspection

132 K 6 2 4 48

(Ø15.10±0.10mm ) SPECIFICATION

Assembly

Customer dissatisfaction at assembly

End User

No Effect

PAGE NO- 10 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with CMM (or) Profile Projector with

control for parameter

moulded paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

PORT 'C' BORE DIAMETER PORT 'C' BORE

132 K Part get rejected at final inspection 6 2 5 60

(Ø15.10±0.10mm ) MISSING

Assembly

Customer dissatisfaction at assembly

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up

2). Key lock for un authorised access & Program inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

PORT 'C' BORE RUNOUT ON ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

Ø15.10 OUT OF Part get rejected at final inspection

183 H 7 2 6 84

SPECIFICATION

( h | 0.10 | D ) Assembly

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

2). Key lock for un authorised access & Program Master program verification at Job set up

No Effect 2). Wrong Tool selection

control for parameter inspection with Surface Roughness tester

3). Key lock for un authorised access & Program

PORT 'C' BORE SURFACE FINISH Subsequent Operation 3). Wrong offset

control for parameter

ON Ø15.10

4). Preventive maintainance Plan

OUT OF Part get rejected at final inspection 4). Machine axis variation (machine wear)

132 G 6 ( ISCII-TS-MTC-PMP/C-R04 ) 2 4 48

SPECIFICATION

( Ra 3.20 Assembly

Rz 16 )

Customer dissatisfaction at assembly

End User

100. (05)

ES. 1352 (G 1/4) Performance Low

PORT FORM TOOL

Ø16.50 & 11.80 - 1 Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

PLACE Master program verification at Job set up

( DATUM "E" 2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with CMM (or) Profile Projector with

OPPOSITE SIDE ) control for parameter

moulded paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

Part get rejected at final inspection

PORT 'C' BORE ANGLE ON Ø15.10 OUT OF

183 I 6 2 4 48

( 15°±1° ) SPECIFICATION

Assembly

Customer dissatisfaction at assembly

End User

No Effect

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with Profile Projector with moulded

control for parameter

paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

OUT OF Part get rejected at final inspection 6 2 4 48

SPECIFICATION

Assembly

Customer dissatisfaction at assembly

End User

PORT 'C' BORE DEPTH ON Ø15.10 No Effect

183 O

( 2.30±0.20mm )

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with Profile Projector with moulded

control for parameter

paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

DEPTH MISSING Part get rejected at final inspection 6 2 5 60

Assembly

Customer dissatisfaction at assembly

End User

No Effect

PAGE NO- 11 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with Profile Projector with moulded

control for parameter

paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

Part get rejected at final inspection

OUT OF

6 2 4 48

SPECIFICATION

Assembly

Customer dissatisfaction at assembly

End User

PORT 'C' BORE OUTER NOSE

183 P RADIUS ON Ø15.10 No Effect

( R0.20±0.10mm X 45° )

Next Operation 1). Tool wear out (Life excess) 1). Alarm & lock in machine for tool life excess

Master program verification at Job set up

2). Key lock for un authorised access & Program

No Effect 2). Wrong Tool selection inspection with Profile Projector with moulded

control for parameter

paste

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong offset

control for parameter

RADIUS MISSING Part get rejected at final inspection 6 2 5 60

Assembly

Customer dissatisfaction at assembly

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess Nos once periodic inspection with CMM (or)

3). Key lock for un authorised access & Program Digital vernier caliper

Subsequent Operation 3). Wrong Tool selection

control for parameter

4). Preventive maintainance Plan

Part get rejected at final inspection 4). Tool worn out

DIAMETER OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

6 3 5 90

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

100. (05) part

ES. 1352 (G 1/4) End User

PORT FORM TOOL HOLE DIAMETER ON G 1/4

Ø16.50 & 11.80 - 1 --- No Effect

( Ø11.80±0.10mm )

PLACE Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

( DATUM "E"

OPPOSITE SIDE ) Possibility for tap broken 2). Tool wear out 2). Alarm & lock in machine for tool life excess Master program verification at Job set up and 5

3). Key lock for un authorised access & Program Nos once periodic inspection with CMM (or)

Subsequent Operation 3). Wrong Tool selection Digital vernier caliper

control for parameter

DIAMETER Part get rejected at final inspection

7 3 4 84

UNDER SIZE Assembly

Tight Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up and

2). Key lock for un authorised access & Program Shift once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

POSITION ON G 1/4 PORT Part get rejected at final inspection

OUT OF

184 7 2 6 84

SPECIFICATION

( j | Ø0.30 | E | F-G | G ) Assembly

Fitment problem not mating with mating part

End User

No Effect

1). Key lock for un authorised access & Program

Next Operation 1). Program change

control for parameter Master program verification at Job set up

2). Key lock for un authorised access & Program inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

CENTER DISTANCE ON G 1/4 PORT Part get rejected at final inspection

91, OUT OF

7 2 6 84

89. ( 15.40±0.15mm ), SPECIFICATION Assembly

( 11.00±0.15mm ).

Fitment problem not mating with mating part

End User

No Effect

PAGE NO- 12 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess Nos once periodic inspection with Groove vernier

3). Key lock for un authorised access & Program caliper (or) CMM

Subsequent Operation 3). Wrong Tool selection

control for parameter

4). Preventive maintainance Plan

Part get rejected at final inspection 4). Tool worn out

DIAMETER OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

6 3 5 90

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

part

End User

GROOVE DIAMETER No Effect

183 Q

( Ø12.20±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess Master program verification at Job set up and 5

3). Key lock for un authorised access & Program Nos once periodic inspection with Groove vernier

Subsequent Operation 3). Wrong Tool selection caliper (or) CMM

control for parameter

DIAMETER Part get rejected at final inspection

7 3 4 84

UNDER SIZE Assembly

Tight Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

4). Key lock for un authorised access & Program

Part get rejected at final inspection 4). Wrong Tool offset

WIDTH OVER control for parameter

8 3 4 96

SIZE 5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

100. (06)

Ø10.00MM No Effect

GROOVE WIDTH ON Ø12.20

GROOVING TOOL 183 V

( 4.50±0.20mm )

FOR 4.20 GROOVE

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

FINISHING - 1

PLACE

( DATUM "E" No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

OPPOSITE SIDE ) Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

4). Key lock for un authorised access & Program

WIDTH UNDER Part get rejected at final inspection 4). Wrong Tool offset

8 control for parameter 3 4 96

SIZE

5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool built up edge 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

4). Key lock for un authorised access & Program

DEPTH OVER Part get rejected at final inspection 4). Wrong Tool offset

8 control for parameter 3 4 96

SIZE

5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

GROOVE DEPTH ON Ø12.20 No Effect

183 U

( 42.15±0.20mm )

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

No Effect 2). Tool wear out 2). Alarm & lock in machine for tool life excess

Master program verification at Job set up and 5

3). Key lock for un authorised access & Program

Subsequent Operation 3). Wrong Tool selection Nos once periodic inspection with Digital Height

control for parameter

Gauge

4). Key lock for un authorised access & Program

DEPTH UNDER Part get rejected at final inspection 4). Wrong Tool offset

8 control for parameter 3 4 96

SIZE

5). Key lock for un authorised access & Program

Assembly 5). Wrong work offset

control for parameter

Fitment problem not mating with mating part

End User

No Effect

PAGE NO- 13 OF192

INDO SHELL CAST PVT LTD Refrence no : ISC-TS-CFT-FMEA-D11

UNIT-II, FAILURE MODE EFFECTIVE ANALYSIS Report no : CP/07/SRD-01

COIMBATORE,

INDIA. Key date : 22.02.2018 FMEA DATE (Orig ) : 22.02.2018

Model/Vehicle : M/S DANFOSS POWER SOLUTIONS (US) COMPANY. Part description : CAT SWL INLET MACHINED Revsion Date : 15.05.2019

Core team : S.Selvam, S.Anandan, P.M.Peter, R.Siva Kumar, O.Ganesan, N.Dinesh Kumar, A.Sridhar,

Part no : 11190722 / D Revsion No. : 04

P.Karthickraja, Arun Kumar, Ranjith Kumar, J.Kumaravel & Ranganathan.

Current Process Action Results

Detection

severity

Responsibility &

class

Occurrence

RPN

Process Potential Potential Cause(s)/Mechanism(s) of

Layout No Requirements Potential effect(s) of failure Recommended Action(s) Target

Function Failure Mode Failures

Controls Prevention Controls Detection Completion Date Action Taken Sev Occ Det RPN

1). Key lock for un authorised access & Program

OPERATION NO :- 10 RAW MATERIAL FROM FOUNDRY TO MACHINE SHOP

Next Operation 1). Program change

control for parameter Master program verification at Job set up and

2). Key lock for un authorised access & Program Shift once periodic inspection with CMM

No Effect 2). Wrong work offset

control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

POSITION ON Ø12.20 GROOVE Part get rejected at final inspection

OUT OF

184 7 2 6 84

SPECIFICATION

( j | Ø0.30 | E | F | G ) Assembly

Fitment problem not mating with mating part

100. (06)

Ø10.00MM End User

GROOVING TOOL

No Effect

FOR 4.20 GROOVE

FINISHING - 1 1). Key lock for un authorised access & Program

Next Operation 1). Program change

PLACE control for parameter Master program verification at Job set up

( DATUM "E" 2). Key lock for un authorised access & Program inspection with CMM

No Effect 2). Wrong work offset

OPPOSITE SIDE ) control for parameter

3). Preventive maintainance Plan Preventive maintainance Record (ISCII-TS-MTC-

Subsequent Operation 3). Machine axis variation (machine wear)

CENTER DISTANCE ON Ø12.20 ( ISCII-TS-MTC-PMP/C-R04 ) PMP-R05) with CMK study

GROOVE Part get rejected at final inspection

91, OUT OF

7 2 6 84

89. SPECIFICATION

( 15.40±0.50mm ), Assembly

( 11.00±0.50mm ).

Fitment problem not mating with mating part

End User

No Effect

Next Operation 1). Improper M/C Setup 1). Proper checked JSIR

Master program verification at Job set up and 5

No Effect 2). Tap built up edge 2). Alarm & lock in machine for tool life excess Nos once periodic inspection & 100% Process

3). Key lock for un authorised access & Program Inspection with Thread Plug Gauge

Subsequent Operation 3). Wrong Tool selection

control for parameter

4). Preventive maintainance Plan

Part get rejected at final inspection 4). Tap worn out

THREAD OVER ( ISCII-TS-MTC-PMP/C-R04 ) Preventive maintainance Record (ISCII-TS-MTC-

6 2 6 72

SIZE 5). Preventive maintainance Plan PMP-R05) with CMK study

Assembly 5). Machine axis variation (machine wear)

( ISCII-TS-MTC-PMP/C-R04 )

Loose Fitment problem not mating with mating

part

End User

THREAD No Effect

183 L

( G 1/4 )