Professional Documents

Culture Documents

MT Form Asme PDF

Uploaded by

Trung Tinh HoOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

MT Form Asme PDF

Uploaded by

Trung Tinh HoCopyright:

Available Formats

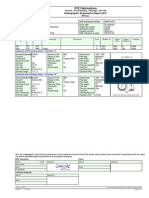

Report No.

MAGNETIC PARTICLE Page:

EXAMINATION REPORT Request No.:

Project: Procedure No.: Job No.:

Client Name: Acceptance Standard: Place of examination:

Item /Object: Drawing No: Temperature of the object:

Welding Process: Extent of examination: Date of examination:

Prepared Edge After PWHT Type of Joint:

State of Examination As weld Repair Material:

Base Metal Other Number of repair:

Brushing As weld Type of Current: AC DC

Surface condition

Grinding Other Light Condition: Day light Supplemental light

Dry Visible Testing Technique: Continuous Residual

Medium

Wet Fluorenscent Lifting power: 10LBs 40LBs

Magnetization Equipment Permanent Yoke Yoke Prod

Equipment Type: Model: Serial No.: Pole distance:

Applying Method: Light Meter Serial No.: 70804551 Light Intensity:

Magnetic Particle (Brand): Lot No.: Manufactured Date: Expiry Date:

Contrast paint (Brand) : Lot No.: Manufactured Date: Expiry Date:

Post-Examination: Demagnetizing Surface cleaning

EVALUATION

Weld Size Imperfection Result

No. Weld Identification Thickness Welder No. Length Location

Test length (mm) Type ACC REJ

(mm) (mm) (mm)

ACC: Accepted REJ: Rejected SI: Slag Inclusion PWHT: Post Weld Heat Treatment

Abbreviation: C: Crack U:Under Cut CP: Cluster Porosity N/A: Not Applicable

LF: Lack of Fusion CR:Crater Crack P: Porosity

ALPHA NDT Review by QC Inspector Review by Clients Review by A.I

Evaluated by: Name: Name: Name:

Qualified:

Signature: Signature: Signature: Signature:

Date: Date: Date: Date:

You might also like

- MT ReportDocument1 pageMT ReportBauyrzhanNo ratings yet

- Paut Inspection Report: Client Rfi NoDocument6 pagesPaut Inspection Report: Client Rfi NoThiru Maran MasterscanNo ratings yet

- Ultrasonic Test Report SummaryDocument6 pagesUltrasonic Test Report SummaryGibson FisherNo ratings yet

- Aws A5 5 PDFDocument55 pagesAws A5 5 PDFNO ONE100% (1)

- Aws B5.1-2003 PDFDocument21 pagesAws B5.1-2003 PDFMonica Yohanna Vera0% (1)

- Long Seam Weld EstimationDocument5 pagesLong Seam Weld EstimationalokbdasNo ratings yet

- Ultrasonic Test Report: Before AfterDocument7 pagesUltrasonic Test Report: Before AfterMenad SalahNo ratings yet

- Magnetic Particle Examination: DateDocument2 pagesMagnetic Particle Examination: DateAbhishek SharmaNo ratings yet

- OD CrackDocument1 pageOD CrackTrung Tinh HoNo ratings yet

- OD CrackDocument1 pageOD CrackTrung Tinh HoNo ratings yet

- OD CrackDocument1 pageOD CrackTrung Tinh HoNo ratings yet

- OD CrackDocument1 pageOD CrackTrung Tinh HoNo ratings yet

- NDT Technqiue Selection For TubesDocument14 pagesNDT Technqiue Selection For TubesTrung Tinh HoNo ratings yet

- NDT Technqiue Selection For TubesDocument14 pagesNDT Technqiue Selection For TubesTrung Tinh HoNo ratings yet

- Juta Bumi Kapital Sdn. BHD: Doc. No. Revision NoDocument2 pagesJuta Bumi Kapital Sdn. BHD: Doc. No. Revision NoSong Kiet ChooNo ratings yet

- Awsd1 1D1 1M-2010Document569 pagesAwsd1 1D1 1M-2010Trung Tinh HoNo ratings yet

- MEENA Internation NDT TrainingDocument45 pagesMEENA Internation NDT Trainingahmzahid100% (1)

- Magnetic Particle Inspection Report DetailsDocument1 pageMagnetic Particle Inspection Report DetailsJindarat Kasemsooksakul100% (1)

- Tr-Cme-Hct-0566bfinal-2022 Drill Tech 9 5-8in Eq. 11542633Document4 pagesTr-Cme-Hct-0566bfinal-2022 Drill Tech 9 5-8in Eq. 11542633Tec ReynosaNo ratings yet

- Calibration of The YokeDocument2 pagesCalibration of The YokeHussain Shariff100% (1)

- Report - Form - MT - PT - RT - Ut - Cal - 2015Document9 pagesReport - Form - MT - PT - RT - Ut - Cal - 2015YuwantoniAlNo ratings yet

- RT Procedure 10.09.16Document9 pagesRT Procedure 10.09.16mukeshsingh6No ratings yet

- Magnetic Particle Examination of WeldsDocument4 pagesMagnetic Particle Examination of WeldsshruthiNo ratings yet

- NDT For WeldersDocument66 pagesNDT For WelderssameeraNo ratings yet

- ECT Detection On Espansion RollDocument1 pageECT Detection On Espansion RollTrung Tinh HoNo ratings yet

- ECT Detection On Espansion RollDocument1 pageECT Detection On Espansion RollTrung Tinh HoNo ratings yet

- Mic in U-BendsDocument1 pageMic in U-BendsTrung Tinh HoNo ratings yet

- Mic in U-BendsDocument1 pageMic in U-BendsTrung Tinh HoNo ratings yet

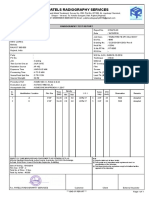

- Radiographic Examination ReportDocument1 pageRadiographic Examination ReportKareem AbdelazizNo ratings yet

- Report NDT r1Document23 pagesReport NDT r1Trinh Thai100% (1)

- NDTDocument38 pagesNDTNishant B MayekarNo ratings yet

- WPS PQR PDFDocument23 pagesWPS PQR PDFtomj9104No ratings yet

- PT NDT ProcedureDocument5 pagesPT NDT ProcedureMohamed AbubackerNo ratings yet

- VISUAL TESTING PROCEDURE FOR WELDDocument4 pagesVISUAL TESTING PROCEDURE FOR WELDCoralSun CravensickNo ratings yet

- Nde ProceduresDocument66 pagesNde Proceduressoumaya yahyaouiNo ratings yet

- QCF302 Radiographic Testing ReportDocument1 pageQCF302 Radiographic Testing ReportminhnnNo ratings yet

- Typical Tube Defects: NDE Associates, IncDocument1 pageTypical Tube Defects: NDE Associates, IncTrung Tinh HoNo ratings yet

- NDT Steel CastingsDocument17 pagesNDT Steel CastingsWoodrow FoxNo ratings yet

- Euro NDT PresentationDocument9 pagesEuro NDT PresentationBetoCordeiroNo ratings yet

- 75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Document1 page75914199-2 - Fu-10-Pad - Eyes-Mpi, 20-May-2024Mohamed El-SawahNo ratings yet

- NDT Application FormDocument4 pagesNDT Application FormAhmed Shaban KotbNo ratings yet

- Field Joint CoatingDocument7 pagesField Joint CoatingTeodor EzaruNo ratings yet

- Ndtspec Radiographic Nde ReportDocument1 pageNdtspec Radiographic Nde ReportcarlosNo ratings yet

- Welding Variable Calculator AS1554.1Document2 pagesWelding Variable Calculator AS1554.1Alin TomozeiNo ratings yet

- LPT Written ProcedureDocument8 pagesLPT Written ProcedureManikantaSumanthNo ratings yet

- Typical Tubes DefectDocument1 pageTypical Tubes DefectTrung Tinh HoNo ratings yet

- Austenitic Weld Inspection Solution OverviewDocument17 pagesAustenitic Weld Inspection Solution OverviewRupam BaruahNo ratings yet

- Taekyung Lee, Chong Soo Lee: Fatigue & Plasticity Lab., Dept. of Materials Science and Engineering, POSTECHDocument12 pagesTaekyung Lee, Chong Soo Lee: Fatigue & Plasticity Lab., Dept. of Materials Science and Engineering, POSTECHTrung Tinh Ho100% (1)

- P 11 CNDT JP41 Ut-Aws D1.1 Rev 07Document22 pagesP 11 CNDT JP41 Ut-Aws D1.1 Rev 07Vimal MenonNo ratings yet

- Digital Radiography ReportDocument7 pagesDigital Radiography ReportadityaromasNo ratings yet

- BK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsDocument69 pagesBK91 1310 CPF VED 003 QAC H03 0001 - A NDE Procedure For Centrifugal PumpsPanneer SelvamNo ratings yet

- D-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionDocument33 pagesD-p5-Bv-pd-006 - Tofd, Issue 01, Rev 00 - Time of Flight Diffraction InspectionThinh NguyenNo ratings yet

- I-2.52-E Ultrasonic ProcedureDocument35 pagesI-2.52-E Ultrasonic ProcedureMohanadNo ratings yet

- Pt. Astar Testing & InspectionDocument2 pagesPt. Astar Testing & InspectionSASINo ratings yet

- Magnetic Particle Testing ReporDocument2 pagesMagnetic Particle Testing ReporGabriela MotaNo ratings yet

- Tndt-frm-ndt-007 Magnetic Particle Inspection ReportDocument2 pagesTndt-frm-ndt-007 Magnetic Particle Inspection ReportKhalid Hidayatullah100% (1)

- 081computed Radiographic Examination ReportDocument1 page081computed Radiographic Examination ReportMarcus AntoniusNo ratings yet

- Hardness TestDocument117 pagesHardness TestMohdHuzairiRusliNo ratings yet

- Patels Radiography Services RT ReportDocument1 pagePatels Radiography Services RT ReportRavi patelNo ratings yet

- AsuuuuuuuuuuuuDocument22 pagesAsuuuuuuuuuuuuyusuf akbar100% (1)

- Coflexip Hose (Tr1-031851clm301)Document1 pageCoflexip Hose (Tr1-031851clm301)RonniNo ratings yet

- 2013-11-030M PT AHUDocument11 pages2013-11-030M PT AHUEdison WalitNo ratings yet

- PTDocument7 pagesPTMohdHuzairiRusliNo ratings yet

- UT Report FormDocument1 pageUT Report FormElisha NguyenNo ratings yet

- MPI Reports for ROMFOR Oilfield EquipmentDocument21 pagesMPI Reports for ROMFOR Oilfield EquipmentMehmet SoysalNo ratings yet

- Reviewed UT Procedure 10-12-2016Document18 pagesReviewed UT Procedure 10-12-2016Muhammad Maulana100% (1)

- Mr-85 en Sds AerosolDocument11 pagesMr-85 en Sds AerosolBala KrishnanNo ratings yet

- Examination Procedures For Ultrasonic Thickness MeasurementDocument13 pagesExamination Procedures For Ultrasonic Thickness MeasurementOsilonya HenryNo ratings yet

- EX - 12.7MM - PLATE 01 PAUT Report TrainingDocument4 pagesEX - 12.7MM - PLATE 01 PAUT Report Trainingagung akbarNo ratings yet

- Ultrasonic Report: Probe Details and Position (Fig 1)Document2 pagesUltrasonic Report: Probe Details and Position (Fig 1)BALA GANESH100% (1)

- RT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeDocument19 pagesRT-Procedure-Native File - For Easy Edit Urgent Doc Submission PurposeShanmuga NavaneethanNo ratings yet

- International Limited: Certificate of Visual Examination and MpiDocument2 pagesInternational Limited: Certificate of Visual Examination and MpiMichael OkwuwaNo ratings yet

- Proc SopDocument90 pagesProc SopJohn Dolan100% (1)

- Scan Plan (PAUT) For Taper Joints and K WeldsDocument4 pagesScan Plan (PAUT) For Taper Joints and K WeldsRamakrishnan AmbiSubbiahNo ratings yet

- ISO 9001 calibration block ultrasonic flaw detectorDocument2 pagesISO 9001 calibration block ultrasonic flaw detectorRamy HusseinNo ratings yet

- JSA Radiographic TestingDocument2 pagesJSA Radiographic TestingAbdul Hakam Mohamed YusofNo ratings yet

- ASNT Sec V A-8Document18 pagesASNT Sec V A-8Trung Tinh HoNo ratings yet

- Improving ECT Reliability: Why ECT Technicians make false callsDocument2 pagesImproving ECT Reliability: Why ECT Technicians make false callsTrung Tinh HoNo ratings yet

- ASNT Sec V A-8Document18 pagesASNT Sec V A-8Trung Tinh HoNo ratings yet

- Surface Crack Detection ECTDocument3 pagesSurface Crack Detection ECTTrung Tinh HoNo ratings yet

- Acceptance Levels For Internal Imperfections in Steel Plate, Strip and Wide Flats, Based On Ultrasonic TestingDocument14 pagesAcceptance Levels For Internal Imperfections in Steel Plate, Strip and Wide Flats, Based On Ultrasonic TestingTrung Tinh HoNo ratings yet

- Improving ECT Reliability: Why ECT Technicians make false callsDocument2 pagesImproving ECT Reliability: Why ECT Technicians make false callsTrung Tinh HoNo ratings yet

- ASNT Sec V A-8Document18 pagesASNT Sec V A-8Trung Tinh HoNo ratings yet

- ASNT Sec V A-8Document18 pagesASNT Sec V A-8Trung Tinh HoNo ratings yet

- Surface Crack Detection ECTDocument3 pagesSurface Crack Detection ECTTrung Tinh HoNo ratings yet

- SAW Flux StorageDocument2 pagesSAW Flux StorageTrung Tinh HoNo ratings yet

- DNV-OS-F101 2000 Submarine Pipeline System PDFDocument168 pagesDNV-OS-F101 2000 Submarine Pipeline System PDFMichael MooreNo ratings yet

- DNV-OS-F101 2000 Submarine Pipeline System PDFDocument168 pagesDNV-OS-F101 2000 Submarine Pipeline System PDFMichael MooreNo ratings yet

- Concepts of Phased Array UltrasonicDocument13 pagesConcepts of Phased Array UltrasonicgunamtechNo ratings yet

- Key Concepts 2 Heat InputDocument4 pagesKey Concepts 2 Heat InputBama RamachandranNo ratings yet

- Tabla de Tipos de CementosDocument1 pageTabla de Tipos de CementosHumberto MorenoNo ratings yet

- Press Tool Questions PaperDocument15 pagesPress Tool Questions PaperSaurabh Kumar 53No ratings yet

- Classification of The Metal Cutting ProcessDocument3 pagesClassification of The Metal Cutting ProcessfatmafarahNo ratings yet

- Byk L-Ag 1 2 2 enDocument6 pagesByk L-Ag 1 2 2 enfatemeh.ahmadkhaniNo ratings yet

- Trellex Traclag Pulley LaggingDocument16 pagesTrellex Traclag Pulley LaggingViet Nam M-TechNo ratings yet

- Pitting Repairs For High-Temperature/ High-Pressure Process VesselsDocument8 pagesPitting Repairs For High-Temperature/ High-Pressure Process VesselsRaghavanNo ratings yet

- CTI NCO Prepo Rubber GranulesDocument7 pagesCTI NCO Prepo Rubber GranulesPamela VillanuevaNo ratings yet

- Mechanical Property - Carbon Steels - Summit SteelDocument5 pagesMechanical Property - Carbon Steels - Summit SteelPrasadNo ratings yet

- Cbn-Katalog Web EnglDocument60 pagesCbn-Katalog Web Engljavier_mor69No ratings yet

- PressWorking SDocument49 pagesPressWorking SRafiqueNo ratings yet

- Sheet Metalworking Lab SheetDocument3 pagesSheet Metalworking Lab SheetZain Aiman100% (1)

- Limitations of Machining Hard Materials On Conventional Milling MachinesDocument6 pagesLimitations of Machining Hard Materials On Conventional Milling MachinesKishanSavaliyaNo ratings yet

- Metal Casting and Welding 15Me35ADocument38 pagesMetal Casting and Welding 15Me35A01061975No ratings yet

- 1.2344 X40Crmov5-1: Chemical CompositionDocument2 pages1.2344 X40Crmov5-1: Chemical CompositionolcayakbulutNo ratings yet

- 1898326827Document551 pages1898326827B_Vieira100% (1)

- En 1 4057 - 1408 Valbruna Nordic EnglishDocument2 pagesEn 1 4057 - 1408 Valbruna Nordic EnglishDorut_b67No ratings yet

- C4C - 1.0303 - SteelNumber - Chemical Composition, Equivalent, PropertiesDocument1 pageC4C - 1.0303 - SteelNumber - Chemical Composition, Equivalent, PropertiesSergiNo ratings yet

- Workshop PolytechnicDocument5 pagesWorkshop PolytechnicAneesh Kumar0% (1)

- Metal FormingDocument7 pagesMetal FormingAl Fredo100% (3)

- Oxy Fuel Cut Chart Victor 1Document2 pagesOxy Fuel Cut Chart Victor 1Sk KrNo ratings yet

- Metal Casting Principles and Techniques: December 2013Document7 pagesMetal Casting Principles and Techniques: December 2013saravanan vNo ratings yet

- Module 1 - Welding TechnologiesDocument39 pagesModule 1 - Welding Technologieschemical labNo ratings yet

- Hollow Aluminium BilletDocument6 pagesHollow Aluminium BilletHasan Halil0% (1)

- Form QB-482 Suggested Format for a Brazing Procedure SpecificationDocument1 pageForm QB-482 Suggested Format for a Brazing Procedure SpecificationChowKC03No ratings yet

- Dr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, ChennaiDocument12 pagesDr. Kishor Kumar Gajrani: IIIT DM Kancheepuram, Chennaim sriNo ratings yet

- Astm A 384 A384mDocument3 pagesAstm A 384 A384medwinbadajosNo ratings yet

- Numeracy Test Forms 2023 2024Document6 pagesNumeracy Test Forms 2023 2024Michael Macaraeg100% (1)

- Ryna Du PlooyDocument8 pagesRyna Du PlooyRosel.RamosNo ratings yet