Professional Documents

Culture Documents

1.1.8. MLCP Technical Specification - SAG - New - E-House - 3BHS353481 - Rev

Uploaded by

LuisOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

1.1.8. MLCP Technical Specification - SAG - New - E-House - 3BHS353481 - Rev

Uploaded by

LuisCopyright:

Available Formats

We reserve all rights in this document and in the information contained therein.

Reproduction, use or disclosure to third parties without express authority is strictly forbidden. ABB Schweiz AG

ABB Switzerland Ltd

LBU Minerals

CH-5401 Baden, Switzerland

Technical Specification

Mill Local Control Panel (MLCP)

EQUIPMENT: MLCP for GMD SAG Mill

PROJECT: Antamina SAG New E-House

CLIENT: Compañia Minera Antamina

CONTRACTOR: -

Project No.: 1-1071771

Equip/Tag: 0310-COA-010

Based on MLCP Technical Specification_SAG_BALL_3BHSXXXXXXX_rev-.dot Project Antamina SAG New E-House Project

I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design

Prep. M. Martins / ATBDE1 08.07.2011 Documents\040 GMD\MLCP\MLCP Technical

Specification_Antamina_SAG_New_E-House_3BHS353481_rev-.doc

Appr. M. Salinas / ATBDE1 08.07.2011

Doc. Kind Specification Doc. MLCP Technical Item

Specification_Antamina_SAG_New_

Title Technical Specification des. E-House_3BHS353481_rev-.doc des.

Mill Local Control Panel

Resp. dept. ATBDE1

Document identity Lang. Rev. ind. Sheet 1

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

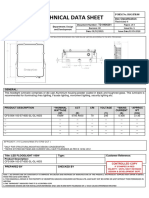

1. LAYOUT

Tag-Nr.: MLCP Sag Mill : 0310-COA-010

Front Door Cut

SAFE MODE E-HOUSE MLCP CENTRAL

MLCP/ CENTRAL

E-HOUSE

SAFE

MODE

2. CONSTRUCTION

Protection Class : IP 65

Size : width x height x depth, 800 x 700 x 300mm

Colour : Stainless Steel, not painted

Cabinet : Stainless Steel

Shockproof up to 6Nm/mm2

Resistant against corrosion, chemicals

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 2

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

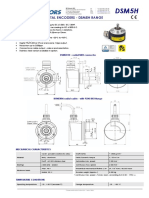

3. CYCLO CONTROL TERMINAL

Mounted inside the MLCP!

Size: width x height x depth, 483 x 355 x 110 mm

The MLCP with integrated CCT (Cyclo Control Terminal) is a full-fledged panel PC with Windows

XP as operating system and the Cycloconverter -specific application. It is operated by touching

the desired menu item on the screen.

When the panel (e.g. after a power outage) is restarted, Windows XP is automatically loaded.

The OPC server is then started, which establishes communication with the PEC controller. The

AC800 PEC must be online for this purpose.

Features:

- Powerful industrial PC with user friendly HMI that runs independently from the system’s

processing unit (AC800 PEC).

- Serial link to the AC800 PEC controller, via OPC (OPC server installed)

- Industrial PC with 15” color touch screen

- control keys for system control

- Analogue signal display

- Event listing

- trending of selectable signals

- Selectable screens showing status of the system in graphical and numerical form

- Uploading and displaying of transient recorder files

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 3

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

4. FUNCTIONAL DESCRIPTION

4.1 Control Place Selection

The mill drive can be operated from different control places like:

- CCR (Central Control Room, normal plant operation)

- MLCP (mainly during mill maintenance)

- E-House (mainly for commissioning & ABB service engineers)

The Control Place is initially set to CCR and can be changed as follows:

CCR Key Switch Control Remarks

command position place

at MLCP

Remote or CENTRAL CCR

local

Remote MLCP/E-HOUSE CCR

Local MLCP/E-HOUSE MLCP/E- Default control place is MLCP. Switchover at

house/Pend Cyclo control terminal using Panel Control

ant Button (See push button functions paragraph

4.3)

MLCP/E- CCR command was in Local before. No

Remote MLCP/E-HOUSE house/Pend switchover control place is possible until key

ant switch is set back to Central.

Local SAFE MODE - Mill is locked, (motor is off and brake is

engaged). No operation is possible.

Notes :

- Remote command is associated with Normal operation of the mill and Local command when

the mill is on Maintenance.

- CCR command change to Local, the default control place is MLCP/Pendant.

4.2 Key Switch

The Key Switch on the panel front door is for selecting between CENTRAL- MLCP/E-HOUSE or

SAFE MODE. The control place selection of the mill is described in the above paragraph 4.1.

For safety reasons, the key can be removed in either position to prevent unauthorized control.

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 4

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

4.3 Panel Control Buttons

The most important operations can be performed using these command buttons. The following

standard commands are available:

Push Action Effect

Button[PB]

Auxiliaries ON Initiates an automatic, normal start-up sequence for all Mill, Motor

and Cyclo Converter auxiliary drives.

Auxiliaries OFF Initiates an automatic, normal shutdown sequence for all Mill,

Motor and Cyclo Converter auxiliary drives.

MCB ON Main Circuit Breakers for Stator & Rotor are switched on

MCB OFF Main Circuit Breakers for Stator & Rotor are switched off

Mill Start Mill start command; the effect is subject to the mill control mode

Mill Stop Mill stop command

UP In Normal & Creeping Mode: speed increase

In Inching Mode : adjustment of angle or No. of liner rows, up

1)

DOWN In Normal & Creeping Mode: speed decrease

In Inching Mode : adjustment of angle or No. of liner rows, down

1)

Forward Direction preselector; enabled during motor standstill

Reverse Direction preselector; enabled during motor standstill

Manual Lowering Manual release of Brakes as long as Button is depressed (The

Function is enabled in creeping mode but only if the Mill is

stopped)

Reduce Mill Rocking Manual Brake soft-apply as long as Button is depressed (The

Function is enabled in normal and inching mode but only if the Mill

is stopped)

Mill Creeping Selecting Creeping mode:

After the Start PB is pressed, the motor speed will increase up to

creeping speed. Pressing the Stop PB will cause immediate Stop,

with applied brakes.

Mill Inching Selecting inching mode:

(Positioning) The Angle/ No. of liners can be preselected via the Display. After

the Start PB is pressed, the Motor speed will increase up to

inching speed. The Motor will stop when the desired angle- or liner

setpoint is reached.

Mill Normal Operation Selecting Normal mode:

Motor is started with the Start PB and speed can be increased/

decreased between MIN and MAX speed by pressing the setpoint

value buttons 1). Pressing the Stop PB will Stop the Mill.

Panel control button For changing control place MLCP or E-house. It changes color

according control status. It is located at the upper right hand side

of the panel.

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 5

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

Reset Reset error messages

1) The setpoint value button is located at the bottom right-hand side of the

panel, below the menu bar. The desired target value for the converter can

be preset here. It may be dependent on the operating mode e.g. normal

operation, inching, creeping, etc.

4.3.1 Inching (Positioning) Mode

To position the mill drive to a specific angle, “Mill Positioning Mode” is selected. The angle/ No.

of Liners can be entered via the control panels, using the value setting buttons. After the Start

PB is pressed, the Mill will turn at inching speed (~1 rpm) until the desired angle setpoint is

reached.

When switching from Central mode to MLCP/E-HOUSE, Inching (Positioning) Mode has to be

selected.

The desired angular position or number of liners, can be set from 0°... 360° or 0…20 liners; the

operator has to enter the angle or number of liners.

Mill brake will not be applied in this mode.

4.3.2 Creeping Mode

To test or maintenance purpose, the drive is operated locally with min. speed, “Mill Creeping

Mode” is selected. By pushing the Start PB the mill will increase to Creeping speed (~ 0.3 … 0.4

rpm) and can be turned until the Stop PB is pressed.

Speed can be increased/ decreased between creeping and inching speed by pressing the value

setting button.

Brakes will be applied immediately after a stop command.

4.3.3 Normal Mode

To run the Mill drive between MIN and MAX speed, “Mill Normal Mode” must be selected and the

Start PB pressed. Speed can be increased / decreased by pressing the value setting buttons.

When pressing the Stop PB, the mill speed decreases according to a ramp function to eliminate

rocking.

Brakes will not be applied in this mode.

Further explanation about GMD start and stop sequence is described in Ball Mill Drive Operation

Manual.

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 6

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

4.3.4 Reduce Mill Rocking

To prevent the mill from rocking, “Reduce Mill Rocking” could be used. It is basically a manual

brake normal -apply as long as the push button is pressed.

“Reduce Mill Rocking” could be used when brakes were released and the mill was not in

equilibrium and starts to rock. This could happen either in case of normal stop, switching from

safe or Creeping to either Inching mode or Normal mode or after an Emergency Stop is

released.

The Reduce Mill Rocking - function is enabled in any mode but only if the mill motor is not

running.

4.3.5 Manual Lowering

Function to bring the mill into equilibrium (balancing the mill).

With manual lowering (which is basically a manual brake release as long as the push button is

pressed), maintenance staff can bring the mill into equilibrium. The Manual Lowering function is

enabled in any mode but only if the mill motor is not running.

4.3.6 Safe Mode

Lock out mode for access into the mill. Brakes are engaged and the ring motor is de-energized.

In the Safe mode any kind of operation is disabled, all control panel pushbuttons are not active,

brake cannot be released and the mill ring motor cannot be energized. It secures, that mill is

standing still, while the selector key switch is in the position “Safe Mode”. Safe mode is foreseen

for the maintenance personnel to “lock-out” the mill ringmotor for their personal safety before

they enter the mill.

4.4 Horn

Relay output (dry contact; maximum switching voltage 250 V AC/DC, maximum continuous

current 6A) is foreseen to control an external mounted start-up warning horn.

(Horn is not ABB scope of supply)

This relay output is energized:

- In normal, inching or creeping mode, 10 seconds before the mill starts to turn.

- 5 seconds before the mode is changing from creeping to normal/inching mode. ( the brakes

will be released)

4.5 Emergency Push Button

The emergency stop push button is maintained when pressed. When pressed, only the

corresponding running ringmotor performs an emergency shutdown.

The GMD system auxiliaries are not stopped. The ringmotor is prohibited from restarting until the

emergency stop push button is released and the trip reset.

(Client must define the control philosophy for emergency shut down).

The brakes will be applied after an emergency stop.

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 7

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

4.6 Control push button station (optional)

The MLCP includes a mill “control push button station” with a 16 meter long flexible cord.

The control via “pendant” will be only active in “Creeping Mode”.

Functions: -Start

-Stop

-Emergency STOP

4.7 Status, Fault & Alarm Signals

Events:

Display of the last 2000 events, alarm and fault messages will be indicated on the event

display.

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 8

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

Trending:

24-hour recording in the ring buffer

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 9

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

4.8 Actual Signals indicated:

Configurable instruments for signal indication. The most frequently signals can be displayed:

- Airgap measurements (max. 12 sensors)

- Line Frequency

- Line Voltage RMS

- Cyclo input current RMS

- Motor current RMS

- Motor voltage RMS

- Motor power (real, apparent, reactive)

- Motor speed

- Motor power factor

- Flux magnitude

- Rotor position (Arrow angle and width)

- Stator and rotor earth resistance

- Excitation line voltage

- Excitation current

- Excitation voltage

- PEC 800 temperatures

- PEC 800 voltages

- Cyclo cooling system measurements

- etc.

Signal indication screen:

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 10

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

One ringmotor screen with airgap measurement, as example:

Project Antamina SAG New E-House Project

Title Technical Specification

Mill Local Control Panel

Document identity Lang. Rev. ind. Sheet 11

ABB Switzerland Ltd 3BHS 353 481 en -

No. of

sheets 11

Template: CHIND Techn doc deliv, A4 P en, R1.DOT; Filename:I:\01D\13Proj\GMD\11071771 Antamina SAG New E-House\02 Design Documents\040 GMD\MLCP\MLCP Technical Specification_Antamina_SAG_New_E-

House_3BHS353481_rev-.doc; Print: 7/8/2011 4:03:00 PM; Save: 7/8/2011 4:03:00 PM; CHIND No. 3BHS102260 ZAB E12 Rev. A; I-Q

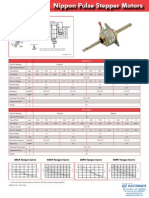

You might also like

- Digital LED Thermometer with Microcontroller AVR ATtiny13From EverandDigital LED Thermometer with Microcontroller AVR ATtiny13Rating: 5 out of 5 stars5/5 (1)

- 305.534 - Electrical Drawing SteinemanDocument337 pages305.534 - Electrical Drawing SteinemanGerardo PerezNo ratings yet

- St12 Series: Microsd Memory Card ConnectorDocument5 pagesSt12 Series: Microsd Memory Card ConnectorMhb AliloNo ratings yet

- SP0793-E951.00-G25-0051-A ABB - LV MCC - TECHNICAL SPECIFICATION - Rev A - 2020-12-08Document19 pagesSP0793-E951.00-G25-0051-A ABB - LV MCC - TECHNICAL SPECIFICATION - Rev A - 2020-12-0818-01-0096No ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- 1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1Document34 pages1KHF334933 - AHS-PS32-1402-B - SAS Functional Description For CCR Rev1kytong100% (1)

- 8MTR Panel in Door Panels DrawingDocument2 pages8MTR Panel in Door Panels DrawingGirish BelagaliNo ratings yet

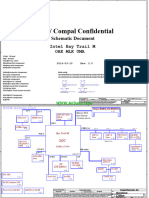

- Compal La-B481p r2.0 SchematicsDocument43 pagesCompal La-B481p r2.0 SchematicsLas DusNo ratings yet

- Data Sheet: ReceivedDocument7 pagesData Sheet: ReceivedStuxnetNo ratings yet

- CFS 504 100 57 60D SL GL NSG - CLF500173 A2Document3 pagesCFS 504 100 57 60D SL GL NSG - CLF500173 A2ganesangNo ratings yet

- Condition:: Models: Musso & Korando With The Btra A/TDocument7 pagesCondition:: Models: Musso & Korando With The Btra A/TGuio MartinezNo ratings yet

- Compal Confidential: ULV Core Logic BoardDocument30 pagesCompal Confidential: ULV Core Logic BoardAnubys 365No ratings yet

- EAO DS Smart-Box 73-00001.2 S84-With-Lens EN-1384723Document4 pagesEAO DS Smart-Box 73-00001.2 S84-With-Lens EN-1384723Pablo GonzalesNo ratings yet

- Technical Specifications: Enviropol Engineers Pvt. LTDDocument17 pagesTechnical Specifications: Enviropol Engineers Pvt. LTDArvind KumarNo ratings yet

- PECELPPF333004A2Document17 pagesPECELPPF333004A2RuddyNo ratings yet

- SMDB M RF PDFDocument7 pagesSMDB M RF PDFFadi Mohd ShaherNo ratings yet

- Schematics Document: NAP10 LA-5812P MBDocument55 pagesSchematics Document: NAP10 LA-5812P MBIIIkwarkaNo ratings yet

- SM G988B Direy 6 WWW - deviceDB.xyzDocument9 pagesSM G988B Direy 6 WWW - deviceDB.xyzimeteorkNo ratings yet

- Dell Inspiron 15 3531 Compal LA-B481P ZBW00 Rev 2.0 SchematicsDocument42 pagesDell Inspiron 15 3531 Compal LA-B481P ZBW00 Rev 2.0 SchematicsYosbelNo ratings yet

- 500 - SET19294-03-Generator Technical SpecificationDocument20 pages500 - SET19294-03-Generator Technical SpecificationAndres DNo ratings yet

- Compal Confidential: JM40-HR M/B Schematics DocumentDocument57 pagesCompal Confidential: JM40-HR M/B Schematics Documentfahmi aNo ratings yet

- Gateway ID47H SJM40-HR Compal LA-241P Rev0.2 SchematicDocument56 pagesGateway ID47H SJM40-HR Compal LA-241P Rev0.2 SchematicElvis SousaNo ratings yet

- 673 HN Ses 23Document5 pages673 HN Ses 23ZAHID IQBALNo ratings yet

- Industrial Cfast Card F-50 Series: Product Fact SheetDocument2 pagesIndustrial Cfast Card F-50 Series: Product Fact SheetM Usman ChaudharyNo ratings yet

- Synchrotact 5Document140 pagesSynchrotact 5zoliNo ratings yet

- Eletro-X - FDI55 LA-J081P (REV 1.0) (A00)Document51 pagesEletro-X - FDI55 LA-J081P (REV 1.0) (A00)ahas viyanaNo ratings yet

- Stores List - 19072017050043Document1 pageStores List - 19072017050043Constantin Emilian AvorniceseiNo ratings yet

- Shuweihat S3 IPP: AE1172 - &EFP020-C-117810 1/1Document6 pagesShuweihat S3 IPP: AE1172 - &EFP020-C-117810 1/1Mayur GuptaNo ratings yet

- CMW58M 00008Document5 pagesCMW58M 00008rubensvaldesNo ratings yet

- Fise Tehnice Jet FanuriDocument5 pagesFise Tehnice Jet FanuriConstantin294No ratings yet

- Inst Hook Up PDFDocument18 pagesInst Hook Up PDFRinaBhattacharya50% (2)

- (500estrela) FN050-4DK.4I.V7P1 153540Document8 pages(500estrela) FN050-4DK.4I.V7P1 153540Giovani RodriguesNo ratings yet

- Centrale A Cycle Combine de Terga 3 400 MW: Revision HistoryDocument23 pagesCentrale A Cycle Combine de Terga 3 400 MW: Revision HistoryOussamaNo ratings yet

- GS95024-2-12 MAGNA Supplement 24.11.20 Ast D3Document30 pagesGS95024-2-12 MAGNA Supplement 24.11.20 Ast D3664bbdfvxnNo ratings yet

- Lv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Document32 pagesLv-168 Prozeal Infra Engineering Pvt. Ltd. Rev-01Chaturbhai Hadiyal0% (1)

- COMPAL LA 3301P IBQ00 REV 1.0 (ComunidadeTecnica - Com.br)Document59 pagesCOMPAL LA 3301P IBQ00 REV 1.0 (ComunidadeTecnica - Com.br)Carlos Tome De SousaNo ratings yet

- M/s. JSW 2250mm Hot Strip Mill: Sizing Calculation Battery and Battery ChargerDocument11 pagesM/s. JSW 2250mm Hot Strip Mill: Sizing Calculation Battery and Battery ChargerNAM PHẠM LÊNo ratings yet

- COMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFDocument5 pagesCOMPAL LS-3803P, 3804P (JBL00, JBL01, JBL02) 2008-05-12, Rev 1.0 (A00) - IO Board PDFGerman ValenciaNo ratings yet

- ETD1000 Instruction ManualDocument28 pagesETD1000 Instruction ManualrgunasekaranNo ratings yet

- Certified Panel Builder: 19-08-2021 P1423-05-21-AD-SCH-R04Document5 pagesCertified Panel Builder: 19-08-2021 P1423-05-21-AD-SCH-R04ahmed samiNo ratings yet

- Exp LG 730076 - 0Document2 pagesExp LG 730076 - 0ANo ratings yet

- 963-R1 - Zeniya OfferDocument8 pages963-R1 - Zeniya OfferDarshit VyasNo ratings yet

- Compal LA-7912P - Schematics. Www.s-Manuals - ComDocument61 pagesCompal LA-7912P - Schematics. Www.s-Manuals - Comwrprogramas serviçosNo ratings yet

- Compal LA-7912P r02Document60 pagesCompal LA-7912P r02Leandrey BicalhoNo ratings yet

- Exp LG 730070 - 0Document1 pageExp LG 730070 - 0Ghadeer AbbasNo ratings yet

- Sil3 Ple - Incremental Encoders - Dsm5H RangeDocument3 pagesSil3 Ple - Incremental Encoders - Dsm5H RangeMAG.NET TechnicNo ratings yet

- Dop Ce RGG - SignedDocument1 pageDop Ce RGG - SignedAvishek GuptaNo ratings yet

- Data Sheet 3KC9000-8CL10: ModelDocument5 pagesData Sheet 3KC9000-8CL10: ModelMARIAMNo ratings yet

- Disassembly & ReaDocument9 pagesDisassembly & ReaТолон СабыркулуулуNo ratings yet

- Acer Aspire E1 v1 v3-531 - 571 - Compal Ls-7912p - Powerboard - Rev 0.5Document3 pagesAcer Aspire E1 v1 v3-531 - 571 - Compal Ls-7912p - Powerboard - Rev 0.5Carlos Alberto Klafke FilhoNo ratings yet

- Ptsi PTD M: Medium VoltageDocument55 pagesPtsi PTD M: Medium VoltageDiBernadNo ratings yet

- 9f09a Compal LA-B102P r1.0 2014Document47 pages9f09a Compal LA-B102P r1.0 2014Kevin DumbravaNo ratings yet

- Compal LA - C771P Rev 1 SchematicDocument34 pagesCompal LA - C771P Rev 1 Schematicbong bernalbongNo ratings yet

- Protection Technical Offer For Dammam Port - Rev 02Document11 pagesProtection Technical Offer For Dammam Port - Rev 02lalitendu jenaNo ratings yet

- SMD Led Product Data Sheet: Ltst-C170KgktDocument12 pagesSMD Led Product Data Sheet: Ltst-C170KgktHemantkumarNo ratings yet

- Date Sr. No. Product / Process Affected:: List of Customer Deviation - 2011 13Document21 pagesDate Sr. No. Product / Process Affected:: List of Customer Deviation - 2011 13Anish KamatNo ratings yet

- MantDocument2 pagesMantAstudillo Garcia DanielNo ratings yet

- HP Compaq CQ40 AMD Compal LA-4111PDocument54 pagesHP Compaq CQ40 AMD Compal LA-4111PIchimmaru KinNo ratings yet

- Dell Inspiron 15 5575 Compal CAL51 LA F121P Rev 1 00A00 PDFDocument61 pagesDell Inspiron 15 5575 Compal CAL51 LA F121P Rev 1 00A00 PDFDeMzo SMpNo ratings yet

- NoteDocument3 pagesNotePandrayar MaruthuNo ratings yet

- Schneider-Electric - PratiKa Plugs and SocketsDocument94 pagesSchneider-Electric - PratiKa Plugs and SocketsLuisNo ratings yet

- ABSOPULSE - Power Supply AC-DC HBC319 - Data SheetDocument1 pageABSOPULSE - Power Supply AC-DC HBC319 - Data SheetLuisNo ratings yet

- ABSOPULSE - Power Supply AC-DC HBC619 - Data SheetDocument1 pageABSOPULSE - Power Supply AC-DC HBC619 - Data SheetLuisNo ratings yet

- ABSOPULSE - Power Supply AC-DC HBC419 - Data SheetDocument1 pageABSOPULSE - Power Supply AC-DC HBC419 - Data SheetLuisNo ratings yet

- Emergency Stop, Configurable Stop Category 0 or 1 (Option +Q979) For ACS880-07/07LC/17/17LC/37/37LC DrivesDocument58 pagesEmergency Stop, Configurable Stop Category 0 or 1 (Option +Q979) For ACS880-07/07LC/17/17LC/37/37LC DrivesLuisNo ratings yet

- 2021 07 02 120237 - 6002428056 PRJDocument137 pages2021 07 02 120237 - 6002428056 PRJLuisNo ratings yet

- Zonestar GuideDocument59 pagesZonestar GuidepepeNo ratings yet

- Lesson 10: Assessment of Learning: Task 1: Circuit AnalysisDocument6 pagesLesson 10: Assessment of Learning: Task 1: Circuit AnalysisAzmi KhanNo ratings yet

- Linde EN Ds t25 t30 1153 en B 0620 WebDocument6 pagesLinde EN Ds t25 t30 1153 en B 0620 WebNadeem AhmedNo ratings yet

- Gefran Manual UserDocument212 pagesGefran Manual UserJhon Syalfiandy100% (3)

- AC Motor Controller With VCLDocument7 pagesAC Motor Controller With VCLalllim88No ratings yet

- Manual For Ac100 Series Frequency Inverter v1 0Document217 pagesManual For Ac100 Series Frequency Inverter v1 0Mohammed aliNo ratings yet

- Operating Instruction MX PlusDocument153 pagesOperating Instruction MX PluspecirepiNo ratings yet

- L010976 - EMJ-04 Servo MotorDocument3 pagesL010976 - EMJ-04 Servo Motor許駿瑋No ratings yet

- Motor CharlynDocument47 pagesMotor Charlyngleisongg86No ratings yet

- Nodal Analysis Indentifies ESP Wellhead Choke ProblemsDocument14 pagesNodal Analysis Indentifies ESP Wellhead Choke ProblemsSufian R EllabbadNo ratings yet

- Chariot 2 Iscrub Operator Instructions EnglishDocument70 pagesChariot 2 Iscrub Operator Instructions EnglishChanning websterNo ratings yet

- Automatic Microprocessor Control Panel For Stand-By GeneratorDocument33 pagesAutomatic Microprocessor Control Panel For Stand-By GeneratorOmarColonNo ratings yet

- CAREL - Inverter Seria FCSDocument2 pagesCAREL - Inverter Seria FCSSarah HortonNo ratings yet

- Efficycle 2018 Information Document For Motor KitDocument3 pagesEfficycle 2018 Information Document For Motor KitSonu RaghuwanshiNo ratings yet

- Design and Analysis Mini CNC Plotter MachineDocument23 pagesDesign and Analysis Mini CNC Plotter MachineUsman BhattiNo ratings yet

- L1408T EqpcchxDocument11 pagesL1408T Eqpcchxmarjorie vargas castroNo ratings yet

- Ac Tech SCF ManualDocument2 pagesAc Tech SCF ManualAriel MestreNo ratings yet

- 27 Technical DataDocument28 pages27 Technical DataaafaqueNo ratings yet

- Light Duty Hybrid Electric Vehicle Specialist ASE FlyerDocument4 pagesLight Duty Hybrid Electric Vehicle Specialist ASE Flyerajib_09No ratings yet

- Flexi-ACiON-User-Manual Manual de CodigosDocument89 pagesFlexi-ACiON-User-Manual Manual de CodigosfranciscoNo ratings yet

- Safety Considerations For The Design of Modern Elevator SystemsDocument72 pagesSafety Considerations For The Design of Modern Elevator SystemsYunus MushagaNo ratings yet

- CAT g500 HSB MF 13523467 en GB PDFDocument452 pagesCAT g500 HSB MF 13523467 en GB PDFRafael HenriquesNo ratings yet

- Lab File Basics of Electronics & Electrical Engg. (For PTU B.Tech. 1st Year)Document49 pagesLab File Basics of Electronics & Electrical Engg. (For PTU B.Tech. 1st Year)Cutie33% (3)

- Lecture Notes-Electrical Machine-II (BEE 1401) Part-I: Veer Surendra Sai University of Technology, BurlaDocument79 pagesLecture Notes-Electrical Machine-II (BEE 1401) Part-I: Veer Surendra Sai University of Technology, BurlaDeependra SinghNo ratings yet

- NPM pfcl25 SpecsheetDocument1 pageNPM pfcl25 SpecsheetElectromateNo ratings yet

- Quick Start Guide - Fans - ECblue BASIC-MODBUS, ECblue BASIC - D (116), GDocument39 pagesQuick Start Guide - Fans - ECblue BASIC-MODBUS, ECblue BASIC - D (116), GRicardo AyarzagoitiaNo ratings yet

- Tracnghiem AvrDocument59 pagesTracnghiem AvrNguyễn Khắc TâmNo ratings yet

- The Problem and Its Scope: 1.1 Rationale of The StudyDocument22 pagesThe Problem and Its Scope: 1.1 Rationale of The StudyDanica BalinasNo ratings yet

- Vibrator Motor-QuantumDocument1 pageVibrator Motor-QuantumSulistyo widiatmokoNo ratings yet

- Group Number - 17: Prof. Saifullah PayamiDocument7 pagesGroup Number - 17: Prof. Saifullah PayamiMayank SinghNo ratings yet