Professional Documents

Culture Documents

Maintenance Checklist Land Mud Cooler

Uploaded by

Apneryanus LepingCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Maintenance Checklist Land Mud Cooler

Uploaded by

Apneryanus LepingCopyright:

Available Formats

Sheet 1 of 1

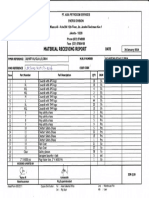

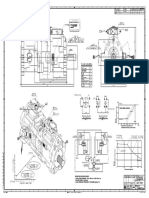

Mud Cooler Service Procedure

Customer: Location: Job No:

Equipment Type:

Date: Rig: Serial No:

Asset No:

MUD COOLER CHECK LIST

Service Interval Period

If OK mark box with If there is a fault or damage mark box with an X and make comment at the bottom of the sheet Daily / Weekly / 1 month / 6Month & W'shop ✓

Ensure Equipment is Isolated with all lock out tags prior to service Daily Weekly Monthly 6 Month OK Replace Engineers Name Date

Daily/Weekly Checklist

1. Check overall condition of Mud Cooler skid for damage or welding cracks X X

2. Check that there are no visible leakages from the plate pack, valves or piping system X X

3. Check that all the tightening bolts are firmly tightened, clean and measure is correct X X

4. Check all valves on strainer in good function, no leak. Clean up filter basket/strainer min.every 4x /day depend on cuttings volume in mud X X

5. Check all pressure/temperature gauges are in good function, replace if you get a broken gauge. X X

6. Check oil water pump, make sure hose, valve in good condition with water line that leads to the spray. Replace spray if you get a broken X X

7. Make sure water spray works optimally to cool the mud flowing through the brass pipe. X X

8. Check water pump 2x3. Determine if the mechanical seal conditions are normal. Apply grease and check for noisy bearings and cavitation. X X

9. Check 2 unit exhaust fan. Make sure all component in good condition and safe. Regularly check fan blade and AC motor (Ampere) X X

10. Make sure the water reservoir underneath the mud cooler's pipe is always in a clean condition and drained regularly. If the water is brown, X X

11. Check the brass pipe, most likely there is a leak in the pipe. X X

12. Check for water line leaks at the mud inlet and outlet, and make sure all brass pipes are in good condition/not leaking X X

13. Ensure all bolt of flanges, valves are clean and greased X X

14. Check mud hog/centrifugal pump. Apply grease and check for noisy bearings and cavitation. Make sure valve, hose in good condition. X X

15. Ensure all bolt of flanges, valves are clean and greased X X

16. While Mud cooler in running or after MC shutdown, filter baskets are to be cleaned daily. Make sure all valves in good function. X X

17. Backflush the Mud Cooler for about 10 minutes using fresh mud, can prevent damage to brass pipes due to cuttings. Do regularly X X

18. Daily record running hours of Mud Cooler, temperature and pressure in mud/sea water line X X

Monthly Checklist

1. Check mud centrifugal pump. Add oil/apply grease to the bearing reservoirs, if required. Clean oiler bulbs and level windows as required. X

2. Replace guards of centrifugal pump (repair if required). Determine if pump unit requires general cleaning by others X

3. Inspect mounting of exhaust fan, make sure there are no cracks on the surface. Make sure all blade of exhaust fan in good condition. X

4. Check water pump. Add oil/apply grease to the bearing reservoirs, if required. Clean oiler bulbs and level windows as required. X

5. Determine if pump unit requires general cleaning by others. X

6. Do backflushing inside mud line with base oil, or fresh mud. Regularly check all valve, brass pipe, suction and discharge line (no leaking). X

7. Regularly drain water underneath brass pipe and fill up the new water for the next operation. X

8. Inspect all sling and pad eye. Make sure all sling in safe area, clean. X

9. Inspect all valve on strainer. Make sure in good function, replace if malfunction/damage X

10. Regularly check all AC motor: centrifugal pump, water pump, exhaust fan. Make sure all in safe condition and clean. X

6-Month Checklist Note: Check for any metal particles on magnetic plugs when checking oil

1. .Inspect all brass pipe, make sure all clean inside. Do corrective action/repair if you get any pipe leaking. X

2. Apply a light coat of rust preventive product to expose machined surfaces to prevent rust and corrosion. X

3. Check water pump and mud centrifugal pump shaft centerline. Adjust if necessary. X

4. Apply grease/change oil for water pump and centrifugal pump. Make sure the mechanical seal still in good function, replace if any damage. X

5. Check all protection plates, bolt, skid of mud cooler, ensure in good condition. Painting job X

6. Inspect all fan cover, insulation and bearings of AC motor: centrifugal pump, water pump and exhaust fan. Make sure all in good function. X

7. Ensure all valve in good condition, pressure/temperature gauge, and replace if any damage X

8. Inspect all blades of exhaust fan. Make sure working normal, replace if necessary. X

Note: If major refurbishment is required all components to be removed for blasting and painting

Service Comments:-

DWM Engineer Supervisor Approval

Serviced by: Accepted by:

Signature:- Signature:-

You might also like

- Monthly HVAC Maint. ScheduleDocument5 pagesMonthly HVAC Maint. ScheduleTawfeeq AhmedNo ratings yet

- Oil Based Rig Maintenance ReportDocument12 pagesOil Based Rig Maintenance Reportelmaadawy2002No ratings yet

- Equipment O&M ChecklistsDocument11 pagesEquipment O&M ChecklistsAsebaho BadrNo ratings yet

- Chapter 12 Physical Inventory and Warehouse ManagementDocument4 pagesChapter 12 Physical Inventory and Warehouse ManagementKamble AbhijitNo ratings yet

- API5b Changes in 16th EditionDocument4 pagesAPI5b Changes in 16th EditionMostafa FikryNo ratings yet

- Frontier School Division Job Safety Analysis for Milling Machine OperationsDocument5 pagesFrontier School Division Job Safety Analysis for Milling Machine OperationsAshok SureshNo ratings yet

- Pump Maintenance ChecklistDocument2 pagesPump Maintenance ChecklistNishanth Gabriel100% (4)

- Tesco Corporation: Unit #: Date: Operating DaysDocument1 pageTesco Corporation: Unit #: Date: Operating Daysboy tryadiNo ratings yet

- Compressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019Document2 pagesCompressive Testing Machine Check List - TPLIPMSSAFETYCTMCL048 Rev00 Dt.22.10.2019MOHAMMEDNo ratings yet

- Skid Wheel Loader Daily ChecklistDocument1 pageSkid Wheel Loader Daily ChecklistAbdus SamadNo ratings yet

- Fire Extinguisher Inspection, Maintenance and Testing ProceduresDocument5 pagesFire Extinguisher Inspection, Maintenance and Testing ProceduresSumathi Sundaram SundaramNo ratings yet

- MaxiRider ManualDocument36 pagesMaxiRider ManualSalam Elec fsuptNo ratings yet

- Broiler Preventive Maintenance ChecklistDocument5 pagesBroiler Preventive Maintenance ChecklistFaysbuk KotoNo ratings yet

- Safe Man Riding LiftsDocument2 pagesSafe Man Riding Liftsreda mesbahNo ratings yet

- Maintenance Instruction V03Document18 pagesMaintenance Instruction V03Farooq AhmadNo ratings yet

- DEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATADocument2 pagesDEN-CON TOOL ELEVATOR MAINTENANCE INSPECTION DATAHector BarriosNo ratings yet

- WINEWISE-Water Management ChecklistDocument3 pagesWINEWISE-Water Management ChecklistCCRNo ratings yet

- Mechanic CV Template PDFDocument2 pagesMechanic CV Template PDFJovana891No ratings yet

- Borang Pemeriksaan Air KompressorDocument1 pageBorang Pemeriksaan Air KompressorAndara Asifa YudianaNo ratings yet

- RA Elevator ManualDocument8 pagesRA Elevator ManualBahman MatouriNo ratings yet

- Daily Factory Cleaning Sheet ChecklistDocument5 pagesDaily Factory Cleaning Sheet ChecklistSaroj KatwalNo ratings yet

- Responsibilities of Rig Superintendent StudyDocument7 pagesResponsibilities of Rig Superintendent StudyAnonymous VNu3ODGavNo ratings yet

- 26 - Welding Machine ChecklistDocument1 page26 - Welding Machine ChecklistZeeshan AbbasiNo ratings yet

- BHDC - 37 WQDocument12 pagesBHDC - 37 WQAli HusseinNo ratings yet

- 1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceDocument2 pages1-11-B 1. Tools and Equipment: Deadline Anchor MaintenanceAbdul Hameed OmarNo ratings yet

- Check ListDocument88 pagesCheck ListRaafat SaadNo ratings yet

- PREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINEDocument1 pagePREVENTIVE MAINTENANCE CHECKLIST FOR POWER PRESS MACHINESanjay MalhotraNo ratings yet

- Daily crane checklistDocument1 pageDaily crane checklistPablo Hidalgo ValenzuelaNo ratings yet

- PM Schedule Plan For All MachinesDocument32 pagesPM Schedule Plan For All MachineskumaresanNo ratings yet

- CP-MP-001 Mud PumpsDocument6 pagesCP-MP-001 Mud PumpsEd CalheNo ratings yet

- Coiled Tubing Troubleshooting SolutionsDocument6 pagesCoiled Tubing Troubleshooting SolutionsMohamed HashemNo ratings yet

- LCI 750SpecSheetDocument5 pagesLCI 750SpecSheetandy131078100% (1)

- 30-100 High-Torque Casing Tong: ApplicationsDocument1 page30-100 High-Torque Casing Tong: ApplicationsLuis Arreaza BelisarioNo ratings yet

- Chiller ChecklistDocument2 pagesChiller Checklistmk saravanan100% (1)

- Form-I-010 Welding Machine Inspection Form: Carry-In CertificateDocument1 pageForm-I-010 Welding Machine Inspection Form: Carry-In CertificateAdhy DarmawanNo ratings yet

- Daily Checklist For DGDocument2 pagesDaily Checklist For DG7Days Facility ManagementNo ratings yet

- Temporary Pipe Installation GuideDocument17 pagesTemporary Pipe Installation GuideTeguh Setiono100% (1)

- Welding Machine ChecklistDocument34 pagesWelding Machine ChecklistShahid BhattiNo ratings yet

- Daily Check List For B.O.PDocument1 pageDaily Check List For B.O.Payman akrab100% (1)

- Care and Use Guide Rig Mate Creeper WinchDocument8 pagesCare and Use Guide Rig Mate Creeper Winchmoha19841No ratings yet

- Lower the Mast SOPDocument2 pagesLower the Mast SOPakv9005No ratings yet

- Almansoori Inspection Services: Lifting Equipment Thorough Examination ReportDocument1 pageAlmansoori Inspection Services: Lifting Equipment Thorough Examination ReportRanjithNo ratings yet

- Checklist RigDocument104 pagesChecklist RigKiryaki Francis100% (2)

- Month - Year - Iq Series Maintenance LogDocument2 pagesMonth - Year - Iq Series Maintenance Logrqu3lNo ratings yet

- Procedure For Agriculture InspectionDocument2 pagesProcedure For Agriculture InspectionPariksha AryaNo ratings yet

- Cautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCEDocument2 pagesCautery Machines and Electrosurgical Units PREVENTIVE MAINTENANCERaymond Ogi100% (2)

- IRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistDocument3 pagesIRE ETS: Uc Davis Fire Prevention Self Inspection ChecklistAsif HameedNo ratings yet

- SW-800 Sidewinder Mixer Installation GuideDocument18 pagesSW-800 Sidewinder Mixer Installation GuideHugo VillcaNo ratings yet

- Zj704500drigcomponentsspecificationagreement PDF FreeDocument102 pagesZj704500drigcomponentsspecificationagreement PDF FreeH 8CNo ratings yet

- Preventive Maintenance of Water Chiller For Blister Packing Machine Converted 2Document2 pagesPreventive Maintenance of Water Chiller For Blister Packing Machine Converted 2Moshi KayandaNo ratings yet

- Method For Cleaning Concrete TankDocument3 pagesMethod For Cleaning Concrete TankSpecial MahooNo ratings yet

- PPM Task Sheet - MPGSDocument4 pagesPPM Task Sheet - MPGSJacobNo ratings yet

- Maintenance Schedule For BOP - 5131086 - 01Document4 pagesMaintenance Schedule For BOP - 5131086 - 01franko guddiNo ratings yet

- 20-1718 Rig Tongs AOTDocument10 pages20-1718 Rig Tongs AOTRahul M.R100% (1)

- Centrifugal Pump ChecklistDocument1 pageCentrifugal Pump ChecklistApneryanus LepingNo ratings yet

- Preventative-Maintenance-ChecklistDocument1 pagePreventative-Maintenance-ChecklistShafiulla BaigNo ratings yet

- Pressurized Air Shock BlowingDocument3 pagesPressurized Air Shock BlowingEmir PayNo ratings yet

- HVAC Maintenance ActivitiesDocument23 pagesHVAC Maintenance ActivitiesLungisaniNo ratings yet

- 5 Maintenance Procedures: 5-1 Introduction 5-2 Maintenance Matrix 5-3 Rainwater Drainage SystemDocument3 pages5 Maintenance Procedures: 5-1 Introduction 5-2 Maintenance Matrix 5-3 Rainwater Drainage SystemKadiri OlanrewajuNo ratings yet

- Preventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSDocument1 pagePreventative Maintenance Activity A B C D E: Type of Visit For Each Specific Year, Running Hours Per Year 8000 HRSSeif AlbaghdadyNo ratings yet

- Thorough Offshore Container Examination ReportDocument14 pagesThorough Offshore Container Examination ReportApneryanus LepingNo ratings yet

- Work Order: Modifikasi Centrifugal Pump 3 Inch (S/N GPB-CP43-01)Document1 pageWork Order: Modifikasi Centrifugal Pump 3 Inch (S/N GPB-CP43-01)Apneryanus LepingNo ratings yet

- MRR 013 Cover All Complete & Plug Valve 2 X 6000 PsiDocument1 pageMRR 013 Cover All Complete & Plug Valve 2 X 6000 PsiApneryanus LepingNo ratings yet

- Pressure Test ProceduresDocument4 pagesPressure Test ProceduresApneryanus LepingNo ratings yet

- Retort Analysis For Drilling Fluid EquipmentDocument2 pagesRetort Analysis For Drilling Fluid EquipmentApneryanus LepingNo ratings yet

- Retort Kit, 50 ML: Drilling Fluids EquipmentDocument2 pagesRetort Kit, 50 ML: Drilling Fluids EquipmentApneryanus LepingNo ratings yet

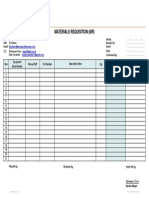

- MR004 - PetronasDocument1 pageMR004 - PetronasApneryanus LepingNo ratings yet

- Workshop Man Hours Form 2022Document1 pageWorkshop Man Hours Form 2022Apneryanus LepingNo ratings yet

- Contoh Pengisian Work Order Maintenance RT 751Document1 pageContoh Pengisian Work Order Maintenance RT 751Apneryanus Leping100% (1)

- Material Request Form 2022Document1 pageMaterial Request Form 2022Apneryanus LepingNo ratings yet

- List Inventory Equipment & MaterialDocument1 pageList Inventory Equipment & MaterialApneryanus LepingNo ratings yet

- List Material & Fab Work For Discharge Line Overboard - CSL PowerDocument1 pageList Material & Fab Work For Discharge Line Overboard - CSL PowerApneryanus LepingNo ratings yet

- Soal FisikaDocument1 pageSoal FisikaApneryanus LepingNo ratings yet

- Centrifugal Pump ChecklistDocument1 pageCentrifugal Pump ChecklistApneryanus LepingNo ratings yet

- 414 Specifications ModifiedDocument5 pages414 Specifications ModifiedApneryanus LepingNo ratings yet

- 5.1 Daily Operations - Startup and ShutdownDocument1 page5.1 Daily Operations - Startup and ShutdownApneryanus LepingNo ratings yet

- DiketahuiDocument1 pageDiketahuiApneryanus LepingNo ratings yet

- Handok Hydraulic - Co: Flow Rate ControlDocument1 pageHandok Hydraulic - Co: Flow Rate Controlanon_485665212No ratings yet

- Lab Note 10 Lab Manual-Heat PumpDocument11 pagesLab Note 10 Lab Manual-Heat Pumpfarah nabila100% (1)

- Fuel System PR TestDocument1 pageFuel System PR TestbejoythomasNo ratings yet

- 1260 Infinity Quaternary Pump VL User ManualDocument230 pages1260 Infinity Quaternary Pump VL User ManualsaidvaretNo ratings yet

- Chapter-2 Drilling Fluids: BariteDocument27 pagesChapter-2 Drilling Fluids: BariteAnggita Dwi LiestyosiwiNo ratings yet

- Restrictors and Compensation of Hydrostatic Bearings - Rowe PDFDocument7 pagesRestrictors and Compensation of Hydrostatic Bearings - Rowe PDFramaanan0% (2)

- Hi Pressure Plunger Pump KPDDocument25 pagesHi Pressure Plunger Pump KPDengrtahir100% (1)

- MT Megachem A2740 0e 5Document22 pagesMT Megachem A2740 0e 5rafael batista de paulaNo ratings yet

- Caterpillar d5b Crawler Parts Manual SN 26x878 and UpDocument8 pagesCaterpillar d5b Crawler Parts Manual SN 26x878 and UpCarmen GarciaNo ratings yet

- Automatic Fuel Oil Transfer Pump Set - DatasheetDocument5 pagesAutomatic Fuel Oil Transfer Pump Set - Datasheetfrankz89No ratings yet

- DokwegII - Auxiliary - Maintenance Oil SystemDocument51 pagesDokwegII - Auxiliary - Maintenance Oil SystemCarlin BabuchasNo ratings yet

- KKS Designation System KKS Designation SystemDocument19 pagesKKS Designation System KKS Designation Systemdexter schmithNo ratings yet

- Prevent Pipe Collapse and Bursting with HWE Air Cushion ValveDocument1 pagePrevent Pipe Collapse and Bursting with HWE Air Cushion ValveniranpaiNo ratings yet

- Submersible Wastewater Pumps With Single Vane Impeller 3" Discharge - 2" SolidsDocument2 pagesSubmersible Wastewater Pumps With Single Vane Impeller 3" Discharge - 2" SolidsAdemir JúniorNo ratings yet

- Ro-En Manual Purtificadora AguaDocument2 pagesRo-En Manual Purtificadora AguaRamiro BravoNo ratings yet

- Bomba Hidraulica Sauer Sustran Serie 90Document88 pagesBomba Hidraulica Sauer Sustran Serie 90mantenedor01100% (1)

- Avds 1790Document17 pagesAvds 1790alexNo ratings yet

- Imm WGZ 2Document60 pagesImm WGZ 2cesar luis gonzalez rodriguezNo ratings yet

- Hydraulics Lecture 2 Part 2Document10 pagesHydraulics Lecture 2 Part 2Desiree RobisoNo ratings yet

- Pelletizing Systems: Gala PelletizersDocument12 pagesPelletizing Systems: Gala PelletizersjjpenetoNo ratings yet

- HWP Datasheet Full-SetDocument10 pagesHWP Datasheet Full-SetPhan Công ChiếnNo ratings yet

- Mud Max Mud Max Compact: Centrifugal Pump Series 250Document32 pagesMud Max Mud Max Compact: Centrifugal Pump Series 250Hussein MohamedNo ratings yet

- Emergency Air FailureDocument17 pagesEmergency Air Failureabhrrajjit SANo ratings yet

- Swimming Pool TechnologyDocument166 pagesSwimming Pool Technologydanateo100% (1)

- Deaerators Explained HandbookDocument14 pagesDeaerators Explained HandbookABRAR KHALILNo ratings yet

- PCM and Hydration UnitsDocument64 pagesPCM and Hydration UnitsBabak Salimifard100% (3)

- Approved Vendor and Subcontractor ListDocument19 pagesApproved Vendor and Subcontractor ListAnand LakshmananNo ratings yet

- Module 1.4 - PumpsDocument16 pagesModule 1.4 - PumpsnavneetNo ratings yet

- OSBL-ETP Instrument ListDocument28 pagesOSBL-ETP Instrument ListINDRAJIT SAONo ratings yet

- User Manual - M42 PDFDocument112 pagesUser Manual - M42 PDFDương Văn KiênNo ratings yet