Professional Documents

Culture Documents

Accutherm FMG FMT LX Turbine Meter 014091110509

Uploaded by

Victor OlguinOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Accutherm FMG FMT LX Turbine Meter 014091110509

Uploaded by

Victor OlguinCopyright:

Available Formats

TURBINE METER SERIES

FMT-Lx

The best way to predict the future is to create it

Introduction Measuring range

The FMT-Lx series turbine meters is a robust meter, designed to perform on the highest level of accuracy. The The measuring range of the FMT-Lx turbine meter determined under atmospheric conditions meets with, and

meters comply with all international standards and are approved for custody transfer. The actual flow sensor, an generally exceeds, the international standards. At higher operating pressures the measuring range of the turbine

exchangeable cartridge, has a build-in multi stage flow conditioner enabling the meter to be installed without any meters will increase since the required kinetic energy transfer to the turbine rotor occurs at lower velocities. The

straight in- and outlet sections. All tested and proved according perturbation test as per international standards. measuring range equation may be used to estimate the minimum flow rate of the meter for various operating

conditions.

The cartridge can be pre-calibrated, under both low and high pressure conditions, then exchanged on-site. The

cartridge is supported in O-rings and isolated from the body, hence unaffected by any influences of the housing.

Pressure Loss

The short length cartridge enables the use of larger sized cartridges than the size of the meter body. The approved

The average pressure loss (see tables pages 6-7) of the FMT-Lx turbine meter using atmospheric natural gas with

maximum capacities of these kind of meters are extremely high and similar to the capacities of ultrasonic meters.

a relative density of 0.6 is measured at one (1) diameter upstream to one (1) diameter downstream of the meter

on straight pipe of the same size as the meter. The pressure loss across the FMT-Lx turbine meter for various gases

To reduce transportation cost, optimize the corrosion protection and improve safety in handling, the FMT-Lx series

and other operating pressures may be approximated from the pressure loss equation:

of turbine meters up to 6’’ (DN150) are also available with low weight aluminum meter bodies.

Measuring range Pressure loss

Principle

The operation of the FMT series of turbine meter is based on the

measurement of the velocity of gas. The flowing gas is acceler- ∆P2 = Pressure drop at P and Qmax Qmax = Max. Flow rate in m3/h

ated and conditioned by the integrated multi stage flow condi- ∆P1 = Pressure drop at Qmax (See tables pages 6 and 7) Qmin = Min. Flow rate at atmospheri¬c pressure in m3/h

P = Operating pressure of the meter in bar absolute d = Relative density of the gas (air = 1)

tioner. The multi stage flow conditioner prepares the gas flow

Patm = Atmospheric pressure in bar absolute (1.01325 bara) ρ = Density of the gas at atmospheric pressure

profile by removing undesirable swirl and asymmetry before Q = Instantaneous flow in m3/h

the gas flows over the freely rotating turbine wheel.

The dynamic forces of the flowing gas cause the rotor to rotate. Main Features

The turbine wheel is mounted on the main shaft, with high-pre- • Flow range 5- 10.000 m3/h

cision, low-friction ball bearings.

• Diameters DN50 - DN500 (2” - 20”)

The turbine wheel has helical blades that have a known angle

• Pressure rates PN 10 - 100, ANSI 150 - 600

relative to the gas flow. The gas flow drives the turbine wheel

at an angular velocity, which is proportional with the gas ve- • MID approved

locity. Using a gearing mechanism, the rotating turbine wheel

• MID temperature range -25 to +70ºC

drives the mechanical counter.

• Length 3 x DN

Applications • Removable meter cartridge

The standard FMT-Lx turbine meter is suitable for custody transfer gas measurement of all non-corrosive gases such • No straight inlet/outlet sections required

as natural gas, propane, butane, air, nitrogen, hydrogen, etc. for low and high operating pressures. Special con- • Oil flushing and lubrication system

structions can be supplied for use under extreme condition like high temperatures or corrosive gases. The FMT-Lx

can be modified to perform as a master meter or transfer master meter. • Multipurpose exchangeable index

• Tamper proof IP67 sealed index

Accuracy

• Special meters on request

Each FMT-Lx turbine gas meter is tested with atmospheric air to traceable calibrated references. The error limits are

typical half of those allowed by MID, EN standards or OIML recommendations. For pressures of above 8 bar even

narrower limits are available. Optionally, meters can be calibrated with natural gas at pressures up to 100 bar, using Installation

test installations traceable to primary standards.

The FMT-Lx fulfills all the requirements of the Europe-

2

an and International directives. In particular those of

Typical metrological characteristics 1.5

the OIML, ISO and EN. With the special integrated flow

1

0.5

straightener the FMT-Lx eliminates the effect of severe

Accuracy 0,2 Qmax to Qmax: ± 1% or better 0 perturbations on gas measurement. Straight inlet and

0 10 20 30 40 50 60 70 80 90 100

Accuracy Qmin to 0,2 Q max: ± 2% or better -0.5

ouletpiping can be 0 X DN. This permits the design of

Repeatability: better than 0,1% -1

very compact installations without losing accuracy.

-1.5

Atmospheric air 16 barg nat. gas

-2

Minimum Installation Configurations

Index High Frequency Sensors

The basic index consists of an UV-resistant polycarbonate cover, glued (IP67) to an aluminum frame. The aluminum FMT-Lx Turbine meters can be equipped with several types of

frame will give strength to the index and as such sufficient protection against mechanical interference (Tamper- high frequency sensors.

ing). The index can be rotated over 350º for all directions. The index can be

equipped with multiple LF switches (Reed or Wiegand principle), “Normally HF main shaft: this high frequency sensor generates two in-

Closed” tamper contacts and encoder technology. The LF pulsers and its driv- dependent phase shifted signals and as such the flow direc-

ing magnet are shielded to overcome tampering with an externally applied tion can be monitored. The signal generated complies with

magnetic field. Magnetic fields up to 500 mT will not have an effect on the Namur.

pulse counting. The index or instrument drive can be equipped with several

options making the meter prepared for the future: HF turbine wheel: this HF sensor can be used to check the

condition of the turbine wheel (missing blades) by comparing

the pulses with the HF main shaft.

HF Main

Double reed plus normally closed contact: Adjustable with Shaft

All basic indexes are equipped with an double reed and a normally closed contact. DIN-3374 sets For both sensors, the electrical separation between the haz-

Reverse Flow Lock: In order to avoid tampering by reverse flow, the index or instru- HF Turbine Wheel ardous and non-hazardous areas is accomplished by an intrin-

ment drive can be equipped with a Reverse Flow Lock. sically safe isolation amplifier

Wiegand Pulsers:

The Index can be equipped with multiple Wiegand pulsers. The Wiegand pulsers do

have significant advantages over the traditionally used Reed contacts. Wiegand

Approved maximum capacities

sensors do not face “bouncing” problems and the actual live time is not limited as

much as the traditional Reed contacts. All metrological characteristics are embedded in the

cartridge, making the meter body a non- essential

Intelligent Index/Encoder:

part of the meter. Hence offering new opportunities

The index can be equipped with an intelligent encoder. The encoder sends out

as using smaller and larger cartridges in respect to the

the total volume with an interval of 400 msec. The encoder uses a standard

meter body size (DN). Thus allowing a large variety of

NAMUR serial data format, and can be modified to special applications on re-

capacities. The approved maximum capacities of these

quest. The encoder is powered by one AA cell battery guaranteed for 12 years

kind of meters is extremely high and similar to the ca-

of operation. On request two AA cells can be installed for a guaranteed life time

pacities of ultrasonic meters.

of 20 years. The encoder is equipped with a special Hall sensor to detect and

register interferences from external magnets. Several programmable inputs/

outputs are available for advanced – anti fraud – functions.

Technical Specification

Lubrication Metrological approvals: compliant with the MID 2004/22/EC

compliant with OIML R137

The FMT series of turbine meters can be equipped with several types of ATEX approvals: sensors compliant with Ex ia IIC T4... T6 Gb (-40ºC ≤ Ta +70ºC)

lubrication systems or with life time lubrication. FMG recommends to use encoder compliant with Ex ib IIB T3... T6 Gb (-25ºC ≤ Ta +55ºC)

the lubrication system. An integrated splash vane will distribute the oil

to all the moving parts and will flush the bearings. The FMT-Lx series Flow rates: 5 m3/h up to 10.000 m3/h

incorporates high quality precision bearings. For optimal life times guar- Nominal diameters: from DN50 to DN500 mm (2” to 20”).

antees it is recommended they should be lubricated and clean. Mounting position: horizontally or vertically

Recommendations as to when to lubricate turbine meters varies by Body compliant with the Pressure Equipment Directive 97/23/EC

product type, operating conditions, customer procedures, and regulatory Temperature Range: ATEX: -25°C to +70°C

requirements. Meter performance is optimized by flushing contamina- MID: -25°C to +70°C (lower temperatures on request)

tion from the bearings and refreshing or adding of oil during operation. PED: -20°C to +70°C (lower temperatures on request)

Heavy duty bearings Materials:

Since gas pressure causes the main force on the bearings the Straightening vane: aluminum Shafts: stainless steel

Low pressure

FMT-Lx series incorporates bearings dedicated to the working Turbine wheel: aluminum Gears: delrin

pressure. FMT-Lx turbine meters which have a low working Cartridge aluminum Index frame: aluminum

pressure are equipped with lighter bearings then the meters Bearing block: stainless steel/aluminum Index frame: polycarbonateECI

High pressure which are used at higher working pressures. This way the best Bearings: stainless steel

measuring ranges and life times can be guaranteed.

Performance Dimensions

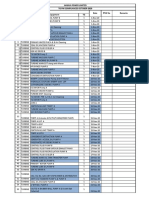

Size G-value Qmax Qmin ∆P1* LF HF Main HF Wheel Dimensions Weight (kg)

C E H L PN10/16 PN10/16 PN25/40 PN64/100

Atm. Air 4 bar NG 8 bar NG ANSI150 ANSI150 ANSI300 ANSI600

(mm) (-) (m3/h) (m3/h) (m3/h) (m3/h) (Pa) (imp/m3) (imp/m3) (imp/m3) (mm) (mm) (mm) (mm) ALU ST ST ST

50 G65 100 10 5 3 900 10 18440 64540 155 175 150 8 17 17 17

G100 160 8 5 3 900 1 22560 67675 155 175 150 8 17 17 17

G160 250 13 8 5 1600 1 8235 28815 155 175 150 8 17 17 17

G250 400 20 13 8 1600 1 5180 20705 155 175 150 8 17 17 17

80 G65 100 10 5 3 900 10 1845 64540 144 178 240 9 22 24 27

H

G100 160 8 5 3 900 1 22560 67675 144 178 240 9 22 24 27

G160 250 13 8 5 900 1 8235 28815 144 178 240 9 22 24 27

G250 400 20 13 8 1600 1 5180 20705 144 178 240 9 22 24 27

G400 650 32 20 13 1600 1 2340 9350 144 178 240 9 22 24 27

100 G65 100 10 5 3 900 10 18440 64540 156 190 300 15 34 41 48

DN

G100 160 8 5 3 900 1 22560 67675 156 190 300 15 34 41 48

G160 250 13 8 5 900 1 8025 24065 156 190 300 15 34 41 48

G250 400 20 13 8 900 1 3915 13700 156 190 300 15 34 41 48

G400 650 32 20 13 900 1 2340 9350 156 190 300 15 34 41 48

G650 1000 50 32 20 1600 1 2950 5165 156 190 300 15 34 41 48

G1000 1600 80 50 32 1600 0.1 1435 2865 156 190 300 15 41 - -

E C

150 G160 250 13 8 5 900 1 8025 24065 180 213 450 27 61 79 98

As per flange dimension

G250 400 20 13 8 900 1 3915 13700 180 213 450 27 61 79 98

G400 650 32 20 13 900 1 4475 6715 180 213 450 27 61 79 98

G650 1000 50 32 20 900 1 2950 5165 180 213 450 27 61 79 98

G1000 1600 80 50 32 1600 0.1 1435 2865 180 213 450 27 61 79 98

G1600 2500 125 80 50 1600 0.1 885 1770 180 213 450 - 73 - -

200 G400 650 32 20 13 900 1 4475 6715 185 243 600 - 75 99 133

G650 1000 50 32 20 900 1 2950 5165 185 243 600 - 75 99 133

G1000 1600 80 50 32 900 0.1 1435 2865 185 243 600 - 75 99 133

G1600 2500 125 80 50 900 0.1 885 1770 185 243 600 - 75 99 133

G2500 4000 125 80 900 0.1 440 1310 185 243 600 - 90 - -

250 G650 1000 50 32 20 900 1 2950 5165 236 282 750 - 200 236 315

G1000 1600 50 32 900 0.1 775 2320 236 282 750 - 200 236 315

G1600 2500 80 50 900 0.1 440 1310 236 282 750 - 200 236 315

G2500 4000 130 80 900 0.1 440 1310 236 282 750 - 200 236 315

G4000 6500 200 130 1600 0.1 245 740 236 282 750 - 240 - -

300 G1000 1600 50 32 900 0.1 775 2320 236 283 900 - 240 285 365

G1600 2500 80 50 900 0.1 440 1320 236 283 900 - 240 285 365

G2500 4000 130 80 900 0.1 245 740 236 283 900 - 240 285 365

L

G4000 6500 200 130 900 0.1 245 740 236 283 900 - 240 285 365

G6500 10000 320 200 1600 0.1 125 370 236 283 900 - 290 - -

400 G1600 2500 80 50 900 0.1 440 1320 295 328 1200 - 290 350 460

G2500 4000 130 80 900 0.1 220 655 295 328 1200 - 290 350 460

G4000 6500 200 130 900 0.1 125 370 295 328 1200 - 290 350 460

G6500 10000 320 200 1600 0.1 125 370 295 328 1200 - 290 - -

*. ∆P1 is measured under atmospheric conditions with natural gas with relative density of 0.6 (air = 1) Values may vary 5% due to machining tolerances

About us

FLOW METER GROUP B.V. (FMG)

FMG is an engineering/manufacturing company specializing in the de-

velopment and production of energy and gas measurement systems.

Located in the Netherlands, FMG produces a wide range of rotary and

turbine gas meters, volume conversion devices, master meters

and calibration benches. Unique product features include self diagnosis Positive Displacement

and tamper prevention. All products and services are certified by the Meters

Dutch NMi and comply with the latest EU and/or OIML directives.

Flow Meters

FMG offers a large variety of flow meters ranging from very small (100

dm3/h) up to very large (10.000 m3/h) flow rates and in pressures

from atmospheric to 100 bar (1440 psi). All FMG meters comply with

international safety and metrological standards. Meters designated for

fiscal use are tested, certified and approved by the Netherlands Metro-

logical Institute NMi.

FMG has added extra features to the meters in terms of increased accu-

racy, protection from manipulation, increased rangeability and superior

performance in order to go beyond the minimum requirements of the

existing standards.

Master Meters

Custody Transfer

Short Length Turbine Meters Flow Computers Test Benches

Contact

Flow Meter Group B.V.

Meniststraat 5c

7091 ZZ Dinxperlo

The Netherlands

Tel: +31 (0)315 651 556

Fax: +31 (0)315 651 448

E-mail: info@flowmetergroup.com

Copyright © Flow Meter Group - 2014 - All Rights Reserved.

Commercial use and distribution of the contents is not allowed without express and prior written consent of the author.

You might also like

- Turbine Meter Series FMT-LX: The Best Way To Predict The FutureDocument5 pagesTurbine Meter Series FMT-LX: The Best Way To Predict The Futurepaulino1k50No ratings yet

- 90 010 0000001rev005Document5 pages90 010 0000001rev005Cleverson BorghezanNo ratings yet

- TRZ / TRZ - Ifs: Turbine Gas Meters For Custody TransferDocument4 pagesTRZ / TRZ - Ifs: Turbine Gas Meters For Custody TransferTomislav PanovNo ratings yet

- Catalogo de Medidor FMG, Rotary Meter Series FMR PDFDocument9 pagesCatalogo de Medidor FMG, Rotary Meter Series FMR PDFMARLON MARIO MELGAREJO ACOSTANo ratings yet

- Elster SM Ri X L g250Document12 pagesElster SM Ri X L g250JM Carrasco HottmanNo ratings yet

- FMR Series Datasheet 2019Document6 pagesFMR Series Datasheet 2019Ahmed Hassan Abd ElhafezNo ratings yet

- Hoja de DatosDocument9 pagesHoja de DatosJhon AlfonsoNo ratings yet

- Aerzen Positive Displacement Blowers for Oil-Free Conveying and CompressionDocument20 pagesAerzen Positive Displacement Blowers for Oil-Free Conveying and CompressionShariq KhanNo ratings yet

- Blower General G1 001 12 EN PDFDocument20 pagesBlower General G1 001 12 EN PDFAbner MarquezNo ratings yet

- Aerzen Positive Displacement Blowers for Oil-Free Conveying and CompressionDocument20 pagesAerzen Positive Displacement Blowers for Oil-Free Conveying and Compressionherrerafarid100% (1)

- Instromet q75 Pressure Diferential PressureDocument12 pagesInstromet q75 Pressure Diferential PressureExcel Fransisco rariNo ratings yet

- CFD Analysis of Axial Spacing Effects on Single Stage Transonic Axial CompressorDocument9 pagesCFD Analysis of Axial Spacing Effects on Single Stage Transonic Axial Compressorinam vfNo ratings yet

- IGTM-CT Gas Turbine Meter: Documentation and Technical SpecificationsDocument12 pagesIGTM-CT Gas Turbine Meter: Documentation and Technical Specificationsajitp123No ratings yet

- Fluxi 2000/TZ: C&I Gas MetersDocument4 pagesFluxi 2000/TZ: C&I Gas MetersjoseNo ratings yet

- MA Staugitter DLT8005 15 AEN 001Document4 pagesMA Staugitter DLT8005 15 AEN 001sumit_waghmareNo ratings yet

- Fluxi 2000 TZ EN-03 - 18Document4 pagesFluxi 2000 TZ EN-03 - 18Praveen KumarNo ratings yet

- Regulating Pumps for Open Loop SystemsDocument24 pagesRegulating Pumps for Open Loop SystemsxxshNo ratings yet

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Eslam MouhamedNo ratings yet

- Handbook: Please Note Newer Operating Instructions!Document27 pagesHandbook: Please Note Newer Operating Instructions!Ibrahim Fadhl KalajengkingNo ratings yet

- Measurement Brochures Cam Ms Turbines Gas-Turbine BRDocument9 pagesMeasurement Brochures Cam Ms Turbines Gas-Turbine BRJhon AnguloNo ratings yet

- Gas Turbine MetersDocument3 pagesGas Turbine Meterssubhadip33coolNo ratings yet

- Vemmtec Igtm-Ct Brochure en 2015Document12 pagesVemmtec Igtm-Ct Brochure en 2015Syach FirmNo ratings yet

- Fundamental Principles of Gas Turbine MetersDocument6 pagesFundamental Principles of Gas Turbine Meterssurya325kiranNo ratings yet

- Optical VibrationDocument6 pagesOptical VibrationKarthick VelayuthamNo ratings yet

- Handbook: Turbine Gas MeterDocument27 pagesHandbook: Turbine Gas MeterBhagyesh BrahmbhattNo ratings yet

- Efficient Operation of Compressed Air SystemsDocument10 pagesEfficient Operation of Compressed Air SystemsdeepikaNo ratings yet

- Sullair TS Series BrochureDocument12 pagesSullair TS Series BrochureKrist San QNo ratings yet

- Gas Metering PT-4Document30 pagesGas Metering PT-4brianNo ratings yet

- Vemmtec-IGTM-Turbine MeterDocument12 pagesVemmtec-IGTM-Turbine MeterErwan Omar Mukhtar100% (1)

- Fundamentals Gas Turbine MetersDocument3 pagesFundamentals Gas Turbine Metersmyself_riteshNo ratings yet

- Aerzen Blowers General Catalogue (ATTACHMENT2)Document20 pagesAerzen Blowers General Catalogue (ATTACHMENT2)Hossein Jalali MoghaddamNo ratings yet

- Rotary Piston Gas Meter: National Accreditation of Certification BodiesDocument8 pagesRotary Piston Gas Meter: National Accreditation of Certification BodiesLuis CasasNo ratings yet

- Turbine Meter Series FMT-LX: The Best Way To Predict The FutureDocument5 pagesTurbine Meter Series FMT-LX: The Best Way To Predict The FuturepedroNo ratings yet

- 2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-MetersDocument7 pages2014 10 09 19 08 Nuflo-Liquid-Turbine-Flow-Metersichi ezzahraNo ratings yet

- Numerical and Experimental Investigation of A Centrifugal Compressor With An Inducer Casing Bleed SystemDocument9 pagesNumerical and Experimental Investigation of A Centrifugal Compressor With An Inducer Casing Bleed SystemDhanasekar KNo ratings yet

- 30 Pneumatic Conveyors: Rs 110 Pneumatic Screw Pumps (FK Pumps)Document3 pages30 Pneumatic Conveyors: Rs 110 Pneumatic Screw Pumps (FK Pumps)Dilnesa EjiguNo ratings yet

- U2ETTM 3WindTunnelsDocument45 pagesU2ETTM 3WindTunnelsmohammedsameera.me25No ratings yet

- Axial Flow CompressorsDocument9 pagesAxial Flow CompressorsAGonzalezNo ratings yet

- L3-PPD - Turbine Selection - Unit 1Document25 pagesL3-PPD - Turbine Selection - Unit 1Amrit PandeyNo ratings yet

- Transonic Axial Compressor Active Boundary Layer Control Concept and Its EvaluationDocument8 pagesTransonic Axial Compressor Active Boundary Layer Control Concept and Its Evaluationinam vfNo ratings yet

- Turbocompressor Antisurge Control, New Solution For An Old ProblemDocument7 pagesTurbocompressor Antisurge Control, New Solution For An Old ProblemAmbardi WicaksonoNo ratings yet

- C-Series Claw: Technologies For All Vacuum and Pressure ApplicationsDocument6 pagesC-Series Claw: Technologies For All Vacuum and Pressure ApplicationsKrzysztof WrzeszczNo ratings yet

- A To Z of Steam Turbine Maintenance PDFDocument157 pagesA To Z of Steam Turbine Maintenance PDFivaturi100% (1)

- Scavenging & TurbochargingDocument25 pagesScavenging & TurbochargingSayem kaifNo ratings yet

- Axial CompresserDocument48 pagesAxial Compresservishnu kadiyalaNo ratings yet

- Rocket Engine Sim PDFDocument8 pagesRocket Engine Sim PDFVidushee GeetamNo ratings yet

- PARTES - TurbineMeterManual212FDocument16 pagesPARTES - TurbineMeterManual212FronaldNo ratings yet

- Ficha Tecnica Bellofram.1Document4 pagesFicha Tecnica Bellofram.1Ever Edinson Monsalve SalcedoNo ratings yet

- Turbulent Mixing with 20° Chute MixerDocument14 pagesTurbulent Mixing with 20° Chute MixerTurk SoloNo ratings yet

- Regulating Pumps For Open LoopDocument24 pagesRegulating Pumps For Open LoopxxshNo ratings yet

- Industrial compressor signal analysis for robust control under pulsationDocument6 pagesIndustrial compressor signal analysis for robust control under pulsationYurlevinson Espinosa CardenasNo ratings yet

- Presentation Centrifugal 02.ppsxDocument97 pagesPresentation Centrifugal 02.ppsxEslam Elmadboly100% (1)

- 2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01Document2 pages2-Way Flow Regulator, Pressure Compensated, Restrictive Style SAE-8 Cartridge - 350 Bar SR08-01controlorNo ratings yet

- Performance of A High-Efficiency Radial/Axial Turbine: Iioiraino Soeiuilj UbiDocument4 pagesPerformance of A High-Efficiency Radial/Axial Turbine: Iioiraino Soeiuilj UbiAnutthara RatnayakeNo ratings yet

- Turbine Flow MeterDocument3 pagesTurbine Flow MeterJatin RamboNo ratings yet

- Objectives:: LAB SESSION 1: Turbomachinery Elements (MR1)Document25 pagesObjectives:: LAB SESSION 1: Turbomachinery Elements (MR1)Arantxa Pons EstruchNo ratings yet

- Pumps PDFDocument31 pagesPumps PDFYURI G. MELLIZANo ratings yet

- Study of a reluctance magnetic gearbox for energy storage system applicationFrom EverandStudy of a reluctance magnetic gearbox for energy storage system applicationRating: 1 out of 5 stars1/5 (1)

- Question Bank - AEDDocument3 pagesQuestion Bank - AEDbhuvan raju t kNo ratings yet

- Chavez, Valencia, Jaramillo, Coronado, Rodriguez - Failure Analysis of A Pelton ImpellerDocument11 pagesChavez, Valencia, Jaramillo, Coronado, Rodriguez - Failure Analysis of A Pelton ImpellerHidan WLNo ratings yet

- Double Ducted Fan 0903 Detailed DescriptionDocument70 pagesDouble Ducted Fan 0903 Detailed DescriptionEnache DanielNo ratings yet

- Jhabua Power Limited TG PM Compliances October-2020 S.No Doc No. JPL/MTP/PM/07/17 Date PTW No Remarks Area Equipment TGDocument2 pagesJhabua Power Limited TG PM Compliances October-2020 S.No Doc No. JPL/MTP/PM/07/17 Date PTW No Remarks Area Equipment TGbhaskarNo ratings yet

- The Modeling and Stress Analysis of Wind Turbine Blade: TELKOMNIKA Indonesian Journal of Electrical EngineeringDocument6 pagesThe Modeling and Stress Analysis of Wind Turbine Blade: TELKOMNIKA Indonesian Journal of Electrical EngineeringAKHIL RAJNo ratings yet

- EWEA 2011 Poster Paper - Yaw Control: The Forgotten Controls ProblemDocument10 pagesEWEA 2011 Poster Paper - Yaw Control: The Forgotten Controls ProblemcatchthewindincNo ratings yet

- Turbo Machinery: Donga Ramesh KumarDocument19 pagesTurbo Machinery: Donga Ramesh KumarxyzNo ratings yet

- Ge Frame 9e Comp & Turbine DesignDocument26 pagesGe Frame 9e Comp & Turbine DesignMuhammad Naveed Akhtar100% (3)

- Airdolphin SeriesDocument8 pagesAirdolphin SeriesmarkNo ratings yet

- Application Note - Shinkawa - VIbration Monitoring System in Thermal Power PlantsDocument16 pagesApplication Note - Shinkawa - VIbration Monitoring System in Thermal Power PlantsbabuaravindNo ratings yet

- MaltaDocument4 pagesMaltaRobert Ionut DinuNo ratings yet

- Study of Solar and Wind Energy Using As Water Pump Drive-Land For Agricultural IrrigationDocument4 pagesStudy of Solar and Wind Energy Using As Water Pump Drive-Land For Agricultural IrrigationdeepthiNo ratings yet

- MICROMAT single-shaft shredder efficiently granulates plasticsDocument2 pagesMICROMAT single-shaft shredder efficiently granulates plasticskarnakesNo ratings yet

- Rotating 1Document22 pagesRotating 1rafieeNo ratings yet

- Air Compressors: Elements of Mechincal Engineering ElectricalDocument24 pagesAir Compressors: Elements of Mechincal Engineering ElectricalHarsun ParanthamanNo ratings yet

- Steam Turbine CompoundingDocument13 pagesSteam Turbine CompoundingDivya Prakash Srivastava100% (3)

- Ips G PM 120Document22 pagesIps G PM 120masoudNo ratings yet

- Conjugate Heat Transfer PDFDocument10 pagesConjugate Heat Transfer PDFbenabedmNo ratings yet

- 135MW CFBC OperationDocument148 pages135MW CFBC OperationDebabrata Ghosh100% (1)

- BTech - 5th - 6th - Sem MEDocument9 pagesBTech - 5th - 6th - Sem MEN KumarNo ratings yet

- Ingersoll Rand Engine Starting Systems Catalog by Zampini Industrial GroupDocument64 pagesIngersoll Rand Engine Starting Systems Catalog by Zampini Industrial GroupZampini Industrial100% (1)

- Erik Dick-Book Turbomachines PDFDocument16 pagesErik Dick-Book Turbomachines PDFmailsk12367% (3)

- UNIT II Reaction Turbine FDPDocument54 pagesUNIT II Reaction Turbine FDPEyob AdNo ratings yet

- Axial Flow Turbines - Dr.K.M.ParammasivamDocument22 pagesAxial Flow Turbines - Dr.K.M.Parammasivammaran2326No ratings yet

- 014 PDFDocument12 pages014 PDFGrootNo ratings yet

- Indian Railway FinalDocument103 pagesIndian Railway FinalViswanathan Balasubramaniam83% (6)

- Generador Eolico Black 600Document19 pagesGenerador Eolico Black 600HENRYNo ratings yet

- 5tgfhdf1 1Document9 pages5tgfhdf1 1SmileNo ratings yet

- Roto Jet OverviewDocument2 pagesRoto Jet Overviewgeverett2765No ratings yet

- Renewable Energy: Wenyi LiuDocument11 pagesRenewable Energy: Wenyi LiuSADULLAHNo ratings yet