Professional Documents

Culture Documents

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Uploaded by

firstyan dhika aldaniCopyright:

Available Formats

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS 2014-002 002 - 1G & 2G S 275 JRDocument2 pagesWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Stoody - Hardfacing GuideDocument3 pagesStoody - Hardfacing GuideDayanaNo ratings yet

- KATO HD2310-3 Excavator Workshop Manual PDFDocument232 pagesKATO HD2310-3 Excavator Workshop Manual PDFBaciu Nicolae93% (15)

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Course: 141 Tig Welding of Stainless SteelDocument17 pagesCourse: 141 Tig Welding of Stainless Steelamir moniriNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure Specification KLPK 2Document2 pagesWelding Procedure Specification KLPK 2Zans 2001No ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)tebetupar.ttNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS 01-111-2023 enDocument2 pagesWPS 01-111-2023 endiogodemoura95No ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- PWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)Document2 pagesPWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)eliskal bahar100% (1)

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- 7-1 Llist of Qualified Welder And&or Welding Operators (DSHI Rev.0)Document2 pages7-1 Llist of Qualified Welder And&or Welding Operators (DSHI Rev.0)이훈No ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- 0W430191-STR-051 - Squadcheck PipingDocument1 page0W430191-STR-051 - Squadcheck PipingNew BossNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- Welding Procedure Specifiction: JOINTS (QW-402)Document3 pagesWelding Procedure Specifiction: JOINTS (QW-402)Ahmad MohammadNo ratings yet

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- Client: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Document7 pagesClient: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Bhargav BbvsNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- Old WPSDocument1 pageOld WPSDHANEESH VELLILAPULLINo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Joint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %Document1 pageJoint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %Houssem EttwilNo ratings yet

- WPS SertipDocument3 pagesWPS SertipMassimo FumarolaNo ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)Mohamad Marwan HamwiNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Sop 04 Work Permit SystemDocument10 pagesSop 04 Work Permit Systemathul subashNo ratings yet

- Paper 4Document10 pagesPaper 4UmaibalanNo ratings yet

- WTR 400Document11 pagesWTR 400Anil FauzdarNo ratings yet

- Ilustre Chapter-2Document5 pagesIlustre Chapter-2JFl BernsNo ratings yet

- ASMEDocument20 pagesASMENorazzah AbdullahNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Arshaya Supplier EvaluationDocument4 pagesArshaya Supplier Evaluationdavid dagarNo ratings yet

- Hastelloy G 35Document16 pagesHastelloy G 35Ir Go JarNo ratings yet

- Submerged Arc Welding Process: ACCESS DLC 2009-02-03Document32 pagesSubmerged Arc Welding Process: ACCESS DLC 2009-02-03Anonymous KeeGB3oxPNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFAhmed Ben NoumaNo ratings yet

- Corrosion Inhibitor Selection Rev1Document33 pagesCorrosion Inhibitor Selection Rev1امينNo ratings yet

- BME Mannual BT 203-1Document41 pagesBME Mannual BT 203-1shivanshu tiwariNo ratings yet

- 14 Inspection and TestingDocument3 pages14 Inspection and TestingelmiraNo ratings yet

- Din 1690Document7 pagesDin 1690saravananNo ratings yet

- Sifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateDocument8 pagesSifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateNamira Putri AuliaNo ratings yet

- 10 GENESIS TCD Sterile Tube Welder - CompressedDocument2 pages10 GENESIS TCD Sterile Tube Welder - Compresseduzair saleemNo ratings yet

- Fire in High Rise BuildingDocument6 pagesFire in High Rise BuildingZuhair NadeemNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Asme Sec Ix 2021Document79 pagesAsme Sec Ix 2021abdelkader bensatal100% (1)

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Sec611 - Steel ReinforcementDocument7 pagesSec611 - Steel ReinforcementAmr Adel HameedNo ratings yet

- QAP For Insulation Procedure1Document4 pagesQAP For Insulation Procedure1Mukesh DakNo ratings yet

- QWS Best Practices GuideDocument34 pagesQWS Best Practices GuidechowhkNo ratings yet

- W350 EngDocument1 pageW350 EngJosue EstradaNo ratings yet

- Fact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYDocument3 pagesFact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYCarlos BustamanteNo ratings yet

- IJ Mar Apr2008 LLADocument24 pagesIJ Mar Apr2008 LLALuciano CimorelliNo ratings yet

- Rd6appspecDocument2 pagesRd6appspecravi00098No ratings yet

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Uploaded by

firstyan dhika aldaniOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Vi-Ik-Eq - En-31-00 Ik For Build Up Raised Faced (31 - 37)

Uploaded by

firstyan dhika aldaniCopyright:

Available Formats

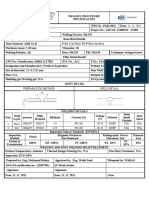

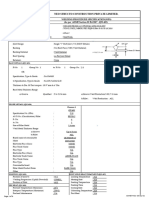

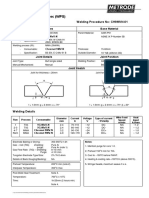

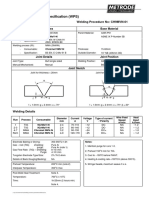

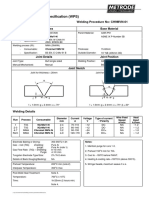

No. Dok : VI-IK-EQ.

EN-31-00

WORKING INSTRUCTION FOR BUILD UP RAISED No. Rev : 00

FACED (CS-GTAW) Date : 17 Apr 2018

Hal : 1 dari 1

Welding Process: GTAW

Job Description BUILD UP Welding Code : ASME Section IX

Material Standard A105, A216 WCB or Equivalent

Material Thickness Refer Drawing Joint Design : BUILD UP

Filler Metal Standard SFA 5.18 Joint Orientation : FLAT

Filler Metal Classification ER70S-G Welding Current : DCEN

Filler Metal Tradename TGS-50 or Equivalent

Shielding Gas Argon 99.9% Flow Rate : 10 - 20 Ltr/mnt

Wire Speed N/A

Reference WPS 002/WPS/ASME/CS/OVERLAY/VI/2015

Welding Current Arc Voltage Travel Speed

Run No Electrode Size (mm) Heat Input (kJ/mm)

(Amps) (Volts) (mm/min)

1-n 2.4 60 - 150 10 - 20 90 - 120 0.30 - 2.00

L

O

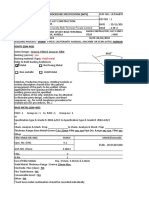

Joint Detail Sketch Welding Sequence

Welding to increase surface

TR

(Based on drawing)

1. Start welding from

middle

N

O

2. Continue welding to

C

outer side until all

grey side filled

N

U

Heat Treatment: N/A (Slow Cooling)

Pre Heat: As per AS 4458 Table 10.1 (12-25mm=Ambient),(25-50mm=80°C)

(Over 50mm=125°C)

Notes:

1 Use 2.4mm thoriated tungsten

2 Close tube of welding rod after using to prevent contamination from dust and othe contaminant

3 Ensure area to be welded is free from any grease , paint , oil and other contaminants.

4 Erect baricades to ensure area is protected by draft or windy conditions to allow adequate

gas coverage where necessary.

Dibuat Oleh: Diperiksa Oleh: Diketahui Oleh:

Welding Engineer QC & Eng Manager Ops Manager General Manager Direktur

Haposan Edward Harry D.H Tunggul P. R. W. Royke Rompis Indra Cayadi

VI-IK-EQ.EN-31-00 IK FOR BUILD UP RAISED FACED ( 31 - 37)

You might also like

- Bridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, OdishaDocument5 pagesBridge & Roof Co - (I) LTD: Iocl Tankage Work (M&I) in PHBPL Paradip, Odishaniraj mouryaNo ratings yet

- WPS 2014-002 002 - 1G & 2G S 275 JRDocument2 pagesWPS 2014-002 002 - 1G & 2G S 275 JRjeswin50% (2)

- Stoody - Hardfacing GuideDocument3 pagesStoody - Hardfacing GuideDayanaNo ratings yet

- KATO HD2310-3 Excavator Workshop Manual PDFDocument232 pagesKATO HD2310-3 Excavator Workshop Manual PDFBaciu Nicolae93% (15)

- Method Statement - STOP-LOGSDocument7 pagesMethod Statement - STOP-LOGSMohammad Bader Al-DeinNo ratings yet

- Aws D1.6 - SS316 WPSDocument1 pageAws D1.6 - SS316 WPSBoby Thomas0% (1)

- For Fillet Weld Joint Project:Production ManifoldDocument1 pageFor Fillet Weld Joint Project:Production Manifoldabdallah ahmed50% (2)

- Course: 141 Tig Welding of Stainless SteelDocument17 pagesCourse: 141 Tig Welding of Stainless Steelamir moniriNo ratings yet

- Je C 008 WPSDocument4 pagesJe C 008 WPScameron toolseeNo ratings yet

- Je C 006 WPSDocument4 pagesJe C 006 WPScameron toolseeNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document3 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmack100% (1)

- APL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - IxDocument2 pagesAPL HEC: Hearoon Engineering Company Welding Procedure Specification Asme Sec - Ixmc160403810 Usman AliNo ratings yet

- Welding Procedure Specification KLPK 2Document2 pagesWelding Procedure Specification KLPK 2Zans 2001No ratings yet

- QW 482 WPSDocument2 pagesQW 482 WPSsmit patelNo ratings yet

- Tz.O.R.C R.O. Project: Second and OtherDocument5 pagesTz.O.R.C R.O. Project: Second and Otherbehzad mohammadiNo ratings yet

- PQR - Gmaw BCCDocument2 pagesPQR - Gmaw BCCBasel MohammadNo ratings yet

- (P22) Nsc-1020-Tr-0102-5a.5a-Wps-04Document9 pages(P22) Nsc-1020-Tr-0102-5a.5a-Wps-04BIIS QAQC Babu SivaNo ratings yet

- Welding Procedure Specification (WPS) : Code: Asme-IxDocument2 pagesWelding Procedure Specification (WPS) : Code: Asme-IxAnonymous 4WzixLwupNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- Note: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldDocument2 pagesNote: For CJP Grove Details Will Be Based From AWS D1.1 2015 Figure 3.3 Prequalified CJP Grove WeldTadaya KasaharaNo ratings yet

- PhuBia-WPS-AWS D1.1-8-6-2011Document2 pagesPhuBia-WPS-AWS D1.1-8-6-2011poulmackNo ratings yet

- Welding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateDocument2 pagesWelding Procedure Specification: Company Dodsal Pte Ltd. Approved by KBRT Signature Name DateS GoudaNo ratings yet

- Welding Proposed Pwps For Our Jubail WorkDocument2 pagesWelding Proposed Pwps For Our Jubail WorkAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)tebetupar.ttNo ratings yet

- Ultrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.ADocument1 pageUltrasonic Test: Χάλυβες Καραλή Α.Ε.Β.Ε. Karalis Steel S.AA. ΒρατσισταNo ratings yet

- WPS CuNiDocument1 pageWPS CuNiDieter Huaman ToscanoNo ratings yet

- WPS 01-111-2023 enDocument2 pagesWPS 01-111-2023 endiogodemoura95No ratings yet

- (P1) NSC-1020-TR-0102-1.1-WPS-06Document6 pages(P1) NSC-1020-TR-0102-1.1-WPS-06BIIS QAQC Babu SivaNo ratings yet

- PWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)Document2 pagesPWPS Structure 01. AWS D1.1 MCE (Lincoln Electric)eliskal bahar100% (1)

- Welding Procedure For Plate - WPSDocument1 pageWelding Procedure For Plate - WPSCristian ZidarescuNo ratings yet

- Wps For Akbtpl E-6013 - ModifiedDocument13 pagesWps For Akbtpl E-6013 - ModifiedvinayNo ratings yet

- 7-1 Llist of Qualified Welder And&or Welding Operators (DSHI Rev.0)Document2 pages7-1 Llist of Qualified Welder And&or Welding Operators (DSHI Rev.0)이훈No ratings yet

- WPS (Welding of Hub To Blade)Document2 pagesWPS (Welding of Hub To Blade)workshop13.asaNo ratings yet

- WPS For A333 ADocument1 pageWPS For A333 ARamzi BEN AHMED100% (1)

- Welding Procedure Specification (WPS) (As Per EN / ISO 15609-1)Document1 pageWelding Procedure Specification (WPS) (As Per EN / ISO 15609-1)ramesh rajaNo ratings yet

- Preliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Document2 pagesPreliminary Welding Procedure Specification (PWPS) : South Pars Gas Field Development Phase 14Vijaya Barani100% (1)

- 0W430191-STR-051 - Squadcheck PipingDocument1 page0W430191-STR-051 - Squadcheck PipingNew BossNo ratings yet

- QW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectDocument6 pagesQW - 482 Welding Procedure Specification (WPS) Tankage Works at Dharmapuri Terminal of VDPL ProjectArijit Ghosh100% (1)

- WPS For SSDocument1 pageWPS For SSdeepakNo ratings yet

- Pessing Libya INC: Weld Detail Preparation MethodDocument1 pagePessing Libya INC: Weld Detail Preparation MethodMahmoud HaggagNo ratings yet

- WPS & PQR VVSPLDocument3 pagesWPS & PQR VVSPLBhargav BbvsNo ratings yet

- Welding Procedure Specifiction: JOINTS (QW-402)Document3 pagesWelding Procedure Specifiction: JOINTS (QW-402)Ahmad MohammadNo ratings yet

- P91 ProfileDocument6 pagesP91 ProfilesrinivasanNo ratings yet

- Client: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Document7 pagesClient: Hindustan Petroleum Corporation Ltd. Contractor: Narmada Offshore Constructions Pvt. Ltd. Doc. No.: NOCPL/HPCL/NWOT/RK/WPS/JP/01 Rev. 00Bhargav BbvsNo ratings yet

- Wps 11Document2 pagesWps 11Avishek GuptaNo ratings yet

- Old WPSDocument1 pageOld WPSDHANEESH VELLILAPULLINo ratings yet

- Welding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeDocument1 pageWelding Procedure Specification (WPS) : Section IX, ASME Boiler and Pressure Vessel CodeKishan ChauhanNo ratings yet

- Joint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %Document1 pageJoint Gap Correction Procedure: Welding Sequence and Control To Be Done: 1-VT:100 %Houssem EttwilNo ratings yet

- WPS SertipDocument3 pagesWPS SertipMassimo FumarolaNo ratings yet

- Welding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2Document2 pagesWelding Procedure Specification (WPS) : Standard Applicable: BS EN ISO 15609 1:2019 & BS EN ISO 15614 1: 2017 Level 2phong NguyenduyNo ratings yet

- WPSDocument2 pagesWPSAlam MD Sazid100% (1)

- Welding Procedure Specification (WPS)Document6 pagesWelding Procedure Specification (WPS)Mohamad Marwan HamwiNo ratings yet

- P91 Profile WpsDocument6 pagesP91 Profile WpsZead Ali Adal100% (2)

- Draft WPSDocument3 pagesDraft WPSWale OyeludeNo ratings yet

- Piping WPS SMAWDocument2 pagesPiping WPS SMAWJk KarthikNo ratings yet

- 07.3 111 FW ML PF WPS 20mm EngDocument1 page07.3 111 FW ML PF WPS 20mm EngViktorNo ratings yet

- Metrode - P92 WPS PDFDocument3 pagesMetrode - P92 WPS PDFXing ChenNo ratings yet

- Welding Procedure Specifications (WPS) : AWS D1.1Document2 pagesWelding Procedure Specifications (WPS) : AWS D1.1BS AhnNo ratings yet

- Welding Procedure Specification (WPS)Document3 pagesWelding Procedure Specification (WPS)Jignasa ShahNo ratings yet

- PQR02 (For SMAW)Document2 pagesPQR02 (For SMAW)workshop13.asaNo ratings yet

- WPS No. ST-CS-02-2Document1 pageWPS No. ST-CS-02-2Hussein JassimNo ratings yet

- Datasheet Sandvik 199l enDocument3 pagesDatasheet Sandvik 199l enpedro rojasNo ratings yet

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsRating: 5 out of 5 stars5/5 (1)

- Sop 04 Work Permit SystemDocument10 pagesSop 04 Work Permit Systemathul subashNo ratings yet

- Paper 4Document10 pagesPaper 4UmaibalanNo ratings yet

- WTR 400Document11 pagesWTR 400Anil FauzdarNo ratings yet

- Ilustre Chapter-2Document5 pagesIlustre Chapter-2JFl BernsNo ratings yet

- ASMEDocument20 pagesASMENorazzah AbdullahNo ratings yet

- 19403955-WPS M.S. Is 2062Document10 pages19403955-WPS M.S. Is 2062Varun Malhotra100% (1)

- Arshaya Supplier EvaluationDocument4 pagesArshaya Supplier Evaluationdavid dagarNo ratings yet

- Hastelloy G 35Document16 pagesHastelloy G 35Ir Go JarNo ratings yet

- Submerged Arc Welding Process: ACCESS DLC 2009-02-03Document32 pagesSubmerged Arc Welding Process: ACCESS DLC 2009-02-03Anonymous KeeGB3oxPNo ratings yet

- Table 6 1 AWS D1 1 D1 1M 2010 PDFDocument1 pageTable 6 1 AWS D1 1 D1 1M 2010 PDFAhmed Ben NoumaNo ratings yet

- Corrosion Inhibitor Selection Rev1Document33 pagesCorrosion Inhibitor Selection Rev1امينNo ratings yet

- BME Mannual BT 203-1Document41 pagesBME Mannual BT 203-1shivanshu tiwariNo ratings yet

- 14 Inspection and TestingDocument3 pages14 Inspection and TestingelmiraNo ratings yet

- Din 1690Document7 pagesDin 1690saravananNo ratings yet

- Sifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateDocument8 pagesSifat Mekanik Dan Struktur Mikro Aluminium Aa1100 Hasil Pengelasan Friction Stir Welding Dengan Variasi Feed RateNamira Putri AuliaNo ratings yet

- 10 GENESIS TCD Sterile Tube Welder - CompressedDocument2 pages10 GENESIS TCD Sterile Tube Welder - Compresseduzair saleemNo ratings yet

- Fire in High Rise BuildingDocument6 pagesFire in High Rise BuildingZuhair NadeemNo ratings yet

- WPS 03 GtawDocument3 pagesWPS 03 GtawBiswajit DeyNo ratings yet

- Asme Sec Ix 2021Document79 pagesAsme Sec Ix 2021abdelkader bensatal100% (1)

- Welding SymbolsDocument12 pagesWelding SymbolsrsrtnjNo ratings yet

- Sec611 - Steel ReinforcementDocument7 pagesSec611 - Steel ReinforcementAmr Adel HameedNo ratings yet

- QAP For Insulation Procedure1Document4 pagesQAP For Insulation Procedure1Mukesh DakNo ratings yet

- QWS Best Practices GuideDocument34 pagesQWS Best Practices GuidechowhkNo ratings yet

- W350 EngDocument1 pageW350 EngJosue EstradaNo ratings yet

- Fact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYDocument3 pagesFact-Sheet-No.-19-Dec-2018 LASER WELDING AND CUTTING SAFETYCarlos BustamanteNo ratings yet

- IJ Mar Apr2008 LLADocument24 pagesIJ Mar Apr2008 LLALuciano CimorelliNo ratings yet

- Rd6appspecDocument2 pagesRd6appspecravi00098No ratings yet