Professional Documents

Culture Documents

Liquid Penetrant Inspection Test Data: Inspector: Name: Date: Signature

Liquid Penetrant Inspection Test Data: Inspector: Name: Date: Signature

Uploaded by

Aaron SvetOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Liquid Penetrant Inspection Test Data: Inspector: Name: Date: Signature

Liquid Penetrant Inspection Test Data: Inspector: Name: Date: Signature

Uploaded by

Aaron SvetCopyright:

Available Formats

1

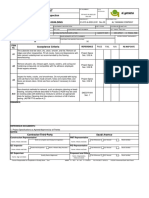

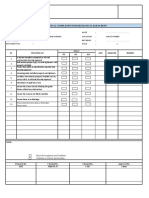

Project: Component:

Customer:

Location:

Shop Welds

IKMI Job # :

Document #:

Specification Welding Quality Control

Raferences:

Liquid Penetrant Inspection

↓↓↓Test Data↓↓↓

Design code: ASME VIII div1

Reference: ASME V article 6 IKMI Fabricator: Isa Khoury

Test Type: Dye penetrant examination

Equipment :

IKMI Test Performer:

Drawing #: See table below

The surface to be inspected is cleaned thoroughly to remove all traces of dirt and grease.

A brightly colored liquid is then applied liberally to the component surface and allowed to penetrate any surface-breaking cracks or cavities.

The time the liquid is allowed to soak into the material's surface is normally about 20 minutes. After soaking, the excess liquid penetrant is

wiped from the surface and a developer applied. The developer is usually a dry white powder, which draws penetrant out of any cracks by

Test Sequence: reverse capillary action to produce indications on the surface. These (colored) indications are broader than the actual flaw and are therefore

more easily visible.

↓↓↓Test Record↓↓↓

Weld

Item Part Length Material Joint Type Date Result Note

No

1

2

3

4

5

6

7

8

9

10

11

12

↓↓↓ Approvals: ↓↓↓

Inspector: Name: Date: Signature:

QC Inspector S.Izvekov

Customer QA/QC

file:///conversion/tmp/activity_task_scratch/602673641.xlsx

You might also like

- MT Form Asme PDFDocument1 pageMT Form Asme PDFTrung Tinh HoNo ratings yet

- Types of ClaimsDocument19 pagesTypes of ClaimsKristina Angelina ReyesNo ratings yet

- Elementary Probability Theory With Stochastic Processes and An Introduction To Mathematical FinanceDocument411 pagesElementary Probability Theory With Stochastic Processes and An Introduction To Mathematical Financevijaygct100% (5)

- National Geographic UK - July 2023Document138 pagesNational Geographic UK - July 2023Ognjen MočevičNo ratings yet

- Hydrostatic Test (Log) : Quality Control FormDocument22 pagesHydrostatic Test (Log) : Quality Control FormAnonymous 4e7GNjzGWNo ratings yet

- Grey Water Discharge Line FEDocument4 pagesGrey Water Discharge Line FEBayu AjiNo ratings yet

- Request For Inspection (Rfi) : OperationDocument3 pagesRequest For Inspection (Rfi) : OperationMohd Jamal Mohd MoktarNo ratings yet

- Material Inspection SheetDocument3 pagesMaterial Inspection Sheetrahid iqubalNo ratings yet

- CQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Document24 pagesCQI-23 For Hitachi (Self Audit Submit 10-Mar-23)Jintara KaewrayaNo ratings yet

- Project Eagle: Quality Management Inspection ReportDocument2 pagesProject Eagle: Quality Management Inspection ReportrcpretoriusNo ratings yet

- Request For Inspection of MaterialDocument3 pagesRequest For Inspection of MaterialSopi Labu100% (1)

- Structural Inspection Report - FinalDocument1 pageStructural Inspection Report - FinaltalhaNo ratings yet

- Checklist - Fire FightingDocument1 pageChecklist - Fire FightingAarnav SinghNo ratings yet

- Solutions to Chapter 4 Problems: 1 2 1 2 1 2 1 2 1 2 1 2 jπt −jπtDocument10 pagesSolutions to Chapter 4 Problems: 1 2 1 2 1 2 1 2 1 2 1 2 jπt −jπtHarry Willsmith100% (3)

- Request For Inspection (Rfi) : Project TitleDocument3 pagesRequest For Inspection (Rfi) : Project TitleehteshamNo ratings yet

- Checklist For Fence Work Rev.2Document9 pagesChecklist For Fence Work Rev.2Ikhsan BakhrullohNo ratings yet

- SML-Sanjeewa Kumara (KAN00129429) NEWDocument67 pagesSML-Sanjeewa Kumara (KAN00129429) NEWAmarshana100% (1)

- ACMV Inspeciton Check ListDocument22 pagesACMV Inspeciton Check ListNaing Win TunNo ratings yet

- Securing Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildFrom EverandSecuring Application Deployment with Obfuscation and Code Signing: How to Create 3 Layers of Protection for .NET Release BuildNo ratings yet

- Industrial Air ControlsDocument195 pagesIndustrial Air ControlsJShearer100% (1)

- Checklist FormworkDocument2 pagesChecklist FormworkSreyleap Nhet100% (4)

- OU500764928 - R0 - Quality Assurance-Manufacturing IDSDocument13 pagesOU500764928 - R0 - Quality Assurance-Manufacturing IDSbecemNo ratings yet

- En Iso 2719 (En 22719 - Its Conversion) PDFDocument23 pagesEn Iso 2719 (En 22719 - Its Conversion) PDFJhon Fredy RinconNo ratings yet

- Module Front OfficeDocument21 pagesModule Front OfficeLorilie Royo RizalonNo ratings yet

- Non Destructive Test Report - Magnetic Particles Inspection (Mpi)Document2 pagesNon Destructive Test Report - Magnetic Particles Inspection (Mpi)Aaron SvetNo ratings yet

- 60-Request For Field Water Test of WindowsDocument1 page60-Request For Field Water Test of WindowsConstruction UpdatePHNo ratings yet

- Liquid Penetrant Report: Quality Control FormDocument1 pageLiquid Penetrant Report: Quality Control Formvarun guptaNo ratings yet

- QAR-QD404-1 Liquid Penetrant Testing Report-GeneralDocument1 pageQAR-QD404-1 Liquid Penetrant Testing Report-GeneralIrwanto ManafNo ratings yet

- Liquid Penetrant Inspection Test DataDocument1 pageLiquid Penetrant Inspection Test DataAaron SvetNo ratings yet

- Piping Visual Quality Control and Inspection Report Form PDFDocument1 pagePiping Visual Quality Control and Inspection Report Form PDFAli HajirassoulihaNo ratings yet

- Toaz - Info Itp For PVC Conduits PRDocument6 pagesToaz - Info Itp For PVC Conduits PRehtesham khanNo ratings yet

- Request For Inspection (Rfi) : Project TitleDocument3 pagesRequest For Inspection (Rfi) : Project TitleehteshamNo ratings yet

- MarcoDocument1 pageMarcobimboNo ratings yet

- Penetrant Test Report (PT)Document1 pagePenetrant Test Report (PT)ibrahim hegazyNo ratings yet

- Penetrant Test Report (PT)Document1 pagePenetrant Test Report (PT)ibrahim hegazyNo ratings yet

- Itp Structural SteelDocument2 pagesItp Structural SteelSahad VarambankallanNo ratings yet

- Liquid Penetrant Inspection Report: Industrial Proforma FormDocument1 pageLiquid Penetrant Inspection Report: Industrial Proforma FormJohn DolanNo ratings yet

- Check List For Alum DoorsDocument2 pagesCheck List For Alum DoorsYash Sharma100% (2)

- Penetrant Test Report (PT)Document1 pagePenetrant Test Report (PT)ibrahim hegazyNo ratings yet

- Ayc Inspection Checklist: Linolium Sheet Pre - Installation InspectionDocument1 pageAyc Inspection Checklist: Linolium Sheet Pre - Installation Inspectionmoytabura96No ratings yet

- ITP 322 - Cummins Rev 03 With JFJV Comment Dec, 13,2022Document5 pagesITP 322 - Cummins Rev 03 With JFJV Comment Dec, 13,2022itac.harrisNo ratings yet

- Rfi 001 PlatformDocument13 pagesRfi 001 PlatformVPN NetworkNo ratings yet

- Form Inspection Report (190515) - PreshipmentDocument9 pagesForm Inspection Report (190515) - Preshipmenttomas liuNo ratings yet

- الأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفDocument1 pageالأسرة وتربية الطفل ، الدكتورة هدى محمود الناشفanon_545606833No ratings yet

- Mechanical Check List Pumps.R5Document2 pagesMechanical Check List Pumps.R5Armando BiringkanaeNo ratings yet

- 61-Request For Field Water Test of PrecastDocument1 page61-Request For Field Water Test of PrecastConstruction UpdatePHNo ratings yet

- 003 - Dye Penetrant Testing Report - Rev00 - 02122015Document2 pages003 - Dye Penetrant Testing Report - Rev00 - 02122015Irwanto ManafNo ratings yet

- Track Roller R996Document5 pagesTrack Roller R996Irwanto ManafNo ratings yet

- Pumps ItpDocument3 pagesPumps Itpkokod9757No ratings yet

- Qip 1907Document1 pageQip 1907talhaNo ratings yet

- Inspection Test Plan For Fabrication PDF FreeDocument4 pagesInspection Test Plan For Fabrication PDF Freesam paulNo ratings yet

- MS-006 - MS For Electrical Works - Rev.1 PDFDocument1 pageMS-006 - MS For Electrical Works - Rev.1 PDFJohn Rey PerlasNo ratings yet

- Visual Inspection Report: Fit-Up CheckDocument4 pagesVisual Inspection Report: Fit-Up CheckIntan AyuNo ratings yet

- Vendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanDocument2 pagesVendor Fabrication Shop Site Construction: QA/QC Inspections: Inspection Test PlanSuraj ShettyNo ratings yet

- WI For Visual InspectionDocument7 pagesWI For Visual InspectionArun KVNo ratings yet

- Etihad Towers Project: Inspection & Test Plan - Block WorksDocument2 pagesEtihad Towers Project: Inspection & Test Plan - Block WorksSagar AliasjackeyNo ratings yet

- PCP Chassis Frame 2801000 BU04Document8 pagesPCP Chassis Frame 2801000 BU04Võ Trung HiếuNo ratings yet

- Form 03 Pile Driving Machine InspectionDocument2 pagesForm 03 Pile Driving Machine InspectionDenny SyafwalufiNo ratings yet

- Carpentry - Factory Inspection Report Inspection Date: Project No: Rfi No: Drawing No: Identification NoDocument1 pageCarpentry - Factory Inspection Report Inspection Date: Project No: Rfi No: Drawing No: Identification NorahulsivaNo ratings yet

- ALF-PRJ-EC-QC-CHK-0001 Installation of Gypsum Wall Boards System - Pre Installation Inspection - Checklist Alfanar PQMISDocument1 pageALF-PRJ-EC-QC-CHK-0001 Installation of Gypsum Wall Boards System - Pre Installation Inspection - Checklist Alfanar PQMISWaqar Ahmad MalikNo ratings yet

- QAR-QD#419-24 Edmo Jack Cylinder GPDocument2 pagesQAR-QD#419-24 Edmo Jack Cylinder GPIrwanto ManafNo ratings yet

- Form 02 Crane Inspection FormDocument2 pagesForm 02 Crane Inspection FormDenny SyafwalufiNo ratings yet

- Checklist For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageChecklist For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- Checklist For Glass DoorDocument1 pageChecklist For Glass DoorGabriel GabeNo ratings yet

- 09 Request For Inspection and Approval - RFIADocument1 page09 Request For Inspection and Approval - RFIAMahmoud Idris100% (1)

- Forms For InspectorsDocument5 pagesForms For Inspectorspavan yadavNo ratings yet

- N5012-CS-PCP-0012-02 - StandpipesDocument17 pagesN5012-CS-PCP-0012-02 - Standpipesdiego ahumadaNo ratings yet

- QAR-QD405-1179 Liquid Penetrant Testing Report-Oil Pan EH4500Document2 pagesQAR-QD405-1179 Liquid Penetrant Testing Report-Oil Pan EH4500Irwanto ManafNo ratings yet

- F I e L D I N S P e C T I o N R e P o R TDocument1 pageF I e L D I N S P e C T I o N R e P o R TMOST PASONNo ratings yet

- RFI FormDocument1 pageRFI FormSaravanan Palanisamy LakshmiNo ratings yet

- The Physical SelfDocument13 pagesThe Physical SelfReyalyn AntonioNo ratings yet

- Chapter IDocument1 pageChapter IVincent louise G. AgustinNo ratings yet

- Etapas de Los ProcesosDocument2 pagesEtapas de Los ProcesosHECTOR VIDALÓN JORGENo ratings yet

- MATH 1300 Limit Worksheet 1/23/15Document3 pagesMATH 1300 Limit Worksheet 1/23/15Kiesha AltheaNo ratings yet

- 4.3 StatDocument2 pages4.3 StatArt CarlNo ratings yet

- A More Beautiful Question: Take-AwaysDocument5 pagesA More Beautiful Question: Take-AwaysrlfemailNo ratings yet

- Engineering Vibration Communication and Information Processing 2019 PDFDocument756 pagesEngineering Vibration Communication and Information Processing 2019 PDFPaulo Venicio Alves VieiraNo ratings yet

- Westminster University DissertationDocument4 pagesWestminster University DissertationBestCustomPapersCanada100% (1)

- Detailed Lesson Plan Compound WordsDocument4 pagesDetailed Lesson Plan Compound WordsChelsea J. DionisioNo ratings yet

- Introduction To Master EquationsDocument23 pagesIntroduction To Master Equationskimia zargarzadehNo ratings yet

- Machine Learning Super Cheatsheet (Prof. Pedram Jahangiry)Document2 pagesMachine Learning Super Cheatsheet (Prof. Pedram Jahangiry)Adan Nicolas Vasquez SmithNo ratings yet

- Enabling A Sustainable Future Through Digitalisation: Powering Clients To A Future Shaped by GrowthDocument54 pagesEnabling A Sustainable Future Through Digitalisation: Powering Clients To A Future Shaped by Growthxopor35982No ratings yet

- Essence of Indian Traditional Knowledge-SyllabuDocument2 pagesEssence of Indian Traditional Knowledge-Syllabusiva kishoreNo ratings yet

- JWI586 UsermanualwebDocument16 pagesJWI586 UsermanualwebengineerNo ratings yet

- Signals and Systems Unit-1: Classification of Signals and SystemsDocument29 pagesSignals and Systems Unit-1: Classification of Signals and SystemsrenukaNo ratings yet

- Anh 9-N2 2021Document12 pagesAnh 9-N2 2021Quỳnh AnhNo ratings yet

- Native Chicken ThesisDocument6 pagesNative Chicken Thesismichelledavisvirginiabeach100% (2)

- TMS1589Document49 pagesTMS1589Gioj MejNo ratings yet

- Operating Procedure ERLDCDocument154 pagesOperating Procedure ERLDCbramhanand vermaNo ratings yet

- 2023 Practice Paper 2 Higher (Calculator)Document20 pages2023 Practice Paper 2 Higher (Calculator)Ege IscanNo ratings yet