Professional Documents

Culture Documents

CH 7 - Project Control

Uploaded by

Jeffrey CaparasOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CH 7 - Project Control

Uploaded by

Jeffrey CaparasCopyright:

Available Formats

CHAPTER 7

PROJECT CONTROL

The limited objective of project control deserves emphasis. Project control procedures are

primarily intended to identify deviations from the project plan rather than to suggest

possible areas for cost savings. This characteristic reflects the advanced stage at which

project control becomes important. The time at which major cost savings can be achieved

is during planning and design for the project. During the actual construction, changes are

likely to delay the project and lead to inordinate cost increases. As a result, the focus of

project control is on fulfilling the original design plans or indicating deviations from

these plans, rather than on searching for significant improvements and cost savings. It is

only when a rescue operation is required that major changes will normally occurring in

the construction plan.

7.1 Problems that may Arise During Construction

In construction, no project, almost, is executed as planned. Control needs to be carried-

out due to the dynamic nature of the construction process. Controlling after project finish

is trivial and updates are usually done periodically. Controlling can be done for project

schedule and/or project cost. As the construction stage of project starts, the project mostly

will face delays and/or cost overruns. The following is a list of the factors that may cause

such problems:

- Change in activity durations and quantities.

- Sudden changes of the availability of resources.

- Change orders.

- Accidents.

- Procurement delays.

Planning & scheduling 148 Dr. Emad Elbeltagi

7.2 Schedule Updating

Construction typically involves a deadline for work completion, so contractual

agreements will force attention to schedules. More generally, delays in construction

represent additional costs due to late facility occupancy or other factors. Just as costs

incurred are compared to budgeted costs, actual activity durations may be compared to

expected durations. In this process, forecasting the time to complete particular activities

may be required.

It is important to devise efficient and cost effective methods for gathering information on

actual project accomplishments. Generally, observations of work completed are made by

inspectors and project managers and then work completed is estimated. Once estimates of

work complete and time expended on particular activities are available, deviations from

the original duration estimate can be estimated.

For example, Figure 7.1 shows the originally scheduled project progress versus the actual

progress on a project. This figure is constructed by summing up the percentage of each

activity which is complete at different points in time; this summation can be weighted by

the magnitude of effort associated with each activity. In Figure 7.1, the project was ahead

of the original schedule for a period including point A, but is now late at point B by an

amount equal to the horizontal distance between the planned progress and the actual

progress observed to date.

In evaluating schedule progress, it is important to bear in mind that some activities

possess float, whereas delays in activities on the critical path will cause project delays. In

particular, the delay in planned progress at time t may be soaked up in activities' float

(thereby causing no overall delay in the project completion) or may cause a project delay.

As a result of this ambiguity, it is preferable to update the project schedule to devise an

accurate portrayal of the schedule adherence. After applying a scheduling algorithm, a

new project schedule can be obtained.

Planning & scheduling 149 Dr. Emad Elbeltagi

B

Figure 7.1: Planned versus actual progress over time on a project

It is common that actual durations of activities differ from those estimated. Furthermore,

there may be additions or deletions to the scope of the contract that will affect the time at

which activities can be started or completed. Schedule updating is a procedure for

introducing the latest progress information into the schedule.

Data have to be collected on the actual progress of completed activities and those under

execution. A completely new estimate of the amount of work remaining to be done

should be made for each activity. The probable output of various resources should be

assessed. If the job is found to be behind schedule, corrective actions must be made to

retrieve position. A procedure for manual schedule updating can be summarized in the

following steps:

-Change the duration of all completed activities to zero.

-Identify all activities on which work is currently processing as Live Activities

-Put early start time of live activities equals the updating date and their durations equal

remaining duration.

-Change duration of future activities as given in the update report.

-Carry-out network analysis in the normal way and prepare a new activity schedule.

Planning & scheduling 150 Dr. Emad Elbeltagi

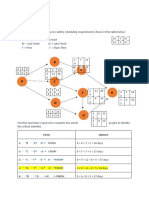

To illustrate the above hand procedure for schedule updating, consider the following

example with the planning data given in Table 7.1. The corresponding precedence

network along with time analysis is shown in Figure 7.2. It is evident that initial project

duration is 20 weeks and the activities A, B, F, and K comprises the critical path.

Table 7.1: Planning data of the example problem

Activity Predecessors Duration (wks) Overlap (wks)

A --- 2

B A 2

C A 5

D A 3

E B 2

F B 6 -3

G C 6

H D 6

I D 4 -2

J E, F 2

K F, G 8 3 with G

L H 3

M H, I 2

At the end of the 7th week, new filed data are collected and the project status activities is

as follows:

-Activities A, B, D, and E have been completed.

-Remaining Duration of activity C is one week.

-Remaining Duration of activity H is 4 weeks.

-Activity G will not start until beginning of week 10.

-Overlap between activities K and G is one week only

-Volume of work of activity L has been increased by 33%.

-Activity J has been omitted.

The updated precedence network and the corresponding updated schedule are shown in

Figure 7.3. It is shown that a new critical path is developed. The new project completion

time is 21 weeks which indicates that a delay of one week is encountered. Corrective

actions should be taken to improve project performance during the remaining portion.

Planning & scheduling 151 Dr. Emad Elbeltagi

4 6

E (2)

16 18

(12, 12)

2 4 7 13 13 15

B (2) -3 F (6) J (2)

2 4 7 13 18 20

(0, 0) (0, 0) (5, 5)

0 2 2 7 7 13 13 20 20 20

A (2) C (5) G (6) 3 K (7) Finish (0)

0 2 5 10 10 16 13 20 20 20

(0, 0) (0, 0) (3, 3) (0, 0) (0, 0)

2 5 5 11 11 14

D (3) H (6) L (3)

8 11 11 17 17 20

ES EF

(6, 0) (3, 0) (6, 6)

D (3) -2

7 11 11 13

LS LF

I (4) M (2)

(TF, FF)

14 18 18 20

(7, 0) (7, 7)

Figure 7.2: Scheduling data of the example problem

E (0)

7 13

B (0) F (6) J (0)

8 14

(0, 0)

7 8 9 15 14 21 21 21

A (0) C (1) G (6) 1 K (7) Finish (0)

8 9 9 15 14 21 21 21

(0, 0) (3, 3) (0, 0) (0, 0)

7 11 11 15

D (0) H (4) L (4)

11 17 17 21

(3, 0) (6, 6)

ES EF 7 11 11 13

D (3) I (4) M (2)

LS LF 15 19 19 21

(TF, FF) (7, 0) (7, 7)

Figure 7.3: Updated network of the example problem

Planning & scheduling 152 Dr. Emad Elbeltagi

7.3 Earned Value Management

For cost control on a project, the construction plan and the associated cash flow estimates

can provide the baseline reference for subsequent project monitoring and control. The

final or detailed cost estimate provides a baseline for the assessment of financial

performance during the project. To the extent that costs are within the detailed cost

estimate, then the project is thought to be under financial control. Overruns in particular

cost categories signal the possibility of problems and give an indication of exactly what

problems are being encountered.

The key to a profitable project is to keep construction costs within the budget and to

know when and where job costs are deviating. The budget determines the amount of cash

that will be required over the various periods of the project. Various techniques are

usually used for cost control such as S-curve method and earned value technique.

Because it is the most widely used method, only earned value technique will be described

next. Earned value technique involves a combination of three measures that are needed

for the analysis. These measures include:

Budgeted Cost of Work Scheduled (BCWS)

BCWS measures what is planned in terms of budget cost of the work that should to

place (i.e., according to the baseline schedule of the project). BCWS curve can be

plotted by accumulating the budget cost of the initial schedule.

Budgeted Cost of Work Performed (BCWP) (Earned value – EV)

BCWP measures what is done in terms of the budget cost of work that has actually

had been accomplished to date. BCWP curve can be plotted point by point after each

reporting period. Here we accumulate the budget cost on the schedule that shows the

actual percent complete.

Actual Cost of Work Performed (ACWP)

ACWP measures what is paid in terms of the actual cost of work that has actually

been accomplished to date. BCWS curve can also be plotted point by point after each

Planning & scheduling 153 Dr. Emad Elbeltagi

reporting period. Here we accumulate the actual expenditures on the schedule that

shows the actual percent complete.

The significance of these three measures is that they directly indicate schedule and

cost performances of the project at different reporting periods. This illustrated as

shown in Figure 7.5. Using these three measures, different project performance

indicators can be calculated. Among these indicators are:

Schedule Variance (SV)

it is the difference between the earned value (BCWP) and the planned budget cost

(BCWS).

SV = BCWP – BCWS; SV > 0 indicates ahead of schedule

Cost Variance (CV)

it is the difference between the actual cost (ACWP) and the earned value or the

budget cost (BCWP).

CV = BCWP – ACWP; CV > 0 indicates cost saving

Money

BCWS

BCWP (EV)

Variance

Cost

ACWP Schedule Variance

Time

Figure 7.5: Earned value measures and indictors

These concepts are best illustrated by the example problem with the planning data given

in Table 7.1. The price of each activity is given Table 7.4.The schedule of the example

Planning & scheduling 154 Dr. Emad Elbeltagi

problem is given in Figure 7.2. At the end of week number 5, the project status is

recorded as given in Table 7.4. Actual costs are also recorded as given in Table 7.5.

Table 7.4: Cost data of the example problem

Activity A B C D E F G H I J K L M

Price (1000) 36 24 145 84 126 168 126 78 80 216 70 228 120

Actual Start 0 2 2 2 4

Projected

2 5 7 6 7

Completion

Table 7.5: Actual cost at the end of week 5

Week 1 2 3 4 5 Total

Cost 18 18 72 72 125 305

Figure 7.6 shows the project schedule in bar chart format. The planned expenditure of

each activity is assumed to be uniformly distributed over activity duration. The BCWP

are calculated as shown in Figure 7.7. The weekly budgets are plotted on a cumulative

basis as the BCWS are as shown in Figure 7.8. In Figure 9.8, BCWS as well as BCWP

and ACWP to the end of week 5 are plotted on the same graph. It now possible to

calculate schedule and cost control indicators as:

SV = 262 – 294 = -ve which indicates that the project is behind schedule.

CV = 262 – 305 = -ve which indicates that the cost is overrun

Example 7.1

A cost control report of a certain contract gives the following figures as percentages

of the contract a-completion budgeted cost:

BCWP = 25% BCWS = 47% ACWP = 72%

Calculate, cost and schedule variances and comment on the status of the contract.

Planning & scheduling 155 Dr. Emad Elbeltagi

Solution

Cost variance (CV) = BCWP – ACWP = 25 – 72 = -47%

Schedule variance (SV) = BCWP – BCWS = 25 – 47 = -22%

The contract is behind schedule with over cost.

Act. Budget/w 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

A 18 18 18

B 12 12 12

C 29 29 29 29 29 29

D 28 28 28 28

E 63 63 63

F 28 28 28 28 28 28 28

G 21 21 21 21 21 21 21

H 13 13 13 13 13 13 13

I 20 20 20 20 20

J 108 108 108

K 10 10 10 10 10 10 10 10

L 76 76 76 76

M 60 60 60

Weekly

18

18

69

69

120

105

42

82

82

82

82

185

185

194

118

10

10

10

10

10

Cumulative

18

36

105

174

294

399

441

523

605

687

769

954

1139

1333

1451

1461

1471

1481

1491

1501

Figure 7.6: Bar chart showing budgeted expenditures (BCWS)

Act. Budget/w 1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20

A 18 18 18

B 18 8 8 8

C 29 29 29 29 29 29

D 21 21 21 21 21

E 42 42 42 42

Weekly

18

18

58

58

100

Cumulative

18

36

94

152

262

Figure 7.7: Bar chart updated at end of week 5 (BCWP)

Planning & scheduling 156 Dr. Emad Elbeltagi

350

BCSW

300

BCWP

250 ACWP

200

150

100

50

0

Figure 7.8: Cost curves

7.4 Exercises

1. The activities involved in the construction of one kilometer of a pipeline are given

together with their estimated durations in the table below. Each of the activities

will be done using a separate gang. All of them are sequential except “Excavate

trench” and “String pipe” are done concurrently. The project consists of 3 similar

kilometers.

Activity name Duration (days)

(LC) Locate and clear 1

(ET) Excavate trench 5

(SP) String pipe 2

(LP) Lay pipe 6

(PT) Pressure test 1

(BF) Backfill 2

a. Prepare complete plan of the works and determine the activity schedule. Mark

the critical path.

Planning & scheduling 157 Dr. Emad Elbeltagi

b. Assume now that the project is being constructed according to ES timings

determined in “a” above. At the end of day 10, the following information is

obtained from the project site:

- Activities LC were completed on schedule.

- Duration of the first part of activity ET was prolonged by 1 day but that of

the second part will be the same as the original duration.

- Activities SP were completed although ES of the third part had been

delayed by 3 days.

- Remaining duration of the first part of activity LP is 3 days.

- The first part of activity PT will not start until beginning of day 16.

Update your network and mark the critical path.

c. If the activities direct cost is listed as below:

Activity Direct Cost (LE)

LC 400

ET 3000

SP 600

LP 1800

PT 200

BF 1000

The contract site overhead amounts to LE77.777/day and distributed among

activities according to their relative direct costs. If the actual cumulative cost at

the end of day 10 is LE9270, calculate schedule and cost performance ratios and

comment on the progress of the contract.

Planning & scheduling 158 Dr. Emad Elbeltagi

REFERENCES

Awani, Alfred O. (1983). “Project Management Techniques.” Petrocelli Books Inc.

Clough, Richard H. & Sears, Gelen A. (1979). “Construction Project Management.”

John Wiley & Sons Inc., NY.

Cormican, David. (1985). “Construction Management: Planning and Finance.”

Construction Press, London.

Eldosouky, Adel I. (1996). “Principles of Construction Project Management.” Mansoura

University Press, Mansoura, Egypt.

Gould, Frederick E. (1997). “Managing the Construction Process: Estimating,

Scheduling, and Project Control.” Prentice-Hall Inc., New Gersy.

Harris, Frank & McCaffer, Ronald. (1983). “Modern Construction Management.”

Granada Publishing, Great Britain.

Harris, Robert. (1978). “Precedence and Arrow Networking Techniques for

Construction.” John Wiley & Sons Inc., NY.

Hegazy, T. (2002). “Computer-Based Construction Project Management.” Prentice Hall,

Upper Saddle River, NJ, USA.

Pilcher, Roy. (1992). “Principles of Construction Management.” Mc-Graw Hill Book

company, 3rd ed.

ElgareAllah, Mohamed Ibrahim & Nawara, Jamal Mohamed. (1984). “Edarat Almsharee’

Alhandaseah.” John Wiley & Sons Inc., NY. (This book is available in Arabic).

.2006 ،ت دار ا، " و تا "إدارة ا ا اھ

Planning & scheduling 159 Dr. Emad Elbeltagi

You might also like

- Chapter12cpm Pert 120130120246 Phpapp01Document38 pagesChapter12cpm Pert 120130120246 Phpapp01Blessy Kamala100% (1)

- HOPE 3A MODULE 1 Introduction To DanceDocument13 pagesHOPE 3A MODULE 1 Introduction To DanceLeo PatrickNo ratings yet

- Natural Juicing Recipes: Balance Your Acidity, Restore Your Health & Lose WeightDocument112 pagesNatural Juicing Recipes: Balance Your Acidity, Restore Your Health & Lose WeightTuryuk Laquindanum100% (1)

- Critical Path Method ProblemDocument2 pagesCritical Path Method ProblemAbdullah Al Noman0% (1)

- Picture DescriptionDocument7 pagesPicture DescriptionAida Mustafina100% (3)

- Health and Safety Plan TranslationDocument17 pagesHealth and Safety Plan TranslationEvaristo MudenderNo ratings yet

- Pumping For WaterDocument17 pagesPumping For WaterJeffrey CaparasNo ratings yet

- Bjmp2033 Workshop A171 Suggestion AnswersDocument20 pagesBjmp2033 Workshop A171 Suggestion AnswersNur Aina Syazwanna100% (1)

- 5G Americas Advanced Antenna Systems For 5G White PaperDocument59 pages5G Americas Advanced Antenna Systems For 5G White PaperArpitha HsNo ratings yet

- Sales Manager or Regional Manager or Senior Sales ExecutiveDocument3 pagesSales Manager or Regional Manager or Senior Sales Executiveapi-77473806No ratings yet

- Solar Power PlantDocument100 pagesSolar Power Plantbaaziz2015100% (3)

- Critical Path Analysis and Scheduling TechniquesDocument5 pagesCritical Path Analysis and Scheduling TechniquesPeña Tahiris100% (2)

- Internal Control QuestionnaireDocument19 pagesInternal Control QuestionnaireIchsanNo ratings yet

- Problems On Network Diagram and Critical Path, CPM 1Document2 pagesProblems On Network Diagram and Critical Path, CPM 1Shahriar KabirNo ratings yet

- Exam Revision - INF3708Document5 pagesExam Revision - INF3708noxaNo ratings yet

- R. Paul Wil - Rico ChetDocument7 pagesR. Paul Wil - Rico ChetJason Griffin100% (1)

- 2022 Consumer Trends ReportDocument29 pages2022 Consumer Trends Reportadelin litan100% (1)

- Project Management Problem of CPMDocument2 pagesProject Management Problem of CPMsyed emon100% (2)

- PM PertDocument4 pagesPM PertstormspiritlcNo ratings yet

- Social Studies For Brunei Darussalam Year 8 TextbookDocument152 pagesSocial Studies For Brunei Darussalam Year 8 TextbookChai Wei Chen100% (1)

- PMG201c SamplePE Fall2019 1Document7 pagesPMG201c SamplePE Fall2019 1Bui Minh Hieu BuiNo ratings yet

- BS 5839 2003 Fire Alarm SystemsDocument42 pagesBS 5839 2003 Fire Alarm SystemsJeffrey CaparasNo ratings yet

- CM CH10 Project ControlDocument20 pagesCM CH10 Project Controlmssrao1977No ratings yet

- Tutorial 3 - Project Network ModelDocument1 pageTutorial 3 - Project Network ModelMUSA AHMED ABDULLAHI ALINo ratings yet

- Systems Analysis and Design ITC 240: Tutorial 3Document3 pagesSystems Analysis and Design ITC 240: Tutorial 3Keanu ReevsNo ratings yet

- PROBLEM SOLVING NETWORK SCHEDULINGDocument6 pagesPROBLEM SOLVING NETWORK SCHEDULINGPrecy Joy TrimidalNo ratings yet

- PM Assigment 22Document13 pagesPM Assigment 22Eden teklemariamNo ratings yet

- Week5 TutorialSolutionsDocument14 pagesWeek5 TutorialSolutionskhadijjatariqNo ratings yet

- Ch.07 Gantt ChartDocument5 pagesCh.07 Gantt ChartPriyaNo ratings yet

- Problems On Network Diagram CPM 1Document2 pagesProblems On Network Diagram CPM 1Asima HumaNo ratings yet

- Tutorial 6Document4 pagesTutorial 6Puvithera A/P GunasegaranNo ratings yet

- CPM322E CH7 Project ControlDocument12 pagesCPM322E CH7 Project Controlpapilolo2008No ratings yet

- Project Management (Ecu 08604X) Tutorial Questions On CPM and PertDocument6 pagesProject Management (Ecu 08604X) Tutorial Questions On CPM and PertOLIVA MACHUMUNo ratings yet

- Network Analysis Questions and WorksheetDocument3 pagesNetwork Analysis Questions and WorksheetMarc WrightNo ratings yet

- PERT and critical path analysis questionsDocument6 pagesPERT and critical path analysis questionsVivienne Lei BolosNo ratings yet

- D31PT Dec14 TZ1Document3 pagesD31PT Dec14 TZ1Amir_Jamal_Qureshi0% (1)

- 1 PDFDocument3 pages1 PDFom100% (1)

- PERT Complete ExersicesDocument18 pagesPERT Complete ExersicesUmair MansoorNo ratings yet

- BC 170400916Document4 pagesBC 170400916aqsa ranaNo ratings yet

- Project Management 1723Document4 pagesProject Management 1723rajushamla9927No ratings yet

- Proj MGMTDocument26 pagesProj MGMTavantikaNo ratings yet

- Introduction To Project Management CPM and CrashingDocument15 pagesIntroduction To Project Management CPM and CrashingArindam VatsaNo ratings yet

- Critical Path AnalysisDocument4 pagesCritical Path AnalysisMarusaha MP SiahaanNo ratings yet

- Mock Final Exam Project Management 3.3.2023Document6 pagesMock Final Exam Project Management 3.3.2023Vũ Ngọc AnhNo ratings yet

- Instructions To Candidates:: Continued OverleafDocument3 pagesInstructions To Candidates:: Continued OverleafLisa DeosaranNo ratings yet

- Question:-: Construct A Table Which Shows The Relationship Between The Activities and Their PredecessorsDocument3 pagesQuestion:-: Construct A Table Which Shows The Relationship Between The Activities and Their PredecessorsMuhammadRizwanNo ratings yet

- Gujarat Technological UniversityDocument5 pagesGujarat Technological UniversityTNo ratings yet

- Problem Solving M7Document7 pagesProblem Solving M7Frances Mae Ortiz MaglinteNo ratings yet

- Resouce Scheduling Problem-UCR-A1Document1 pageResouce Scheduling Problem-UCR-A1Vikash KumarNo ratings yet

- ResourcesDocument11 pagesResourcesMontaser El DadahNo ratings yet

- Khaing Lae Thaw Assignment-2 ProjectDocument7 pagesKhaing Lae Thaw Assignment-2 ProjectJacqueline Ja Seng AungNo ratings yet

- CLASS ACTIVITIES GANTT PERTDocument16 pagesCLASS ACTIVITIES GANTT PERTchabatsanemega24No ratings yet

- Problem Set Network ModelsDocument3 pagesProblem Set Network ModelsCIAN CARLO ANDRE TANNo ratings yet

- Homework/Assignment: Answers/WorksDocument3 pagesHomework/Assignment: Answers/WorksChiNo ratings yet

- PPMP20010 Project Status Report - TemplateDocument3 pagesPPMP20010 Project Status Report - TemplateAnkit DholariyaNo ratings yet

- 14-CI-A7 Construction Project Management November 2016 SessionDocument6 pages14-CI-A7 Construction Project Management November 2016 SessionWael MaroukNo ratings yet

- Network Analysis Questions and Worksheet - July - 2022-Wednesdays and FridaysDocument2 pagesNetwork Analysis Questions and Worksheet - July - 2022-Wednesdays and FridaysMarc WrightNo ratings yet

- Project management techniques for critical path analysisDocument23 pagesProject management techniques for critical path analysisBee ParindaNo ratings yet

- TEST 1 ΑΠΟ ΑΣΚΗΣΗ 1-18Document11 pagesTEST 1 ΑΠΟ ΑΣΚΗΣΗ 1-18JerryNo ratings yet

- Project ControlDocument12 pagesProject ControlShridhar H MujumdarNo ratings yet

- Class: U14OE 601B-Project ManagementDocument2 pagesClass: U14OE 601B-Project ManagementN.vijay krishnaNo ratings yet

- Financial Analysis of Projects Paper C23 (2)Document5 pagesFinancial Analysis of Projects Paper C23 (2)Soham DeNo ratings yet

- Activity 7.6 - Module Problems: 495346184Document3 pagesActivity 7.6 - Module Problems: 495346184JayramNo ratings yet

- Module 7 - Activity 7.6 Problems Bill CohenDocument12 pagesModule 7 - Activity 7.6 Problems Bill CohenDouglas EspinozaNo ratings yet

- Activity On NodeDocument11 pagesActivity On NodeZain uddinNo ratings yet

- Home Work From PERTDocument5 pagesHome Work From PERTFreedom WolaytaNo ratings yet

- Assignment 3 4 5Document11 pagesAssignment 3 4 5Ayush GoyalNo ratings yet

- CPM & PERT Project Management TechniquesDocument66 pagesCPM & PERT Project Management Techniquessafoun peyalNo ratings yet

- Network Analysis: CPM & PertDocument32 pagesNetwork Analysis: CPM & Pertdebojyoti31No ratings yet

- Project Planning NotesDocument13 pagesProject Planning NotesEljah NjoraNo ratings yet

- Operational Management AssignmentDocument8 pagesOperational Management AssignmentLatambhat GmailNo ratings yet

- V BeltsDocument6 pagesV BeltsJeffrey CaparasNo ratings yet

- ValvesDocument86 pagesValvesJeffrey CaparasNo ratings yet

- Water Supply and Distribution Systems for Mid-Rise to High-Rise BuildingsDocument54 pagesWater Supply and Distribution Systems for Mid-Rise to High-Rise BuildingsJeffrey CaparasNo ratings yet

- Resd Load CalcDocument5 pagesResd Load CalcOre Ulil DesuNo ratings yet

- BS 5588-9 Fire Precautions in Designs, ConstructionsDocument30 pagesBS 5588-9 Fire Precautions in Designs, ConstructionsJeffrey CaparasNo ratings yet

- BS 5266 Part 7Document13 pagesBS 5266 Part 7Jeffrey CaparasNo ratings yet

- MGS 4301 Decision Making Sample ExerciseDocument1 pageMGS 4301 Decision Making Sample ExerciseMarielle AllouNo ratings yet

- Rizal's Extensive Travels Abroad for Education and Revolution (1882-1887Document6 pagesRizal's Extensive Travels Abroad for Education and Revolution (1882-1887Diana JeonNo ratings yet

- 302340KWDocument22 pages302340KWValarmathiNo ratings yet

- Xray Order FormDocument1 pageXray Order FormSN Malenadu CreationNo ratings yet

- Guidelines For Submitting An Article To Gesta: General InformationDocument1 pageGuidelines For Submitting An Article To Gesta: General InformationneddyteddyNo ratings yet

- Intensive ReadingDocument3 pagesIntensive ReadingKarina MoraNo ratings yet

- Roberson-FRIT 7236 Assessment PlanDocument13 pagesRoberson-FRIT 7236 Assessment PlanMarie RNo ratings yet

- Frame Fit Specifications 2019 MTB Components Rev CDocument167 pagesFrame Fit Specifications 2019 MTB Components Rev Cpicko 86No ratings yet

- SG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarDocument1 pageSG CD FR 175 Levelness V 531 Lmi 001 Firmar SellarLuis VelazcogarciaNo ratings yet

- Unit 1 Lesson 2 PDFDocument20 pagesUnit 1 Lesson 2 PDFKristyll ArguellesNo ratings yet

- American Cows in Antarctica R. ByrdDocument28 pagesAmerican Cows in Antarctica R. ByrdBlaze CNo ratings yet

- Jerome KaganDocument5 pagesJerome KaganMandeep morNo ratings yet

- The Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiDocument192 pagesThe Dilemma of Recognition Experienced Reality of Ethnicised Politics in Rwanda and BurundiShenandoa LeãoNo ratings yet

- B2 - PlatoDocument1 pageB2 - PlatoVeda Leigh SyNo ratings yet

- Module 1: Lecture 1 What Is Guidance?Document10 pagesModule 1: Lecture 1 What Is Guidance?Prakash RautNo ratings yet

- Uss Port Royal (CG 73)Document9 pagesUss Port Royal (CG 73)samlagroneNo ratings yet

- 2013 Course Structure BTech CSEDocument32 pages2013 Course Structure BTech CSEMankush JainNo ratings yet

- Well Plug and Abandonment Using HwuDocument1 pageWell Plug and Abandonment Using HwuJuan Pablo CassanelliNo ratings yet

- Abcd AirtelDocument12 pagesAbcd AirtelPrakhar RatheeNo ratings yet

- Math TestDocument3 pagesMath TestGhalyanAtulNo ratings yet