Professional Documents

Culture Documents

CHECKLIST FOR UPGRADING HIGHWAY PAVEMENT

Uploaded by

Ismail MydeenOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

CHECKLIST FOR UPGRADING HIGHWAY PAVEMENT

Uploaded by

Ismail MydeenCopyright:

Available Formats

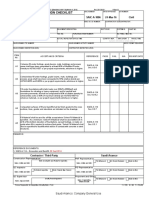

CHECK LIST - Pavement Road Works

UPGRADING OF E15 HIGHWAY from GHAYATHI to RUWAIS

Project Name Employer Abu Dhabi General Services Company,Musanada

(PHASE 1)

Client DOT Department of Transport Engineer AAW Consulting Engineers

Contractor BIN HAFEEZ GEN. CONT. L.L.C. WIR Ref: 54350-00SIT-GE-BHG119-CRW-WIR-

Checklist Title: Check List For Pavement Road Works Checklist No. 54350-00SIT-GE-BHG119-CRW-FRM-0010-0

Works Location: As per WIR Related ITP # 54350-00SIT-GE-BHG119-CRW-ITP-0010-02

Related Drawing(s) As per WIR Related MS # 54350-00SIT-GE-BHG119-CRW-MST-0010-0

Status - Acceptable

SN Stage Description of checking to be carried out Remarks

Yes No NA

Check required NOC from concern Authorities

Check Existing Utilities /Services Prior starting of work through Trial Trench

1 Prior Activities Ensure sampling of existing material to check suitability has been done.

Ensure the setting out of line and level through survey as per approved shop

drawings

Road Check Coordinates, levels, depth, and width as per approved shop drawings.

Check compacted density ≥ 95% MDD.

2 Formation level at existing Check CBR ≥ 10.

soil Check levels, inspect for any soft spongy areas.

Check thickness as per approved shop drawings.

Check Coordinates, levels, depth, and width as per approved shop drawings.

3 Embankment Check compacted density ≥ 95% MDD.

Check CBR ≥ 20

Check thickness as per approved shop drawings.

Check Coordinates, levels, depth, and width as per approved shop drawings.

4 Imported Fill / Sub-grade Check compacted density ≥ 95% MDD.

Check CBR ≥ 30

Installation of Geotextile Check type of material as per approved material approval.

Check for absence of any wrinkles, fold, holes, rips, or damages.

5 (In Case Water Check overlapping. Check that geotextile installed to enclose the pervious backfill

Logged Area) material.

Pervious Backfill Material-

Check thickness as per approved shop drawings.

Type III & V

6 Check Coordinates, levels, depth, and width as per approved shop drawings.

(In Case Water Check compaction vusually at least 8 passess.

Logged Area)

Check thickness as per approved shop drawings.

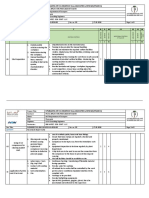

Recycled Crushed Check Coordinates, levels, depth, and width as per approved shop drawings.

7

Aggregate Sub base course Check compacted density 100% MDD with no single value below 98%. Check

CBR ≥ 120

Check thickness as per approved shop drawings.

Recycled Crushed Check Coordinates, levels, depth, and width as per approved shop drawings.

9 Check compacted density 100% MDD with no single value below 98%. Check

Aggregate Base course

CBR ≥ 120

Check thickness as per approved shop drawings.

Recycled Crushed Check Coordinates, levels, depth, and width as per approved shop drawings.

8

Aggregate Wet mix Check compacted density 100% MDD with no single value below 98%. Check

CBR ≥ 80

Check surface of aggregate base course is free of excessive dust, dirt and loose

soil prior to apply prime coat.

10 Prime coat Check temperature of prime coat within 60° C and 85° C .

Check that rate of application 0.25 to 0.50 kg/m2 .

Check surface of asphalt base course including the faces of the joints contact

surfaces of curbs, gutters, manholes and similar structures are painted with thin

11 Tack Coat uniform coating of tack.

Check that rate of application maximum rate of 0.50 kg/m2

Check delivery note as per required asphalt mix design.

Check temperature not less than 135 ˚C and not more than 163 ˚C.

Asphalt Base/Binder/ Check sample taken by site Laboratory for quality test.

12 Check Coordinates, levels, depth, and width as per approved shop drawings.

Wearing Course

Check density and core thickness.

Check surface irregularity test Base/Binder: ±6mm and Wearing: ±4mm

Remarks:

Accompanying document :

For Contractor

For Supervision Consultant (Engineer)

Quality Inspector Quality Engineer

Name

Signature

Date

Form Ref: TMT114, Rev-1, Date: 09-Feb-17

You might also like

- Field Book for Quality Control in Earthwork Operations: Project Construction Management BookFrom EverandField Book for Quality Control in Earthwork Operations: Project Construction Management BookNo ratings yet

- CL 0010 00Document1 pageCL 0010 00Ismail MydeenNo ratings yet

- Quality Control of The Road PDFDocument73 pagesQuality Control of The Road PDFHamze Mahdi100% (1)

- Quality Control & Quality Assurance in National HighwaysDocument76 pagesQuality Control & Quality Assurance in National HighwaystauheedrameezNo ratings yet

- A Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Document5 pagesA Guide For FLUOR & BASF Painting Specification of Typical Storage Tanks (Part 03 of 05)Adam Michael GreenNo ratings yet

- Construction of Water Tanks Work InstructionDocument6 pagesConstruction of Water Tanks Work InstructionHiren ThakkarNo ratings yet

- HHHI Compaction ChecklistDocument3 pagesHHHI Compaction ChecklistShabbar Abbas MalikNo ratings yet

- Inspection Report-Hdpec BlankDocument2 pagesInspection Report-Hdpec BlankJoseph Perez100% (1)

- LNG-80-100937-RA-6065-00023-0000 HT PipingDocument7 pagesLNG-80-100937-RA-6065-00023-0000 HT PipingMohammad AftabNo ratings yet

- Final Fill Inspection ChecklistDocument1 pageFinal Fill Inspection ChecklistShabbar Abbas MalikNo ratings yet

- Inspection: Kenneth A. Trimber and William D. CorbettDocument26 pagesInspection: Kenneth A. Trimber and William D. CorbettvvpvarunNo ratings yet

- Spec - Rev A.groundworksDocument10 pagesSpec - Rev A.groundworksery achjariNo ratings yet

- GRP Inspection Report SummaryDocument2 pagesGRP Inspection Report SummaryJoseph Perez100% (1)

- Procedure For LPTDocument8 pagesProcedure For LPTmd quasid rabbaniNo ratings yet

- API 650 Tank Fabrication and Inspection RequirementsDocument14 pagesAPI 650 Tank Fabrication and Inspection RequirementsFucKerWengieNo ratings yet

- 018 Insitu FlooringDocument4 pages018 Insitu FlooringAnonymous 3eHGEDbxNo ratings yet

- JC For Tile Installation On WallDocument1 pageJC For Tile Installation On WallGrace tpplNo ratings yet

- IBI Chematur Civil Work InstructionDocument7 pagesIBI Chematur Civil Work InstructionHiren ThakkarNo ratings yet

- Saic A 1006Document1 pageSaic A 1006munibbarcaNo ratings yet

- Shic A 0005Document2 pagesShic A 000501095902062ahmedNo ratings yet

- Check List For Alum DoorsDocument1 pageCheck List For Alum DoorsYash SharmaNo ratings yet

- Check List For Backfilling WorksDocument1 pageCheck List For Backfilling WorksYash Sharma100% (2)

- Infrastructure Inspection Test PlanDocument3 pagesInfrastructure Inspection Test PlanABDO ALLIANo ratings yet

- True Blue Inspection-Test-Plan - Issued For ReviewDocument4 pagesTrue Blue Inspection-Test-Plan - Issued For ReviewJohn HartNo ratings yet

- Check List PaintingDocument4 pagesCheck List PaintingYash Sharma100% (3)

- Tender Documents Site Works Compaction SpecificationsDocument4 pagesTender Documents Site Works Compaction SpecificationsAli KayaNo ratings yet

- Procedure For Hardness TestingDocument8 pagesProcedure For Hardness TestingVinayaga MoorthiNo ratings yet

- WIweld10 Dye Penetrant Examination Rev 00Document3 pagesWIweld10 Dye Penetrant Examination Rev 00Gautam KumarNo ratings yet

- Guidelines for Engineered Fill layersDocument5 pagesGuidelines for Engineered Fill layersKiran JoshiNo ratings yet

- Architectural Painting Works Ins ChecklistDocument2 pagesArchitectural Painting Works Ins Checklistmunna100% (1)

- Checklist For Fabrication & Installation of Tensile Fabric ShadesDocument1 pageChecklist For Fabrication & Installation of Tensile Fabric ShadesSun ShadeNo ratings yet

- Proposed QAP For Adani Internal CTR JobDocument2 pagesProposed QAP For Adani Internal CTR JobSasanka SekharNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Niel TanedoNo ratings yet

- Trench Backfill Review NoteDocument1 pageTrench Backfill Review NoteAnonymous Vy9KooDNo ratings yet

- DPT ProcedureDocument4 pagesDPT ProcedureRohit Attri100% (1)

- Saic A 1001Document2 pagesSaic A 1001Son AbanadorNo ratings yet

- Dimensional Control ProcedureDocument12 pagesDimensional Control ProcedureBethel NdifonNo ratings yet

- Saic A 1006Document1 pageSaic A 1006Saragadam DilsriNo ratings yet

- SAUDI ARAMCO INSPECTION CHECKLISTDocument1 pageSAUDI ARAMCO INSPECTION CHECKLISTJagdishNo ratings yet

- China Harbour Engineering Co.L.L.C. Concrete Blinding Works Check ListDocument1 pageChina Harbour Engineering Co.L.L.C. Concrete Blinding Works Check ListYash SharmaNo ratings yet

- Saudi Aramco: Soil Sampling ChecklistDocument2 pagesSaudi Aramco: Soil Sampling ChecklistyazNo ratings yet

- SUBRAMANI VEDIAPPAN - VelosiDocument11 pagesSUBRAMANI VEDIAPPAN - VelosiKshama RaiNo ratings yet

- Check List For Roof Waterproofing Works: Stage Item Checked by DateDocument1 pageCheck List For Roof Waterproofing Works: Stage Item Checked by DaterajatNo ratings yet

- QAP 3.0 3 Surface Inspection Acceptance CriteriaDocument6 pagesQAP 3.0 3 Surface Inspection Acceptance CriteriaPablo OchoaNo ratings yet

- Masonry Testing 101 - 2018 04 12Document57 pagesMasonry Testing 101 - 2018 04 12Jeff LongoriaNo ratings yet

- Cost EconomicsDocument14 pagesCost Economicsamitvaze316No ratings yet

- Procedure D'inspectionDocument9 pagesProcedure D'inspectionsalahjallali100% (2)

- MS-Soil StabilazationDocument7 pagesMS-Soil StabilazationMihir PatelNo ratings yet

- QCV Test CertificatesDocument1 pageQCV Test CertificatesShashank RajputNo ratings yet

- Satr M 1063Document3 pagesSatr M 1063jerin100% (1)

- Checklist For Installation of Underground Checmical Waste TanksDocument1 pageChecklist For Installation of Underground Checmical Waste TanksDiana Abu Hassan HatoumNo ratings yet

- SPYTL - Anti TermiteDocument6 pagesSPYTL - Anti TermiteMohd TameziNo ratings yet

- Enct. - : - Ref. 01..:.. '. MS TotDocument2 pagesEnct. - : - Ref. 01..:.. '. MS TotninatenaNo ratings yet

- Saudi Aramco Soil Sampling ChecklistDocument3 pagesSaudi Aramco Soil Sampling ChecklistTayyab KhanNo ratings yet

- Design of Flexible Pavement by Various MethodDocument3 pagesDesign of Flexible Pavement by Various MethodAmul KotharkarNo ratings yet

- Site MiniDocument18 pagesSite Miniamare addisNo ratings yet

- Quality checklist for site works road and drainsDocument2 pagesQuality checklist for site works road and drainsLordgie AgtucaNo ratings yet

- Visit To Induction HardeningDocument9 pagesVisit To Induction Hardeningdada kolekarNo ratings yet

- Project Quality Plan MINDAR/PQP/B.EMAS/001/2021Document1 pageProject Quality Plan MINDAR/PQP/B.EMAS/001/2021Rafiq RahimiNo ratings yet

- Code For Negative Stock BlockingDocument1 pageCode For Negative Stock BlockingIsmail MydeenNo ratings yet

- TDL of Ledger, Stock ReportsDocument2 pagesTDL of Ledger, Stock ReportsIsmail MydeenNo ratings yet

- Delete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Document4 pagesDelete Unwanted Ledger (Only Sundry Creditors and Sundry Debtors Group)Ismail MydeenNo ratings yet

- User Define Amt of Discount in Sale EntryDocument1 pageUser Define Amt of Discount in Sale EntryIsmail MydeenNo ratings yet

- TDL of Symbols and PrefixesDocument1 pageTDL of Symbols and PrefixesIsmail MydeenNo ratings yet

- Auto To Manual Vourchar NoDocument7 pagesAuto To Manual Vourchar NoIsmail MydeenNo ratings yet

- A Drill Down Group Summary ReportDocument1 pageA Drill Down Group Summary ReportIsmail MydeenNo ratings yet

- ITP-00010 Pavement Road WorksDocument3 pagesITP-00010 Pavement Road WorksIsmail MydeenNo ratings yet

- Voucher ReportDocument2 pagesVoucher ReportIsmail MydeenNo ratings yet

- MST-0010-00 For Pavement Road WorksDocument13 pagesMST-0010-00 For Pavement Road WorksIsmail MydeenNo ratings yet

- RAS 0010 Pavement Road WorksDocument8 pagesRAS 0010 Pavement Road WorksIsmail MydeenNo ratings yet