Professional Documents

Culture Documents

SL DMA 1072 Numerical Control Programming

Uploaded by

farizanOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

SL DMA 1072 Numerical Control Programming

Uploaded by

farizanCopyright:

Available Formats

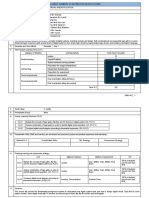

SYLLABUS: SUMMARY OF INFORMATION ON EACH COURSE

1. Name of Course: NUMERICAL CONTROL PROGRAMMING

2. Course Code: DMA 1072

3. (a) Names of Subject 1. Mohd Syafiq Bin Mohd Rosdi 6. Fauziah Binti Mohd Sanip

Matter Expert: 2. Mohamed Zulfakar Jafney 7. Mohd Adly Hakeem Bin Abd

Bin Zulkifli Aziz

3. Wan Zarizi Bin Wan 8. Ahmad Farhan Bin Ludin

Kamarulzaman 9. Ameline Sem

4. Nurul Wahida Binti Hanapiah 10. Nuraniza Binti Muslaini

5. Nor Syazana Binti Halim

(b) Names of academic Nama Pengajar

staff:

4. Rationale for the inclusion of the course in the programme:

The aims of this course is to give a comprehensive knowledge and practical of numerical control

programming especially in CNC Lathe and CNC Milling application.

5. Semester and Year offered: Semester 1 Year 1

6. Total Student Learning Time (SLT):

Category of Activities Learning Activity Total Hours / Semester

Lecture 11

Guided learning Tutorial / Practical 28

Student Centered Learning activities 3

Preparation for assignments / projects 15

Self-learning Independent study / Revision 11

Preparation for assessment 6

Continuous assessments 6

Formal assessments Final examination sitting for theory 0

Final examination sitting for practical 0

Total SLT 80

7. Credit Value: 2 credits

8. Prerequisite (if any): None

9. Course Learning Outcomes (CLO):

CLO1 Apply the knowledge of numerical control programming method accordance to

technical drawing requirement in various written documentation. (C3, PLO11)

CLO2 Demonstrate numerical control programming strategies and simulation using CNC

simulator software based on specification given. (P3, PLO2)

CLO3 Comply the basic principle of numerical control programming technique to meet

technical drawing specification. (A2, PLO6)

10 Transferable Skills (Skills and how they are developed and assessed, project and practical

KURIKULUM DMA 2021 1

. experience and internship):

Related PLO Transferable skills Skills development Skill of assessment

PLO6 Personal Skills Case Study, Project Practical Work, Project

and Group Work

11 Teaching-learning and assessment strategies:

.

Method of Method of

CLO KPI

delivery assessment

CLO Apply the knowledge of Lecture,

100%

1 numerical control programming Tutorial, Case

students

method accordance to technical Study, Project,

Assignment, Written obtain

drawing requirement in various and Student-

Test 50%

written documentation. (C3, Centered

marks

PLO11) Learning

and above

Activities

CLO Demonstrate numerical control Lecture, 100%

2 programming strategies and Tutorial, Case students

simulation using CNC simulator Study, Project, obtain

software based on specification Group Work, Practical Work, 50%

given. (P3, PLO2) and Student- Project marks

Centered and above

Learning

Activities

CLO Comply the basic principle of Case Study, 100%

3 numerical control programming Project, Group students

technique to meet technical Work and obtain

Practical Work,

drawing specification. (A2, Student- 50%

Project

PLO6) Centered marks

Learning and above

Activities

12 Course Synopsis:

.

Technical Drawing For CNC Machining, Introduction to CNC, NC Milling Programming, NC Lathe

Programming and Numerical Control Simulation

13 Mode of Delivery (e.g. Lecture, Tutorial, Workshop, Seminar etc):

.

Practical, Demonstration, Case Study, Lecture, Project, Tutorial, Group Work & Student-Centered

Learning Activities

KURIKULUM DMA 2021 2

14 Assessment Methods and Types:

. Written Test, Assignment, Practical Work, and Project

Course Evaluation:

Type of Assessment Marks

Continuous Assessment: 100%

1. Written Test 25%

Theory 2. Assignment 15% 40%

- -

3. Practical Work 20%

Practical 60%

4. Project 40%

Final Assessment: -

Theory Theory Examination -

-

Practical Practical Examination -

Total 100%

15 Mapping of the course to the Programme Educational Objectives (PEO):

.

PEO

PEO1 PEO2 PEO3

4

PLO 11 X

PLO 2 X

PLO 6 X

KURIKULUM DMA 2021 3

16. Mapping of the course (CLO) to the Programme Learning Outcomes (PLO):

Content PLO1 PLO2 PLO3 PLO4 PLO5 PLO6 PLO7 PLO8 PLO9 PLO10 PLO11

Apply the knowledge of numerical control

programming method accordance to

X

technical drawing requirement in various

written documentation. (C3, PLO11)

Demonstrate numerical control

programming strategies and simulation

X

using CNC simulator software based on

specification given. (P3, PLO2)

Comply the basic principle of numerical

control programming technique to meet X

technical drawing specification. (A2, PLO6)

KURIKULUM DMA 2021 4

17. Content outline of the course and the SLT (lecture hours) per topic:

SLT (Hours)

Formal

Face-To-Face Non-Face-To-Face

Assessment

Total

Assignments

Examination

Independent

Assessment

Assessment

Preparation

Preparation

Continuous

Week Content

/ Projects

Theory +

Practical

Revision

SLT

Tutorial

Study /

Final

SCL

for

for

1 TECHNICAL DRAWING FOR CNC MACHINING 1 2 15 11 6 6 0 80

1.1 Introduction to Technical Drawing

1.2 Anatomy of Technical Drawing

1.2.1 Title Block

1.2.2 Pictorial (Isometric) View

1.2.3 Orthographic View

1.2.4 Section View

1.2.5 Detail View

1.2.6 Notes To The Manufacture

1.3 GDT (Geometrical and Dimensional Tolerances)

1.3.1 Introduction

1.3.2 Symbols

1.3.3 Tolerance

1.3.4 Datum

1.3.5 Feature Control Frame

1.3.6 Material Condition

2 INTRODUCTION TO CNC 1 2

2.1 Introduction to NC and CNC

2.2 Major Elements of CNC

2.3 Types of CNC Control System

2.4 Types of CNC Machine Tools

2.5 Advantages and Disadvantages

3-7 NC MILLING PROGRAMMING 5 10

KURIKULUM DMA 2021 5

3.1 Type of Programming Method

3.2 Type of Machining Process

3.3 Basic Tooling Selection

3.4 Control Axis of CNC Milling

3.5 Cartesian Coordinate System

3.6 Machine and Work Coordinate System

3.7 Preparatory Function (G-Codes)

3.8 Miscellaneous Function (M-Codes)

3.9 Feed and Speed Calculation

3.10 Main Structure Program

3.11 Machining Process Planning

3.12 Actual Programming

8-12 NC LATHE PROGRAMMING 5 10

4.1 Type of Programming Method

4.2 Type of Machining Process

4.3 Basic Tooling Selection

4.4 Control Axis of CNC Lathe

4.5 Cartesian Coordinate System

4.6 Machine and Work Coordinate System

4.7 Preparatory Function (G-Codes)

4.8 Miscellaneous Function (M-Codes)

4.9 Feed and Speed Calculation

4.10 Main Structure Program

4.11 Machining Process Planning

4.12 Actual Programming

13-14 NUMERICAL CONTROL SIMULATION 2 4

5.1 Program Checking and Verifying

5.2 Program Input Device

5.3 Parameter Setting

5.4 Program Execution and Simulation

5.5 Simulation Review and Improvement

KURIKULUM DMA 2021 6

15 Study Week

16 Final Exam (Theory)

17 Final Exam (Practical)

Total SLT 14 0 28 15 11 6 6 0 80

Notional Hours 40

Credit Value 2

18. Main and additional references supporting the course:

Main References:

Peter J. Hoffman, Eric S. Hopewell & Brian Janes, “Precision Machining Technology”, Cengage Learning, Second Edition, 2015

Additional References:

P. Smid, “CNC Programming Handbook: A Comprehensive Guide to Practical CNC Programming”, Industrial Press, Inc., Third Edition,

2008

19. Other additional information: -

KURIKULUM DMA 2021 7

You might also like

- Practical Course in Project Management: Over 40 Exercises & 1 Real Project developed with all its Templates, to learn and act like a great Project ManagerFrom EverandPractical Course in Project Management: Over 40 Exercises & 1 Real Project developed with all its Templates, to learn and act like a great Project ManagerNo ratings yet

- Jabatan Teknologi Maklumat Dan Komunikasi Teknologi Sistem Komputer Dan RangkaianDocument6 pagesJabatan Teknologi Maklumat Dan Komunikasi Teknologi Sistem Komputer Dan RangkaianazzkvbesutNo ratings yet

- SL - DMA 3243 - Rekabentuk Dan Pembangunan ProdukDocument8 pagesSL - DMA 3243 - Rekabentuk Dan Pembangunan ProdukRahimi ZabidinNo ratings yet

- Silibus - Dka 1323Document5 pagesSilibus - Dka 1323azzkvbesutNo ratings yet

- Silibus - DKB3343 Edited 15apr2019Document6 pagesSilibus - DKB3343 Edited 15apr2019Muhammad Afham100% (1)

- 4.syllabus - Deb1143 - Digital Electronic and ApplicationDocument7 pages4.syllabus - Deb1143 - Digital Electronic and ApplicationadibNo ratings yet

- Silibus - DKB1323 Edited 29nov2018Document7 pagesSilibus - DKB1323 Edited 29nov2018mohd nasaran bin haronNo ratings yet

- CLP Inb21703Document4 pagesCLP Inb21703Zahirah ZairulNo ratings yet

- Dea 3333 SilibusDocument11 pagesDea 3333 SilibusRoger JohnNo ratings yet

- Dea 3333Document12 pagesDea 3333clairons84No ratings yet

- Syllabus: Summary of Information On Each CourseDocument7 pagesSyllabus: Summary of Information On Each CourseASMANo ratings yet

- Silibus - DKB4333Document7 pagesSilibus - DKB4333azzNo ratings yet

- Table 3: Summary of Information On Each Course Design Development StageDocument15 pagesTable 3: Summary of Information On Each Course Design Development StageSani Oghang PekanNo ratings yet

- Dea 2313 Jan 2019Document13 pagesDea 2313 Jan 2019ASMANo ratings yet

- Deb 1313Document11 pagesDeb 1313sadariahNo ratings yet

- Jabatan Teknologi Maklumat Teknologi Maklumat (Rangkaian Komputer)Document5 pagesJabatan Teknologi Maklumat Teknologi Maklumat (Rangkaian Komputer)Alhasnor Binti KamaruddinNo ratings yet

- Table 3: Summary of Information On Each Course Design Development StageDocument11 pagesTable 3: Summary of Information On Each Course Design Development StageSani Oghang PekanNo ratings yet

- Course Outline: CE112 - Computer Programming: Air UniversityDocument10 pagesCourse Outline: CE112 - Computer Programming: Air UniversityMuhammad HasnainNo ratings yet

- 5.syllabus - Deb1053 - Electronic WorkshopDocument8 pages5.syllabus - Deb1053 - Electronic WorkshopadibNo ratings yet

- 3.syllabus Deb 1133Document8 pages3.syllabus Deb 1133Izlaikha AzizNo ratings yet

- SL - DMA 2122 - Asas Elektrik Dan ElektronikDocument7 pagesSL - DMA 2122 - Asas Elektrik Dan ElektronikfarizanNo ratings yet

- DMD 3062 - Final Year Project IDocument10 pagesDMD 3062 - Final Year Project IShafiq KhaleedNo ratings yet

- PIM-NMB40103 - Course Learning Plan-Jan 2017Document5 pagesPIM-NMB40103 - Course Learning Plan-Jan 2017FirzanNo ratings yet

- Produce Existing Building Drawing: Table 3: Summary of Information On Each CourseDocument7 pagesProduce Existing Building Drawing: Table 3: Summary of Information On Each CourseSani Oghang PekanNo ratings yet

- Syllabus: Summary of Information On Each Course Metal Fabrication ActivitiesDocument10 pagesSyllabus: Summary of Information On Each Course Metal Fabrication ActivitiesAhmadFahmiMohdAdniNo ratings yet

- 1.syllabus - DMB 2113 Welding Quality ControlDocument11 pages1.syllabus - DMB 2113 Welding Quality Controlnurulhuda_84No ratings yet

- Supervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdaraDocument5 pagesSupervisory Skill: Jabatan Teknologi Mekanikal Dan Pembuatan Teknologi Penyejukan Dan Penyamanan UdarajanurtpatNo ratings yet

- Khwaja Fareed University of Engineering & Information TechnologyDocument3 pagesKhwaja Fareed University of Engineering & Information TechnologyEntertainment HouseNo ratings yet

- Course Outline Dec2012 Dee Dis16Document4 pagesCourse Outline Dec2012 Dee Dis16Sofwan wandNo ratings yet

- DMD 4113 Automotive ManagementDocument7 pagesDMD 4113 Automotive ManagementThe MagnificentNo ratings yet

- Syllabus: Summary of Information On Each Course Final Year Project 1Document8 pagesSyllabus: Summary of Information On Each Course Final Year Project 1HAZWANI BT SAPAR MoeNo ratings yet

- Dea 3314Document7 pagesDea 3314clairons84No ratings yet

- Section A: Course Details: Unikl MicetDocument3 pagesSection A: Course Details: Unikl MicetColours Of LifeNo ratings yet

- CLP - Course Learning Plan SAB 24603 Applied Digital Electronics January 2019Document6 pagesCLP - Course Learning Plan SAB 24603 Applied Digital Electronics January 2019MOHAMAD FADZLI BIN HANIFF 14668No ratings yet

- SL - DMA 2233 - Lukisan CAD 2Document8 pagesSL - DMA 2233 - Lukisan CAD 2Mohamed Zulfakar Jafney ZulkfliNo ratings yet

- Facultytechnology Management and Business: Lecture PlanDocument4 pagesFacultytechnology Management and Business: Lecture PlanTickson TanNo ratings yet

- 3.syllabus Deb 1133Document7 pages3.syllabus Deb 1133AngelinaNo ratings yet

- Design Comprehension Process: Table 3: Summary of Information On Each CourseDocument9 pagesDesign Comprehension Process: Table 3: Summary of Information On Each CourseSani Oghang PekanNo ratings yet

- Syllabus 9) DMD 3213 - Engine Management System (2020)Document8 pagesSyllabus 9) DMD 3213 - Engine Management System (2020)Jason MaldonadoNo ratings yet

- 2.syllabus - Deb 2323Document9 pages2.syllabus - Deb 2323AngelinaNo ratings yet

- Table 3 - Diploma Projek Tahun Akhir 1Document4 pagesTable 3 - Diploma Projek Tahun Akhir 1Ford KatimNo ratings yet

- Total Student Learning Time (SLT) :: Table 3: Summary of Information On Each CourseDocument4 pagesTotal Student Learning Time (SLT) :: Table 3: Summary of Information On Each CourseNadzri YahayaNo ratings yet

- DMD 3123 - Automatic Vehicle TransmissionDocument7 pagesDMD 3123 - Automatic Vehicle TransmissionShafiq KhaleedNo ratings yet

- Syllabus: Summary of Information On Each CourseDocument9 pagesSyllabus: Summary of Information On Each CoursekseraphicNo ratings yet

- Syll A Bus: Summary of Information On Each CourseDocument6 pagesSyll A Bus: Summary of Information On Each CourseASMANo ratings yet

- Supervising Skills DevelopmentDocument5 pagesSupervising Skills DevelopmentjanurtpatNo ratings yet

- Bab2 .2Document5 pagesBab2 .2siti nabilahNo ratings yet

- Table 3 - Diploma Projek Tahun Akhir 2Document4 pagesTable 3 - Diploma Projek Tahun Akhir 2Ford KatimNo ratings yet

- DFP5013 CoDocument5 pagesDFP5013 CoFarihan ZahariNo ratings yet

- Fail Kursus DEB1133 Fundemental of Electronic $ Circuit TheoryDocument268 pagesFail Kursus DEB1133 Fundemental of Electronic $ Circuit TheoryAiman AmnNo ratings yet

- Course PRICE ANALYSIS OF CONSTRUCTION WORKS - AIMSDocument10 pagesCourse PRICE ANALYSIS OF CONSTRUCTION WORKS - AIMSMuhd FathiNo ratings yet

- Rpp04-Real Estate Investment and Appraisal 2018-3-1Document5 pagesRpp04-Real Estate Investment and Appraisal 2018-3-1jcobNo ratings yet

- Faculty of Mechanical and Manufacturing Engineering: Lecture PlanDocument4 pagesFaculty of Mechanical and Manufacturing Engineering: Lecture PlanIddin ZalamiNo ratings yet

- Faculty of Mechanical and Manufacturing Enginering: Lesson PlanDocument18 pagesFaculty of Mechanical and Manufacturing Enginering: Lesson PlanNatalia Fitri Clerin SusilowatiNo ratings yet

- Silibus Dca 1143 Soil Mechanics - Jun 2022Document8 pagesSilibus Dca 1143 Soil Mechanics - Jun 2022yatiNo ratings yet

- PF OutlineDocument6 pagesPF OutlineyjadarahaNo ratings yet

- EEB334 Computer Programming I Course Outline and Teaching Plan 2022Document3 pagesEEB334 Computer Programming I Course Outline and Teaching Plan 2022Bosics BenomNo ratings yet

- Department of Computer Science and Engineering (CSE) : United International University Course OutlineDocument3 pagesDepartment of Computer Science and Engineering (CSE) : United International University Course Outlineغلام كبرياNo ratings yet

- IT103 Programming1 SY2022-2023Document12 pagesIT103 Programming1 SY2022-2023Lance Dominic LabisNo ratings yet

- Syllabus: Summary of Information On Each CourseDocument9 pagesSyllabus: Summary of Information On Each CourseAfiza TumijanNo ratings yet

- CO DMA 1132 Workshop Safety and ManagementDocument9 pagesCO DMA 1132 Workshop Safety and ManagementfarizanNo ratings yet

- CO DMA 1042 MetrologyDocument9 pagesCO DMA 1042 MetrologyfarizanNo ratings yet

- CO DMA 1072 Numerical Control ProgrammingDocument9 pagesCO DMA 1072 Numerical Control ProgrammingfarizanNo ratings yet

- CHAP (35) 35 Engr Metrology & InstrumentationDocument4 pagesCHAP (35) 35 Engr Metrology & InstrumentationfarizanNo ratings yet

- 01-Course Outline Material Science 14 Weeks (Edit Syam Nov 19)Document7 pages01-Course Outline Material Science 14 Weeks (Edit Syam Nov 19)farizanNo ratings yet

- 01-Silibus Material ScienceDocument9 pages01-Silibus Material SciencefarizanNo ratings yet

- SL - DMA 2122 - Asas Elektrik Dan ElektronikDocument7 pagesSL - DMA 2122 - Asas Elektrik Dan ElektronikfarizanNo ratings yet

- Kolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)Document4 pagesKolej Vokasional Batu Lanchang Rancangan Sesi Latihan (RSL)farizanNo ratings yet

- Chapter 5 Limit, Fit, and TolerencesDocument12 pagesChapter 5 Limit, Fit, and TolerencesfarizanNo ratings yet

- RSL Mpi 601Document5 pagesRSL Mpi 601farizanNo ratings yet

- Chapter 3 Computerised Numerical Control (CNC)Document37 pagesChapter 3 Computerised Numerical Control (CNC)farizanNo ratings yet

- Limited Edition 2017 Limited Edition 2017 Limited Edition 2017Document1 pageLimited Edition 2017 Limited Edition 2017 Limited Edition 2017farizanNo ratings yet

- Perbandingan Kursus MPI7023Document1 pagePerbandingan Kursus MPI7023farizanNo ratings yet

- Sarah AnDocument1 pageSarah AnfarizanNo ratings yet

- Ele Ctric Dis Cha Rge Ma ChiningDocument48 pagesEle Ctric Dis Cha Rge Ma ChiningfarizanNo ratings yet

- Chapter 1 Introduction of MetrologyDocument7 pagesChapter 1 Introduction of Metrologyfarizan100% (1)

- Penerangan Hasil Pembelajaran Yang Lebih Jelas Dan Dihubungkait Dengan PLODocument1 pagePenerangan Hasil Pembelajaran Yang Lebih Jelas Dan Dihubungkait Dengan PLOfarizanNo ratings yet

- Perbandingan Kursus MPI8033Document3 pagesPerbandingan Kursus MPI8033farizanNo ratings yet

- Special Theory of RelativityDocument16 pagesSpecial Theory of RelativityBrigita SteffyNo ratings yet

- NCERT Exemplar Class 8 Maths Solutions Chapter 3 Square-Square Root & Cube-Cube RootDocument77 pagesNCERT Exemplar Class 8 Maths Solutions Chapter 3 Square-Square Root & Cube-Cube Rootdeep34No ratings yet

- DLP - Projectile Motion-2Document11 pagesDLP - Projectile Motion-2christianlozada000No ratings yet

- Devesh ResumeDocument4 pagesDevesh ResumeNitinNo ratings yet

- Unit 7 - Vesicular MoleDocument43 pagesUnit 7 - Vesicular MoleN. Siva100% (1)

- Fibre Optic Cable SplicingDocument33 pagesFibre Optic Cable SplicingAmax TeckNo ratings yet

- Pneumatic Valve With Diaphragm: Instruction, Use and Maintenance ManualDocument50 pagesPneumatic Valve With Diaphragm: Instruction, Use and Maintenance ManualRicardo CalderonNo ratings yet

- Part Catalogo RMZ250Document67 pagesPart Catalogo RMZ250jesus moralesNo ratings yet

- Definition, Classification and Diagnosis of Diabetes, Prediabetes and Metabolic SyndromeDocument6 pagesDefinition, Classification and Diagnosis of Diabetes, Prediabetes and Metabolic SyndromemandaNo ratings yet

- Nike Strategy AnalysisDocument24 pagesNike Strategy AnalysisasthapriyamvadaNo ratings yet

- Web 24 - Teti Madiadipoera - Treatment and Management of Rhinitis AllergyDocument38 pagesWeb 24 - Teti Madiadipoera - Treatment and Management of Rhinitis AllergyEdzhar HasiholanNo ratings yet

- Tle q4 l5 Quiz Google FormsDocument5 pagesTle q4 l5 Quiz Google FormsEdilbert Bonifacio GayoNo ratings yet

- Full Report XeriaDocument11 pagesFull Report XeriaHamierul MohamadNo ratings yet

- Final Edit Na Talaga ToDocument82 pagesFinal Edit Na Talaga ToExequel DionisioNo ratings yet

- Syeilendra Pramuditya - Example of Motivation LetterDocument1 pageSyeilendra Pramuditya - Example of Motivation LetterSyeilendra PramudityaNo ratings yet

- Induction Motor NotesDocument20 pagesInduction Motor NotesMani SaiNo ratings yet

- Benefits of BIM For Master PlumbersDocument2 pagesBenefits of BIM For Master PlumbersDavid GeminaNo ratings yet

- Sheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNDocument4 pagesSheet #6 Ensemble + Neural Nets + Linear Regression + Backpropagation + CNNrowaida elsayedNo ratings yet

- Physics1ist Year Practical FilDocument27 pagesPhysics1ist Year Practical FilManish GoyalNo ratings yet

- Surigao Del Sur State University: Mathematics in The Modern World Module Number 2Document11 pagesSurigao Del Sur State University: Mathematics in The Modern World Module Number 2TOP ERNo ratings yet

- Human Resource ManagementDocument86 pagesHuman Resource ManagementK V S PRASD REDDYNo ratings yet

- Module Bar PTX1.6 PDFDocument8 pagesModule Bar PTX1.6 PDFkumelachewbirre22No ratings yet

- Part 8 - Bibliography and ReferencesDocument31 pagesPart 8 - Bibliography and Referencessibhat mequanintNo ratings yet

- Sebaceous Gland Secretion Is A Major Physiologic Route of Vitamin E Delivery To SkinDocument5 pagesSebaceous Gland Secretion Is A Major Physiologic Route of Vitamin E Delivery To SkinumegeeNo ratings yet

- Tutorial ControlDocument161 pagesTutorial ControlQuangNguyenDuy100% (1)

- Stochastic Epidemic ModellingDocument15 pagesStochastic Epidemic ModellingIRJMETS JOURNALNo ratings yet

- The Lateral Trochanteric Wall Gotfried 2004 PDFDocument5 pagesThe Lateral Trochanteric Wall Gotfried 2004 PDFluis perezNo ratings yet

- AC405 Assignment R185840RDocument3 pagesAC405 Assignment R185840RDiatomspinalcordNo ratings yet

- Assembly Senate Response.2.10.21. Final PDFDocument16 pagesAssembly Senate Response.2.10.21. Final PDFZacharyEJWilliamsNo ratings yet

- 4.11 Radiation Protection - AHDocument112 pages4.11 Radiation Protection - AHGina RNo ratings yet