Professional Documents

Culture Documents

SAFETY WALL - REPORT - R0 - With Annexures

Uploaded by

Gajendra Patil0 ratings0% found this document useful (0 votes)

16 views14 pagesOriginal Title

SAFETY WALL_REPORT_R0 - With Annexures

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

16 views14 pagesSAFETY WALL - REPORT - R0 - With Annexures

Uploaded by

Gajendra PatilCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 14

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 1 of 6

ANALYSIS AND DESIGN OF SAFETY WALL

A0 8th Feb 2022 Issued for Approval PPH GP MK

APPR. BY

REV DATE REVISION DESCRIPTION PRPD. BY CHKD. BY APPR. BY

CLIENT

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 2 of 6

TABLE OF CONTENTS

1.0 SCOPE .................................................................................................................................................... 3

2.0 REFERENCE .......................................................................................................................................... 3

2.1 CODES AND STANDARDS .................................................................................................................... 3

3.0 MODELLING INFORMATION ................................................................................................................. 3

3.1 ASSIGNED MATERIAL AND PROPERTIES .......................................................................................... 4

4.0 BOUNDARY CONDITIONS..................................................................................................................... 5

5.0 LOADING INFORMATION ...................................................................................................................... 6

5.1 DEAD LOAD ........................................................................................................................................... 6

5.2 WATER PRESSURE LOAD .................................................................................................................... 6

5.3 LOAD COMBINATION ............................................................................................................................ 7

6.0 ANALYSIS AND DESIGN ....................................................................................................................... 7

ANNEXURE A: DESIGN OF BASE SLAB

ANNEXURE B: DESIGN OF WALL

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 3 of 6

1.0 SCOPE

The scope of this document is the analysis and design of safety wall having wall thickness of 150mm.

The thickness of base slab 150mm. The dimension of base slab is 21.125m x 16m and height of wall

is 1.0m. Staad Pro software is used for the analysis. Dead load and water pressure load are applied

to the module. The module is designed for worst load combinations.

2.0 REFERENCE

2.1 Codes and Standards

Sr No. Abbreviation Title

1 ACI 350-06 Code Requirements for Environmental Engineering

Concrete Structures

3.0 MODELLING INFORMATION

Following figure shows proposed geometry of structure.

Figure 1: 3D model of structure

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 4 of 6

Figure 2: C/C distances of structure

3.1 ASSIGNED MATERIAL AND PROPERTIES

Following figure shows assigned properties of members as per given input.

Concrete and reinforcement bar materials are used for base slab and wall.

Concrete: -

Unit weight = 24 kN/m3

Young's Modulus = 25000 Mpa

Grade of concrete = M25 Mpa

Rebar: -

Unit weight = 78.5 kN/m3

Young's Modulus = 210000 N/mm2

Yield strength of rebar (fy) =420 MPa

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 5 of 6

Figure 3: Highlighted Plates are 150mm thick

4.0 BOUNDARY CONDITIONS

Figure 4: Boundary conditions

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 6 of 6

5.0 LOADING INFORMATION

5.1 Dead Load

Figure 5: Dead Load (self-weight)

5.2 Water Pressure Load

Hydrostatic pressure on wall = density of water x height of wall

= 10 x 1

= 10 kN/m2.

Figure 6: Water Pressure on wall

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 7 of 6

Figure 7: Water Pressure on base slab

5.3 Load Combination

DEAD LOAD

LOAD CASES

WATER PRESSURE LOAD

1.0DEAD LOAD + 1.0WATER PRESSURE LOAD

LOAD COMBINATION

1.4DEAD LOAD + 1.2WATER PRESSURE LOAD

6.0 ANALYSIS AND DESIGN

Description Thickness (mm) Reinforcement

Longer direction Shorter direction

Base Slab 150 10mm dia. @ 150mm 10mm dia. @ 150mm

Vertical direction Horizontal direction

Concrete Wall 150 10mm dia. @ 150mm 10mm dia. @ 150mm

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 8 of 6

ANNEXURE A: DESIGN OF BASE SLAB

Inital Date Sheet Information Sheet

Raised by Project: SAFETY WALL Proj No.

Designed Structure: SAFETY WALL Scale

Checked Description: DESIGN OF 150 MM BASE SLAB Rev

Approved Calc no.

Item Calculation Procedure Reference/Notes

1 DESIGN PARAMETERS

Material strength:

Concrete comp. Strength, fc' = 25 MPa

Reinf. Yield Strength, fy = 420 MPa

Section properties:

Base slab thickness, h = 150 mm

Conc. Cover, Cc = 75 mm

Effective cover, Cs = 80 mm

Effective depth, d1(for Short reinf) = 60 mm

Effective depth, d2(for Long reinf) = 70 mm

Unit width, b = 1000 mm

Short reinf. bar size, db,v = 10 mm

Long reinf. bar size, db,h = 10 mm

Short bar spacing, Sv = 150 mm

Long bar spacing, Sh = 150 mm

Short area reinforcement, As,v = 523.33mm2

Long area reinforcement, As,h = 523.33 mm2

2 SHEAR CHECK

Ultimate shear force, Vu = 3.69 kN

Conc. Shear capacity, ɸVc = ɸ sqrt(fc') b d1 where, ɸ = 0.75 11.3.1.1_ACI 350-06

6

ɸVc = 37.50 kN Section safe in shear

3 FLEXURE CHECK ALONG SHORTER DIRECTION

Depth of compression block factor, β1 = 0.80 10.2.7.3_ACI 350-06

Balanced steel ratio, ρb = 0.85 β1 fc' 600 = 0.02369

fy x (600+fy)

Maximum steel ratio. ρmax = 0.75ρb = 0.01777

Actual steel ratio, ρactual = As,V = 0.00748

bd2

Minimum steel ratio, ρmin = sqrt(fc') = 0.00298 10.5_ACI 350-06

4 fy Steel yields

Actual steel ratio > minimum, okay

ɸ = 0.9

∑ Forces; C = T; 0.85 fc' β1 c b = As,V fy 10.3_ACI 350-06

Solve for depth of neutral axis, c = 12.99 mm

Depth of compression block, a = β1 x c = 10.34 mm

Ultimate moment capacity, ɸ Mn = 0.9(As,Vfy)(d2-a/2)

= 10.8 kNm

Design short moment, Mux+ = 5.95 kNm

Design short moment, Mux- = 5.69 kNm

Section Adequate for ultimate moment

4 FLEXURE CHECK ALONG LONGER DIRECTION

Depth of compression block factor, β1 = 0.80 10.2.7.3_ACI 350-06

Balanced steel ratio, ρb = 0.85 β1 fc' 600 = 0.02369

fy x (600+fy)

Maximum steel ratio. ρmax = 0.75ρb = 0.01777

Actual steel ratio, ρactual = As,h = 0.00748

bd2

Minimum steel ratio, ρmin = sqrt(fc') = 0.00298 10.5_ACI 350-06

4 fy Steel yields

Actual steel ratio > minimum, okay

ɸ = 0.9

∑ Forces; C = T; 0.85 fc' β1 c b = As,h fy 10.3_ACI 350-06

Solve for depth of neutral axis, c = 12.99 mm

Depth of compression block, a = β1 x c = 10.34 mm

Ultimate moment capacity, ɸ Mn = 0.9(As,hfy)(d2-a/2)

= 11.5 kNm

Design Long moment, Muy+ = 5.96 kNm

Design Long moment, Muy- = 5.52 kNm

Section Adequate for ultimate moment

5 CRACK WIDTH CHECK

Acting service moment, Mservice = 3.38 kNm

.

Stress in steel in flexure, fs = = 93.79 MPa

β = 1.2

If Cc>50, Cc = 50mm C10.6.4_ACI350-06

2

Area, A = 2CcS = 15000 mm Fig.RC.10.6.4 ACI 350

Crack width check for flexure, w

= 0.076 β fs (CC A)1/3 x 0.001 = 0.1 mm 4.2.1_ACI224_R

(English units formula)

Allowable crack width = 0.1 mm

Safe against cracking width

6 SHRINKAGE AND TEMPERATURE REINFORCEMENT CHECK: 7.12_ACI 350-06

2

Minimum shrinkage and temperature reinforcement = 0.005 bt/2 mm > 40FT

2

= 375 mm Each Face

Shrinkage and temperature okay

Design Summary

Description Long Direction Short Direction

Ast Min (mm2) 208.33 178.57

2

Ast Actual (mm ) 523.33 448.57

2

Ast Prov. (mm ) 523.33 523.33

Bar Dia. (mm) 10.00 10.00

Bar Spacing (mm) 150.00 150.00

CLIENT CONTRACTOR

FIELD GATHERING SYSTEM

TRUNKLINES DETAILED ENGINEERING

OMV (YEMEN BLOCK S2) ANALYSIS AND DESIGN OF SAFETY GRIFFIN ENERGY LTD. /

EXPLORATION GMBH ZEN CHEMTECH / RISK WRITERS

WALL

Project Code: 03 Doc. No. YS2-03-C10017-TL-DRA-C-005 Rev A0 Page 9 of 6

ANNEXURE B: DESIGN OF WALL

Inital Date Sheet Information Sheet

Raised by Project: SAFETY WALL Proj No.

Designed Structure: SAFETY WALL Scale

Checked Description: DESIGN OF 150MM WALL Rev

Approved Calc no.

Item Calculation Procedure Reference/Notes

1 DESIGN PARAMETERS

Material strength:

Concrete comp. Strength, fc' = 25 MPa

Reinf. Yield Strength, fy = 420 MPa

Section properties:

Wall thickness, h = 150 mm

Conc. Cover, Cc = 75 mm

Effective cover, Cs = 80 mm

Effective depth, d1(for vertical reinf) = 70 mm

Effective depth, d2(for horizontal reinf) = 60 mm

Unit width, b = 1000 mm

Vertical reinf. bar size, db,v, inside water face = 10 mm

Vertical reinf. bar size, db,v, outside water face = 0 mm

Horizontal reinf. bar size, db,h = 10 mm

Vertical bar spacing, Sv, inside water face = 150 mm

Vertical bar spacing, Sv, outside water face = 150 mm

Horizontal bar spacing, Sh = 150 mm

Vertical area reinforcement, As,v-inside water face = 523.33 mm2

Vertical area reinforcement, As,v-outside water face = 0.00 mm2

Horizontal area reinforcement, As,h-both face = 523.33 mm2

2 SHEAR CHECK

Ultimate shear force, Vu = 9.9 kN

Conc. Shear capacity, ɸVc = ɸ sqrt(fc') b d1 where, ɸ = 0.75 11.3.1.1_ACI 350-06

6

ɸVc = 43.75 kN Section safe in shear

3 FLEXURE CHECK ALONG VERTICAL -INSIDE WATER FACE

Depth of compression block factor, β1 = 0.80 10.2.7.3_ACI 350-06

Balanced steel ratio, ρb = 0.85 β1 fc' 600 = 0.02369

fy x (600+fy)

Maximum steel ratio. ρmax = 0.75ρb = 0.01777

Actual steel ratio, ρactual = As,V = 0.00748

bd1

Minimum steel ratio, ρmin = sqrt(fc') = 0.00298 10.5_ACI 350-06

4 fy Steel yields

Actual steel ratio > minimum, okay

ɸ = 0.9

∑ Forces; C = T; 0.85 fc' β1 c b = As,V fy 10.3_ACI 350-06

Solve for depth of neutral axis, c = 12.99 mm

Depth of compression block, a = β1 x c = 10.34 mm

Ultimate moment capacity, ɸ Mn = 0.9(As,Vfy)(d1-a/2)

= 11.5 kNm

Design vertical moment, Muy + = 1.49 kNm

Section Adequate for ultimate moment

5 FLEXURE CHECK ALONG HORIZONTAL

Depth of compression block factor, β1 = 0.80 10.2.7.3_ACI 350-06

Balanced steel ratio, ρb = 0.85 β1 fc' 600 = 0.02369

fy x (600+fy)

Maximum steel ratio. ρmax = 0.75ρb = 0.01777

Actual steel ratio, ρactual = As,h = 0.00872

bd2

Minimum steel ratio, ρmin = sqrt(fc') = 0.00298 10.5_ACI 350-06

4 fy Steel yields

Actual steel ratio > minimum, okay

ɸ = 0.9

∑ Forces; C = T; 0.85 fc' β1 c b = As,h fy 10.3_ACI 350-06

Solve for depth of neutral axis, c = 12.99 mm

Depth of compression block, a = β1 x c = 10.34 mm

Ultimate moment capacity, ɸ Mn = 0.9(As,hfy)(d2-a/2)

= 10.8 kNm

Design horizontal moment, Mux + = 9.88 kNm

Design horizontal moment, Mux - = 5.25 kNm

Section Adequate for ultimate moment

6 CHECK FOR TENSION

Design tension force, Tu = 53.61 kN

Tension at service loading, T = 23.85 kN

Total Ast = 2 x As,h = 1046.667 mm2

Allowable tension, T = 0.85Ast Fy Φ= 0.9 10.3.7.1_ACI 350-06

ɸT = 336.294 kN

7 CRACK WIDTH CHECK

Acting service moment, Mservice = 5.75 kNm

Stress in steel in flexure, fs = = 161.44 MPa

β = 1.2

If Cc>50, Cc = 50mm C10.6.4_ACI350-06

Area, A = 2CcS = 15000 mm2 Fig.RC.10.6.4 ACI 350

Crack width check for flexure, w

= 0.076 β fs (CC A)1/3 x 0.001 = 0.194 mm 4.2.1_ACI224_R

(English units formula)

Allowable crack width = 0.10 mm

Safe against cracking width

Stress in steel in tension, fsx = T/Ast = 22.787 MPa

Crack width check for tension, w

= 0.1 fsx (Cc A)1/3 x 0.001 0.03 mm 4.8_ACI224_R

(English units formula)

Allowable crack width = 0.1 mm

Safe against cracking width

8 SHRINKAGE AND TEMPERATURE REINFORCEMENT CHECK: 7.12_ACI 350-06

Minimum shrinkage and temperature reinforcement = 0.005 bt/2 mm2 > 40FT

2

= 375 mm Each Face

Shrinkage and temperature okay

9 CHECK FOR COMBINED TENSION AND HORIZONTAL MOMENT

Design tension force, Tu = 53.609 kN

Ast required for tension = Tu/(ϕx0.85xFy) = 166.85 mm2

Design horizontal moment, Mu inside face = 5.2468 kNm

Ast required for moment = Mu/(ϕ0.9Fy(d2-a/2)) = 281.29 mm2

Total area of horizontal steel required = 448.14 mm2

Total area of horizontal steel provided = 1046.67 mm2

SAFE

Design Summary

Description Horizontal Direction Vertical Direction

Ast Min (mm2) 178.57 208.33

2

Ast Actual (mm ) 523.33 523.33

Ast Prov. (mm2) 523.33 523.33

Bar Dia. (mm) 10.00 10.00

Bar Spacing (mm) 150.00 150.00

You might also like

- On-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsFrom EverandOn-Chip Electro-Static Discharge (ESD) Protection for Radio-Frequency Integrated CircuitsNo ratings yet

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- YS2-03-C10017-TL-BOD-L-001 Rev A0 - Piping Design BasisDocument26 pagesYS2-03-C10017-TL-BOD-L-001 Rev A0 - Piping Design BasisameerNo ratings yet

- YS2-03-C10017-TL-BOQ-Z-001 Rev. 0 (BoQ CP)Document10 pagesYS2-03-C10017-TL-BOQ-Z-001 Rev. 0 (BoQ CP)Gajendra PatilNo ratings yet

- YS2-03-C10017-TL-SPC-Z-001 Rev. 0 (Cathodic Protection Specification)Document31 pagesYS2-03-C10017-TL-SPC-Z-001 Rev. 0 (Cathodic Protection Specification)Gajendra PatilNo ratings yet

- Design & Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign & Calculation Cathodic Protection Impressed Cureent SystemLuthfiSiradj96% (27)

- Flexible Roads and Paving SpecificationDocument33 pagesFlexible Roads and Paving Specificationrasnowmah2012No ratings yet

- 66kV Outdoor Surge ArresterDocument6 pages66kV Outdoor Surge Arresterm khNo ratings yet

- DSLP CalculationDocument23 pagesDSLP CalculationMunusamyKarthikeyan100% (1)

- Jitpl Lightning Protection Cal.-Dm 20.09.11Document6 pagesJitpl Lightning Protection Cal.-Dm 20.09.11BasabRaj100% (1)

- CNOOC Southeast Sumatra Pipeline CoatingsDocument12 pagesCNOOC Southeast Sumatra Pipeline CoatingsRokan Pipeline100% (1)

- Lightning Protection Design for Bhadradri TPP FGD SystemDocument16 pagesLightning Protection Design for Bhadradri TPP FGD SystemRukma Goud ShakkariNo ratings yet

- MST For Cathodic ProtectionDocument7 pagesMST For Cathodic ProtectionDelta akathehusky100% (1)

- Design Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign Calculation Cathodic Protection Impressed Cureent Systemadeoye_okunoyeNo ratings yet

- Design Calculation Cathodic Protection Impressed Cureent SystemDocument13 pagesDesign Calculation Cathodic Protection Impressed Cureent SystemPandipperumal SankaralingamNo ratings yet

- MM Met D19084 RP 012Document96 pagesMM Met D19084 RP 012Dass DassNo ratings yet

- Earthing and Lightning Protection InstallationDocument16 pagesEarthing and Lightning Protection Installationwagwahkiabathe100% (1)

- Design, Engineering and Installation Manual FOR Permanent Cathodic Protection System FOR Underground PipelineDocument48 pagesDesign, Engineering and Installation Manual FOR Permanent Cathodic Protection System FOR Underground PipelinemeratiNo ratings yet

- SGC 19 094 Omm 001Document38 pagesSGC 19 094 Omm 001Pro MNo ratings yet

- G3A Barkan S MethodDocument38 pagesG3A Barkan S MethodHsein WangNo ratings yet

- Manual Crane CalculationDocument98 pagesManual Crane CalculationLarry Bea67% (15)

- Lex p1 C Eac f01 Ms 008 Rev. B TNBJ SideDocument36 pagesLex p1 C Eac f01 Ms 008 Rev. B TNBJ SideDetoned StonedNo ratings yet

- Lightning RequirementsDocument48 pagesLightning RequirementsMubeezi ConseptarNo ratings yet

- Engineering mobile pig launcherDocument4 pagesEngineering mobile pig launcherGajendra PatilNo ratings yet

- Client: Dhamra LNG Terminal Private LimitedDocument13 pagesClient: Dhamra LNG Terminal Private LimitedbalajikrishnanNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- Cable Sizing CalculationDocument15 pagesCable Sizing CalculationKhairul AshrafNo ratings yet

- Paseo Curtain Wall Strutural Calculation Ver. 2 March 18 2020 PDFDocument93 pagesPaseo Curtain Wall Strutural Calculation Ver. 2 March 18 2020 PDFVictor Dlreyes100% (1)

- 376100009-R-13-T-C-0007-B Calculation Note For Slab & Beam Scaffolding (DMF Building) PDFDocument27 pages376100009-R-13-T-C-0007-B Calculation Note For Slab & Beam Scaffolding (DMF Building) PDFxyzhynNo ratings yet

- CP SYSTEM - DESIGN DOCUMENT (Rev.01)Document46 pagesCP SYSTEM - DESIGN DOCUMENT (Rev.01)suman ghoshNo ratings yet

- Calculation Sheets FOR 3P-9171A D/S FOUNDATION Pump: TASNEE Petrochemicals Ethylene Project Al-Jubail, Saudi ArabiaDocument22 pagesCalculation Sheets FOR 3P-9171A D/S FOUNDATION Pump: TASNEE Petrochemicals Ethylene Project Al-Jubail, Saudi ArabiaCarlo BarceloNo ratings yet

- Design Calculation - Wall PanelDocument32 pagesDesign Calculation - Wall PanelSankar AnandNo ratings yet

- Structural Calculation/Stress Analysis: SiplanDocument4 pagesStructural Calculation/Stress Analysis: SiplanMEPMANNo ratings yet

- Document Review - CP System - Hamriyah Pipeline, Rev. CDocument33 pagesDocument Review - CP System - Hamriyah Pipeline, Rev. CkpunchepadyNo ratings yet

- Pipe SupportDocument8 pagesPipe SupportVignesh GandhirajNo ratings yet

- Pipe SupportDocument8 pagesPipe SupportVignesh GandhirajNo ratings yet

- S-30-000-1270-002_1_0010_SPECIFICATION_FOR_CATHODIC_PROTECTIONDocument10 pagesS-30-000-1270-002_1_0010_SPECIFICATION_FOR_CATHODIC_PROTECTIONsenthilkesavanpNo ratings yet

- Ph12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC ChecksDocument5 pagesPh12-3a-10-22-P007 - Rev - A - 40mva Oltc Ac and DC Checksaravindhana1a1No ratings yet

- Method Statement For Inst Cable LayingDocument24 pagesMethod Statement For Inst Cable LayingMallikarjun DevarapalliNo ratings yet

- Lightning Protection Calculation DetailsDocument9 pagesLightning Protection Calculation Detailsanmaruthi100% (1)

- Pileload Tes ReportDocument21 pagesPileload Tes ReportMahmudle HassanNo ratings yet

- CP CalculationDocument20 pagesCP CalculationkermaniNo ratings yet

- Sincor: Sincor, C.A. Upstream Surface Facilities Project Basic EngineeringDocument31 pagesSincor: Sincor, C.A. Upstream Surface Facilities Project Basic EngineeringJose Antonio Salazar HidalgoNo ratings yet

- MC - CP Rev. 1Document12 pagesMC - CP Rev. 1Anonymous AtAGVssJNo ratings yet

- Task Force Master: Kutch ChemicalsDocument165 pagesTask Force Master: Kutch ChemicalsJainam ShahNo ratings yet

- Sleeper Design Calculation for Bio-fuel Ethanol Plant ProjectDocument13 pagesSleeper Design Calculation for Bio-fuel Ethanol Plant ProjectajmainNo ratings yet

- MD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICDocument151 pagesMD1-0-T-030-05-00370-C - ITP For CFBC Boiler Installation-ICTran KhuynhNo ratings yet

- Asl C GD Lps Spec 01 r0Document13 pagesAsl C GD Lps Spec 01 r0Agrawal PrajaktaNo ratings yet

- Wind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsFrom EverandWind Turbines in Cold Climates: Icing Impacts and Mitigation SystemsNo ratings yet

- Gain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipFrom EverandGain-Cell Embedded DRAMs for Low-Power VLSI Systems-on-ChipNo ratings yet

- Compendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)From EverandCompendium of Atomic Alkali Resistant Optical Thin Films, Diffusion and Electrical Mobility in Diode Pumped Alkali Lasers (DPALs)No ratings yet

- Design for High Performance, Low Power, and Reliable 3D Integrated CircuitsFrom EverandDesign for High Performance, Low Power, and Reliable 3D Integrated CircuitsNo ratings yet

- Ceramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesFrom EverandCeramic Materials for Energy Applications V: A Collection of Papers Presented at the 39th International Conference on Advanced Ceramics and CompositesJosef MatyášNo ratings yet

- CCTV Surveillance: Video Practices and TechnologyFrom EverandCCTV Surveillance: Video Practices and TechnologyRating: 5 out of 5 stars5/5 (2)

- Advanced and Refractory Ceramics for Energy Conservation and EfficiencyFrom EverandAdvanced and Refractory Ceramics for Energy Conservation and EfficiencyHua-Tay LinNo ratings yet

- Welding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985From EverandWelding for Challenging Environments: Proceedings of the International Conference on Welding for Challenging Environments, Toronto, Ontario, Canada, 15–17 October 1985No ratings yet

- We Love People Who Love Travelling!Document3 pagesWe Love People Who Love Travelling!Gajendra PatilNo ratings yet

- Appointment Letter - Nikhil KhedekarDocument3 pagesAppointment Letter - Nikhil KhedekarGajendra PatilNo ratings yet

- We Love People Who Love Travelling!Document3 pagesWe Love People Who Love Travelling!Gajendra PatilNo ratings yet

- Nikhil Khedekar - Experience CertificateDocument1 pageNikhil Khedekar - Experience CertificateGajendra PatilNo ratings yet

- Misbahul Soharwardi - Experience CertificateDocument1 pageMisbahul Soharwardi - Experience CertificateGajendra PatilNo ratings yet

- Att-6 Revised Clause 4.20 & Exibits For Assset CapitalizationDocument24 pagesAtt-6 Revised Clause 4.20 & Exibits For Assset CapitalizationGajendra PatilNo ratings yet

- For Covid-19 Tests Fasting Is Not Required: Your Appointment DetailsDocument3 pagesFor Covid-19 Tests Fasting Is Not Required: Your Appointment DetailsGajendra PatilNo ratings yet

- We Love People Who Love Travelling!Document3 pagesWe Love People Who Love Travelling!Gajendra PatilNo ratings yet

- RFQ For Safety Studies OF Dukhan Gas Lift System Upgrade - Phase1 ProjectDocument38 pagesRFQ For Safety Studies OF Dukhan Gas Lift System Upgrade - Phase1 ProjectGajendra PatilNo ratings yet

- YS2 03 C10017 TL DTS Z 001 Rev. 0 (Material Data Sheet)Document20 pagesYS2 03 C10017 TL DTS Z 001 Rev. 0 (Material Data Sheet)Gajendra PatilNo ratings yet

- LNT JGCP 0069-R0 7Document2 pagesLNT JGCP 0069-R0 7Gajendra PatilNo ratings yet

- We Love People Who Love Travelling!Document3 pagesWe Love People Who Love Travelling!Gajendra PatilNo ratings yet

- 6" Mobile Pig Launcher and ReceiverDocument1 page6" Mobile Pig Launcher and ReceiverGajendra PatilNo ratings yet

- QRA Study Reference ListDocument1 pageQRA Study Reference ListGajendra PatilNo ratings yet

- YS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Document4 pagesYS2-03-C10017-TL-DTS-M-004 Rev 0 (6 Inch Mobile Pig Receiver)Gajendra PatilNo ratings yet

- 12" Mobile Pig Launcher and ReceiverDocument1 page12" Mobile Pig Launcher and ReceiverGajendra PatilNo ratings yet

- YS2-03-C10017-TL-DRA-Y-004 Rev. 0 (Typical Anchor Block For 12 Inch TL)Document1 pageYS2-03-C10017-TL-DRA-Y-004 Rev. 0 (Typical Anchor Block For 12 Inch TL)Gajendra PatilNo ratings yet

- Engineering mobile pig launcherDocument4 pagesEngineering mobile pig launcherGajendra PatilNo ratings yet

- YS2-03-C10017-TL-DRA-Y-001 Rev.0 (Typical 3rd Party Utility - Flowline Crossing)Document1 pageYS2-03-C10017-TL-DRA-Y-001 Rev.0 (Typical 3rd Party Utility - Flowline Crossing)Gajendra PatilNo ratings yet

- YS2-03-C10017-TL-BOM-C-001 Rev.0 (Civil-Structural BoQ)Document1 pageYS2-03-C10017-TL-BOM-C-001 Rev.0 (Civil-Structural BoQ)Gajendra PatilNo ratings yet

- Predict-Socrates 10Document4 pagesPredict-Socrates 10Gajendra PatilNo ratings yet

- Course Syllabus 2018-2019: Program TitleDocument4 pagesCourse Syllabus 2018-2019: Program TitleGajendra PatilNo ratings yet

- Root Cause Analysis Lab ErrorsDocument60 pagesRoot Cause Analysis Lab ErrorsrwillestoneNo ratings yet

- Course SyllabusDocument8 pagesCourse SyllabusGajendra PatilNo ratings yet

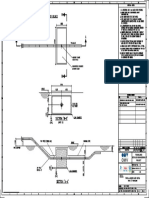

- YS2-03-C10017-TL-DRA-C-005 Rev 0 (Safety Wall GA Section & Details BVS 1 & 2)Document1 pageYS2-03-C10017-TL-DRA-C-005 Rev 0 (Safety Wall GA Section & Details BVS 1 & 2)Gajendra PatilNo ratings yet

- Welder Outline July 2013 PDFDocument175 pagesWelder Outline July 2013 PDFGajendra PatilNo ratings yet

- An Introduction To Vibration Analysis Theory and PracticeDocument42 pagesAn Introduction To Vibration Analysis Theory and PracticeAbu Aseoche PunzalanNo ratings yet

- Concreting SpecDocument66 pagesConcreting Specezma bestNo ratings yet

- Bridge Systems PDFDocument25 pagesBridge Systems PDFAndrei SanduNo ratings yet

- 4TNV88Document30 pages4TNV88parahu ariefNo ratings yet

- Aircraft Hardware CATDocument4 pagesAircraft Hardware CATJowiNo ratings yet

- IAY Vigyan Bhavan PPT 6052010Document80 pagesIAY Vigyan Bhavan PPT 6052010Vasudha GandhiNo ratings yet

- Design and Analysis of Storage Vessel (Silo) : ISSN: 2455-2631 © May 2019 IJSDR - Volume 4, Issue 5Document19 pagesDesign and Analysis of Storage Vessel (Silo) : ISSN: 2455-2631 © May 2019 IJSDR - Volume 4, Issue 5Peter IosifidisNo ratings yet

- Dangote Refinery Project Review MeetingDocument36 pagesDangote Refinery Project Review Meetingsanjay gautamNo ratings yet

- PMC Pitch 2Document2 pagesPMC Pitch 2Aashish PardeshiNo ratings yet

- PE 06 Seepage FlownetsDocument22 pagesPE 06 Seepage FlownetsIshmam Shahid100% (1)

- Re-Bar Staggered Lap SplicesDocument4 pagesRe-Bar Staggered Lap Splicestyger089100% (2)

- Test Report-STP Limited-Shali Grout HSDocument2 pagesTest Report-STP Limited-Shali Grout HSRana MahatoNo ratings yet

- Astm A106 A106mDocument4 pagesAstm A106 A106mmahamad AziNo ratings yet

- On Off Valve Bypass - Industrial Professionals - CheresourcesDocument5 pagesOn Off Valve Bypass - Industrial Professionals - Cheresourcesvenkatrangan2003No ratings yet

- VHB Exhaust Only HoodDocument3 pagesVHB Exhaust Only HoodVenkata Sai MvsNo ratings yet

- The Platina commercial space investment opportunityDocument10 pagesThe Platina commercial space investment opportunityaman3327No ratings yet

- Design of SpillwaysDocument29 pagesDesign of SpillwaysALvin SaLvaNo ratings yet

- Syllabus of Hydraulic Engineering Section CE-213 Fluid Mechanics Course Category: DC L - T - P: 3 - 1-0 Credit: 4Document35 pagesSyllabus of Hydraulic Engineering Section CE-213 Fluid Mechanics Course Category: DC L - T - P: 3 - 1-0 Credit: 4subxaanalahNo ratings yet

- Eden WondwossenDocument50 pagesEden WondwossenHULE ADDIS ENTERTAINMENTNo ratings yet

- Intro To PRC-1Document68 pagesIntro To PRC-1hannan mohsinNo ratings yet

- A3DXYZ 3D Printing Design RulesDocument1 pageA3DXYZ 3D Printing Design Rulespaxiyo5216No ratings yet

- 6-T-1200R SPECTRUM EMEIA 54819-1-PM (Rev. 1.0)Document201 pages6-T-1200R SPECTRUM EMEIA 54819-1-PM (Rev. 1.0)huo sunNo ratings yet

- ASTM A106 Seamless Carbon Steel PipeDocument2 pagesASTM A106 Seamless Carbon Steel PipeCarlosNo ratings yet

- 37 Sustainable Construction and Building MaterialsDocument9 pages37 Sustainable Construction and Building Materials薇神No ratings yet

- Design Report IIDocument215 pagesDesign Report IIONo ratings yet

- MSS SP ListDocument5 pagesMSS SP Listle wang100% (1)

- Dualwatersystems DWFSOM145Document4 pagesDualwatersystems DWFSOM145Moyukh MoitraNo ratings yet

- Comapany Profile Gogreen OverseasDocument23 pagesComapany Profile Gogreen OverseasKunal SuhagiyaNo ratings yet

- Tri Clamp Dimensions & Sizing Guide: Glacier Tanks' Holiday Hours Until 1/2/2020 (View Here)Document7 pagesTri Clamp Dimensions & Sizing Guide: Glacier Tanks' Holiday Hours Until 1/2/2020 (View Here)Sharad KokateNo ratings yet

- 60T0 Taurus v2 ENDocument16 pages60T0 Taurus v2 ENxianzaiegNo ratings yet

- DPWH mechanical coupler specificationDocument5 pagesDPWH mechanical coupler specificationRay Ramilo100% (1)