Professional Documents

Culture Documents

INDONESIA PONDASI RAYA TBK, PT-Lproject Detroid Deltamas Cikarang - fc'32 - ...

Uploaded by

deny susantoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

INDONESIA PONDASI RAYA TBK, PT-Lproject Detroid Deltamas Cikarang - fc'32 - ...

Uploaded by

deny susantoCopyright:

Available Formats

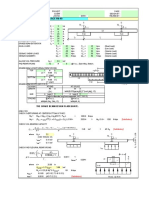

PT.

Pionirbeton Industri

TECHNICAL DEPARTMENT

Jl Rawa Sumur IV Blok BB 9

Kawasan Industri Pulogadung

021- 46836344 - 50

CONCRETE MIX DESIGN SUMMARY

Client : PT. INDONESIA PONDASI RAYA TBK

Project : Project Detroid Deltamas Cikarang

Address Cikarang

1.66 1.65

Ref : MD22070038-002 2.91 2.89

Date : July. 5th, 2022 0.996 0.999

Type of Concrete fc' 32 fc' 32

Slump (cm) 18+/-2 18+/-2

F32180CMKDBZA00 F32180CTKDBZA00

TYPE 5 + FA OPC + FA + SF

Structure - Agg 20mm Structure - Agg 20mm

Specified Strength (MPa) in 28 days based on cylinder dia. 15 cm x height 30 cm 32 32

Cement content ( kg ) Indocement 312 280

Fly Ash content ( kg ) Indramayu 104 93

Silica Fume content ( kg ) 40

Free Water Content ( litres ) 160 160

Coarse Agg. max 20 mm ( kg ) Purwakarta 950 950

Coarse Agg. max 12.5 mm ( kg ) Purwakarta 0 0

Fine Aggregate ( kg ) Belitung 775 820

Admixture, Retarder ( litres ) RT10 0.83 - 2.49 0.83 - 2.48

Admixture, Max High Super Plasticizer ( litres ) Viscoflow 3660LR 2.08 - 3.74 2.07 - 3.72

W/B Ratio 0.38 0.39

Target fc'r - For Supply Mix 100% fc' at 28 days subject to ACI 318M-14, Clause 26.12.3

Client Spec.

Slump Retention 6 Hours 6 Hours

Max. W/C or W/B Ratio 0.45 0.45

Fly Ash Content (%) 25% 25%

Admixture dosage, Retarder ( ml / 100 kg of cementitious ) RT10 200 - 600 200 - 600

Admixture dosage, High Super Plasticizer ( ml / 100 kg of cementitious ) Viscoflow 3660LR 500 - 900 500 - 900

Total Weight of Cementitious ( kg ) 416 413

0.83 0.83

Note : 2.49 2.48

1. The batch weight are in kilogram (kg) or liters per cubic meter 2.08 2.07

2. Yield measurements shall comply with ASTM Standard (C 138 M) 3.74 3.72

3. All batch weights are in saturated surface dry (SSD) condition

4. Admixture dosage rate :

a. Milliliters (ml) per 100 kg cementitious material

b. Liter per cubic meter

5. Cementitious content may include cement, fly ash or silica fume depending on the requirement/project specification and testing is carried out in accordance with the relevant ASTM

6. Dosage of split and fine aggregate to depend on the material characteristics of the above materials (SG, Water Absorption, Fineness modulus) at the time of supply and also

The above mixes will comply with all the current requirements of ACI - 318 ( Properties of Materials, Fresh/Hardened/ In-Situ concrete) provided all aspects of sampling and tests are carried

out in accordance with current editions of ASTM.

“This mix design and any attached document shall contain a confidential and/or privileged information from PT Pionirbeton Industri and the ownership of such design and/or

information shall remain the property of PT Pionirbeton Industri. Any information provided herein shall not be disclosed, copied, distributed, assigned, transferred and/or

used by the Customer and any other party without prior consent of PT Pionirbeton Industri. Any breach of this provision shall give the right for PT Pionirbeton Industri to

claim any loss and damages from the Customer and the Customer shall indemnify and hold PT Pionirbeton Industri harmless against any claims or damages resulting from

the Customer’s in not having obtained all the required consent and/or any other necessary permission.”

Approved by,

Dr. Arvind Suryavanshi

GM Technical

You might also like

- Exterior Finishes FinalDocument14 pagesExterior Finishes FinalAshish Marwha0% (1)

- Workshop PT Sinar Anugerah Mitra Abadi-SINAR ANUGERAH MITRA ABADI fc'40 6+-2 - SD Water Ratio 4 DigitDocument1 pageWorkshop PT Sinar Anugerah Mitra Abadi-SINAR ANUGERAH MITRA ABADI fc'40 6+-2 - SD Water Ratio 4 Digitdeny susantoNo ratings yet

- Brosur Beton KomposisiDocument4 pagesBrosur Beton KomposisiSiti SyarifahNo ratings yet

- Mix Design Request Printing (Pt. Prima Graha Bangun Tunggal)Document1 pageMix Design Request Printing (Pt. Prima Graha Bangun Tunggal)fannyNo ratings yet

- Data Survey MaretDocument42 pagesData Survey Maretamirhamzah2503No ratings yet

- Q1Co 3000 Q1Co 3620 3620-DIT - 288Document2 pagesQ1Co 3000 Q1Co 3620 3620-DIT - 288JHONATAN RODRIGUEZ VENTONo ratings yet

- Longjian - Kec JV: Subject: Proposal For Increased Time of Retention For Concrete Mixes at DC-02 ProjectDocument2 pagesLongjian - Kec JV: Subject: Proposal For Increased Time of Retention For Concrete Mixes at DC-02 Projectravi raghavNo ratings yet

- Ds-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Document3 pagesDs-pp-0015 - Data Sheet For Expansion Joint (Rev.0)Panisa BanimaNo ratings yet

- 14-00636 Mill Certificates PRO FORMA 14-00219 (12pz Ø800)Document14 pages14-00636 Mill Certificates PRO FORMA 14-00219 (12pz Ø800)fabianNo ratings yet

- Bill AbstrakeDocument31 pagesBill AbstrakeDIPANKAR GIRINo ratings yet

- BBS Link OrderDocument4 pagesBBS Link OrderLallamaNo ratings yet

- PQC Mix DesignDocument38 pagesPQC Mix DesignSandeep Nanda100% (3)

- Information Archieve - 2-3-2020Document15 pagesInformation Archieve - 2-3-2020Mizanul HoqueNo ratings yet

- Hasil LabDocument4 pagesHasil LabHanafi Yusuf AviansyahNo ratings yet

- Pt. Budijaya Makmursentosa: Qty (PC)Document1 pagePt. Budijaya Makmursentosa: Qty (PC)Fendy ShirahNo ratings yet

- Col Lapsk: Abstract of Concrete Mix Design of M30 GradeDocument3 pagesCol Lapsk: Abstract of Concrete Mix Design of M30 GradeLeelaKrishna QNo ratings yet

- Ircx Hdpe Plant: Specification For Flexible Joints - NonmetalDocument7 pagesIrcx Hdpe Plant: Specification For Flexible Joints - NonmetalmohsenNo ratings yet

- Diarab RoadDocument6 pagesDiarab RoadHishmat EzzelarabNo ratings yet

- Rig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present OperationDocument7 pagesRig: GD Chitra 14.06.2022 LAST CSG: 20"/423M Well Date Final TD: PHASE: 17 1/2" Phase TD: Drilled Depth: 540M. Present Operationongcchemist gd chitraNo ratings yet

- Mix Designs: #106, Mao Tse Tung BLVD, Khan Chamkamorn, Phnom Penh, Cambodia Tel: + (855-23) 958 958, M: + (855-67) 555 721Document1 pageMix Designs: #106, Mao Tse Tung BLVD, Khan Chamkamorn, Phnom Penh, Cambodia Tel: + (855-23) 958 958, M: + (855-67) 555 721Vorn Ra VuthNo ratings yet

- Nomenclator Retete Beton 2021 Model Excel (1) SemnatDocument3 pagesNomenclator Retete Beton 2021 Model Excel (1) SemnatZgripcea CristianNo ratings yet

- Concrete Mix Design M 30 Grade With Konark Opc 43 Grade CementDocument12 pagesConcrete Mix Design M 30 Grade With Konark Opc 43 Grade CementTapan Mishra Pinu100% (2)

- Technical Specification Sandvik LH209L 06 PDFDocument3 pagesTechnical Specification Sandvik LH209L 06 PDFEnrique CalquínNo ratings yet

- M-25 OPC Cement Without AdmixtureDocument5 pagesM-25 OPC Cement Without Admixturesnigdha.0613No ratings yet

- Test CostingDocument186 pagesTest CostingMohammad FiqiNo ratings yet

- Concrete Spec Japek 2 ElevatedDocument1 pageConcrete Spec Japek 2 ElevatedjimdabrondNo ratings yet

- Material Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFDocument117 pagesMaterial Submittal For Al Sarh Trading & Cont. (C20 &C25 Screed) PDFBikasNo ratings yet

- Indra: SonatrachDocument8 pagesIndra: SonatrachhichamNo ratings yet

- Casappa - PL-04-T-ADocument92 pagesCasappa - PL-04-T-AMihai Popa100% (1)

- Coatings 09 00812 s001Document9 pagesCoatings 09 00812 s001cavoixanh89No ratings yet

- 003 PDFDocument52 pages003 PDFengsonikaNo ratings yet

- Batch 127232 Hexindo BalikpapanDocument2 pagesBatch 127232 Hexindo BalikpapanlilikNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 286Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 286JHONATAN RODRIGUEZ VENTONo ratings yet

- SGGP Reference No: P0116-TAK-P01-0200-01Document6 pagesSGGP Reference No: P0116-TAK-P01-0200-01Jabel Oil Services Technical DPTNo ratings yet

- ANCHOREDocument2 pagesANCHOREIrshad HussainNo ratings yet

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFDocument4 pagesShapeshell - Steel Structure Painting Technical Specification 2020-02-10 PDFmorisNo ratings yet

- Shapeshell - Steel Structure Painting Technical Specification 2020-02-10Document4 pagesShapeshell - Steel Structure Painting Technical Specification 2020-02-10morisNo ratings yet

- Ra Bill VoltasDocument11 pagesRa Bill VoltasHARSHADNo ratings yet

- A.S.T.M. B584-09a: WWW - Okendo.mxDocument4 pagesA.S.T.M. B584-09a: WWW - Okendo.mxShariq KhanNo ratings yet

- Mix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Document2 pagesMix Design - Qatar Trading & Contracting Group C40 SRC Rev 1Sudhakar JayNo ratings yet

- Lotte Titanpro PM803 Product DataDocument1 pageLotte Titanpro PM803 Product DataJoni Sie MssNo ratings yet

- PALL FILTER - Process Data SheetDocument2 pagesPALL FILTER - Process Data SheetThirukkumaranBalasubramanianNo ratings yet

- FILTER-OIL 2409393 - CaterpillarDocument3 pagesFILTER-OIL 2409393 - CaterpillarRjg EarthmoversNo ratings yet

- Plumbness Check ReportDocument50 pagesPlumbness Check ReportMuhammad Fitransyah Syamsuar Putra88% (8)

- Plumbness Check ReportDocument50 pagesPlumbness Check ReportYusuf KhoirNo ratings yet

- (Varia Beton) Concrete Mix Design K250 PDFDocument1 page(Varia Beton) Concrete Mix Design K250 PDFAnnas AchoNo ratings yet

- AKHPL Concrete Mix Design Summary.Document3 pagesAKHPL Concrete Mix Design Summary.dipl labNo ratings yet

- Daily Progress Report (CPEC-2C) : Right Abutment Approach Road (3.2 KM)Document5 pagesDaily Progress Report (CPEC-2C) : Right Abutment Approach Road (3.2 KM)M. Aamir Saeed0% (1)

- TM GDR-413Document2 pagesTM GDR-413Ahmat RamadaniNo ratings yet

- Arat At: Length of RopeDocument2 pagesArat At: Length of RopeNiranjan KumarNo ratings yet

- JI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1Document1 pageJI-2044-OC1-TRC-FAB-JC-ST-1758: Bill of Materials OC-1weerachai phosoongNo ratings yet

- 0421 - 16 MS PT Meindo Elang EndahDocument1 page0421 - 16 MS PT Meindo Elang EndahJoel Alfonso ManurungNo ratings yet

- Q1Co 3000 Q1Co 3620 3620-FIT - 186Document2 pagesQ1Co 3000 Q1Co 3620 3620-FIT - 186JHONATAN RODRIGUEZ VENTONo ratings yet

- PP - Sasol - HKR 102Document2 pagesPP - Sasol - HKR 102Luis ArciaNo ratings yet

- ENGGBOQABSTRACTREPORT NewDocument1,274 pagesENGGBOQABSTRACTREPORT NewUTTAL RAYNo ratings yet

- JHANJHARPURDocument11 pagesJHANJHARPURAbhimanyu KumarNo ratings yet

- Satya Engineer Services: Item No. As Per WODocument2 pagesSatya Engineer Services: Item No. As Per WOanand sharmaNo ratings yet

- 20&21072018 Magarmc Krrbproject C35aDocument3 pages20&21072018 Magarmc Krrbproject C35aDileepa DissanayakeNo ratings yet

- 8 5-MM85DHDocument3 pages8 5-MM85DHnappyNo ratings yet

- ATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDocument2 pagesATT - 1.2.0 - Global GC Bid Template MV1 - CGK-063 - CIVIL EXT WORKS REVDeri AnggaraNo ratings yet

- Joints in ConstructionDocument25 pagesJoints in ConstructionWaqarSaleemChNo ratings yet

- Description Unit Qty. Unit Price, Birr Item No. Total Amount, BirrDocument5 pagesDescription Unit Qty. Unit Price, Birr Item No. Total Amount, BirrARSENo ratings yet

- Ramos Copper Piping For The Refrigeration System Layout2Document1 pageRamos Copper Piping For The Refrigeration System Layout2Piolo Gabrielle RamosNo ratings yet

- Daniel T. Li: Grade Beam Design Based On ACI 318-99Document2 pagesDaniel T. Li: Grade Beam Design Based On ACI 318-99RamadanNo ratings yet

- Uick Start GuideDocument3 pagesUick Start GuideAmigo SecretoNo ratings yet

- Air ConditioningDocument12 pagesAir ConditioningSNo ratings yet

- Plumbing - Technical Specifications PDFDocument18 pagesPlumbing - Technical Specifications PDFEdzon LacayNo ratings yet

- Alnor Product Catalogue 20190109Document1,009 pagesAlnor Product Catalogue 20190109nazgulNo ratings yet

- Ayrshire Steel FramingDocument34 pagesAyrshire Steel FramingjohnautodidacteNo ratings yet

- Trane MultisplitDocument6 pagesTrane MultisplitEl Manú ManúNo ratings yet

- Guidelines For Installation of SWHS in High Rise Buildings PDFDocument4 pagesGuidelines For Installation of SWHS in High Rise Buildings PDFBonaventure NzeyimanaNo ratings yet

- Passive Solar ArchitectureDocument59 pagesPassive Solar ArchitectureJUAN_LUIS_MENARES100% (2)

- Leed Vs Lotus - 11.2017 - EngDocument28 pagesLeed Vs Lotus - 11.2017 - EngthaiNo ratings yet

- HKR ProfileDocument28 pagesHKR ProfileTariq AhmedNo ratings yet

- TACO HARDWARE BOOK - DigitalDocument32 pagesTACO HARDWARE BOOK - DigitalembenNo ratings yet

- Optimal Deign of Pile FoundationDocument13 pagesOptimal Deign of Pile FoundationJustin Johnson100% (1)

- T150mm - Beam and Blocks PDFDocument2 pagesT150mm - Beam and Blocks PDFErnie ErnieNo ratings yet

- SaprodgdeDocument6 pagesSaprodgdeA MahmoodNo ratings yet

- Pert - CPM: Construction of Warehouse in Support To Consolidation, Trading and Marketing of Whole NutsDocument1 pagePert - CPM: Construction of Warehouse in Support To Consolidation, Trading and Marketing of Whole Nutscarl_orbeNo ratings yet

- HC-300 Product Guide PDFDocument2 pagesHC-300 Product Guide PDFtintucinbNo ratings yet

- Figure 01-Shows Maximum Displacement Around OpeningsDocument9 pagesFigure 01-Shows Maximum Displacement Around OpeningsKevin CadenaNo ratings yet

- Firepro: Strong Defense Against FireDocument16 pagesFirepro: Strong Defense Against FireramkumarNo ratings yet

- Hyrib User Guide PDFDocument35 pagesHyrib User Guide PDFYoong Lai YeeNo ratings yet

- Paroc Extra: Product DatasheetDocument2 pagesParoc Extra: Product Datasheetturkertalayman1660No ratings yet

- RHPC & RMCDocument2 pagesRHPC & RMC3deepNo ratings yet

- Micropile Underpinning Brackets PDFDocument4 pagesMicropile Underpinning Brackets PDFPrakashNo ratings yet

- Doserver Project City Link TNB TENDER - EE 1101-TNB ReDocument1 pageDoserver Project City Link TNB TENDER - EE 1101-TNB ReMohamad JohairieNo ratings yet

- Vol Keramik HTDocument408 pagesVol Keramik HTrajef FathNo ratings yet

- Homemade HRV, PDF, Jan 2004Document39 pagesHomemade HRV, PDF, Jan 2004JohnNo ratings yet