Professional Documents

Culture Documents

Performance Sheet Drill Collar

Uploaded by

simmsbopOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Performance Sheet Drill Collar

Uploaded by

simmsbopCopyright:

Available Formats

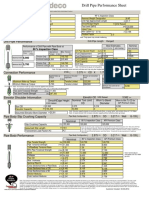

Size: 3.125'' x 1.

250''

Type: Spiral

Drill Collar Performance Sheet MYS (ksi): 120

Asset Number(s): 16695 Tool Joint: 3.125'' x 1.250'' 2 7/8" HTPAC

Drill Collar Body: Drill Collar Assembly:

Nominal Approximate Length (ft): 31.5

100% RBW Adjusted Weight (lbs): 21.65

OD (in): 3.125 Type of Drill Collar: Spiral

Wall Thickness (in): 0.938 Fluid Displacement (gal/ft): 0.336

Nominal ID (in): 1.250 Fluid Displacement (bbls/ft): 0.0080

Fluid Capacity (gal/ft): 0.063

Fluid Capacity (bbls/ft): 0.0015

Drift Size (in): 1.125

Connection: 2 7/8" HTPAC

Tool Joint OD (in): 3.125 Max MUT (ft-lbs): 6,200

Tool Joint ID (in): 1.250 Tension at Shoulder Separation @ Max MUT (lbs): Tensile Limited

Tension at Connection Yield @ Max MUT (lbs): 278,200

Connection MYS (ksi): 120 Min MUT (ft-lbs): 5,100

Ab/Ap Ratio (Area Box/Area Pin): 0.90 Tension at Shoulder Separation @ Min MUT (lbs): 319,400

Tension at Connection Yield @ Min MUT (lbs): 331,100

N/A Tool Joint Torsional Strength (ft-lbs): 10,300

N/A Tool Joint Tensile Strength (lbs): 331,100

2 7/8" HTPAC is a trademark of NOV Grant-Prideco.

Note: MUT values are based on a friction factor of 1.0. There is no published pressure rating for this connection.

The technical information containted herein, including the product performance sheet and other attached documents, has been extracted from information available from the manufacturer and is for reference only and not a recommendation. The user is fully responsible for the accuracy and suitability of use of the technical

information. Workstrings International cannot assume responsibility for the results obtained through the use of this material. No expressed or implied warranty is intended. Drill pipe assembly properties are calculated based on uniform OD and wall thickness. No safety factor is applied. The information provided for various

inspection classes and for various wear conditions (remaining body wall) is for information only and does not represent or imply acceptable operation limits. It is the responsibility of the customer and the end user to determine the appropriate performance ratings, acceptable use of the product, maintain safe operational practices,

and to apply a prudent safety factor suitable for the application. For API connections that have different pin and box IDs, tool joint ID refers to the pin ID. Per Chapter B, Section 4 VII of the IADC drilling manual, it is recommended that drilling torque should not exceed 80% of MUT.

www.workstringsinternational.com 08-Jan-16

Download the Workstrings International Pipe Specification App on the App Store℠ or Google Play™

You might also like

- Standard Is Ed Reading PassagesDocument6 pagesStandard Is Ed Reading PassagesPreston Jenny BoboNo ratings yet

- Stars - A Golden GuideDocument164 pagesStars - A Golden GuideKenneth100% (12)

- HWDPDocument15 pagesHWDPjinyuan74No ratings yet

- Especificaciones de Tuberia Pesada HW 5 1/2 F.HDocument1 pageEspecificaciones de Tuberia Pesada HW 5 1/2 F.HAlberto Cárdenas100% (1)

- Smart Facade PDFDocument9 pagesSmart Facade PDFRameshwarDas KumawatNo ratings yet

- Torre MayorDocument24 pagesTorre MayorJoshua100% (1)

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarNaman ShahNo ratings yet

- Drill Collar 4.75 NC38 - SpiralDocument1 pageDrill Collar 4.75 NC38 - SpiralFernando OlaveoNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarashadNo ratings yet

- 5948 DCPSDocument1 page5948 DCPSGarcia MarinNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument2 pagesPerformance Sheet Drill CollarAboozar FathinejadNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarabelardoNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarPopovici AlexandruNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarabelardoNo ratings yet

- DC 6.5in 120ksi 90.61ppf NC46 R2 SpiralDocument2 pagesDC 6.5in 120ksi 90.61ppf NC46 R2 SpiralKevin MuellerNo ratings yet

- HWDP Performance Sheet: Pipe Body: Tubular AssemblyDocument1 pageHWDP Performance Sheet: Pipe Body: Tubular AssemblyKevin MuellerNo ratings yet

- WS46-02 - Tubing 3.5Document1 pageWS46-02 - Tubing 3.5Carlos PerdomoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJosh SabimanNo ratings yet

- 2,7,8, DP Aoh Condiciones TecnicasDocument3 pages2,7,8, DP Aoh Condiciones TecnicasFernando EncisoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- 7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Document3 pages7.625 OD 0.625 Wall V-150 MaXit807 (9.750 X 6.250 TJ)Abelardo Castro EstupiñanNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyjohangomezruizNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFStowartNo ratings yet

- TBPSDocument1 pageTBPSElvis E Prado PNo ratings yet

- DPPS PDFDocument2 pagesDPPS PDFPablo SantisNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyAboozar FathinejadNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyFranklynMartinezNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Especificaciones Tecnicas DP 5.5 FH R2 PDFDocument1 pageEspecificaciones Tecnicas DP 5.5 FH R2 PDFDiego Fabian Ruiz VacaflorNo ratings yet

- WS41-53 DPPSDocument3 pagesWS41-53 DPPSRocard NgomaNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- 5.5 HWDPDocument3 pages5.5 HWDPözgüncNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument3 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblySamuel PerezNo ratings yet

- Heavy Weight Drill Pipe PerformanceDocument3 pagesHeavy Weight Drill Pipe PerformanceHomero NavarroNo ratings yet

- 7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Document3 pages7.625 OD 0.688 Wall V-150 MaXit807 (9.750 X 6.125 TJ)Abelardo Castro EstupiñanNo ratings yet

- 6.625 HWDPDocument23 pages6.625 HWDPözgüncNo ratings yet

- No. 27Document3 pagesNo. 27UPGM Ingenieria petroleraNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- Performance Sheet Tubing: Pipe Body: Tubular AssemblyDocument1 pagePerformance Sheet Tubing: Pipe Body: Tubular Assemblykm1790No ratings yet

- HWDP Configuration: Performance of HWDP AssemblyDocument3 pagesHWDP Configuration: Performance of HWDP AssemblyMamani Vargas WiljhoNo ratings yet

- Performance Sheet Drill Pipe: Pipe Body: Tubular AssemblyDocument2 pagesPerformance Sheet Drill Pipe: Pipe Body: Tubular AssemblyJohnsNo ratings yet

- WS38-16 DPPS PDFDocument1 pageWS38-16 DPPS PDFJohnsNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument7 pagesDrill Pipe Configuration: 80 % Inspection ClassWaleedm MariaNo ratings yet

- WS43-11 LSPSDocument1 pageWS43-11 LSPSAbelardo Castro EstupiñanNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection ClassLuis Manuel García GuillénNo ratings yet

- 5.5英寸短钻杆 HT55质量文件包裹模板Document17 pages5.5英寸短钻杆 HT55质量文件包裹模板zhaibo666No ratings yet

- 5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) SpiralDocument1 page5.000 HWDP With NC50 (4.5IF) (6.625 X 3.0625 TJ) Spiralfaishal hafizhNo ratings yet

- 8.500 SKC713MDocument1 page8.500 SKC713MMiguelNo ratings yet

- Drill Pipe Configuration: 80 % Inspection ClassDocument3 pagesDrill Pipe Configuration: 80 % Inspection Classalekz89No ratings yet

- DrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Document3 pagesDrillPipe, 80%, 5.000 OD, 0.500 Wall, IEU, S-135.. XT50 (6.625 X 3.500)Luis Alberto García CórdovaNo ratings yet

- 3-1/2Document1 page3-1/2Mohamed FikryNo ratings yet

- Workstring International MaXit 807 Completion Landing StringDocument2 pagesWorkstring International MaXit 807 Completion Landing StringzhiqianxuNo ratings yet

- 4英寸短钻杆 HT40质量文件包裹模板Document17 pages4英寸短钻杆 HT40质量文件包裹模板zhaibo666No ratings yet

- Archer DP 5.875 Inch XT 57 SpecsDocument3 pagesArcher DP 5.875 Inch XT 57 SpecsMamani Vargas Wiljho100% (1)

- Tubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Document1 pageTubing 3.500" 9.30 LB/FT: Pipe Grade: N80 / Range: 2 Tool Joint: 4.500'' X 2.992'' EUE (8 RD)Êfrên Rôdrîgûêz TôrrêsNo ratings yet

- 5.5 Drill Pipe W Cet54 ConnectionsDocument1 page5.5 Drill Pipe W Cet54 Connectionsfarhad iqbalNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Scan 2Document2 pagesScan 2simmsbopNo ratings yet

- Scan 3Document2 pagesScan 3simmsbopNo ratings yet

- Scan 2Document1 pageScan 2simmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- Performance Sheet Drill CollarDocument1 pagePerformance Sheet Drill CollarsimmsbopNo ratings yet

- SP025 SummaryDocument42 pagesSP025 Summaryain amaliaNo ratings yet

- Water Adsorption and Desorption ModelDocument14 pagesWater Adsorption and Desorption ModelmanigandanNo ratings yet

- Corrosion in PulpDocument11 pagesCorrosion in PulpSatyam MadameNo ratings yet

- Cyclone Presentation PDFDocument47 pagesCyclone Presentation PDFArchana BhartiNo ratings yet

- 2003-Novel PEEK Membranes For Fuel Cell ApplicationsDocument2 pages2003-Novel PEEK Membranes For Fuel Cell Applicationssomething100% (1)

- Comet2015 S6 P2 PaperDocument14 pagesComet2015 S6 P2 PaperMohammed MushtahaNo ratings yet

- Radiation Heat Transfer Mathcad SolutionsDocument176 pagesRadiation Heat Transfer Mathcad SolutionsThebe HanyaneNo ratings yet

- 317114162-EDDY-CURRENT-AND-APPLICATIONS-PROJECT Class 12 Physics Investigatory ProjectDocument9 pages317114162-EDDY-CURRENT-AND-APPLICATIONS-PROJECT Class 12 Physics Investigatory Projectpseudo network67% (9)

- Tic Tac Toe Choice BoardDocument2 pagesTic Tac Toe Choice Boardapi-529100008No ratings yet

- Protein FoldingDocument9 pagesProtein FoldingAyush ZalaNo ratings yet

- Effect of Asphaltene and Resins On The Stability of Water-In-Waxy Oil EmulsionsDocument20 pagesEffect of Asphaltene and Resins On The Stability of Water-In-Waxy Oil EmulsionsSoleiman ChatrsimabNo ratings yet

- JEE Main 2023 Jan 24th Morning Shift - Physics: QuestionsDocument14 pagesJEE Main 2023 Jan 24th Morning Shift - Physics: Questionsychiru540No ratings yet

- Application of Aerogels in Textile IndustryDocument8 pagesApplication of Aerogels in Textile IndustrySanmedha AmbureNo ratings yet

- CH 1Document48 pagesCH 1RoczNo ratings yet

- Group 6 - Lab Experiment PhypharmDocument7 pagesGroup 6 - Lab Experiment PhypharmNichole Win MallariNo ratings yet

- 2019 - Super Moisture-Absorbent Gels For All-Weather PDFDocument7 pages2019 - Super Moisture-Absorbent Gels For All-Weather PDFDanh TruongNo ratings yet

- UV Radiation Filter Using Phenyl Salicylate-Sepiolite SystemsDocument8 pagesUV Radiation Filter Using Phenyl Salicylate-Sepiolite SystemsHERNANDEZ1010No ratings yet

- Tutorial 5 - 2023Document4 pagesTutorial 5 - 2023Prithu PareshNo ratings yet

- CHEM 115 PLTL Activity Sheet 12Document4 pagesCHEM 115 PLTL Activity Sheet 12Temp WorkNo ratings yet

- Structural Steel Trusses Analysis and DesignDocument39 pagesStructural Steel Trusses Analysis and DesignSai Sasank CHNo ratings yet

- Types of Hydropower TurbinesDocument2 pagesTypes of Hydropower TurbinesLidya AnastasyaNo ratings yet

- Para Consulta: Glass Capillary Kinematic ViscometersDocument25 pagesPara Consulta: Glass Capillary Kinematic ViscometersJUAN CARLOSNo ratings yet

- Try LangDocument22 pagesTry Lang마비 니제시카No ratings yet

- Comparision - RC - Building ETABS and Midas GenDocument16 pagesComparision - RC - Building ETABS and Midas Genmarkespino100% (2)

- Calculating Power and EfficiencyDocument4 pagesCalculating Power and EfficiencyAdam ChiangNo ratings yet