Professional Documents

Culture Documents

SIRA Certificate No FSP 16002 (Versa - Solenoid Valve D Series)

Uploaded by

Anonymous cKdbnUHOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SIRA Certificate No FSP 16002 (Versa - Solenoid Valve D Series)

Uploaded by

Anonymous cKdbnUHCopyright:

Available Formats

FUNCTIONAL SAFETY CERTIFICATE

This is to certify that the

D-Series – Direct Acting Solenoid Valves

Manufactured by

Versa Products Company, Inc.

22 Spring Valley Rd

Paramus NJ 07652

USA

Has been assessed by Sira Certification Service with reference to the

CASS methodologies and found to meet the requirements of

IEC 61508-2:2010

Routes 1H & 1S

Systematic Capability (SC3)

As an element/subsystem suitable for use in safety related systems performing safety

functions up to and including

SIL 2 capable with HFT=0 (1oo1)*

SIL 3 capable with HFT=1 (1oo2)*

When used in accordance with the scope and conditions of this certificate.

*

This certificate does not waive the need for further functional safety verification to

establish the achieved Safety Integrity Level (SIL) of the safety related system

Certification Manager:

Wayne Thomas

Initial Certification : 09/08/2016

This certificate re-issued : 09/08/2016

Renewal date : 08/08/2021

This certificate may only be reproduced in its entirety, without any change.

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Hawarden, CH5 3US, United Kingdom.

Certificate No.: Sira FSP 16002/00 Tel: +44 (0) 1244 670900

Form 7016 issue 5 Email: ukinfo@csagroup.org

Page 1 of 6 Web: www.csagroupuk.org

Product description and scope of certification

The D-Series – Direct Acting Solenoid Valves are 3 port 2-position and can be configured as normally

open or normally closed. The main body is manufactured from 316 stainless steel and is designed to

operate with pressures between 0 and 175 psi and with media’s including dry air, natural gas, inert

gases, nitrogen, water (liquid form), and petroleum oils.

Figure 1. D-Series – Direct Acting Solenoid Valve – Typical Image.

A typical application of the D-series valve in a normally closed configuration would be to isolate a

process from its pressurised media. In normal operation (valve energised) the valve would be in the

open position allowing its media to flow uninhibited through the valve. This is achieved by energising

the solenoid which moves the valve shuttle via the solenoid stem to a valve open position. When the

solenoid is de-energised the force acting upon the solenoid stem is removed and the valve shuttle

returns to a valve closed position via spring return. As a result the process is isolated from its media.

Element Safety Function

The safety function of the certified equipment is:

‘To return the valve to its closed position (spring extended) when de-energised’.

Certified Data in support of use in safety functions

The assessment has been carried out with reference to the Conformity Assessment of Safety-related

Systems (CASS) methodology using the Route 1H approach.

Based on the documents submitted by Versa Products company, Inc. the Failure Mode and Effect

Analysis (FMEA) of the D-Series – Direct Acting Solenoid Valves has verified the documents as evidence

of Conformity to IEC 61508-2:2010 in respect of ‘hardware safety integrity’. The components failure

rates and modes for the D-Series Valves have been extracted from or calculated using Item software

reliability package and RIAC Automated Data book.

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Certificate No.: Sira FSP 16002/00 Hawarden, CH5 3US, United Kingdom.

Form 7016 issue 5 Tel: +44 (0) 1244 670900

Page 2 of 6 Email: ukinfo@csagroup.org

Web: www.csagroupuk.org

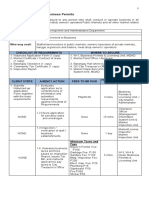

Table 1: Summary of assessment (1oo1)

1oo1 EQUATIONS

Parameter name Symbol Equation / source Value/Result

Proof Test Interval T1 IEC 61508-4 clause 3.8.5 8760 hrs

Mean Time To Restoration MTTR IEC 61508-4 clause 3.6.21 2 hrs

Mean Repair Time (Once revealed) MRT IEC 61508-4 clause 3.6.22 2 hrs

Type A/B Type IEC 61508-2 clause 7.4.4.1.2 & 7.4.4.1.3 type A

Total failures: λ IEC 61508-4 clause 3.6.4 1.79E-07

Safe diagnosed failures: λSD 0.00E+00

IEC 61508-4 clause 3.6.8

Safe undiagnosed failures: λSU 1.43E-07

Dangerous diagnosed failures: λDD 0.00E+00

IEC 61508-4 clause 3.6.7

Dangerous undiagnosed failures: λDU 3.62E-08

Diagnostic coverage: DC λDD / (λDU + λDD) 0%

Safe Failure Fraction: SFF (λSD + λSU + λDD) / λ 80%

PFDAVG PFDAVG λDU (T / 2+MRT) + (λDD MTTR) 1.59E-04

SIL capability (Low demand mode) SIL SIL 2**

Table 2: Summary of assessment (1oo2)

1oo2 EQUATIONS

Parameter name Symbol Equation / source Value/Result

Proof Test Interval T1 IEC 61508-4 clause 3.8.5 8760 hrs

Mean Time To Restoration MTTR IEC 61508-4 clause 3.6.21 2 hrs

Mean Repair Time (Once revealed) MRT See IEC 61508-4 3.6.22 2 hrs

Type A/B Type IEC 61508-2 clause 7.4.4.1.2 & 7.4.4.1.3 type A

Total failures: λ IEC 61508-4 clause 3.6.4 1.79E-07

Safe diagnosed failures: λSD 0.00E+00

IEC 61508-4 clause 3.6.8

Safe undiagnosed failures: λSU 1.43E-07

Dangerous diagnosed failures: λDD 0.00E+00

IEC 61508-4 clause 3.6.7

Dangerous undiagnosed failures: λDU 3.62E-08

Diagnostic coverage: DC λDD / (λDU + λDD) 0%

Safe Failure Fraction: SFF (λSD + λSU + λDD) / λ 80%

2[(1-β)λDD + (1-β) λDU]2 tCE tGE + βλDD MTTR

PFDAVG PFDAVG 1oo2

+ βλDU ((T/2)+MTTR) 1.59E-05

SIL capability (Low demand mode) SIL SIL 3**

** Note 1: The failure data:

1) The PFDAVG figure shown is for illustration only assuming a proof test interval of 8760 hours and

MTTR of 2 hours. Refer to IEC 61508-6 for guidance on PFDAVG calculations from the failure data.

2) The verified failure rates used in the safe failure fraction and diagnostic coverage do not include

(λ no part or no effect) failures in the calculation.

The failure data above is supported by the base information given in Table 3 below.

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Certificate No.: Sira FSP 16002/00 Hawarden, CH5 3US, United Kingdom.

Form 7016 issue 5 Tel: +44 (0) 1244 670900

Page 3 of 6 Email: ukinfo@csagroup.org

Web: www.csagroupuk.org

Table 3: Base information for the D-Series – Direct Acting Solenoid Valve

1 Product identification: D-Series – Direct Acting Solenoid Valve.

2 Functional specification: To return the valve to its closed position (spring extended)

when de-energised.

3-5 Random hardware failure rates: Refer to tables 1 & 2 of this certificate.

6 Environment limits: Operating temperature ranges (due to chemical

composition of internal seals):

-20°c to +90°c (FKM seals)

-40°c to +90°c (Low Temp Nitrile seals, option -44)

-52°c to +90°c (Fluorosilicone seals, option T -40)

7 Lifetime/replacement limits: 20 years

8 Proof Test requirements: Refer to safety manual – ENG 75.

9 Maintenance requirements: Refer to safety manual – ENG 75.

10 Diagnostic coverage: 0% diagnostic coverage.

11 Diagnostic test interval: Refer to safety manual – ENG 75.

12 Repair constraints: Refer to safety manual – ENG 75.

13 Safe Failure Fraction: See Tables 1 & 2 above

14 Hardware fault tolerance (HFT): See Tables 1 & 2 above.

15 Highest SIL (architecture/type A/B): See Tables 1 & 2 above.

16 Systematic failure constraints: The hardware safety integrity assessment was based on

a proof test interval of 1 year. For further information

refer to safety manual – ENG 75.

17 Evidence of similar conditions in previous Not applicable for this product.

use:

18 Evidence supporting the application Not applicable for this product.

under different conditions of use:

19 Evidence of period of operational use: Not applicable for this product.

20 Statement of restrictions on functionality: See systematic report R70060544B.

21 Systematic capability (SC1, SC2, SC3) SC3 - See systematic report R70060544B.

22 Systematic fault avoidance measures: Compliance with techniques and measures from IEC

61508-2 Annex B to SIL 2 - See systematic report

R70060544B.

23 Systematic fault tolerance measures: Compliance with techniques and measures from IEC

61508-2 Annex A to support the SFF achieved – see

hardware safety integrity report R70060544A.

24 Validation records: All documents that have been used in support of the

hardware have been documented in section 5.26 of

report R70060544A; this includes the FMEA document.

Management of functional safety

The assessment has demonstrated that the product is supported by an appropriate functional safety

management system that meets the relevant requirements of IEC 61508-1:2010 clause 6, see report

R70060544B.

Identification of certified equipment

The certified equipment and its safe use is defined in the manufacturer’s documentation listed in Table

4 below.

Table 4: Certified documents

Document no. Rev Date Document description

DSM-3301-316- 3/2 Three Way Multi-Purpose Direct Acting Valve

A 11/12/2015

XDD(TAB)-VOLT Assembly.

DSM-3301-316-M- 3/2 Three Way Multi-Purpose Direct Acting Valve

B 03/03/2016

XXD(TAB)-VOLT Assembly With Manual Override.

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Certificate No.: Sira FSP 16002/00 Hawarden, CH5 3US, United Kingdom.

Form 7016 issue 5 Tel: +44 (0) 1244 670900

Page 4 of 6 Email: ukinfo@csagroup.org

Web: www.csagroupuk.org

DSM-3301-316- 3/2 Three Way Multi-Purpose Direct Acting Valve

XDD(TAB)-356BN- B 03/03/2016 Assembly Latching In NC Position, Pull To Reset.

VOLT

ENG 75 E 06/06/2016 Safety Manual Type A Control Valves.

Conditions of Certification

The validity of the certified base data is conditional on the manufacturer complying with the following

conditions:

1. The manufacturer shall analyse failure data from returned products on an on-going basis. Sira

Certification Service shall be informed in the event of any indication that the actual failure rates

are worse than the certified failure rates. (A process to rate the validity of field data should be

used. To this end, the manufacturer should co-operate with users to operate a formal field-

experience feedback programme).

2. Sira shall be notified in advance (with an impact analysis report) before any modifications to the

certified equipment or the functional safety information in the user documentation is carried out.

Sira may need to perform a re-assessment if modifications are judged to affect the product’s

functional safety certified herein.

3. On-going lifecycle activities associated with this product (e.g., modifications, corrective actions,

field failure analysis) shall be subject to surveillance by Sira in accordance with ‘Regulations

Applicable to the Holders of Sira Certificates’.

Conditions of Safe Use

The validity of the certified base data in any specific user application is conditional on the user

complying with the following conditions:

1. The user shall comply with the requirements given in the manufacturer’s user documentation in

regard to all relevant functional safety aspects such as application of use, installation, operation,

maintenance, proof tests, maximum ratings, environmental conditions, and repair.

2. Selection of this product for use in safety function and the installation, configuration, overall

validation, maintenance and repair shall only be carried out by competent personnel, observing

all the manufacturer’s conditions and recommendations in the user documentation.

3. All information associated with any field failures of this product should be collected under a

dependability management process (e.g., IEC 60300-3-2) and reported to the manufacturer.

4. The safety device is to have an independent power supply, it must not share the same power

supply as non-safety devices that may cause a fault to the safety device.

5. A proof test interval of 1 year.

General Conditions and Notes

1. This certificate is based upon a functional safety assessment of the product described in Sira Test

& Certification Assessment Report R70060544A and R70060544B.

2. If the certified product or system is found not to comply, Sira Certification Service should be

notified immediately at the address shown on this certificate.

3. The use of this Certificate and the Sira Certification Mark that can be applied to the product or

used in publicity material are subject to the ‘Regulations Applicable to the Holders of Sira

Certificates’ and ‘Supplementary Regulations Specific to Functional Safety Certification’.

4. This document remains the property of Sira and shall be returned when requested by the issuer.

5. No part of the Functional safety related aspects stated in the instruction manual shall be changed

without approval of the certification body.

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Certificate No.: Sira FSP 16002/00 Hawarden, CH5 3US, United Kingdom.

Form 7016 issue 5 Tel: +44 (0) 1244 670900

Page 5 of 6 Email: ukinfo@csagroup.org

Web: www.csagroupuk.org

6. This certificate will remain valid subject to completion of one surveillance audit within the five year

certification cycle, and upon receipt of acceptable response to any findings raised during this

period. This certificate can be withdrawn if the manufacturer no longer satisfies scheme

requirements.

Certificate History

Issue Date Report no. Comment

09/08/2016 R70060544A The release of the prime certificate.

00

R70060544B

Sira Certification Service

Part of CSA Group UK

Unit 6 Hawarden Industrial Park,

Certificate No.: Sira FSP 16002/00 Hawarden, CH5 3US, United Kingdom.

Form 7016 issue 5 Tel: +44 (0) 1244 670900

Page 6 of 6 Email: ukinfo@csagroup.org

Web: www.csagroupuk.org

You might also like

- Functional Safety Certificate: ICO3S, ICO4S, ICO4D, ICO4N and SOV 1 To 6Document5 pagesFunctional Safety Certificate: ICO3S, ICO4S, ICO4D, ICO4N and SOV 1 To 6Ignacio Benito100% (1)

- Sira Sil Certifacate - FSP 04001-08Document5 pagesSira Sil Certifacate - FSP 04001-08Miguel ZeaNo ratings yet

- SIL CertificateDocument6 pagesSIL CertificateHOOMAN afaghiNo ratings yet

- CT720g S774AAR5S2NCDocument45 pagesCT720g S774AAR5S2NCAnonymous CJnGHNNo ratings yet

- 1260 ManualDocument215 pages1260 ManualGaurav AcharyaNo ratings yet

- 8 Series Type Test Report EMI Power Frequency Immunity Test IEC60255-22-7: 2003Document11 pages8 Series Type Test Report EMI Power Frequency Immunity Test IEC60255-22-7: 2003andrez880103No ratings yet

- Material Specifications Cell: Technical Specification OFDocument8 pagesMaterial Specifications Cell: Technical Specification OFkajale.shrikantNo ratings yet

- Jenway 6310 Service ManualDocument84 pagesJenway 6310 Service ManualJorge OliveiraNo ratings yet

- 869 PowerQualityTests - IEC255-11 - 07 - 03 - 14 - r002Document18 pages869 PowerQualityTests - IEC255-11 - 07 - 03 - 14 - r002andrez880103No ratings yet

- Manual SmartcellDocument34 pagesManual Smartcelldwight ferrer100% (1)

- Zelio Control RM4TU02Document2 pagesZelio Control RM4TU02Susi SumeilyahNo ratings yet

- Saso Iec 61557-6 2010Document12 pagesSaso Iec 61557-6 2010mrafiq9002No ratings yet

- Rivertrace Manual 2015 - SseDocument44 pagesRivertrace Manual 2015 - SseRomankoNo ratings yet

- Habonim SIL CertificationDocument7 pagesHabonim SIL Certificationjamil vora0% (1)

- Allengers 325 RF - Installation and Service ManualDocument63 pagesAllengers 325 RF - Installation and Service Manualleopa7880% (20)

- Saudi Standard SASO IEC 61557-2/2010Document9 pagesSaudi Standard SASO IEC 61557-2/2010AtesNo ratings yet

- Zelio Control RM4TR32 Document-1561572 PDFDocument8 pagesZelio Control RM4TR32 Document-1561572 PDFGustavo SchermanNo ratings yet

- 8series Type Test Report Safety Insulation Resistance Test EN/IEC60255-5: 2000Document7 pages8series Type Test Report Safety Insulation Resistance Test EN/IEC60255-5: 2000andrez880103No ratings yet

- 3500 - Proximitor and Seismic MonitorDocument41 pages3500 - Proximitor and Seismic MonitortestvsptestNo ratings yet

- Norm e CoLDocument2 pagesNorm e CoLSTEFANALINLUCIANNo ratings yet

- Oslon SSL White (CCT 2500 K - 6500 K) : IES LM-80-08 Test ReportDocument21 pagesOslon SSL White (CCT 2500 K - 6500 K) : IES LM-80-08 Test ReportAnonymous qD4jTcEXNo ratings yet

- 59714602rvC - OPMANPXS5 822 822WBDocument19 pages59714602rvC - OPMANPXS5 822 822WBCalidad CocoNo ratings yet

- Zelio Control RM4TR34Document7 pagesZelio Control RM4TR34AbdulSattarNo ratings yet

- RM4TG20: Product Data SheetDocument6 pagesRM4TG20: Product Data SheetEduardo Jose JohnNo ratings yet

- Test Report No.: Version-No.: Date: Subsystem: Model:: TÜV Rheinland ItaliaDocument23 pagesTest Report No.: Version-No.: Date: Subsystem: Model:: TÜV Rheinland ItaliaSugeng WahyudiNo ratings yet

- 109080-x Smart Cell - Bilge - Manual High ResDocument36 pages109080-x Smart Cell - Bilge - Manual High ResDandy IkhwalNo ratings yet

- User Manual: CS 5000 Model 11674xxDocument47 pagesUser Manual: CS 5000 Model 11674xxandreasprovostNo ratings yet

- TR 220 Operational ManualDocument76 pagesTR 220 Operational Manualian Lopez CuetoNo ratings yet

- GRD140D 6F2S0897 5.0Document438 pagesGRD140D 6F2S0897 5.0boopelectraNo ratings yet

- Zelio Control RM4TA32 PDFDocument7 pagesZelio Control RM4TA32 PDFariessukmawanNo ratings yet

- GRL100B 6F2S0835 2.7Document392 pagesGRL100B 6F2S0835 2.7Nazi SweetNo ratings yet

- DeltaV SIS With Electronic Marshalling Certificate Rev 1.2 Oct 2 2014Document2 pagesDeltaV SIS With Electronic Marshalling Certificate Rev 1.2 Oct 2 2014Danny PuchaNo ratings yet

- Jenway 6310 Service Manual PDFDocument84 pagesJenway 6310 Service Manual PDFArdo IsküllNo ratings yet

- Zelio Control RM4TG20Document6 pagesZelio Control RM4TG20AbdulSattarNo ratings yet

- 11-1518 Schneider Electric ION8650 CertificateDocument2 pages11-1518 Schneider Electric ION8650 CertificatesameeraNo ratings yet

- SIKADocument5 pagesSIKAMukund IndianNo ratings yet

- RM4TR32: Product Data SheetDocument7 pagesRM4TR32: Product Data Sheetsergio montañaNo ratings yet

- ODS HTQ CB Certificates Reports 62368 1 60950 1Document345 pagesODS HTQ CB Certificates Reports 62368 1 60950 1technical.managerNo ratings yet

- Micom P439: Distance Protection and Control UnitDocument834 pagesMicom P439: Distance Protection and Control UnitRazvan Stoica TartaNo ratings yet

- Product Guide Specification: Cyberex Superswitch 4 (4-Pole STS)Document14 pagesProduct Guide Specification: Cyberex Superswitch 4 (4-Pole STS)voNo ratings yet

- MCC PanelDocument86 pagesMCC PanelRavindra TiwariNo ratings yet

- PFD Calculation MethodDocument6 pagesPFD Calculation Methodirfan22in100% (1)

- 869 - IEC - 61000-4-6 Conducted RF ImmunityDocument7 pages869 - IEC - 61000-4-6 Conducted RF Immunityandrez880103No ratings yet

- GRZ100B 6F2S0846 0.3Document447 pagesGRZ100B 6F2S0846 0.3Vivek KhedgaonkarNo ratings yet

- RM4TG20Document2 pagesRM4TG20cyrano1091No ratings yet

- LG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202Document42 pagesLG 32ls3500-Ud 32ls3510-Ua Chassis La25a mfl67454202noguri25No ratings yet

- 6MD61xx KEMA-Certificate IEC61850 V4Document2 pages6MD61xx KEMA-Certificate IEC61850 V4Nguyễn Tuấn ViệtNo ratings yet

- 109080-q Smart Cell - Bilge - ManualDocument29 pages109080-q Smart Cell - Bilge - Manualabuzer1981No ratings yet

- Zelio Control RM4TR32Document3 pagesZelio Control RM4TR32Yuwono WaluyoNo ratings yet

- RE9TA11MW: Product Data SheetDocument5 pagesRE9TA11MW: Product Data Sheetahmedalllam1993No ratings yet

- C60 26924Document1 pageC60 26924mathianandmNo ratings yet

- WI-NG-6460-002-065 Work Instruction For Circuit Breaker Fail Protection (5062) Rev00Document6 pagesWI-NG-6460-002-065 Work Instruction For Circuit Breaker Fail Protection (5062) Rev00Mohamed NasrNo ratings yet

- RHR411M: Product Data SheetDocument2 pagesRHR411M: Product Data SheetAkhilNo ratings yet

- I&M No. V - 9512 - R10: Operation & Maintenance GuideDocument18 pagesI&M No. V - 9512 - R10: Operation & Maintenance GuideJosé ZamoraNo ratings yet

- Micom P132: Feeder Management and Bay ControlDocument796 pagesMicom P132: Feeder Management and Bay ControlHung Cuong PhamNo ratings yet

- LG 47ls4600-Ua Chassis La21b mfl67402828Document44 pagesLG 47ls4600-Ua Chassis La21b mfl67402828Fidelio AdonisNo ratings yet

- NPN Epitaxial Silicon Transistor: NPN General Purpose AmplifierDocument3 pagesNPN Epitaxial Silicon Transistor: NPN General Purpose AmplifierCarlos Sergio Costa CostaNo ratings yet

- Transistor Electronics: Use of Semiconductor Components in Switching OperationsFrom EverandTransistor Electronics: Use of Semiconductor Components in Switching OperationsRating: 1 out of 5 stars1/5 (1)

- Offshore Electrical Engineering ManualFrom EverandOffshore Electrical Engineering ManualRating: 4 out of 5 stars4/5 (9)

- Incident Sharing BEDIDI - 1XDocument1 pageIncident Sharing BEDIDI - 1XAnonymous cKdbnUHNo ratings yet

- Lessons Learned - MTC - Sperry Sarulla - 23 Aug 2015Document1 pageLessons Learned - MTC - Sperry Sarulla - 23 Aug 2015Anonymous cKdbnUHNo ratings yet

- Flash Alert 141 Lift PlanningDocument1 pageFlash Alert 141 Lift PlanningAnonymous cKdbnUHNo ratings yet

- Lessons Learned - RWC - Marunda - 2 Jul 2015Document1 pageLessons Learned - RWC - Marunda - 2 Jul 2015Anonymous cKdbnUHNo ratings yet

- MVA in Sarulla September 2015 Rev.0Document1 pageMVA in Sarulla September 2015 Rev.0Anonymous cKdbnUHNo ratings yet

- Incident Sharing (Template)Document1 pageIncident Sharing (Template)Anonymous cKdbnUHNo ratings yet

- 0721 Indonesia Weekly Incident Report 2014Document42 pages0721 Indonesia Weekly Incident Report 2014Anonymous cKdbnUHNo ratings yet

- Sertifikat BRTDocument1 pageSertifikat BRTAnonymous cKdbnUHNo ratings yet

- Method of Classification For Routine and Non-Routine JMPDocument8 pagesMethod of Classification For Routine and Non-Routine JMPAnonymous cKdbnUHNo ratings yet

- Method of Classification For Routine and Non-Routine JMP - IndonesiaDocument15 pagesMethod of Classification For Routine and Non-Routine JMP - IndonesiaAnonymous cKdbnUHNo ratings yet

- Hfacs - SisDocument23 pagesHfacs - SisAnonymous cKdbnUHNo ratings yet

- Baroid IncidentDocument6 pagesBaroid IncidentAnonymous cKdbnUHNo ratings yet

- Asia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Document15 pagesAsia Pacific Weekly Incident Summary 08-Jul-2014 (Indonesia)Anonymous cKdbnUHNo ratings yet

- HAZOP FormDocument7 pagesHAZOP FormAnonymous cKdbnUHNo ratings yet

- List of JourneyDocument1 pageList of JourneyAnonymous cKdbnUHNo ratings yet

- Lampiran 6 - Daftar Tolerance Event FrequencyDocument1 pageLampiran 6 - Daftar Tolerance Event FrequencyAnonymous cKdbnUHNo ratings yet

- Cost Estimate - FEED Karamba FieldDocument4 pagesCost Estimate - FEED Karamba FieldAnonymous cKdbnUHNo ratings yet

- PIU - Isi ProposalDocument6 pagesPIU - Isi ProposalAnonymous cKdbnUHNo ratings yet

- Flyer SIL-SISDocument2 pagesFlyer SIL-SISAnonymous cKdbnUHNo ratings yet

- FMEA Worksheet Template - Grup 6Document8 pagesFMEA Worksheet Template - Grup 6Anonymous cKdbnUHNo ratings yet

- Lampiran 4 Daftar DeviationDocument1 pageLampiran 4 Daftar DeviationAnonymous cKdbnUHNo ratings yet

- Quotation of Hazid & Hazop - FEED Karamba Field Production FacilitiesDocument3 pagesQuotation of Hazid & Hazop - FEED Karamba Field Production FacilitiesAnonymous cKdbnUHNo ratings yet

- 02-B - Stature 4.6 - Workflow NavigationDocument13 pages02-B - Stature 4.6 - Workflow NavigationAnonymous cKdbnUHNo ratings yet

- Unit 0414 Assess Individual Needs and PreferencesDocument8 pagesUnit 0414 Assess Individual Needs and PreferencesAnonymous cKdbnUHNo ratings yet

- Analisa HFACS SISDocument206 pagesAnalisa HFACS SISAnonymous cKdbnUHNo ratings yet

- MO - Leadership Succession Planning - 04162012Document19 pagesMO - Leadership Succession Planning - 04162012Anonymous cKdbnUHNo ratings yet

- 06-A - Stature 4.0 - Study-Based Workflow DescriptionDocument7 pages06-A - Stature 4.0 - Study-Based Workflow DescriptionAnonymous cKdbnUHNo ratings yet

- 02-A - Stature 4.6 - Working With StudiesDocument28 pages02-A - Stature 4.6 - Working With StudiesAnonymous cKdbnUHNo ratings yet

- 01-Bs - Stature 4.6 - Rich-Client InstallationDocument8 pages01-Bs - Stature 4.6 - Rich-Client InstallationAnonymous cKdbnUHNo ratings yet

- 07-A - Stature 4.2 - Func Admin - Managing TemplatesDocument21 pages07-A - Stature 4.2 - Func Admin - Managing TemplatesAnonymous cKdbnUHNo ratings yet

- 5D Bends Combine RFQDocument376 pages5D Bends Combine RFQMuhammad Ghufran KhanNo ratings yet

- DeVry TranscriptDocument3 pagesDeVry TranscriptNicole Smith-GambleNo ratings yet

- General Interview LetterDocument2 pagesGeneral Interview LetterAbinashNo ratings yet

- Od Cig 021 - August 2019Document11 pagesOd Cig 021 - August 2019aramirezharoNo ratings yet

- Section 3) Instructions & Maintenance ManualDocument19 pagesSection 3) Instructions & Maintenance ManualstuNo ratings yet

- Yash Sault SopDocument4 pagesYash Sault SopEminence SOP WritersNo ratings yet

- Civil Service 2019 - QualificationDocument6 pagesCivil Service 2019 - Qualificationnanie1986No ratings yet

- Aadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryDocument4 pagesAadhaar Update Form: Aadhaar Enrolment Is Free & VoluntaryLaxmi GudadarNo ratings yet

- Annex A BOIS Form Revised 2023Document2 pagesAnnex A BOIS Form Revised 2023DILG LBP100% (2)

- (Overseas Trained Applicants) Registration/ Registration Certificate/ Practising Licence ApplicationDocument2 pages(Overseas Trained Applicants) Registration/ Registration Certificate/ Practising Licence ApplicationJohan VargasNo ratings yet

- Mdad Services 2020Document16 pagesMdad Services 2020Hambeca PHNo ratings yet

- PSI Online - Test-DetailsDocument1 pagePSI Online - Test-DetailsEvandro SantosNo ratings yet

- Top 10 Hottest IT CertificationsDocument8 pagesTop 10 Hottest IT Certificationsvjbrainiac7No ratings yet

- Security in Wireless MANDocument12 pagesSecurity in Wireless MANAnanthavenkatesh GummidiNo ratings yet

- Certificate Validation Using BlockchainDocument4 pagesCertificate Validation Using BlockchainHarshikantNo ratings yet

- Discovery 2: Configure Initial Cisco ISE Setup, GUI Familiarization, System Certificate UsageDocument27 pagesDiscovery 2: Configure Initial Cisco ISE Setup, GUI Familiarization, System Certificate UsagebounprakopNo ratings yet

- IATF-16949-2016 - HutchinsonDocument2 pagesIATF-16949-2016 - HutchinsonUğurNo ratings yet

- Chapter 1BDocument54 pagesChapter 1BnadiaNo ratings yet

- Office of The President Department of Civil Registration Application For A Birth CertificateDocument1 pageOffice of The President Department of Civil Registration Application For A Birth CertificateJotham MunalaNo ratings yet

- BCC 2022 Undergraduate Student Rulebook v407032022Document60 pagesBCC 2022 Undergraduate Student Rulebook v407032022Lukho TseleNo ratings yet

- EnglishDocument24 pagesEnglishyesica rojasNo ratings yet

- Radiation Import / Export Authorisation Application Form: Fill in Here. Fill in Here. Fill in HereDocument2 pagesRadiation Import / Export Authorisation Application Form: Fill in Here. Fill in Here. Fill in HereSam AbdollahNo ratings yet

- Job Description For API InspectorDocument1 pageJob Description For API InspectornizamuddinNo ratings yet

- F3367 20 High Intensity RadiatedDocument8 pagesF3367 20 High Intensity RadiatedlucasNo ratings yet

- What Is CCNADocument14 pagesWhat Is CCNAhamid shahNo ratings yet

- E329 PDFDocument10 pagesE329 PDFINARQ1979No ratings yet

- SI 21-09 Amdt. 0 - Procedure For Completion and Used of DGAC Form 21-18, Airworthiness Approval TagDocument15 pagesSI 21-09 Amdt. 0 - Procedure For Completion and Used of DGAC Form 21-18, Airworthiness Approval TagDoti Tri PrasetioNo ratings yet

- SBD Information Systems (ICB) - November-FinalDocument140 pagesSBD Information Systems (ICB) - November-FinalFowzi MohammedNo ratings yet

- IMS ISO 9001 - ISO 14001 - PurchasingDocument3 pagesIMS ISO 9001 - ISO 14001 - PurchasingASHU PURINo ratings yet

- Resume For Quality EngineerDocument8 pagesResume For Quality Engineervyp0bog1w1m3100% (2)