Professional Documents

Culture Documents

4.1.1.2 - Section 05521, Pipe & Tube Railings

Uploaded by

Ehtesham AliOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4.1.1.2 - Section 05521, Pipe & Tube Railings

Uploaded by

Ehtesham AliCopyright:

Available Formats

Bombardier Transp~ · n UK Ltd.

RIYADH METRO PROJECT

Utchurch Lane Derby 24 SAO ~, STATIO. S A D BUILDINGS CONSTRUCTIO SPECIFICATIO S

Company House No 35994 ./

SE ON 0552 1 - P l~.l\11J _Tl,.!l3.E RAI_LINGS

.,. ,.,. / i''··,.,r ~...,.

PART I ·GENERA\: ;;Y~~

,__ •.

\:_;/ -

1. 1 RELATED DOCUMENTS

A. Drawings and general provisions of the Contract, including General and Supplementary

Conditions and Division I Specification Sections. apply to this Section.

1.2 SUMMARY

A. Section Includes:

I. Steel pipe and tube railings.

2. Stainle s-stcel pipe and tube rai lings.

B. Related Sections include the following:

I. Division I Sections for contractual requirements.

2. Division 6 Section " Miscellaneous Carpentry" for wood blocking for anchoring

ra il ings.

1.3 PERFORMA CE REQUIREME TS

A. Delegated De ign: Design railings. including comprehensive engineering analysis by a

qualified profcs ional engineer, using performance requirements and design criteria

I.

indicated.

B. General: In engineering railings to withstand structural loads indicated. determine allowable

design working stresses of railing materi als based on the following:

I. Steel: 72 percent of minimum yie ld strength.

2. Stainless Steel: 60 percent of minimum yield strength.

Structural Performance: Railings shall withstand the effect of gravity load and the

following load and tresses within limit and under conditions indicated:

I. Handrails and Top Rai ls of Guards:

a. Uniform load of 0.73 kN/m applied in any direction.

b. Concentrated load of0.89 kN applied in any direction.

c. Uniform and concentrated loads need not be assumed to act concutTently.

2. lnfi ll o f Guards:

a. Concentrated load of 0.22 kN applied horizontally on an area o f 0.093 sq. m.

b. lnfi ll load and o ther loads need not be assumed to act concutTcntly.

D. Thermal Movements: Allo na l movements from ambient and surface temperature

changes acting on ex terior:Jlleta' ~....f~bt . ations by preventing buckling, opening of joints,

overstressing of com{one.nfs, ~~yre ~'{ nections, and other detrimental effects.

· J ••

PIPE AND TUBE RAI L! GS 05521 - Page I of I I

508035-SPC-AR-01 REV I

r portation UK Ltd.

Bombardie! T RIYADH METRO PROJECT

Utchurch l erby De24 8AD STATIONS AND BUILD! GS CO STRUCTION SPECIFICATIONS

Compa11y H u No 02235994

I. Te craturc Change: 67 deg C, ambient; I00 dcg C, material surfaces.

E. Control of Co1Tosion: Prevent galvanic action and o h~~J.<n:lJ~ of Gorros[on by insulating

metals and other materials from direct contact with inc mpatibre initerials. '

CTlJ....s..... • ~

1.4 SUBMITTALS VERIFIED

A. Product Data: For the following:

I.

2.

..,

.).

B. Shop Drawings:

c. Samples for Initial Selection: For products invo lving selection of color. text ure. or

design. including mechanical finishes on stainless steel.

D. Samples for Verification: For each type of exposed fini sh required.

I. Sections of each distinctly different linear rail ing member. including handrail s, top

::6

rails. posts, and balusters.

2. Fittings and brackets.

..,

.). Assembled Sample of rail ing system, made from full -size components, including top

rail. post. handrail. and inti!!. Samp le need not be ful l height.

a. Show method of finishing and connecting members at intersections. ~ ., ~

1 1

•

E. Delegated-Design Submittal: For installed products indicated to comply with perf6i·mancc

requirements and design criteria, including analysis data signed and scaled by tbe quaJified

professional engi neer responsible for their preparation.

F. Qualification Data: For qualified professional engineer and testing agency.

G. Mil l Certifica tes : Signed by manufacturers of stainless-steel products ce11 ifying; tha) 1\J

products furnished comply with requirements. ~1

H. Welding certificates.

l. Paint Compatibility Certificates: From manufacturers of topcoats applied over shop primers

cc11ify ing that shop primers arc compatible with topcoats.

J. Product Test Reports: Based on evaluation of comprehensive tests performed by a quaiEfied

testing agency, according to ASTM E 894 and ASTM E 935.

K. Warranty: Sample copy of manufacturer's proposed warranty complying with specified re-

quirements, and stating obligations, remedies, limitations, and exclusions of warranty.

1.5 QUALITY ASSURANCE

A. Source Limitations: Ob~ of railing from single source from si ngle

manufacturer. (/~ .·

I / .. : ·_ \

\ )

PIPE AND TUBE RAIUNGS ____.-<--- / 0552 I - Page 2 of ll

$08035-SPC·AR·O I REV I

lding Qualifications: Qualify procedures and personnel according to the following:

AWS D l.l/Dl.lM, "StructUJal Welding Code - Steel."

A WS D 1.6, "Structmal Welding Code- Stainless Steel."

1.6 P ROJECT CONDITIONS

A. Field Measurements: Verify actual locations of walls and o ther construction contiguous

with metal fabrications by fi eld measurements before fabrication.

1.7 COORDINATION AND SCHEDULING

~ A. Coordinate selection of shop primers with topcoats to be applied over them. Comply with

paint and coating manufacturers' written recommendations to ensure that shop p ri mers and

topcoats are compatible with one another.

~ B. Coordinate installation of anchorages for railings. Fumish setting drawings. templates, and

directions for installing anchorages, including sleeves, concrete inserts, anchor bolts, and

items with integral anchors, that are to be embedded in concrete or masonry. Deliver such

items to Project site in time for installation .

C. Schedule installation so wall attachments are made only to completed walls. Do not suppot1

rail ings temporarily by any means that do not satisfy structural performance requirements

1.8 WARRA TY

Pipe and Tube Railings Warranty: Provide complete wananty in which Manufacti.trcr,

Contractor and Installer are jointly and severall y responsible and agree to repair or replace

without limitations. all or any part of the metal fabrications specified in this section which

fails or becomes defective in materials or workmanship witl~in specified warranty period. I

I. A ll pipe and tube railings are guaranteed to be of good material and workman hip and

fl-ee from defects that render it unserviceable for the usc for which it is intended.

2. Warranty shall also include:

a. Installation and finishing that may be required due to repa ir or replacement of

defective metal fabrications.

b. Metal, sealants, adhesive, insulation, fasteners , and all other components of

pipe and tube railings specified in this section.

3. Fai lure includes, but is not limited to:

a. Deterioration in pipe and tube railings materials and coatings; other than due to

normal age ing and weathering; and any defects in adhesives, sea lants, fixings ,

coverings and other components oftbe work.

4.

To be protected by, tlie guara?te pipe and tube railings products must be stored in a

suitable enclosuyt re,conm~ynded a d approved by the manufacturer of pipe and tube

railings items. / . 1 :~ .:, '• \

5. Warranty Peri d: five (5j.years T lal Wan·anty from date of Substantial Completion.

··? \ :o C I rr ~

PfPE AND TUBE RAILINGS

S08035-SPC-AR-OI REV I

·.· -·~

• ..,;

2 -;-; uf'" 0552 1 - Page 3 of I I

B.ombard1er Transportation UK Ltd.

---Litchurch Lane De e24 BAD RIYADH METRO PROJECT

STATIONS AND BUILDfNGS CO STR UCTION SPECIFICATIONS

Company Hous · . 02235994

PART 2 - PRODU

2.1

(T) 1- ' ·• I " ~ I

A. Manufacturers: Subject to compliance with requireme1t~_, ~va~~~le manu_facturers offering

products that may be incorporated into the Work include, but arc not limited to, the

followin g:

I. Steel Pipe and Tube Railings:

a. Pisor Industries, Inc.

b. Wagner, R & B, Inc. ; a division of the Wagner Companies.

2. Stainless-Stee l Pi pe and Tube Railings:

a. Blum. Julius & Co .. Inc.

b. Paragon Aquatics: Division of Pcntair. Inc.

c. Pisor Industries, lnc.

d. Stainless Fabricators, Inc.

c. Sterling Dula Architectural Products, Inc.; Div. of Kane Manufacturing.

f. Tri Tech, Inc.

g. Tubular Specialties Manufacturi ng, Inc. ...

h. Tuttle Railing Systems: Div. of Tuttle Aluminum & Bronze. Inc.

·~ /

I. Wagner. R & B, lnc.; a divis ion of the Wagner Companies.

J, 6

2.2 METALS, GE ERAL

A. Metal Surfaces, General: Provide materia ls with smooth surfaces. without scam marks.

roller marks, rolled trade names, stains. discolorations, or blemishes.

.-'

B. Brackets. Flanges, and Anchors: Cast or fanned metal of same type of material and finish J

as supponed rails unless otherwise indicated.

2.3 STEEL AND lROJ

A. Tubing: ASTM A 500 (cold formed) or ASTM A 513.

B. Pipe: ASTM A 53/A 53M, Type F or TypeS. Grade A. Standard Weigh t (Schedule 40).

unless another grade and weight arc required by structural loads.

I. Provide galvanized finish for exterior installations and where indicated.

C. Plates, Shapes, and Bars: ASTM A 36/A 36M.

I I

D. Cast Iron: Either gray iron, ASTM A 48/A 48M, or malleable iron, ASTM A 47/A 47M ,

unless otherwise indicated.

2.4 STATN LESS STEEL

A. Tubing: ASTM A 554, Grade MT 3)"6L.

B. Pipe: ASTM A 3 12/ A 312M, Gra ' e ~p 3l'6L.

PIPE A D TUBE RAILI GS 05521- Page4 of I I

508035-SPC-AR-01 REV I

RIYADH METRO PROJECT

Bombardler"T; sportatlon

:

Utchurch Lan roy OeZ4 SAO

UK Ltd STATIO SA D BUILDINGS CONSTRUCTION SPECIFICATIONS

- ---~

I

Company Ho 02~ngs: ASTM A 743/A 743M, Grade CF 8M or CF 3M. _-;· ·- -

D. Plate and Sheet: ASTM A 240/A 240M or ASTM A 666, Type 316 ~ \i~:-~·; ~,_;.o

';!::> • I

·:'3 :,:; I

A. General: Provide the following:

\~.· · ~' e·-~\fJ

-- ---~

.,... ,

I. Hot-Dip Galvanized Railings: Type 304 stainless-steel or hot-dip zinc-coated steel

fasteners complying with ASTM A 153/ A 153M or ASTM F 2329 for zinc coating.

2. Stainless-Steel Railings: Type 316 stainless-stee l fasteners.

l

Fasteners for Anchoring Rail ings to Other Construction: Select fasteners of type, grade, and

cia s required to produce connections suitable for anchoring railings to other types of

construction indicated and capable of withstanding design loads.

c. Fasteners for Interconnecting Railing Components:

I. Provide concealed fasteners for interconnecting railing components and for attaching

them to other work. unless otherwise indicated.

D. Post-Installed Anchors: Torque-controlled expansion anchor or chemical anchors capable

of ustaining, without failure, a load equal to six times the load imposed when installed in

unit masonry and four times the load imposed when installed in concrete, as determined by

testing according to ASTM E 488. conducted by a qualified independent testing agency.

I. Material for Interior Locations: Carbon-steel components zinc-plated to comply with

ASTM B 633 or ASTM F 1941 M, Class Fe/Zn 5, unle s otherwise indicated.

2. Material for Exterior Locations and Where Stainless Steel is Indicated: Alloy Group

A4 stainless-steel bolts, ASTM F 738M, and nuts, ASTM F 836M.

2.6 MISCELLANEOUS MATERIALS

A. Welding Rods and Bare Electrodes: Select according to AWS specifications for metal alloy

welded.

I. For stainless-steel railings, provide type and alloy as recommended ·by producer of

metal to be welded and as required for color match. trcngth. and compatibility in

fab1icatcd items.

B. Etching Cleaner for Gal vanized Metal: Complying with MP1#25.

~

i'·

(,) c. Galvanizing Repair Paint: High-zinc-dust-content paint complying with SSPC-Paint 20 and

(j") compatible with paints specified to be used over it.

\U.\

D. Shop Primers: Provide primers that comply with Division 9 Section "High-Pe1formance

Coatings."

E. Intermediate Coats and Topcoats: Provide products that comply with Division 9 Section

I •

"H igh-Perfonnance Coatings."

F. Bituminous Paint:

PIPE A D TUBE RAILINGS 05521- Page 5 of 11

508035-SPC-AR-01 REV I

B.Drnoardier ansportation UK ltd. RIYADH M ETRO PROJECT

lrtchurch L . erby oe 24 BAD STATIONS AND BUILDINGS CONSTRUCTION SPECIFICATIO S

Company e No. 02235994

G. Nonshri nk, Nonmetal lic Grout: Factory-packaged, nonstaining, noncorTosivc, non

grout complying with ASTM C 1107. Provide grout specifically rcc ----~

manufacturer for interior and exterior applications.

>-

2.7 FABRICATION !Y> h.U·

.. .. -·, _,·' '2.· ·'t'

·~

-- ~ ':.Q

0

A. General: Fabricate railings to comply with requirements indicated for des 0'111\.Tw

member sizes and spacing, deta ils, fin ish, and anchorage, but not less than th o

support structural loads. ~

B. Assemb le rai lings in the shop to greatest extent possible to minimize field splicing

assembl y. Disassemble units only as necessary for shipping and handling limitati s.

Clearly mark units for reassembly and coordinated installation. Use connections that

maintain structural value of joined pieces.

c. Cut, drill , and punch metals clean ly and accurately. Remove burrs and case edges to a

radius of approximately I mm unless otherwise indicated. Remove ·harp or rough areas on

exposed surface .

D. Fonn work true to \;nc and level whh accurate angles and surfaces. /;·:· •kt/

E. Fabricate connections that will be exposed to weather in a manner ~o exc lude water( )

Provide weep holes where water may accumulate.

F. Cut. reinforce, drill , and tap as indicated to receive fini sh hardware. screws, and similar

itcms.

G. Connections: Fabricate railings with either welded or non welded connections unless

otherwise indicated.

H. Welded Con nections (for steel handrail s): Cope components at connections to provide close

fit. or usc fittings designed for thi s purpose. Weld all around at connections. including at

fittings.

I. Usc materials and methods that mrmmrzc distortion and develop strength and /'C)

corro ion resistance of base metals. 10-

2. 0btain fus ion without undercut or overlap.

3. Remove flux immediately.

4. At exposed connections, fini sh exposed surfaces smooth and blended so no roughness

shows after finishing and welded surface matches contou rs of adjoining surfaces.

I. Nonwelded Connections (for stainless steel handrails): Connect members with concealed

mechanical fasteners and fitt ings. Fabricate members and fittings to produce flush , smooth ,

rigid, hairline joints.

I. Fabricate splice joints for field connection using an epoxy struct ural adhesive if this is

manufacturer's standard splicing method.

J. Form changes in direction as follows:

I.

PIPE A D TUBE RAIL! GS 05521 - Page 6 o f I I

S08035-SPC-AR-01 REV 1

Bombardier 1ran~

P. rtation UK-ttd~ RIY ADH METRO PROJECT

Utcnurch La D De24 SAO STATI01 SA 1D BUlLDJNGS COl STRUCTIO SPECTFICATIO S

Company ous. . 02235994 'r'

" ~

K. Be9d members in jigs to produce uniform curvature for each configuration required:

aintajn cross section of member throughout entire bend without buckling, twisting,

rackjog, or otherwise def01ming exposed surfaces of components.

se exposed ends of railing members wi th prefabricated end :fittings.

Close

Brackets, Flanges, Fittings, and Anchors: Provide wa11 brackets. flange s, misce11aneous

fittings, and anchors to interconnect railing members to other work unless otherwise

indicated.

I. At brackets and fittings fastened to plaster or gypsum board partitions, provide crush-

resistant fillers, or other means to transfer loads tlu·ough wa ll fini shes to stmctural

supports and prevent bracket or fitting rotation and crushing of substrate.

0. Provide insert - and other anchorage devices for connecting railings to concrete or masonry

work. Fabricate anchorage devices capable of withstanding load impo ed by railings.

Coordinate anchorage devices with supporting stmcture.

P. For railing posts set in concrete, provide stainless-steel sleeves not less than I 50 mm long

with inside dimensions not less than I3 mm greater than outside dimensions of post, with

metal plate form ing bottom closure.

For removable railing posts, fabricate slip-fit sockets from stainless-steel tube or pipe whose

ID is sized for a close fit with posts; limjt movement of post without lateral load, measured

at top. to not more than one-fortieth of po t height. Provide socket cover designed and

fabricated to rc ist being dislodged.

I. Provide chain with eye, snap hook, and staple aero s gaps formed by removable

railing sections at locations indicated. Fabricate from ame metal a railings.

R. Toe Boards: Where indicated, provide toe boards at rai li ngs around openings and at edge of

~··

open-sided floors and platf01ms. Fabricate to dimensions and details indicated. I

2. FI1\'ISHES. GE ' ERAL

I

<:\ A. Comply with 'AAMM's "Metal Fini hes Manual for Architectural and Metal Products" for

\U

B.

recommendations for applying and designating finishes.

Protect mechanical finishes on exposed surfaces from damage by applying a strippable,

I

temporary protective covering before sh ipping.

c. Appearance of Finished Work: Variations in appearance of abutting or adjacent pieces arc

acceptable if they are within one-half of the range of approved Samples. Noticeable

variations in the same piece are not acceptable. Variations in appearance of other

components are acceptable if they are within the range of approved Samples and are

assembled or installed to minimize contrast.

2.9

A.

PIPE AND TUBE RAIUNGS 0552 I - Page 7 of I I

S08035-SPC-AR-01 REV I

STATIONS AND BUILDINGS CO

I.

3.

4.

5. Fill vent and drain holes that will be exposed in the fini shed Work, unless ~ndicatcd to

remain as weep holes, by plugging with zinc solder and filing off smooth.

B. For galvanized railings, provide hot-dip galvanized fittings, brackets, fasteners, sleeves, and ~

other fe rrous components. ~

c. Preparing Galva nized Railings for Shop Priming: After ga lvanizing, thoroughly clean

railings of grease, dirt, oil , nux, and other foreign matter, and treat with etching clea ner.

D. For nonga lvanizcd steel rai lings. provide nongalvanizcd ferrous-metal fittings, brackets,

faste ners. and sleeves, except galvanize anchors to be embedded in exterior concrete or

masonry.

E. Preparation for Shop Priming: Prepare uncoated ferrous-metal surfaces to comply wi th

requirements indicated below:

I. Exterior Railings : SSPC-SP 6 ACE No.3, "Commerc ial Blast Cleaning."

2. Railings Indi cated to Receive Zinc-Rich Primer: SSPC-SP 6/NACE No. 3.

"Commercial Blast Clean ing."

3. Railings Indicated to Receive Primers Specifi ed in Di vision 9 Section "High-

Pcrfonnancc Coatings": SS PC-S P 6 ACE No.3, "Commercial Blast Cleaning."

4. Other Railings: SSPC-S P 3. "Power Tool Cleaning."

F. Primer Application: Apply shop primer to prepared surfaces of railings unless otherwise

indicated. Comply with requirements in SSPC-PA I, "Paint Application Specification

No. I: Shop. Field. and Maintenance Painting of Steel," for shop painting. Primer need not

be applied to surfaces to be embedded in copcrctc or masonry. G-'\1 "

I. Shop prime uncoated railings with primers specified tn Division 9 Section "High-

Performance Coatings" arc indica ted.

2. Do not apply primer to galvanized surfaces.

G. Shop-Painted Finish: Comply wit h Divi sion 9 Section "High-Performance Coatings.''

I. Color: As selected by Engi neer from manufacturer's fu ll range.

.... ,' '

2.10 STAINLESS-STEEL FfNI SHES I

''&;;

·'::--

•

A. Remove tool and die marks and stretch lines, or blend into fini sh.

B. Directional Satin Finish: to. 4.

PfPE AND TUBE RAIUNGS 05521- Page 8 of I I

$08035-SPC-AR-01 REV I

RIYADH METRO PROJECT

LDINGS CO 'STRUCTIOt SPEC!FICATIO S

~

INSTALLATION, GE ERAL

Fit exposed connections together to form tight, hairline joints.

B. Perfo rm cutting, drilling, and fitting required for installing railings. Set railings accurately

in location, alignment, and elevation; mea urcd from established lines and levels and free of

rack.

l. Do not weld, cut, or abrade surface of railing components that ha,·c been coated or

fini hcd after fabrication and that arc intended for field connection by mechanical or

other means without further cutting or fitting.

2. Set posts plumb within a tolerance of2 mm in I m.

~· Align rails so variations from level for horizontal members and vanat1ons from

parallel with rake of steps and ramps for sloping members do not exceed 5 mm in 3

m.

Adjust railings before anchoring to ensure matching alignment at abutting joints.

D. Fastening to In-Place Construction: Usc anchorage device and fasteners where necessary

for securing railing and for properly tran fcrring loads to in-place con truction.

3.3 RAILING CO ECTlONS

A. onweldcd Connections (for stainless steel handrails): Usc mechanical or adhesive joints

for pcnnancntly connecting railing components. Seal recessed holes of exposed locking

screws using plastic cement filler colored to match finish of railing .

B. Welded Connections (for steel handrails): Use fully welded joint for pennanently

connecting railing components. Comply with requirements for welded connections 111

"Fab1ication" A1t icle whether welding is performed in the shop or in the field.

c. Expansion Joints: Install expansion joints at locations indicated but not farther apart than

required to accommodate thermal movement. Provide slip-joint internal sleeve extending

50 mm beyond joint on either side, fasten internal sleeve securely to one side, and locate

joint within 150 mm of post.

3.4 Al\CHORI 1G POSTS

A. Use metal sleeves preset and anchored into concrete for installing posts. After posts have

been inserted into sleeves, fill annular space between post and sleeve with nonshrink,

nonmetallic grout, mixed and mply with anchoring material manufacturer's

written instructions.

PIPE AI~D TUBE RAILINGS

508035-SPC-AR-01 REV I

05521 - Page 9 of II I

Bombardier Transp rt •· n UK Ltd.

Utchurch Lane e De24 SAO RIY /\01-1 METRO PROJECT

Company Ho . 2235994 STATIONS A D BUILDINGS CONSTRUCTIO SPECIFICATIONS

I

B. Fom1 o core-dri ll holes not less than 125 mm deep and 20 mm larger than 00 of post for

instal · g posts in concrete. Clean holes of loose material,/ insert-pests.,-ancL.f!U _annular

space between post and concrete with nonshrink, nonmetaiEc.;.gLOLI:4.:m!..xed,.and _place,d to

comply with anchoring material manufacturer's written instrl.l tions.

(T) ~ •' ~·.., .

~ ~ ~

~

I

C. Cover anchorage joint with flange of same metal as post, velded_.to_ po~ er pla g

anchoring material. l:l> VERIFIED

D. Leave anchorage joint exposed with 3-mm buildup, sloped away from post.

E.

I.

2.

F. Install removable railing sections. where indicated, in slip-fit metal sockets casr in ....concrete.

~

3.5 ATTACHING RAILINGS , '· ~

A. Anchor railing ends at walls with round flanges anchored to wal l construction and welded to

railing ends or connected to railing ends using nonwclded connections as applicable to type

of railing.

B. Anchor railing ends to metal surfaces with flanges bolted to metal surfaces and welded to

railing ends or connected to railing ends using nonwcldcd connections as applicable to type

·of railing.

c. Attach railings to wall with wall brackets. except where end flanges arc used. Provide

brackets with 38-mm clearance from inside face of handrail and tinished wal l surface.

Locate brackets as indicated or. if not indicated, at spacing required to support structural

loads. )

I. Usc type of bracket with flange tapped for concealed anchorage to threaded hanger

bolt .

2. Locate bracket as indicated or. if not indicated. at spacing required to support

stmctural loads.

D. Secure wa ll brackets and railing end flanges to building constructi on as follows:

I. For concrete and solid masomy anchorage, use drilled-in expansion shields and

hanger or lag bolts.

2. For hollow masomy anchorage, use toggle bolts.

3. For steeJ-fralned partitions ~ use se1f-tapping scrc\VS fastened to steel framing or to

concealed steel reinforcements.

4. For steel-framed partitions, use toggle bolts installed through flanges of steel framing

or through concealed steel reinforcements.

3.6 ADJUSTING A D CLEANlNG

A.

clean water. (~ v

~ '

Clean stainless steel by washing thoroughly with clean water and soap and rinsing with

PIPE AND TUBE RAILI GS

508035 -SPC-AR -01 REV I

~ _- j~

,,..

05521 • P•go 10 of II

RIYADH METRO PROJECT

Bombardier 1ra~rtation UK Ltd. STATIO SA 10 BUILDfNGS CO 1STRUCTI01 SPECIFICATIO S

utcnurch Lane YDe24 Sl\~

company Hous ; 022~Juchup Painting: Cleaning and touch up painting of field welds, bolted c01mections, and

abraded areas of shop paint are specified in Division 9 Section "High-Performance

Coatings."

urfaces: Clean field welds, bolted connections, and abraded areas and repair

comply with ASTM A 780.

Protect finishes of railings from damage during construction pc1iod with temporary

protective coverings approved by railing manufacturer. Remove protective coverings at

time of Substantial Completion.

END OF SECTIO 0552 1

,_

I

PIPE AND TUBE RAILI 1GS 05521 -Page II of II

508035-SPC-AR-01 REV I

You might also like

- Pipe and Tube RailingsDocument10 pagesPipe and Tube RailingssobhiNo ratings yet

- Material Submittal HANDRAILDocument6 pagesMaterial Submittal HANDRAILManu Mohan0% (1)

- GRATINGS Rev.1Document7 pagesGRATINGS Rev.1mohdNo ratings yet

- Section 034501 - Miscellaneous Architectural Precast ConcreteDocument6 pagesSection 034501 - Miscellaneous Architectural Precast ConcreteWENDING HUNo ratings yet

- Sec 05720 - Space FrameDocument6 pagesSec 05720 - Space Frametiju2005hereNo ratings yet

- FL - Ta1056Document8 pagesFL - Ta1056ery achjariNo ratings yet

- Part 1 GeneralDocument6 pagesPart 1 GeneralCamilo Eduardo Celis MeloNo ratings yet

- Tieback Anchors - 1.24.11Document7 pagesTieback Anchors - 1.24.11xcvNo ratings yet

- Open Web Steel Joists KSeriesDocument5 pagesOpen Web Steel Joists KSeriesjack.simpson.changNo ratings yet

- PVC SpecificationDocument17 pagesPVC SpecificationDavid Ruelas50% (2)

- PFEIFER Structures Section 133100 PVC SpecificationDocument17 pagesPFEIFER Structures Section 133100 PVC Specificationtidipa8386No ratings yet

- 05 21 00 Steel Joist FramingDocument6 pages05 21 00 Steel Joist FramingTaher AmmarNo ratings yet

- STRUCTURAL STEEL Rev.1Document11 pagesSTRUCTURAL STEEL Rev.1mohdNo ratings yet

- Section 07 4000 - Metal Panel SystemDocument20 pagesSection 07 4000 - Metal Panel SystemMuhammad AbuBakarNo ratings yet

- SECTION 09960 High-Performance Coatings Rev 0Document48 pagesSECTION 09960 High-Performance Coatings Rev 0rachedNo ratings yet

- GratingsDocument6 pagesGratingsHusen ZahranNo ratings yet

- Louver SpecDocument10 pagesLouver SpecCyril J PadiyathNo ratings yet

- 1.5 Sample BRB Specification - bw2sDocument7 pages1.5 Sample BRB Specification - bw2sKen SuNo ratings yet

- Section 055000 - Metal FabricationsDocument15 pagesSection 055000 - Metal FabricationsWENDING HUNo ratings yet

- Civil - Technical SpecificationsDocument28 pagesCivil - Technical SpecificationskhalidNo ratings yet

- Facade SpecificationDocument150 pagesFacade SpecificationKavi PrakashNo ratings yet

- 03 4110 Precast Double Tees1Document11 pages03 4110 Precast Double Tees1M OdebrechtNo ratings yet

- Hollow Core Slab PDFDocument4 pagesHollow Core Slab PDFStraus WaseemNo ratings yet

- AnnexuresDocument29 pagesAnnexuresammarashraf91No ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument13 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionTaher AmmarNo ratings yet

- CCCC Et Ha Spec ST 649 00 Reply BDocument14 pagesCCCC Et Ha Spec ST 649 00 Reply B黄赛赛No ratings yet

- Central Business District of The New Administrative Capital: Prestressed Concrete Construction 348313 - Page of 10Document11 pagesCentral Business District of The New Administrative Capital: Prestressed Concrete Construction 348313 - Page of 10lf chNo ratings yet

- 05 40 00ssbDocument12 pages05 40 00ssbJerico NamucoNo ratings yet

- 1 - . - Hot Dip Galvanizing AESS, Where Indicated, Is Specified in Section 05 05 156. - . - 1Document10 pages1 - . - Hot Dip Galvanizing AESS, Where Indicated, Is Specified in Section 05 05 156. - . - 1Jagatheesh RadhakrishnanNo ratings yet

- Pages From Hollow Core Slab DesingDocument8 pagesPages From Hollow Core Slab DesingMahmoud ShakerNo ratings yet

- Aisc 303-05Document16 pagesAisc 303-05hetpinNo ratings yet

- Outline SpecsDocument171 pagesOutline Specsmohamed fawzyNo ratings yet

- Sec 05520 - Handrails and RailingsDocument5 pagesSec 05520 - Handrails and Railingstiju2005hereNo ratings yet

- PCI Hollowcore Specifications 4-8-11Document8 pagesPCI Hollowcore Specifications 4-8-11Roberto Pérez LeónNo ratings yet

- FL - Metal Pan StairsDocument17 pagesFL - Metal Pan StairsdeviationzNo ratings yet

- SECTION 05 12 00 Structural Steel FramingDocument9 pagesSECTION 05 12 00 Structural Steel FramingJuanPaoloYbañezNo ratings yet

- V04 (Decorative Metal)Document25 pagesV04 (Decorative Metal)Cyril J PadiyathNo ratings yet

- Uniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionDocument10 pagesUniform General Conditions For Construction Contracts, State of Texas, 2010 (UGC) - ConstructionsbunNo ratings yet

- Maintenance EquipmentDocument7 pagesMaintenance Equipmentwalid abou kachfeNo ratings yet

- FL Cold Formed Metal FramingDocument10 pagesFL Cold Formed Metal FramingTaher AmmarNo ratings yet

- Section 07 42 13 - Corrugated Metal Façade Panels Part 1 - General 1.01 Related DocumentsDocument8 pagesSection 07 42 13 - Corrugated Metal Façade Panels Part 1 - General 1.01 Related DocumentsSharlette SaulNo ratings yet

- 03 48 00clcDocument5 pages03 48 00clcAira LauzonNo ratings yet

- 31 63 29 Drilled Concrete PiersDocument13 pages31 63 29 Drilled Concrete PierssbunNo ratings yet

- Appendix 6A: CSI Specifications For Cathodic ProtectionDocument25 pagesAppendix 6A: CSI Specifications For Cathodic Protectionzaheer ahamedNo ratings yet

- Overhead Coiling Doors SpecsDocument10 pagesOverhead Coiling Doors SpecsAHMAD SHNo ratings yet

- King Abdullah Bin Abdulaziz Project Third Saudi Expansion of The Holy Haram Makkah and Surrounding AreasDocument9 pagesKing Abdullah Bin Abdulaziz Project Third Saudi Expansion of The Holy Haram Makkah and Surrounding AreaswooderNo ratings yet

- Asm XDocument6 pagesAsm XAlijihad2001aoNo ratings yet

- 05120-Structural SteelDocument10 pages05120-Structural SteelHusen ZahranNo ratings yet

- Code For Design and Construction For High Strenght BoltDocument33 pagesCode For Design and Construction For High Strenght BoltTimothy HancockNo ratings yet

- Hollowcore SpecificationsDocument5 pagesHollowcore SpecificationsshindidyNo ratings yet

- 05 - 12 - 00 - 00 (05120) - Steel FramingDocument12 pages05 - 12 - 00 - 00 (05120) - Steel FramingMatthew Ho Choon LimNo ratings yet

- Structural SteelDocument4 pagesStructural Steelrize1159No ratings yet

- Section 03410-Precast Structural ConcreteDocument5 pagesSection 03410-Precast Structural ConcreteMØhãmmed ØwięsNo ratings yet

- Section051200 StructuralsteelDocument5 pagesSection051200 StructuralsteelZeljko VasicNo ratings yet

- Tensile Membrane Structures: Name of Project Page - of - July 9, 2013Document18 pagesTensile Membrane Structures: Name of Project Page - of - July 9, 2013jackNo ratings yet

- SECTION 03 41 00 Structural Precast Concrete Part 1 - GeneralDocument16 pagesSECTION 03 41 00 Structural Precast Concrete Part 1 - Generalraja qammarNo ratings yet

- 09 22 16.13mbaDocument11 pages09 22 16.13mbaHanamanthNo ratings yet

- Section 05500 Metal FabricationsDocument7 pagesSection 05500 Metal FabricationsMØhãmmed ØwięsNo ratings yet

- 16410-Enclosed Switches and Circuit BreakersDocument4 pages16410-Enclosed Switches and Circuit BreakersAhmed Sherif IsmailNo ratings yet

- Gantry Pole StaadDocument28 pagesGantry Pole StaadEhtesham AliNo ratings yet

- Proof of Address Proof of Address:, WWW - Address.gov - SaDocument1 pageProof of Address Proof of Address:, WWW - Address.gov - SaEhtesham AliNo ratings yet

- 35M GRD Tower Design Report STCDocument10 pages35M GRD Tower Design Report STCEhtesham AliNo ratings yet

- 30m Anchor and Base Plate MonopoleDocument6 pages30m Anchor and Base Plate MonopoleEhtesham AliNo ratings yet

- JBL0435 GRD ZAIN Report - Rev - ADocument77 pagesJBL0435 GRD ZAIN Report - Rev - AEhtesham AliNo ratings yet

- Dry Shallow Foundation-100 KpaDocument11 pagesDry Shallow Foundation-100 KpaEhtesham AliNo ratings yet

- 35M GRD TosmacDocument41 pages35M GRD TosmacEhtesham AliNo ratings yet

- GENERIC - 9.0m DECORATIVE POLE - REV. CDocument36 pagesGENERIC - 9.0m DECORATIVE POLE - REV. CEhtesham AliNo ratings yet

- 30m Single Operator W Crown Design CalculationDocument47 pages30m Single Operator W Crown Design CalculationEhtesham AliNo ratings yet

- Description & InstalationDocument3 pagesDescription & InstalationEhtesham AliNo ratings yet

- 40m GRD Tower PapersDocument13 pages40m GRD Tower PapersEhtesham AliNo ratings yet

- Syed Ehtesham Ali, Resume, P. 1Document5 pagesSyed Ehtesham Ali, Resume, P. 1Ehtesham AliNo ratings yet

- Ashpower L-Ashoury For Power, Telecom, and Steel Industry Technical Design Calculation For 20M Stadium Mast PoleDocument14 pagesAshpower L-Ashoury For Power, Telecom, and Steel Industry Technical Design Calculation For 20M Stadium Mast PoleEhtesham AliNo ratings yet

- Ijirt151362 PaperDocument5 pagesIjirt151362 PaperEhtesham AliNo ratings yet

- Printix's Print Solution For Microsoft Azure AD Now Available On Microsoft's AppSourceDocument3 pagesPrintix's Print Solution For Microsoft Azure AD Now Available On Microsoft's AppSourcePR.comNo ratings yet

- Introduction To Session BeansDocument36 pagesIntroduction To Session BeansAman Destiny UnfoldedNo ratings yet

- PHP HowtoDocument61 pagesPHP Howtoeminem_bNo ratings yet

- BG RFCDocument31 pagesBG RFCdanveg100% (2)

- SonicOS 5.6.5 Active-Active Clustering Full Mesh TechNoteDocument6 pagesSonicOS 5.6.5 Active-Active Clustering Full Mesh TechNotenguyenkhanhvanNo ratings yet

- Tes-K-100.01-R-1 - Hvac PDFDocument87 pagesTes-K-100.01-R-1 - Hvac PDFMohammed Abdul Moied100% (2)

- KonaKart User Guide PDFDocument288 pagesKonaKart User Guide PDFMuhammad Zulhilmi Wak JongNo ratings yet

- ReadmeDocument2 pagesReadmeNiraj BhakdeNo ratings yet

- Solutions-Mid TermDocument4 pagesSolutions-Mid TermAbdullah HolifNo ratings yet

- HP nc6000 PDFDocument67 pagesHP nc6000 PDFMarcos Alessandro Santana SantosNo ratings yet

- Insp Checklist - Piping AlignmentDocument1 pageInsp Checklist - Piping AlignmentRickesh NunkooNo ratings yet

- Specification Sheet RM 300 M5Document1 pageSpecification Sheet RM 300 M5iwanNo ratings yet

- Hilti Hit Hy 70 1Document26 pagesHilti Hit Hy 70 1Mihnea-Bogdan NicolaescuNo ratings yet

- Huawei OCSDocument2 pagesHuawei OCSLuthfie Setya NugrahaNo ratings yet

- Fishing & Cable Pulling: Ultra Tugger 2 Cable Puller CR25 Cable Roller Guide Ultr Tug Light Base SheaveDocument48 pagesFishing & Cable Pulling: Ultra Tugger 2 Cable Puller CR25 Cable Roller Guide Ultr Tug Light Base SheavePeter KlassenNo ratings yet

- READMEDocument4 pagesREADMEElias DelgadoNo ratings yet

- DBMS KorthDocument21 pagesDBMS KorthAmartya KhanNo ratings yet

- Hurd H3 WindowsDocument13 pagesHurd H3 WindowsaugustashNo ratings yet

- Erwin Panofsky-Meaning in The Visual ArtsDocument469 pagesErwin Panofsky-Meaning in The Visual ArtsBojan Drazic100% (5)

- Multiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsDocument24 pagesMultiple Stiffened Cold-Formed Steel Profiles For Cylindrical Vault Roofing SystemsTiago LopesNo ratings yet

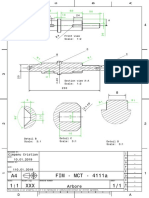

- 1:1 XXX 1/1 A4 FIM - MCT - 4111a: ArboreDocument1 page1:1 XXX 1/1 A4 FIM - MCT - 4111a: ArboreCristianCimpanuNo ratings yet

- "Dos de Mayo" - High School: Qualified PracticeDocument6 pages"Dos de Mayo" - High School: Qualified PracticeFatima C. DiazNo ratings yet

- Logoapp v30 Enus En-UsDocument40 pagesLogoapp v30 Enus En-Uszeus_33No ratings yet

- Magliba ThesisDocument87 pagesMagliba Thesisromae de asis0% (1)

- Ultra Petronne Interior Supply Corporation - Boards Price ListDocument1 pageUltra Petronne Interior Supply Corporation - Boards Price ListAlberto Dorupa50% (2)

- RC-1 Example NewDocument23 pagesRC-1 Example NewAnonymous VUXxu1gT100% (1)

- SPMDT PORT ChecksumDocument17 pagesSPMDT PORT ChecksumDwilmar DhiazNo ratings yet

- General InformationDocument27 pagesGeneral InformationMadhur DeshmukhNo ratings yet

- SQL Developer Data Modeler OverviewDocument27 pagesSQL Developer Data Modeler OverviewsatishvshNo ratings yet

- AD&D Adventure Gamebooks Escape From Castle QuarrasDocument195 pagesAD&D Adventure Gamebooks Escape From Castle QuarrasWerewolf67100% (4)