Professional Documents

Culture Documents

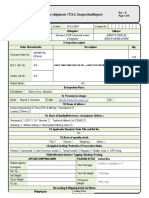

PNiaga Truck Tanker Checklist Rev 1.0

Uploaded by

Lee Kuok NgeiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PNiaga Truck Tanker Checklist Rev 1.0

Uploaded by

Lee Kuok NgeiCopyright:

Available Formats

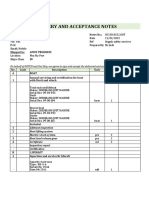

Rev 1.

INSPECTION CHECKLIST FOR TRUCKS/ TRUCK TANKER

Driver Representative : Signature : Company Name:

Lorry No: Trailer No.:

Date:

Terminal : (Bulk / LPG)

Please mark ✓ in the space provided and if applicable

No. Checklist ✓ X N/A Risk Guidelines Remarks

Part 1: Documents inspected

1 Valid driver and vocational license. H

Maximum of 15 years from 1st register (Refer to

2 Age of the truck/truck tanker H

Truck/Truck Tanker Greencard)

3 Road tax. H

4 PUSPAKOM/Passed periodic exams. H

5 Fire Extinguisher Certificate/ FIRE Certificate. H

The certificate and plate affixed to the truck tanker

6 Tank calibration certificate. H

are the same. Tank calibration is valid for 5 years.

7 No. emergency phone. M

Valid PMT certificate from JKKP (DOSH) for LPG bulk

8 Certificate Presurized Vessel (PMT) H

trucks.

No signs of leaks and certificates from

9 Hydrostatic test evidence. H

manufacturers or service records from third parties.

Part 2: Physical inspection (driver outside the cabin)

10 Wire connection. H No torn wire insulation and exposed wires.

Cables and connecting hoses/hydraulic hoses from "prime

11 H In good condition and no signs of cracking.

mover".

12 The tank is in good condition. H No signs of severe leaks and crushing.

The label is clear and the same as the tank

13 Label the size of the "compartment" on the tank. M

calibration certificate and plate.

Use an inspection mirror and a flashlight to look for

14 Foot valve & bottom tank pipe H

any signs of leaks.

15 30” hose (1.5” and 1 ”) & dust cap cover. M

16 Discharge valve. M No signs of leaks, moisture and dust.

17 Battery. H Covered and greased.

2 Nos. 9kg fire extinguishers in good condition.

18 Fire extinguisher. H

Green pressure marker.

The stickers are in good condition and have safety

19 Hazchem stickers. H

information and safety numbers.

20 Earthing Strip. M Touching the earth.

In good condition, no obvious or non -parallel

21 "Man-hole" and "PV vent" cover. H

damage.

Rev 1.0

INSPECTION CHECKLIST FOR TRUCKS/ TRUCK TANKER

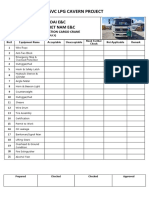

P/Mover

BDM:

BTM:

BG 1:

BG 2:

BG 3:

22 BTM/BDM (JPJ Standard) on the left. H

Trailer

BDM:

BTM:

BG 1:

BG 2:

BG 3:

At least 2 tyre spare with minimum of 2mm of tread

in a continuous band throughout the central three-

23 Spare tyre H

quarters of the tread width and over the whole

circumference of the tyre.

24 Safety cone. M Good condition and has reflective stickers.

25 First aid kit. M

26 Torchlight. L Explosion -proof and functional

27 Handrail in good condition. M

28 Pressure & Temperature Gauges (LPG Tanker). H Functional and clear.

29 Safety Nets (PETROS LPG Trucks only). H In good condition and no signs of tearing.

30 Truck Cleanliness (No web and clean) M

31 No severe damage and leakage to the truck structure. H

Only for new trucks entering Bulk Terminal only. The

32 The height of the truck H

height limit is 3.4m.

Part 3: Physical inspection (driver in the cabin)

33 Rear view mirror (left & right). H No cracks and view's interference.

34 Driver's mirror. H No cracks .

35 Seat belt (3 points) in good condition. H No tears and do the snap test.

Make sure there is no error indication on dashboard

36 "Speedometer" and "dashboard" work. M

while the engine is running.

37 "Foot paddle" works. H Anti - slip rubber is in good condition.

38 First aid kit. (No expired item recorded) M

39 Fire extinguisher in the cabin. H 1 nos 1kg Fire Extingusher and in good condition.

Instruct driver to activate the handbrake while the

40 Handbrake H

engine is running.

Activate the wiper's fluid and ensure there no

41 Wiper. H

residue left.

Make sure there is no significant dust discharge from

42 Exhaust H the exhaust system. Exhaust installed with Spark

Arrestor

No sign of crack/ broken and looseness. All lights are

43 Vehicle lights. H

fully function.

44 Alarms and reverse lights. H Function well.

Rev 1.0

INSPECTION CHECKLIST FOR TRUCKS/ TRUCK TANKER

Part 4: Safety Critical Equipment Inspection

Open all Foot Valves and activate Emergency Shut

45 Master Cut Off Switch/Emergency Shut Off H

Off. All Food Valve will close.

Use Overfill Sensor Tester and controlled by the

46 "Compartment Overfill Sensor" works H

Operator.

Ensure Pneumatic air have enough air supply. Lift up

guard bar and instruct driver to drive the truck

47 Interlock system: Guard Bar/loading arm manifold. H without raise up the Hand Brake. The truck should

be not moving/static. Make sure there is adequate

distance around truck to move.

Open stair's cover and instruct driver to drive the

truck without raise up the Hand Brake. The truck

48 Interlock system: stairs. H

should be not moving/static. Make sure there is

adequate distance around the truck to move.

Install Vapor Hose connector dan instruct driver to

drive the truck without raise up the Hand Brake. The

49 Interlock system: "vapor hose". H

truck should be not moving/static. Make sure there

is adequate distance around the truck to move.

Part 5: Tire inspection.

50 Tires In good condition and not bald. Tread depth 2mm and no nut loss. Use the diagram below for marking if there are any findings.

Additional Inspected by Operations Representative Checked by Securities Representative

Comment:

Name: Name:

Signature: Signature:

Date: Date:

You might also like

- Inspection Report FORMATDocument6 pagesInspection Report FORMATVinay Yadav100% (1)

- Mep Risk AssessmentDocument2 pagesMep Risk AssessmentIm Chinith100% (1)

- SA 9505 Fuel Tanker Inspection ChecklistDocument2 pagesSA 9505 Fuel Tanker Inspection ChecklistRabban100% (3)

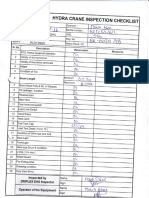

- Inspection Checklist HydraDocument1 pageInspection Checklist Hydraanon_106345234100% (1)

- Crane Inspection ChecklistDocument1 pageCrane Inspection ChecklistsudhakarNo ratings yet

- Dump Truck 740 CatDocument12 pagesDump Truck 740 Catkkmech100% (1)

- Monthly Walk Aroung Fuel Tanker Inspection ChecklistDocument1 pageMonthly Walk Aroung Fuel Tanker Inspection ChecklistRabban100% (1)

- Maintenance Checklist Land Mud CoolerDocument1 pageMaintenance Checklist Land Mud CoolerApneryanus LepingNo ratings yet

- Tanker Inspection ChecklistDocument5 pagesTanker Inspection ChecklistRachit GulatiNo ratings yet

- Legal Drafting Assignment 1 - Memorandum - Toy Squared - Peta Gaye Arthurs - Norman Manley Law School 2021/2022 - ScribdDocument6 pagesLegal Drafting Assignment 1 - Memorandum - Toy Squared - Peta Gaye Arthurs - Norman Manley Law School 2021/2022 - ScribdGetaNo ratings yet

- Sprinkler Report NFPA 25 03.27.13Document8 pagesSprinkler Report NFPA 25 03.27.13redbire100% (1)

- Petrol Station Checklist AuditDocument10 pagesPetrol Station Checklist AuditrizamryNo ratings yet

- Field Training Program On FTTH: Introduction To FTTH, PON Technologies FTTH Link Design Aspects FTTH Tariffs and PlansDocument60 pagesField Training Program On FTTH: Introduction To FTTH, PON Technologies FTTH Link Design Aspects FTTH Tariffs and Plansnetfrog100% (3)

- Location: Split A/C No.: Monthly PM Check List For SPLIT A/C'sDocument1 pageLocation: Split A/C No.: Monthly PM Check List For SPLIT A/C'ssiruslara6491No ratings yet

- Manual C4 C5Document78 pagesManual C4 C5Leslie Morales75% (4)

- Module 1 & 2Document55 pagesModule 1 & 2Amit TiwaryNo ratings yet

- Service Station Operators ChecklistDocument6 pagesService Station Operators Checklistdkishore28100% (1)

- LDV - Pre - Start ChecklistDocument1 pageLDV - Pre - Start ChecklistDavid Festus100% (1)

- Crane Pre Mobilization Check ListDocument2 pagesCrane Pre Mobilization Check ListvadivvelkavinNo ratings yet

- Hydro Test FormDocument2 pagesHydro Test FormAnonymous 6S9tcbhNo ratings yet

- Networking Straight-Through and Cross OverDocument25 pagesNetworking Straight-Through and Cross OverJan GolimanNo ratings yet

- Turbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionFrom EverandTurbine Main Engines: The Commonwealth and International Library: Marine Engineering DivisionRating: 5 out of 5 stars5/5 (4)

- Airconditioning Daily Maintenance ChecklistDocument1 pageAirconditioning Daily Maintenance ChecklistOdyssey Bartolome100% (1)

- RCD-PAU ChecklistDocument8 pagesRCD-PAU ChecklistPrabhaker AllampallyNo ratings yet

- Air Compressor-RegDocument1 pageAir Compressor-RegBeeNo ratings yet

- EHS VI 16 AmbulanceDocument1 pageEHS VI 16 Ambulanceshamshad ahamedNo ratings yet

- Air Compressor ChecklistDocument1 pageAir Compressor ChecklistJr FaizalNo ratings yet

- Concrete Truck and Mixing InformationDocument4 pagesConcrete Truck and Mixing InformationandyhrNo ratings yet

- Monthly Checklist Cargo CraneDocument1 pageMonthly Checklist Cargo CraneHong Hai PhamNo ratings yet

- EHS VI 08 FaranaDocument2 pagesEHS VI 08 Faranashamshad ahamedNo ratings yet

- Date: Decanted By:: Decantation ChecklistDocument4 pagesDate: Decanted By:: Decantation Checklistdjha3750% (2)

- Concrete Truck and Mixing InformationDocument4 pagesConcrete Truck and Mixing InformationMohammed Mammar KouadriNo ratings yet

- Monthly Vehicle Safety Inspection ChecklistDocument1 pageMonthly Vehicle Safety Inspection ChecklistMatthewBennettNo ratings yet

- 2012 Van Biosecurity Checklist v2Document4 pages2012 Van Biosecurity Checklist v2philson aceronNo ratings yet

- Installation Checklist For Fire PumpsDocument1 pageInstallation Checklist For Fire PumpsAmie GTunedNo ratings yet

- Dos and Donts For Pol Tank Truck Unloading at Customer'S PremisesDocument1 pageDos and Donts For Pol Tank Truck Unloading at Customer'S PremisesAkshay SuryawanshiNo ratings yet

- TT Decantation Procedure 2Document3 pagesTT Decantation Procedure 2pushpak lamjaneNo ratings yet

- Power Transformer - For SwitchayrdDocument20 pagesPower Transformer - For SwitchayrdSindhuKumarNo ratings yet

- EHS-VI-10-Tower CraneDocument1 pageEHS-VI-10-Tower Craneshamshad ahamedNo ratings yet

- HSE Inspection Form 2.1.1 - Boom Truck Daily Inspection Checklist Rev BDocument1 pageHSE Inspection Form 2.1.1 - Boom Truck Daily Inspection Checklist Rev BMuhammad hussainNo ratings yet

- 4.tipper Checklist OKDocument2 pages4.tipper Checklist OKPradeep SharmaNo ratings yet

- Checklist 20211102 0001Document7 pagesChecklist 20211102 0001Ritesh kumarNo ratings yet

- N2 Tank STEM 1 ChecklistDocument1 pageN2 Tank STEM 1 ChecklistJIHED PRIMA PHONESTORENo ratings yet

- Bunkering Safety ChecklistDocument1 pageBunkering Safety ChecklistZakariya KareemNo ratings yet

- Reactor - For SwitchayrdDocument10 pagesReactor - For SwitchayrdSindhuKumarNo ratings yet

- AhuDocument1 pageAhusiruslara6491No ratings yet

- Inspection Fact Sheet Remote Operated Choke Units - R42 V2 May2010Document1 pageInspection Fact Sheet Remote Operated Choke Units - R42 V2 May2010eng7mohamed7hashimNo ratings yet

- HWDocument20 pagesHWAnonymous zpitrB80oNo ratings yet

- MTV Checklist OKDocument2 pagesMTV Checklist OKPradeep SharmaNo ratings yet

- REPORT NO.-TUVAT/2015/2412/056/BULLDOZER/025: Bangladesh Erectors LimitedDocument2 pagesREPORT NO.-TUVAT/2015/2412/056/BULLDOZER/025: Bangladesh Erectors LimitedMirajul AnwarNo ratings yet

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- ATV Inspection - Check List OKDocument2 pagesATV Inspection - Check List OKPradeep SharmaNo ratings yet

- Tunnel Loading Machine ITC 120N #0516 Check MinutesDocument24 pagesTunnel Loading Machine ITC 120N #0516 Check MinutesARMANDO ROJO100% (1)

- 1340 Hse FRM - 16 Crane Safety ChecklistDocument1 page1340 Hse FRM - 16 Crane Safety Checklistvenkateshr.193No ratings yet

- Checklist Mini RollerDocument9 pagesChecklist Mini Rollershamshad ahamedNo ratings yet

- C0M-07 FRP Tank-VesselDocument2 pagesC0M-07 FRP Tank-VesselHong Trung DuongNo ratings yet

- Check List Freight TransportationDocument9 pagesCheck List Freight TransportationScribdTranslationsNo ratings yet

- F-LLS-02c - International Loadline Survey ChecklistDocument3 pagesF-LLS-02c - International Loadline Survey Checklistmtgeneral3cobNo ratings yet

- Transformer Test Report: Transformers Technical Data Field Service RepresentiveDocument14 pagesTransformer Test Report: Transformers Technical Data Field Service RepresentiveAldhi PriambudiNo ratings yet

- Power Transformer (110kV/66kV/33kV/22kV) General:: The Tata Power Company LTDDocument3 pagesPower Transformer (110kV/66kV/33kV/22kV) General:: The Tata Power Company LTDSaiyan PrideNo ratings yet

- Check List Truck MixerDocument4 pagesCheck List Truck MixeralongNo ratings yet

- Bien Ban Nghiem Thu Ban Giao (S3-21) .Document3 pagesBien Ban Nghiem Thu Ban Giao (S3-21) .Quang DoanNo ratings yet

- Rake Test LHBDocument17 pagesRake Test LHBManoj BairwaNo ratings yet

- Telescopic Boom Pre-Mob Inspection Report: Description To Be CheckedDocument28 pagesTelescopic Boom Pre-Mob Inspection Report: Description To Be CheckedyogiNo ratings yet

- Atul Anand. Appointment LetterDocument2 pagesAtul Anand. Appointment Letteramritam yadavNo ratings yet

- E Brochure-Fdc PDFDocument6 pagesE Brochure-Fdc PDFJahjaNo ratings yet

- What Is Further InvestigationDocument6 pagesWhat Is Further Investigationmohit kumarNo ratings yet

- Bag Filters: Amerseal Cube Filters Dripak Dripak 2000Document4 pagesBag Filters: Amerseal Cube Filters Dripak Dripak 2000Bayu SamudraNo ratings yet

- Pertemuan 4. KewirausahaanDocument27 pagesPertemuan 4. KewirausahaanSalsabila LuthfiNo ratings yet

- Quiz 1 RepairedDocument6 pagesQuiz 1 RepairedTran Pham Quoc ThuyNo ratings yet

- Luca Utzeri, A087 211 857 (BIA July 16, 2014)Document10 pagesLuca Utzeri, A087 211 857 (BIA July 16, 2014)Immigrant & Refugee Appellate Center, LLCNo ratings yet

- Magdusa vs. AlbaranDocument4 pagesMagdusa vs. AlbaranXtine CampuPotNo ratings yet

- Film Processor: Operation ManualDocument42 pagesFilm Processor: Operation ManualCamila LopezNo ratings yet

- Revised Penal CodeDocument31 pagesRevised Penal CodeArchie AgustinNo ratings yet

- Binary-to-BCD Converter: Basic IdeaDocument5 pagesBinary-to-BCD Converter: Basic IdeaNguyễn LongNo ratings yet

- Chapter 1Document10 pagesChapter 1Jean Salaveria CenasNo ratings yet

- HP LaserJet 3200 Service ManualDocument252 pagesHP LaserJet 3200 Service ManualstevanreljicNo ratings yet

- Name: Case Study On Organizational EfficiencyDocument2 pagesName: Case Study On Organizational EfficiencyLoriel50% (2)

- TYBAF 138 Mohnish MehtaDocument10 pagesTYBAF 138 Mohnish MehtaKomal JainNo ratings yet

- Volatile Matter - Technical Visit ICC 2023Document8 pagesVolatile Matter - Technical Visit ICC 2023ICC Independent Cement ConsultantsNo ratings yet

- Manual TV Sansumg UN40F5500Document170 pagesManual TV Sansumg UN40F5500albafloNo ratings yet

- Technical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet P 800 M P 800 M P 800 M P 800 MDocument4 pagesTechnical Data Sheet Technical Data Sheet Technical Data Sheet Technical Data Sheet P 800 M P 800 M P 800 M P 800 MMounir YousfiNo ratings yet

- Jose C. Guico For Petitioner. Wilfredo Cortez For Private RespondentsDocument5 pagesJose C. Guico For Petitioner. Wilfredo Cortez For Private Respondentsmichelle m. templadoNo ratings yet

- Literature Review UnemploymentDocument2 pagesLiterature Review UnemploymentMalik MuzaffarNo ratings yet

- Design Impact: Darin Grice Creates New Protective HeadgearDocument2 pagesDesign Impact: Darin Grice Creates New Protective HeadgearspencergriceNo ratings yet

- Canon Ir3300 BrochureDocument6 pagesCanon Ir3300 BrochurenazmiNo ratings yet

- Electronic Theses and Dissertations (Etds)Document208 pagesElectronic Theses and Dissertations (Etds)jasimnddNo ratings yet

- SPJ RB Script Group 3 - Final 1 1.2 2Document7 pagesSPJ RB Script Group 3 - Final 1 1.2 2YamSiriOdarnohNo ratings yet