Professional Documents

Culture Documents

HE - Set 3

Uploaded by

Synthia Rashid0 ratings0% found this document useful (0 votes)

13 views3 pagesOriginal Title

HE_set 3

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

13 views3 pagesHE - Set 3

Uploaded by

Synthia RashidCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

HE_Set_3

Date: 7/26/2021

St.ID: 1602026 Name: K.M. Nazmus Sakib

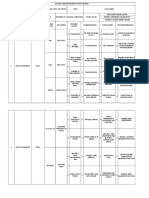

Study node: Steam supply line

Parameter Guide word Deviation Possible causes Possible consequences Existing safeguards Required actions/

recommendations

Flow High High flow 1. Steam source failure 1. Higher water None 1. Prepare and maintain pre-

resulting in evaporation, startup checklist to make sure

uncontrolled steam resulting in steam source is functioning well.

flow deterioration of 2. Use a fail-close control valve in

2. No control valve sugar quality supply line and a PSV in the

3. Operator error 2. Pressure buildup evaporator

in the evaporator 3. Use a high flow alarm,

resulting in emergency shutdown

possible

rupture/accident

3. Same as 1 &2

Low/No flow 1. Steam source failure 1. lower evaporation of Control valve 1.Prepare and maintain pre-

Low/No 2. Plugging in supply line water resulting in low startup checklist to make sure

3. Leakage in supply line product quality steam source is functioning well

4. Leakage in heat exchanger 2. Same as 1 2. Periodic maintenance and

tube 3. Same as 1 checking

4. Contamination and 3 periodic maintenance, install

deterioration of product no flow alarm

4. Same as 2 & 3

Study Node: Steam supply line

Parameter Guide word Deviation Possible causes Possible consequences Existing safeguards Required action/

Recommendations

Temperature High High temperature 1. surrounding atmosphere 1. Higher water None 1. Install high temperature

is too hot evaporation, resulting in alarm, maintaining pre-startup

2. Steam source failure, deterioration of sugar checklist

operator error quality, 2. Use a fail-close control valve in

2. rupture/accident due to supply line and a PSV in the

pressure build up evaporator

Low Low temperature 1. Surrounding atmosphere 1. lower evaporation of Control valve None

is too cold water resulting in low

2. Steam source failure, product quality in spite of

operator error having a control valve in

the product stream line

2. Same as 1

You might also like

- 737NG QuestionDocument18 pages737NG QuestionPedro Casas Espinosa89% (9)

- Engineering Design Basis GADocument67 pagesEngineering Design Basis GAswabrightNo ratings yet

- V-103 HAZOP Study Nodes and ParametersDocument15 pagesV-103 HAZOP Study Nodes and ParametersEdna TanNo ratings yet

- Shop Manual KOMATSU D475A-EODocument388 pagesShop Manual KOMATSU D475A-EODeyvid Bañez EspinozaNo ratings yet

- HAZOP for R-101 Reactor Process ParametersDocument2 pagesHAZOP for R-101 Reactor Process ParametersHuda100% (1)

- GMV Valve 3010 - S + DVL A3 02-04-2014 Ver.D Table.04 - 008.ENDocument2 pagesGMV Valve 3010 - S + DVL A3 02-04-2014 Ver.D Table.04 - 008.ENDimitrios Koustas100% (4)

- HAZOP Neautralization ReactorDocument4 pagesHAZOP Neautralization ReactorIssyahira Ernie100% (1)

- Industrial Safety Engineering SyllabusDocument27 pagesIndustrial Safety Engineering SyllabusBalamurugan83% (6)

- 12 Air Starting of Diesel EnginesDocument26 pages12 Air Starting of Diesel EnginesCurtler PaquibotNo ratings yet

- Sr220 Case - PartesDocument882 pagesSr220 Case - PartesJorge Diaz Nestor MonsalveNo ratings yet

- Vinyl Chloride Production Flowsheet and Hazop AnalysisDocument11 pagesVinyl Chloride Production Flowsheet and Hazop AnalysisHabib Maulana YasmintoNo ratings yet

- Valves DatasheetDocument1 pageValves DatasheetLuis Acevedo AyalaNo ratings yet

- Hazop of FurnaceDocument2 pagesHazop of FurnaceTouhidBinAnwarNo ratings yet

- HB20-II / HB30-II / HB40-II: Operation and Maintenance ManualDocument91 pagesHB20-II / HB30-II / HB40-II: Operation and Maintenance ManualLuisa Fernanda Salazar Pulgarin100% (1)

- 3TNE74Document30 pages3TNE74Syahroni0% (1)

- HAZOP FinalDocument2 pagesHAZOP Finalchiang95100% (3)

- Tutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredDocument3 pagesTutorial Hazop: Node Guide Word Deviation Possible Cause Consequences Action RequiredSyafiyatulMunawarahNo ratings yet

- HAZOP Study For DAP Process-Mysha - 0419022037 PDFDocument3 pagesHAZOP Study For DAP Process-Mysha - 0419022037 PDFMysha MomtazNo ratings yet

- Distillation Column HAZOPDocument6 pagesDistillation Column HAZOPAhmer SohailNo ratings yet

- HAZOP Study for Process Heater and ReactorDocument14 pagesHAZOP Study for Process Heater and Reactorquik silvaNo ratings yet

- Transformer Alarm GuideDocument8 pagesTransformer Alarm GuideAhmed SallahNo ratings yet

- Revise Hazop Nga Ni Ka FermenterDocument2 pagesRevise Hazop Nga Ni Ka FermenterRomel Leo100% (2)

- SM KBF (E2.1) 12-2013 - enDocument108 pagesSM KBF (E2.1) 12-2013 - enVictor Ruiz50% (2)

- HAZOP studies on critical reactor processDocument12 pagesHAZOP studies on critical reactor processGregory Eleazar D. AngelesNo ratings yet

- Safety and Hazard Analysis ProjectDocument16 pagesSafety and Hazard Analysis ProjectGautham Krishna KbNo ratings yet

- C3 HazopDocument9 pagesC3 HazopGian Michael Boyero100% (1)

- Example: HAZOP Analysis of A Fueling Terminal For A BargeDocument4 pagesExample: HAZOP Analysis of A Fueling Terminal For A BargeBharat LalNo ratings yet

- FA-30 Air to Water Heat Pump SpecificationsDocument16 pagesFA-30 Air to Water Heat Pump SpecificationsqwasawsewNo ratings yet

- Appendix 1 HAZOPWorksheets 1 PDFDocument37 pagesAppendix 1 HAZOPWorksheets 1 PDFSDP02No ratings yet

- Process Safety for Lotion ManufacturingDocument8 pagesProcess Safety for Lotion ManufacturingAltheaBNo ratings yet

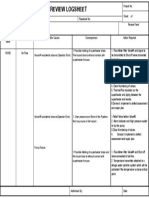

- Hazop Review Logsheet Hazop Review LogsheetDocument1 pageHazop Review Logsheet Hazop Review Logsheetsalman hussainNo ratings yet

- HAZOP Studies On Distillation ColumnDocument3 pagesHAZOP Studies On Distillation ColumnHaneen HamamNo ratings yet

- Avr Trouble ShootingDocument2 pagesAvr Trouble ShootingJAYKUMAR SINGHNo ratings yet

- Troubleshooting alarms and signalsDocument3 pagesTroubleshooting alarms and signalsCidi ComNo ratings yet

- Pump HazopDocument3 pagesPump HazopUzair AftabNo ratings yet

- Hazop Distillation ColumnDocument4 pagesHazop Distillation ColumnMUSNo ratings yet

- 1PH Growatt SPI 750-5500W - MANUALDocument12 pages1PH Growatt SPI 750-5500W - MANUALabdullahNo ratings yet

- AFC 1 Case Study: BFW Valve FailureDocument3 pagesAFC 1 Case Study: BFW Valve FailureAmmonia 1 EngineersNo ratings yet

- Beacon EnglishDocument1 pageBeacon EnglishKiranNo ratings yet

- CPD Assignmnet 3 (CH-16059)Document3 pagesCPD Assignmnet 3 (CH-16059)Juni Sidd100% (1)

- Horton Toubleshooting GuideDocument1 pageHorton Toubleshooting GuideGabriel Castillo MuñozNo ratings yet

- English (GB) Installation and Operating Instructions: 2. ApplicationsDocument1 pageEnglish (GB) Installation and Operating Instructions: 2. Applicationsselmir_9No ratings yet

- Production of 1-Heptene from C3/C4 Hydrocarbons"TITLE"PHA of Heptane Production Process Including HAZOP, FTA, ETA" TITLE"Reflux Drum, Reboiler, C3/C4 Tower PHA for Heptane ProductionDocument30 pagesProduction of 1-Heptene from C3/C4 Hydrocarbons"TITLE"PHA of Heptane Production Process Including HAZOP, FTA, ETA" TITLE"Reflux Drum, Reboiler, C3/C4 Tower PHA for Heptane ProductionmiexaraNo ratings yet

- Electrical Flocculation System Operation ManualDocument10 pagesElectrical Flocculation System Operation ManualNelsonNo ratings yet

- Manual Baño Maria - VWRDocument12 pagesManual Baño Maria - VWRAsesoria tecnica Azul DiagnosticNo ratings yet

- Hazop PDFDocument1 pageHazop PDFUsama MughalNo ratings yet

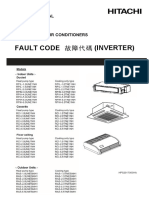

- Fault Code InverterDocument11 pagesFault Code InverterHuawei HuaweiNo ratings yet

- Integrated Case StudyDocument3 pagesIntegrated Case StudyNURUL AQILAH AHMAD NASIRNo ratings yet

- Hazard and Operability Study (Hazop)Document16 pagesHazard and Operability Study (Hazop)Usman KhalidNo ratings yet

- Salt Spray Test Chamber ManualDocument5 pagesSalt Spray Test Chamber ManualNguyễn Tiến Dũng0% (1)

- PSOH AssignmentDocument9 pagesPSOH AssignmentRuth sNo ratings yet

- E39 Ahsop 03Document3 pagesE39 Ahsop 03Sanjit SinghNo ratings yet

- Hazop Worksheet Hazard Identification Study WorkDocument2 pagesHazop Worksheet Hazard Identification Study Workssat111No ratings yet

- Case Study 2Document2 pagesCase Study 2SyafiyatulMunawarahNo ratings yet

- I. Brief On Process Unit Description Including Design Intents.Document6 pagesI. Brief On Process Unit Description Including Design Intents.izzhamizmNo ratings yet

- APW3 Power Supply Maintenance ReferenceDocument5 pagesAPW3 Power Supply Maintenance ReferenceIndanet TelecomNo ratings yet

- Installation, Operation and Maintenance ManualDocument76 pagesInstallation, Operation and Maintenance ManualAravindhan ENo ratings yet

- 4W04 Slides HAZOPDocument16 pages4W04 Slides HAZOPharveyNo ratings yet

- SCB Chemical Solutions - HAZOPDocument20 pagesSCB Chemical Solutions - HAZOPGuillyNo ratings yet

- Disassemble IMBRC PartsDocument4 pagesDisassemble IMBRC PartsJoseph DavidNo ratings yet

- UntitledDocument6 pagesUntitledNour AzziNo ratings yet

- Yeast Tub Process Management SOP ExampleDocument6 pagesYeast Tub Process Management SOP ExampleJulissa CepedaNo ratings yet

- Hazard and Operability Studies (HAZOP) 2Document15 pagesHazard and Operability Studies (HAZOP) 2jeevanantham 5846No ratings yet

- HAzopDocument2 pagesHAzopMehran IsgandarliNo ratings yet

- Hazard and Operability StudyDocument43 pagesHazard and Operability Studyhell oNo ratings yet

- MNT 028-03 Operating Procedure Boiler OperationDocument3 pagesMNT 028-03 Operating Procedure Boiler OperationAniket kopateNo ratings yet

- Step by Step RMC Analysis of Centrifugal PumpDocument1 pageStep by Step RMC Analysis of Centrifugal Pumpnathanael tayorNo ratings yet

- R - Set 2 HazopDocument2 pagesR - Set 2 HazopSynthia RashidNo ratings yet

- Hydrothermal Properties of Materials: Experimental Data on Aqueous Phase Equilibria and Solution Properties at Elevated Temperatures and PressuresFrom EverandHydrothermal Properties of Materials: Experimental Data on Aqueous Phase Equilibria and Solution Properties at Elevated Temperatures and PressuresVladimir ValyashkoNo ratings yet

- Electrical Characterization of Organic Electronic Materials and DevicesFrom EverandElectrical Characterization of Organic Electronic Materials and DevicesNo ratings yet

- Sauerdanfoss Series s90 Motors CatalogueDocument44 pagesSauerdanfoss Series s90 Motors CatalogueAdrian Alonso Bustos GonzalezNo ratings yet

- Instruction Manual HP VHP Series - PN7950 8093 R2Document31 pagesInstruction Manual HP VHP Series - PN7950 8093 R2Allyson RincónNo ratings yet

- GT22 Operation ManualDocument72 pagesGT22 Operation ManualSyed Asim Ur RahmanNo ratings yet

- Engine Repair Procedures and Estimated TimesDocument8 pagesEngine Repair Procedures and Estimated Timescarlos javierNo ratings yet

- 10 Testing Equipment 8 eDocument28 pages10 Testing Equipment 8 epankajNo ratings yet

- Cessna ConquestDocument18 pagesCessna ConquestsandyNo ratings yet

- Augusta, Maine 04336. York 14649. 14649.Document17 pagesAugusta, Maine 04336. York 14649. 14649.deepaNo ratings yet

- Chem-Feed Diaphragm Metering Pump: FeaturesDocument4 pagesChem-Feed Diaphragm Metering Pump: FeaturesAlejandro MoralesNo ratings yet

- Nbs Bfy ValveDocument72 pagesNbs Bfy Valvedj22500No ratings yet

- FCI Standards for Control Valves, Strainers, Regulators and MoreDocument2 pagesFCI Standards for Control Valves, Strainers, Regulators and MorecukimayNo ratings yet

- English Instruction For ZYC200B-B1Document33 pagesEnglish Instruction For ZYC200B-B1sokimjamesNo ratings yet

- LPU GeneralDocument8 pagesLPU GeneralgeomariolisNo ratings yet

- K32 Flexigun: Instruction ManualDocument4 pagesK32 Flexigun: Instruction ManualJod RichNo ratings yet

- Directions For Use Standard Filter Cartridges and Mini CartridgesDocument38 pagesDirections For Use Standard Filter Cartridges and Mini CartridgesTit fuckerNo ratings yet

- US Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Document274 pagesUS Army - Operator and Unit Maintenance Manual, Locomotive, Model B-B-160 and 160-4GE747-A1 TM 55-2210-224-12Leonardo MirandaNo ratings yet

- Air Cooled VW VW Fuel Injection L-Jetronic Trouble Shooting Guide - Mid America MotorworksDocument2 pagesAir Cooled VW VW Fuel Injection L-Jetronic Trouble Shooting Guide - Mid America MotorworksWesley FernandesNo ratings yet

- SECTION 07 Hydraulics2 9020-9030Document16 pagesSECTION 07 Hydraulics2 9020-9030Vjz10997100% (2)

- Training ManualDocument49 pagesTraining ManualMahaveer ChaudhariNo ratings yet

- GMX Complete KnowledgeDocument36 pagesGMX Complete KnowledgeSoumen PandaNo ratings yet