Professional Documents

Culture Documents

Helical Gear Design

Uploaded by

dhruv dabhiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Helical Gear Design

Uploaded by

dhruv dabhiCopyright:

Available Formats

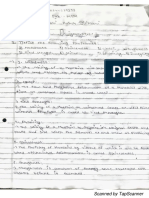

Helical Gear Design steps

Equivalent number of teeth 𝑍 = , α = Helix Angle

1) Identify the weaker Gear

a) When both the pinion (smaller gear) and other gear are made of same material, then pinion is

weaker.

b) When the pinion and gear are made of different material than calculate ( σb* Y’)for both the gears.

The less value suggests the weaker gear.

Y’=0.124-0.684/Z’ for 14.5 pressure angle. Y’=0.39-2.148/Z’ for 14.5 pressure angle.

Y’=0.154-0.912/Z’ for 20 Full depth pressure Y’=0.484-2.865/Z’ for 20 Full depth pressure

angle. angle.

Y’=0.175-0.841/Z’ for 20 stub pressure angle Y’=0.55-2.642/Z’ for 20 stub pressure angle

If this is given then multiply by π (3.14) If not given then select as per above

2) Calculate the beam strength (Apply the Lewis equation for weaker gear)

𝐹 = (𝝈 𝑌′) 𝑏 m

b= Face width=If not given then assume 10mn (10 times module)

mn= Normal Module in mm

mn= mtcosα and mt is the transverse module= d/z

3) Calculate the wear strength (Calculate only if load stress factor(k)/hardness-BHN/ wear strength is

mentioned in data)

𝐷 𝑏𝑄𝑘

𝐹 =

cos 𝛼

Dp= Pitch circle diameter of pinion in mm, =mt* Zp b=face width of weaker gear in mm,

Q=ratio factor

Q= for external gear

Q= for internal gear

k= load stress factor

𝟐

𝑩𝑯𝑵

𝒌 = 𝟎. 𝟏𝟔 𝑭𝒐𝒓 𝑺𝒕𝒆𝒆𝒍 𝒈𝒆𝒂𝒓 & 𝑠𝑡𝑒𝑒𝑙 𝑝𝑖𝑛𝑖𝑜𝑛 @ 20 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑎𝑛𝑔𝑙𝑒

𝟏𝟎𝟎

Dr. Hardik Chothani, Asst Professor, GEC Bhavnagar Page 1 of 4

Helical Gear Design steps

𝐵𝐻𝑁

𝑘 = 0.21 𝐹𝑜𝑟 𝐶𝑎𝑠𝑡 𝑖𝑟𝑜𝑛 𝑔𝑒𝑎𝑟 & 𝑐𝑎𝑠𝑡 𝑖𝑟𝑜𝑛 𝑝𝑖𝑛𝑖𝑜𝑛 @ 20 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑎𝑛𝑔𝑙𝑒

100

𝐵𝐻𝑁

𝑘 = 0.18 𝐹𝑜𝑟 𝑐𝑎𝑠𝑡 𝑖𝑟𝑜𝑛 𝑔𝑒𝑎𝑟 & 𝑠𝑡𝑒𝑒𝑙 𝑝𝑖𝑛𝑖𝑜𝑛 @ 20 𝑃𝑟𝑒𝑠𝑠𝑢𝑟𝑒 𝑎𝑛𝑔𝑙𝑒

100

(OR)

(𝝈 ) Ø

k=

.

𝝈 = 𝑆𝑢𝑟𝑓𝑎𝑐𝑒 𝑒𝑛𝑑𝑢𝑟𝑎𝑛𝑐𝑒 𝑙𝑖𝑚𝑖𝑡 in N/mm2

Ep= Young modulus for pinion material in N/mm2

Eg=Young modulus for gear material in N/mm2

4) If Fb < Fw, It is required to design gear pair against the bending load, for safe design effective load

(Feff) should be less than the Fb. And ) If Fb > Fw, It is required to design gear pair against the wear

load, for safe design effective load (Feff) should be less than the Fw.

5) Effective load calculation

𝐾 𝐾 𝐹

𝐹 =

𝐾

Ka= Service factor, It depends on the driving machine and driven machine,

Driving machine Driven machine

pump, multi cylinder Press machine, shear

Conveyors, elevators

piston machine, crusher

Electric motor, turbine 1 1.25 1.75

Multi cylinder IC engine 1.25 1.50 2

Single Cylinder IC

1.5 1.75 2.25

engine

Km= Load distribution factor, it depends on accuracy and face width, if not given then assume 1.

Kv (Cv) = Velocity factor

The value of velocity (m/s) CV

Less than 12.5 for regular gear 𝟑

𝟑+𝒗

Less than 12.5 for Precise gear 4.5

4.5 + 𝑣

Less than 20 for regular gear 6

6+𝑣

Dr. Hardik Chothani, Asst Professor, GEC Bhavnagar Page 2 of 4

Helical Gear Design steps

Less than 20 for Precise gear 0.75

0.75 + √𝑣

(Remember- v is always in meter/second)

Ft= Tangential Load

𝑃

𝐹 =

𝑣

P =Input power in watt, V=Velocity in m/s,

Find out velocity (V)

𝑣=

πDN=m/s

D= Pitch circle diameter of any one gear in meter

N=Speed of the same gear

𝐷1 𝑍1 𝑁2

𝑔= = =

𝐷2 𝑍2 𝑁1

G= speed ratio or gear ratio

Other dimensions

Center distance= Radius of pinion +radius of gear

Z=Number of teeth

6) Check the design is safe/unsafe in bending

6.1) If Fb<Fw, check design for bending

𝐹 < 𝐹 𝑓𝑜𝑟 𝑠𝑎𝑓𝑒 𝑑𝑒𝑠𝑖𝑔𝑛

𝐹 ∗ 𝐹𝑂𝑆 = 𝐹

𝐹𝑂𝑆 = 𝐹𝑎𝑐𝑡𝑜𝑟 𝑜𝑓 𝑠𝑎𝑓𝑒𝑡𝑦

6.2) If Fb>Fw, check design for Wear

𝐹 < 𝐹 𝑓𝑜𝑟 𝑠𝑎𝑓𝑒 𝑑𝑒𝑠𝑖𝑔𝑛

𝐹 ∗ 𝐹𝑂𝑆 = 𝐹

𝐹𝑂𝑆 = 𝐹𝑎𝑐𝑡𝑜𝑟 𝑜𝑓 𝑠𝑎𝑓𝑒𝑡𝑦

Dr. Hardik Chothani, Asst Professor, GEC Bhavnagar Page 3 of 4

Helical Gear Design steps

7) Calculate the dynamic load by using buckingham’s equation

(If dynamic load factor C is given/ mention dynamic load then use only)

21𝑣(𝑏𝐶 + 𝐹𝑒𝑓𝑓 ∗ 𝐾𝑣)

𝐹

21𝑣 + 𝑏𝐶 + 𝐹𝑒𝑓𝑓 ∗ 𝐾𝑣

b =face width in mm

C=dynamic factor in N/mm

Velocity v= M/s

Dynamic factor is based on the tooth error, material and pressure angle. Either select from the table or

calculate based on equation.

𝐾𝑒

𝐶=

1 1

+

𝐸𝑝 𝐸𝑔

K=factor for form of teeth

K=0.107 for 14.5 pressure angle.

K=0.111 for 20 full depth pressure angle.

K=0.115 for 20 stub pressure angle

e=tooth error in mm

Ep= Young modulus for pinion material in N/mm2

Eg=Young modulus for gear material in N/mm2

𝐹 = 𝐹 ∗𝐾 +𝐹

Check design for dynamic load

𝐹 < 𝐹 𝑓𝑜𝑟 𝑠𝑎𝑓𝑒 𝑑𝑒𝑠𝑖𝑔𝑛

𝐹 ∗ 𝐹𝑂𝑆 = 𝐹

𝐹𝑂𝑆 = 𝐹𝑎𝑐𝑡𝑜𝑟 𝑜𝑓 𝑠𝑎𝑓𝑒𝑡𝑦

Dr. Hardik Chothani, Asst Professor, GEC Bhavnagar Page 4 of 4

You might also like

- CR14DE Timing Engine PDFDocument334 pagesCR14DE Timing Engine PDFVictor Mamani Vargas100% (5)

- Enterprise 1675 ManualDocument91 pagesEnterprise 1675 ManualBakhtiyar Gandevia57% (7)

- WA500-1 10001-UpDocument933 pagesWA500-1 10001-UpRavinder Singh100% (5)

- Design Consideration of Corn Sheller MachineDocument6 pagesDesign Consideration of Corn Sheller MachineIJIRST100% (2)

- HYSTER c108Document21 pagesHYSTER c108sergio reca0% (1)

- ch09 3Document155 pagesch09 3abdallah ghannamNo ratings yet

- Spur GearsDocument5 pagesSpur GearsMalibongwe NgcoboNo ratings yet

- Gear Force & StressDocument30 pagesGear Force & StressRanjeethkumar JalalNo ratings yet

- Common Terms Used:: Bevel, Worm and Cross Helical GearsDocument15 pagesCommon Terms Used:: Bevel, Worm and Cross Helical GearsSurulivelrajantNo ratings yet

- Computer Aided Modeling Cost Estimation of A Hand TruckDocument4 pagesComputer Aided Modeling Cost Estimation of A Hand TruckIJARP PublicationsNo ratings yet

- Module 2 Spur&HelicalDocument76 pagesModule 2 Spur&HelicalDhruvanth SJNo ratings yet

- DTS - Unit - 2 PDFDocument14 pagesDTS - Unit - 2 PDFmani100% (1)

- 7B - Gears-B - (FUE) - Spur GearDocument14 pages7B - Gears-B - (FUE) - Spur GearKNNo ratings yet

- Chapter 9 Spur Gear DesignDocument31 pagesChapter 9 Spur Gear DesignRamesh Martha100% (1)

- Whiteboard-Shifter (2) Final Print (Repaired)Document19 pagesWhiteboard-Shifter (2) Final Print (Repaired)Aklesh GuptaNo ratings yet

- Numerical TillCrankshaftBMDocument60 pagesNumerical TillCrankshaftBMmohammad umairNo ratings yet

- Numerical-Till-Assignment 2 and Assignment3Document76 pagesNumerical-Till-Assignment 2 and Assignment3mohammad umairNo ratings yet

- Not For Commercial Use: TedataDocument2 pagesNot For Commercial Use: Tedatawilly rojas zeballosNo ratings yet

- Rigid Pavement Design 200mm Alipingal-KhairaDocument15 pagesRigid Pavement Design 200mm Alipingal-KhairaPradeepta PatraNo ratings yet

- A Design Approach For Automatic Tyre Inflation SystemDocument3 pagesA Design Approach For Automatic Tyre Inflation Systemseid negashNo ratings yet

- Machine Design-Ii: GearsDocument50 pagesMachine Design-Ii: Gearsmuhammad hamzaNo ratings yet

- Design Spur Gear Study Material LectDocument6 pagesDesign Spur Gear Study Material Lectprashant mishraNo ratings yet

- EG1020 Gear Drive HelpDocument4 pagesEG1020 Gear Drive Helptimbs2004No ratings yet

- Computer Aided Spur Gear Design and AnalysisDocument8 pagesComputer Aided Spur Gear Design and AnalysisKevin MalarkeyNo ratings yet

- Drilling Torque & DragDocument66 pagesDrilling Torque & DragShamit Rathi100% (1)

- TỶ LỆ HƠN 6 TDocument12 pagesTỶ LỆ HƠN 6 TDương CaoNo ratings yet

- Helical Gear DesignDocument8 pagesHelical Gear Design140120119060No ratings yet

- Gears PresentationDocument33 pagesGears PresentationNaveen YadavNo ratings yet

- Detailed DesignDocument39 pagesDetailed Designchathura buddhikaNo ratings yet

- Design of Differential For Automobile Teaching Aid: © AUG 2019 - IRE Journals - Volume 3 Issue 2 - ISSN: 2456-8880Document6 pagesDesign of Differential For Automobile Teaching Aid: © AUG 2019 - IRE Journals - Volume 3 Issue 2 - ISSN: 2456-8880Obaida BawezNo ratings yet

- Design Calculation of Gearbox: ST ND RD TH THDocument50 pagesDesign Calculation of Gearbox: ST ND RD TH THKaung KhantNo ratings yet

- Report - Steel Beam CalculatorDocument6 pagesReport - Steel Beam CalculatorchriscundyNo ratings yet

- Spur Gear PDFDocument8 pagesSpur Gear PDFLovely BalajiNo ratings yet

- Spur Gear Design by IIT MadrasDocument28 pagesSpur Gear Design by IIT MadrasC.S.ABHILASHNo ratings yet

- 144 TeamDaksh CAEEvaluationReportDocument15 pages144 TeamDaksh CAEEvaluationReportPrathap YaraNo ratings yet

- BISRAT GIRMA Gearbox DesignDocument92 pagesBISRAT GIRMA Gearbox DesignŠmřű Žăm Ğ Bøýž0% (1)

- Ngasi Consulting Engineers: REF CalculationDocument18 pagesNgasi Consulting Engineers: REF CalculationUday UdmaleNo ratings yet

- Geometric Design of HighwaysDocument51 pagesGeometric Design of HighwaysJed EnricusoNo ratings yet

- Design and Construction of A Connecting Rod PDFDocument21 pagesDesign and Construction of A Connecting Rod PDFTeshome Dengiso0% (1)

- 1.SIMPLE SCREW JACK SQ ThreadsDocument6 pages1.SIMPLE SCREW JACK SQ ThreadsService MMINo ratings yet

- Design and Analysis of Planetary Gearbox For All-Terrain VehicleDocument10 pagesDesign and Analysis of Planetary Gearbox For All-Terrain VehicleIJRASETPublications100% (1)

- Padeye Calculation Design AssumptionsDocument7 pagesPadeye Calculation Design AssumptionsRajat KatyalNo ratings yet

- Lect 3Document16 pagesLect 3Ahmed El-SaeedNo ratings yet

- Op-014. Procedure For Determination of Bending Moment: Work Instructions For EngineersDocument10 pagesOp-014. Procedure For Determination of Bending Moment: Work Instructions For Engineersjinwook75No ratings yet

- Vehicle Dynamics and Modelling: Tractive EffortDocument8 pagesVehicle Dynamics and Modelling: Tractive EffortKrishi ShahNo ratings yet

- Pont Dalle en Ba Groupe Gci ADocument20 pagesPont Dalle en Ba Groupe Gci Aken koemhongNo ratings yet

- Design and Analysis of A Sprocket-Hub AssemblyDocument7 pagesDesign and Analysis of A Sprocket-Hub AssemblyJackson PhinniNo ratings yet

- MD - Chapter 02 - Design of Helical GearDocument17 pagesMD - Chapter 02 - Design of Helical Gearmohil thakorNo ratings yet

- 01.2.SIMPLE SCREW JACK Vee ThreadsDocument6 pages01.2.SIMPLE SCREW JACK Vee ThreadsService MMINo ratings yet

- References:: Third-All Branches Machine Design I (Lecture 28) Mechanical Eng. DeptDocument11 pagesReferences:: Third-All Branches Machine Design I (Lecture 28) Mechanical Eng. DeptOmar loayzaNo ratings yet

- Spur GearDocument107 pagesSpur GearMuhammadUmairShafiqNo ratings yet

- Optimization of Gear To Improve Performance of GearboxDocument4 pagesOptimization of Gear To Improve Performance of GearboxChandrakiran AlapatiNo ratings yet

- DME MiniProjectDocument17 pagesDME MiniProjectJinmay KalitaNo ratings yet

- Gears: Dr. Mostafa Rostom A. Atia Associate ProfDocument41 pagesGears: Dr. Mostafa Rostom A. Atia Associate ProfKOMATSU SHOVELNo ratings yet

- Gears Presentation BubuDocument37 pagesGears Presentation BubuAbebaw AyeleNo ratings yet

- NX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)From EverandNX 9 for Beginners - Part 2 (Extrude and Revolve Features, Placed Features, and Patterned Geometry)No ratings yet

- Southern Marine Engineering Desk Reference: Second Edition Volume IFrom EverandSouthern Marine Engineering Desk Reference: Second Edition Volume INo ratings yet

- Pressuremeter Testing: Methods and InterpretationFrom EverandPressuremeter Testing: Methods and InterpretationRating: 5 out of 5 stars5/5 (2)

- Classification, Parameter Estimation and State Estimation: An Engineering Approach Using MATLABFrom EverandClassification, Parameter Estimation and State Estimation: An Engineering Approach Using MATLABRating: 3 out of 5 stars3/5 (1)

- GTU Central TechFestDocument1 pageGTU Central TechFestdhruv dabhiNo ratings yet

- Icmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)Document2 pagesIcmr Specimen Referral Form For Covid-19 (Sars-Cov2) : (These Fields To Be Filled For All Patients Including Foreigners)nitish mahatoNo ratings yet

- SIHMBrochure 2019Document22 pagesSIHMBrochure 2019dhruv dabhiNo ratings yet

- Gmail - Ajay Baraiya. 190210119011Document1 pageGmail - Ajay Baraiya. 190210119011dhruv dabhiNo ratings yet

- Er No.-190280119133, Harsh D. Solanki, MSM Assignment 1Document4 pagesEr No.-190280119133, Harsh D. Solanki, MSM Assignment 1dhruv dabhiNo ratings yet

- Vatsal MSM Assignment-1Document12 pagesVatsal MSM Assignment-1dhruv dabhiNo ratings yet

- Enrollment NO. - 190210119035 - DhruvDocument1 pageEnrollment NO. - 190210119035 - Dhruvdhruv dabhiNo ratings yet

- Experiment No. 5: Mechanical Engg Dept., GEC, BhavnagarDocument5 pagesExperiment No. 5: Mechanical Engg Dept., GEC, Bhavnagardhruv dabhiNo ratings yet

- 2020 MSM Lab ManualDocument31 pages2020 MSM Lab Manualdhruv dabhiNo ratings yet

- Rupa Goswami Sri Lalita Madhava (640-696)Document57 pagesRupa Goswami Sri Lalita Madhava (640-696)dhruv dabhiNo ratings yet

- Ujjvala Nilamani (Hindi)Document1,024 pagesUjjvala Nilamani (Hindi)Maria Celeste Camargo Casemiro100% (2)

- Utkalika-Vallari 1st Ed HindiDocument87 pagesUtkalika-Vallari 1st Ed HindiSudhir MaherwalNo ratings yet

- American Machinist Gear BookDocument374 pagesAmerican Machinist Gear BooknamerandomNo ratings yet

- 30 Series PC Low Resolution PDFDocument226 pages30 Series PC Low Resolution PDFSarvesh GuptaNo ratings yet

- Din-981 KMDocument5 pagesDin-981 KMChris StefanouNo ratings yet

- ScrewDocument20 pagesScrewIxora MyNo ratings yet

- Torx - Wikipedia, The Free EncyclopediaDocument6 pagesTorx - Wikipedia, The Free EncyclopediaJames WoodNo ratings yet

- M CH 0119 PDFDocument57 pagesM CH 0119 PDFhungNo ratings yet

- Honda CBF125 Technical Specifications PDFDocument1 pageHonda CBF125 Technical Specifications PDFRoyal ENo ratings yet

- D5M Transm - Testing and Diagrams PDFDocument92 pagesD5M Transm - Testing and Diagrams PDFJoseNicolásPerez100% (1)

- XVS950 Catalogo de Partes 5S71 - 2009Document72 pagesXVS950 Catalogo de Partes 5S71 - 2009Exiquio SánchezNo ratings yet

- Me 8651Document10 pagesMe 8651selvam cNo ratings yet

- Sl2012-552 Crankcase InspectionDocument4 pagesSl2012-552 Crankcase Inspectionargentum19619692No ratings yet

- Armado Bomba D7 5BFDocument8 pagesArmado Bomba D7 5BFFrancisco HernandezNo ratings yet

- ECD45B - HYDRAULIC CIRCUIT & ELECTRIC CIRCUIT Rev.000Document14 pagesECD45B - HYDRAULIC CIRCUIT & ELECTRIC CIRCUIT Rev.000rolandNo ratings yet

- Teck 90Document1 pageTeck 90fernandoNo ratings yet

- Deutz TD 4l2009 Engine Parts Manual 913282b Rs5 19 Telescopic HandlerDocument4 pagesDeutz TD 4l2009 Engine Parts Manual 913282b Rs5 19 Telescopic Handlerflorine100% (42)

- Rotator Baltrotors GR30PFDocument3 pagesRotator Baltrotors GR30PFAnonymous 80HAPYsoNo ratings yet

- Hatlapa Most LikelyDocument2 pagesHatlapa Most LikelyMugenLensrichNo ratings yet

- Kartar Valves Price ListDocument16 pagesKartar Valves Price ListPankaj105100% (1)

- Catálogo de RolamentosDocument22 pagesCatálogo de RolamentosFD Santos SilvaNo ratings yet

- Manual TransmissionDocument60 pagesManual Transmissionʞǝǝs Uǝ ƎpıɥNo ratings yet

- Seminar FinalDocument21 pagesSeminar FinalLOKENDRA91No ratings yet

- Parts list FORTUNE110 (ΖΥ110-3) aDocument53 pagesParts list FORTUNE110 (ΖΥ110-3) aGARAGE PREMIUMNo ratings yet

- HARDWARE2Document102 pagesHARDWARE2Benedict CarandangNo ratings yet

- Technical Manual Gear Hub Systems: EnglishDocument84 pagesTechnical Manual Gear Hub Systems: EnglishЕвгений ЕвсеевNo ratings yet

- Fed STD H28 20BDocument30 pagesFed STD H28 20BL FNo ratings yet

- Dodge CouplingDocument8 pagesDodge Couplingpassword2002No ratings yet