Professional Documents

Culture Documents

Annex E (Table 1, SZ No. (Xii) )

Uploaded by

SvapneshOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Annex E (Table 1, SZ No. (Xii) )

Uploaded by

SvapneshCopyright:

Available Formats

IS 1154 : 2000

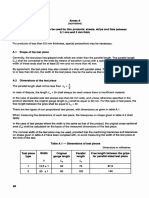

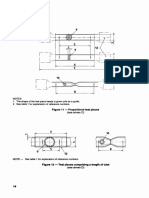

ANNEX E

[Table 1, SZNo. (xii)]

TEST FOR WATER DISPLACEMENT PROPERTY

E-l APPARATUS E-3 PREPARATION OF THE MILD STEEL

PANELS

E-l.1 Glass Desiccator

Polish the panels on both sides by means of a pad of

The glass desiccator shall be provided with tight-fitting filter paper and Carborundum powder and then

lid. Its dimensions shall be such that when the test degrease with toluene. Rinse the panels with acetone

panels are suspended there is at least 38 mm gap and then dry for a few minutes in warm dry air. During

between the panels and any side of the desiccator as and after degreasing, cam shall be taken not to handle

the test surface with bare hands.

well as between the surface of the liquid and thebottom

of the panels. E-4 PROCEDURE

E-2 MATERIALS E-4.1 Carry out the test in quadruplicate.

E-2.1 Mild Steel Panels E-4.2 Immerse, one by one, the clean and degreased

panels completely in the sodium chloride solution for

The mild steel required for this test shall be of Panel 30 seconds. Withdraw momentarily to ensure that the

Sheet (Type P) specified in IS 513. The panels shall film is complete. Then immerse for a further period

be approximately 76 mm x 38 mm x 1.25 mm (or 18 of 90 seconds. (If a complete film is not formed, the

BG) in size and shall have one 6-mm diameter hole, panels have been insufficiently cleaned and the

cleaning process shall be repeated.) Withdraw the

drilled centrally near one of the shorter edges. The

panels and allow to drain at room temperature for

panels shall be free from mill scale or oxides, pits,

10 seconds. Immediately immerse the panels in the

scratches and surface imperfections. temporary corrosion preventive for a period of two

.

minutes, withdraw and examine the panels visually

E-2.2 Carborundum Powder (No. 150)

to find out whether complete displacement of water

E-2.3 Sodium Chloride Solution has taken place. Allow to hang in a vertical position

for one hour at room temperature.

The sodium chloride shall be of analytical reagent

grade (see IS 4408). The strength of the solution shall E-4.3 Suspend the panels vertically in a closed

desiccator containing sodium carbonate solution to

be 3 percent (m/v).

maintain the appropriate humidity. Space the panels

E-2.4 Toluene so that they are 38 mm apart between themselves as

also from the sides of the desiccator and liquid surface.

Sulphur-free, conforming to IS 1839. Leave the panels in the desiccator for 72 hours at room

temperature after which examine the panels for

E-2.5 Acetone corrosion.

Sulphur-free and conforming to IS 170. E-4.4 The temporary corrosion preventive shall be

taken to have satisfied the requirement of the test, if

E-2.6 Sodium Carbonate Solution complete displacement of water takes place and three

out of four panels do not show any sign of corrosion.

Saturated, containing an excess of solid sodium Any corrosion extending up to 6 mm from the edges

carbonate conforming to IS 296. shall be ignored.

You might also like

- GAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Document2 pagesGAP-015 - Rev D (2015 - 06 - 02 18 - 24 - 57 UTC)Epuran Liviu100% (2)

- Surface Prepairation STD For PC ASTM D6386Document4 pagesSurface Prepairation STD For PC ASTM D6386Rohit SangwanNo ratings yet

- TM 10-4930-220-13PDocument133 pagesTM 10-4930-220-13PAdvocateNo ratings yet

- E 676 - 02 - Rty3ngDocument4 pagesE 676 - 02 - Rty3ngjayakumarNo ratings yet

- Failure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreDocument8 pagesFailure and Fracture of Short Flass Fibre Reinforced Nylon Composites MooreGerardo XZNo ratings yet

- Experiment A Test For Lipid Result: Result When Added To WaterDocument5 pagesExperiment A Test For Lipid Result: Result When Added To WaterSuu Wan0% (2)

- Regents Homeostasis and EnzymesDocument5 pagesRegents Homeostasis and Enzymesapi-3031203990% (1)

- Asme Sec Viii D1 Nma App KDocument2 pagesAsme Sec Viii D1 Nma App KADRIANNo ratings yet

- C 325 - 81 R97 - QzmynqDocument2 pagesC 325 - 81 R97 - Qzmynqcurt volvoNo ratings yet

- Penstock Painting - As Per Indian StandardsDocument3 pagesPenstock Painting - As Per Indian StandardsAziz ul HakeemNo ratings yet

- E 133 Â " 92 R96 - RTEZMY05MLI5NGDocument4 pagesE 133 Â " 92 R96 - RTEZMY05MLI5NGhans ccNo ratings yet

- Tinanium Anodising Space PDFDocument7 pagesTinanium Anodising Space PDFgramuiitmNo ratings yet

- D 2325 - 68 R00 Rdizmju - PDFDocument6 pagesD 2325 - 68 R00 Rdizmju - PDFLupita CarelyNo ratings yet

- Asphalt Roof Coatings - Asbestos-Free: Standard Specification ForDocument4 pagesAsphalt Roof Coatings - Asbestos-Free: Standard Specification ForMalak HindiNo ratings yet

- (Table 1, SZ No. (Ix) ) : Annex BDocument1 page(Table 1, SZ No. (Ix) ) : Annex BSvapneshNo ratings yet

- Glass Serological Pipets (General Purpose and Kahn) : Standard Specification ForDocument2 pagesGlass Serological Pipets (General Purpose and Kahn) : Standard Specification ForAhmed AlzubaidiNo ratings yet

- Astm D36Document4 pagesAstm D36Esteban FinoNo ratings yet

- Methods of Sampling Anri Test For Varnishes: Paints, and Related ProductsDocument5 pagesMethods of Sampling Anri Test For Varnishes: Paints, and Related ProductsSimbu ArasanNo ratings yet

- Astm e 1044 - 96Document2 pagesAstm e 1044 - 96MarceloNo ratings yet

- 1 BelzonaDocument41 pages1 BelzonashakeelahmadjsrNo ratings yet

- Distillation Equipment: Standard Specification ForDocument4 pagesDistillation Equipment: Standard Specification ForAhmed AlzubaidiNo ratings yet

- Copper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDocument4 pagesCopper Strip Corrosion by Liquefied Petroleum (LP) Gases: Standard Test Method ForDennise ChicaizaNo ratings yet

- ASTM D113 Ductility of Bituminous Materials 33Document3 pagesASTM D113 Ductility of Bituminous Materials 33frengki jmNo ratings yet

- Determination of A Volatile Distillate Fraction of Cold Asphalt MixturesDocument3 pagesDetermination of A Volatile Distillate Fraction of Cold Asphalt Mixturesmohammed karasnehNo ratings yet

- Material PerformanceDocument5 pagesMaterial PerformanceYousuf MemonNo ratings yet

- NSF 61 PaintDocument2 pagesNSF 61 Paintraviraj londheNo ratings yet

- Cemtec A1 Black PUDocument2 pagesCemtec A1 Black PUAhmad ElghazolyNo ratings yet

- Stress Corrosion Cracking Susceptibility of A Super Duplex ValveDocument15 pagesStress Corrosion Cracking Susceptibility of A Super Duplex ValveMubeenNo ratings yet

- Smarter Building Systems SBS-R30 Insulating Paint InstructionsDocument5 pagesSmarter Building Systems SBS-R30 Insulating Paint InstructionsJJ Sherem MoraNo ratings yet

- Glass Volumetric (Transfer) Pipets: Standard Specification ForDocument2 pagesGlass Volumetric (Transfer) Pipets: Standard Specification ForOlga Karina Toro SayasNo ratings yet

- HR 48 (Trivalent Temper Resistant Chromate Passivation)Document4 pagesHR 48 (Trivalent Temper Resistant Chromate Passivation)Sinar Cemaramas AbadiNo ratings yet

- ASTM D113 Ductility AASHTO T51Document3 pagesASTM D113 Ductility AASHTO T51Praveen Kumar M CNo ratings yet

- IPC-TM-650 Test Methods Manual: Association Connecting Electronics IndustriesDocument2 pagesIPC-TM-650 Test Methods Manual: Association Connecting Electronics Industriesk_arifahNo ratings yet

- Insta-Blak 333 Blackening BrochureDocument8 pagesInsta-Blak 333 Blackening BrochureLuuThiThuyDuongNo ratings yet

- E 676 Â " 02 - RTY3NGDocument4 pagesE 676 Â " 02 - RTY3NGhans ccNo ratings yet

- Venus VectraDocument2 pagesVenus Vectradeepakshi.inNo ratings yet

- iKOTE CM 30R (TDS) 02-APRIL-2024Document2 pagesiKOTE CM 30R (TDS) 02-APRIL-2024nguyen hoang AnhNo ratings yet

- Macroetch Testing of Tool Steel Bars: Standard Practice ForDocument2 pagesMacroetch Testing of Tool Steel Bars: Standard Practice ForAmir AlikhaniNo ratings yet

- Astm A239 95 1999 PDFDocument4 pagesAstm A239 95 1999 PDFSandip JadhavNo ratings yet

- Fouling-Repellent Coating For Shell-And-Tube Heat ExchangersDocument3 pagesFouling-Repellent Coating For Shell-And-Tube Heat Exchangersزيد عدنان عبد الحسين100% (1)

- Specification For KM-F-120ADocument7 pagesSpecification For KM-F-120APhạm DươngNo ratings yet

- Distillation of Cut-Back ASTM D402Document5 pagesDistillation of Cut-Back ASTM D402mohamedNo ratings yet

- Surface Finish of Brewing Process Vessels: March 1993Document11 pagesSurface Finish of Brewing Process Vessels: March 1993decio ventura rodrigues miraNo ratings yet

- C 283 - 97 R02 - Qzi4mwDocument4 pagesC 283 - 97 R02 - Qzi4mwEmre DalgicNo ratings yet

- Astme1251-Espect - Ems.opt Alumninios PDFDocument5 pagesAstme1251-Espect - Ems.opt Alumninios PDFalejandroNo ratings yet

- Technical Submittal: Product Name Nitoflor EPU100Document14 pagesTechnical Submittal: Product Name Nitoflor EPU100rayNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- Burnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Document8 pagesBurnt Clay Tiles For Use in Lining Irrigation and Drainage Works - Specification (Second Revision)Anonymous i6zgzUvNo ratings yet

- AAB 084413 Glazed CurtainwallDocument9 pagesAAB 084413 Glazed CurtainwallTewodros TeferaNo ratings yet

- Rust-Preventing Characteristics of Steam Turbine Oil in The Presence of Water (Horizontal Disk Method)Document6 pagesRust-Preventing Characteristics of Steam Turbine Oil in The Presence of Water (Horizontal Disk Method)Sai HS BodduNo ratings yet

- Dupont Dryfilm PhotoresistDocument8 pagesDupont Dryfilm Photoresistsaandeep arduinoNo ratings yet

- ALUMON EN - MIES - NA - 201614 - 16jul18Document7 pagesALUMON EN - MIES - NA - 201614 - 16jul18Sarai Aracely melendez garciaNo ratings yet

- Lab P10-P11 - 4th Lithography (Aluminum Metal-Line)Document1 pageLab P10-P11 - 4th Lithography (Aluminum Metal-Line)Anh LuuNo ratings yet

- Balmor Al Tanks: Epoxy Coated Steel TanksDocument12 pagesBalmor Al Tanks: Epoxy Coated Steel TanksYutt WattNo ratings yet

- C 484 - 99 Qzq4nc05oqDocument2 pagesC 484 - 99 Qzq4nc05oqMarceloNo ratings yet

- STC Cleaning ProcedureDocument1 pageSTC Cleaning Procedurejuan saezNo ratings yet

- Micrometer Bend Test For Ductility of ElectrodepositsDocument2 pagesMicrometer Bend Test For Ductility of ElectrodepositsJohnnyNo ratings yet

- Metallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingDocument5 pagesMetallic Sample Preparation For EBSD by Mechanical Method and Argon Ion Beam MillingGee AbrahamNo ratings yet

- Nitoflor EPU100Document4 pagesNitoflor EPU100Allan DerickNo ratings yet

- Denison Filterability TP-02100 PDFDocument2 pagesDenison Filterability TP-02100 PDFRIZKY FIQRINo ratings yet

- D 1881Document4 pagesD 1881seterisparigusNo ratings yet

- High-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesFrom EverandHigh-Temperature Brazing in Controlled Atmospheres: The Pergamon Materials Engineering Practice SeriesNo ratings yet

- Is 1608 - 2005 - 34Document1 pageIs 1608 - 2005 - 34SvapneshNo ratings yet

- Table K.1 - Results From Interlaboratory Tensile Tests: Test Programme ADocument1 pageTable K.1 - Results From Interlaboratory Tensile Tests: Test Programme ASvapneshNo ratings yet

- ISO 6892: 1998 Annex K: Related To Material. TestDocument1 pageISO 6892: 1998 Annex K: Related To Material. TestSvapneshNo ratings yet

- (Rpo, 2) in The CaseDocument1 page(Rpo, 2) in The CaseSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripDocument1 pageIS 1608: 2005 ISO 6892: 1998: 2,5 D From The GripSvapneshNo ratings yet

- Is 1608 - 2005 - 39Document1 pageIs 1608 - 2005 - 39SvapneshNo ratings yet

- (Ijo) N: Is 1608: 2005 Iso 6892: 1998Document1 page(Ijo) N: Is 1608: 2005 Iso 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 36Document1 pageIs 1608 - 2005 - 36SvapneshNo ratings yet

- J2 J2 J2 J4 J2: Parameter Tensile PropertiesDocument1 pageJ2 J2 J2 J4 J2: Parameter Tensile PropertiesSvapneshNo ratings yet

- Is 1608 - 2005 - 27Document1 pageIs 1608 - 2005 - 27SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesDocument1 pageIS 1608: 2005 ISO 6892: 1998: C.2.3Original Gauge Length C.2.3.1 Proportional Test PiecesSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: III IIIDocument1 pageIS 1608: 2005 ISO 6892: 1998: III IIISvapneshNo ratings yet

- J.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998Document1 pageJ.2.3 Total Measurement Uncertainty: IS 1608: 2005 ISO 6892: 1998SvapneshNo ratings yet

- Is 1608 - 2005 - 25Document1 pageIs 1608 - 2005 - 25SvapneshNo ratings yet

- Is 1608 - 2005 - 23Document1 pageIs 1608 - 2005 - 23SvapneshNo ratings yet

- Is 1608 - 2005 - 30Document1 pageIs 1608 - 2005 - 30SvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMDocument1 pageIS 1608: 2005 ISO 6892: 1998: Width Original Gauge Lengtn Original Cross - Sec - Ronal Area Thickness MMSvapnesh100% (1)

- Figure 13 - Test Piece Cut From A TubeDocument1 pageFigure 13 - Test Piece Cut From A TubeSvapneshNo ratings yet

- Is 1608 - 2005 - 29Document1 pageIs 1608 - 2005 - 29SvapneshNo ratings yet

- Annex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthDocument1 pageAnnex 0: D, and Its Shape Shall Be Such That It Does Not Interfere With The Gauge LengthSvapneshNo ratings yet

- MM MM: A.2 Dimensions of The TestDocument1 pageMM MM: A.2 Dimensions of The TestSvapneshNo ratings yet

- IS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionDocument1 pageIS 1608: 2005 ISO 6892: 1998: Figure 3 - Proof Strength, Non-Proportional ExtensionSvapneshNo ratings yet

- Is 1608 - 2005 - 20Document1 pageIs 1608 - 2005 - 20SvapneshNo ratings yet

- Is 1608 - 2005 - 31Document1 pageIs 1608 - 2005 - 31SvapneshNo ratings yet

- Is 1608 - 2005 - 24Document1 pageIs 1608 - 2005 - 24SvapneshNo ratings yet

- Is 1608 - 2005 - 15Document1 pageIs 1608 - 2005 - 15SvapneshNo ratings yet

- Figure 9 - Machined Test Pieces of Rectangular Cross SectionDocument1 pageFigure 9 - Machined Test Pieces of Rectangular Cross SectionSvapneshNo ratings yet

- Is 1608 - 2005 - 10Document1 pageIs 1608 - 2005 - 10SvapneshNo ratings yet

- Is 1608 - 2005 - 18Document1 pageIs 1608 - 2005 - 18SvapneshNo ratings yet

- 11 Determination of Percentage Elongation After FractureDocument1 page11 Determination of Percentage Elongation After FractureSvapneshNo ratings yet

- Orthodontic Wires - Properties / Orthodontic Courses by Indian Dental AcademyDocument226 pagesOrthodontic Wires - Properties / Orthodontic Courses by Indian Dental Academyindian dental academy100% (1)

- Evaporation-An IntroductionDocument23 pagesEvaporation-An IntroductionKusmakarNo ratings yet

- AlkalinityDocument3 pagesAlkalinityNgatchieNo ratings yet

- Cambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelDocument20 pagesCambridge International Examinations Cambridge International Advanced Subsidiary and Advanced LevelharshanauocNo ratings yet

- Types of Chemical ReactionsDocument7 pagesTypes of Chemical ReactionsAirene PalerNo ratings yet

- MasterCast 140Document4 pagesMasterCast 140robin rezkNo ratings yet

- Effect of Corrosion in StructuresDocument32 pagesEffect of Corrosion in StructuresasvihariNo ratings yet

- Zatamaru Cjenovnik PregledatiDocument8 pagesZatamaru Cjenovnik PregledatiNemanja StrkicNo ratings yet

- Culligan MedallistDocument58 pagesCulligan MedallistskballNo ratings yet

- Additional Pressure and Temperature Switch Application InformationDocument2 pagesAdditional Pressure and Temperature Switch Application InformationJean GonzalezNo ratings yet

- Microfine Cement Grouts & Applications in Grouting PracticeDocument38 pagesMicrofine Cement Grouts & Applications in Grouting PracticeGrigas GeorgeNo ratings yet

- Who We Are: Case Study-Mahindra ChlorisDocument25 pagesWho We Are: Case Study-Mahindra ChlorisSUNIDHI VERMANo ratings yet

- Bioconversion of Fish Waste Into A Liquid Fertilizer and Its Impact On Semi - Arid Tropical Crops. 2020Document10 pagesBioconversion of Fish Waste Into A Liquid Fertilizer and Its Impact On Semi - Arid Tropical Crops. 2020José Antonio MaquénNo ratings yet

- The Municiplaity of Busia Solid Waste Management PlanDocument15 pagesThe Municiplaity of Busia Solid Waste Management PlanToi JanetNo ratings yet

- Nepro PVC PipesDocument11 pagesNepro PVC PipesAhrian BenaNo ratings yet

- Module 2 - Fire SafetyDocument68 pagesModule 2 - Fire Safetyjairath100% (1)

- Indian Regulations On Food PackgingDocument20 pagesIndian Regulations On Food PackgingchoudhurykisanNo ratings yet

- E - 2 - Effect of Casting Shape and Size On Solidification TimeDocument6 pagesE - 2 - Effect of Casting Shape and Size On Solidification Timeoğuz kağanNo ratings yet

- Tds Chemical Resistant CoatingDocument3 pagesTds Chemical Resistant CoatingUtilities2No ratings yet

- Principles of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyDocument25 pagesPrinciples of Topical Therapy: Presented By: DR .Anjali Singh Junior Resident Department of DermatologyRiyaSinghNo ratings yet

- Worksheet2-Water QualityDocument4 pagesWorksheet2-Water QualityJoewellyn LimNo ratings yet

- 444 Data SheetDocument2 pages444 Data SheetSabareesh MylsamyNo ratings yet

- Quiz BiochemistryDocument100 pagesQuiz BiochemistryMedShare88% (25)

- SOP For DISDocument5 pagesSOP For DISSidhu S100% (1)

- 2 6 12 Microbial Enumeration Tests PDFDocument5 pages2 6 12 Microbial Enumeration Tests PDFThao TrangNo ratings yet

- Use of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si EngineDocument6 pagesUse of Hydrogen Gas As Suppymentry Fuel in 4 - Stroke Si Enginepetchiappan pNo ratings yet