Professional Documents

Culture Documents

QGX T Arn CS 00101

QGX T Arn CS 00101

Uploaded by

Omar Tocmo0 ratings0% found this document useful (0 votes)

25 views38 pagesOriginal Title

QGX-T-ARN-CS-00101

Copyright

© © All Rights Reserved

Available Formats

PDF or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

0 ratings0% found this document useful (0 votes)

25 views38 pagesQGX T Arn CS 00101

QGX T Arn CS 00101

Uploaded by

Omar TocmoCopyright:

© All Rights Reserved

Available Formats

Download as PDF or read online from Scribd

You are on page 1of 38

&

vw

ARCHIRODON GROUP NV

CORPORATE MANAGEMENT SYSTEM

‘System Procedure CORP-SYS-02 Control of Documents and Data

Document Transmittal

Project or Office 0176 Marine Civil Works for QGII LNG. ‘3; Ras Laffan, QATAR,

Ras Laffan, QATAR sen

Archirodon Construction (0) Co. 8. KREGER"

Attn: Mr. Adel Monsef ee

P O. Box 22256, Doha,

Ras Laffan-Port Area

o

Qatar

Tel + 974 4735050

Fax +974 4735039 =

Contract No.

Transmittal Ref, QGX-T-ARN/CS-00101

Issued by _Adel Monsef Position _ Project Manager

To _Mr, Isamu Kuroda_ Organisation _Chiyoda ~ Technip Joint Venture

The documents itemised below are for your attention and action as indicated.

i Document Codes

MS | Management system document _MA_| Material submittal Fel

D_| Drawing © | Other Contract document

[TE [Blectronie file R_[ Report

a Action Codes Et

1 [Tnformation, no response required R_| Review and return comments

C | Construction or Use R2_ | Return to originator after amendment

‘A__| For approval, please reph Ft i

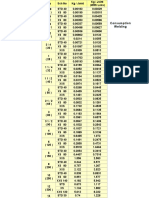

Te Document Code and Title Reference * | Rev | Size | Cop. | Aetion

| m e

Method Statement for the Construction of

1 | MS the Abutment by Placing Quarry Run, 0176-MS-04 4 Ad 1 A

Armour Rock and Concrete Armour Blocks

‘Remarks a 7 e

t = 2

Signature hat AUT Date of Issue _3 May 2007

* Note: Foran expiration of the references for management system documents, see Table 7.1

and Table 7.3 of this system procedure.

Document ref. CORP-SYS-02-F02 Rev.

ARCHIRODON CONSTRUCTION OVERSEAS CO. S. A.

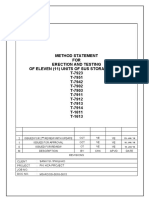

METHOD “Document Ref.

STATEMENT 0176-MS-04

PROJECT MANAGEMENT SYSTEM Es

a

CO

MARINE CIVIL WORKS FOR

LNG BERTH NO.5

OF QGIT LNG EXPANSION PROJECT

AT RAS LAFFAN, QATAR

Revision 4 | Page lof 11

Method Statement

For the Construction of the Abutment by

Placing Quarry Run, Armour Rock and

Concrete Armour Blocks

if Issued for approval.

eee. Deletion of COW! method to complete the abutment construction under

ener Loading Platform Deck (COWI Report P.64036-dated 24-05-2006)

Prepared by |” Reviewed by | Approved by

Document, | Rev. | Issue Date | Construction | Project QC Project

Section Section Manager

0176-MS-04 403 May 2007 M. Wadie M. Naguib ‘A. Monsef

Appendix A 3 | 08 Feb.2007

Appendix B 1 | 04 Jan. 2007 dhe

Appendix C 1 | 03 May 2007 Nn rw

Appendix D 2 | 03 May 2007

Appendix E_ 1_| 04 Jan. 2007 = =

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref a

| STATEMENT 0176Ms-04 | Revision 4 Page 2 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

LIST OF CONTENTS

Page

1.0 Introduetion. 3

2.0 Document Control... 3

3.0 Health, Safety and the Environment

3.1 Health and Safety Hazards... 3

3.2 Adverse Environmental Impacts 4

3.3 Transportation. 4

34 Communications. 4

3.5 Noise Monitorin, 5

3.6 Dust control 5

40

41

4.2 Personnel.

5.0 References.

6.0 Methodology

G1 Schedule Of Work....eeseseceescsees : 8

6.2 Removal of Antifer Armoured Cubes from Land and from sea. 9

63 Demolish of the Crown Wall Blocks .. 9

6.4 Installation of screened quarry run . 9

6.5 Installation of rubble material 9

6.6 Installation of armoured rock . 9

6.7 Installation of concrete armoured cubes 10

68 Placing of structural fill . 10

78 Quality Control... 10

Appendices:

Appendix A Job Safety Analysis

Appendix B Environmental Impact Statement

Appendix C Inspection and Test Plan / QC Forms

‘Appendix D Drawings

Appendix E Night Shift Procedure CORP-GEN-15 Rev. 1

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD | Document Ret

STATEMENT. 0176-MS-04

Revision 4 Page 3 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour |

Blocks

1.0

1d

12,

2.0

21.

22,

23.

3.0

3.1

INTRODUCTION

‘This document describes the methods to be implemented and resources to be utilised for the

removal of Antifer Armour Cubes, placing of screened quarry run (II) 1-500 Kg covered by

armour rock 500-2,000 Kg and protected with a revetment of conerete armour cubes type I, II

and IIL At final stage gunny bags will be installed by hand to close the gaps under the loading

platform. A Geotextile membrane will be installed and a compacted structural fill will be

Placed to give access to the loading platform. The steel casing of the first two rows of piles

will be protected by Timber Jacket before covering them with rocks and Armour Cubes, for

Berth # 5 Marine Works part of QGX project...

This method statement and attached job safety analysis are hereby developed within these

clements to describe in more detail the methods used, the resources deployed and the controls

ut into place to eliminate or mitigate safety hazards and adverse environmental impacts.

DOCUMENT CONTROL

‘This method statement is a controlled document as required by the system procedure Quality

Planning and issued in accordance with the system procedure Control of Documents and

Data.

‘The method statement is subject to amendment during the execution of the Works as a result

of periodic review and whenever circumstances require subject to CTIV approval. Revisions

will be issued in accordance with the system procedure Control of Documents and Data

whenever the main text changes or when an appendix is added or removed. Revised

appendices for substitution will be issued separately and, where appropriate, will include a

separate schedule of contents.

This document's revision and appendix issue status is shown in the Project Register of

Management System Documents, a copy of which may be obtained from the Project Office

upon request.

HEALTH, SAFETY AND THE ENVIRONMENT

Health and Safety Hazards

sl 3.1.1 As required by the Project Health & Safety Plan, the significant health and safety

hazards of this work have been analysed in accordance with the Risk Assessment & Work

Execution Procedure (QGX/20/00/SA/PC/NA/107 1) and are listed below.

Security Hazard / Possible unauthorized access

Falling of personnel and equipment into the sea, drowning

Lifting hazard / Falling object

Noise level

Night time working

Exposure to concrete

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

STATEMENT 0176-MS-04

en DocumentRef | Revision 4 Page 4 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

32

3.21

3.22

3.3

3.1

34

3.41

Blocks

* Electrical hazards / Welding (working near or over water)

Controls will be implemented to minimise these hazards as set out in the form Safety Hazard

Control Programme included in Appendix A.

Adverse Environmental Impacts

As required by the Project Environmental Plan, the significant adverse environmental im

of this work have been analysed in accordance with the general procedure Hazard Analysis

and Environmental Impact Assessment and ate listed below.

Waste and debris disposal

Pollution from equipment due to leakage or during refuelling

Pollution from the washing out of the concrete truck mixer

Pollution from hydraulic hose leakage / burst

Noise level

Controls will be implemented to minimise these adverse impacts, as set out in the form

Environmental Impact Statement included in Appendix B,

‘Transportation.

‘The transportation of all project materials such as the armoured rock, concrete blocks etc. to

Berth # 5 arca will be by Sea via tug boats and barges,

‘The access for equipment and personnel to the working area, for Berth # S area will be through

the existing temporary jetty at Archirodon site facilities inside Ras Laffan Port, Also an

alternative access to personnel will be through the roadway on the breakwater to reach Berth #

5 area, where applicable.

Communications.

Marine Equipment will be provided with VHF station. They shall co-ordinate each other in VHT

Frequency different than the one used at Ras Laffan Port in order not to interfere with their

operations. Communication between CTJV and Archirodon shall be held through mobile

telephones.

S/N | Company Name Title Ch./Mobile No.

1} RLIC Harbour Master Harbour Master Pa eat Chs

& 12 &16

2 crv Jean Pierre Tholozan | Construction Manager 5570327

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref.

STATEMENT. 0176-MS-04 Romeo Page Sof 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

ar ie Marine Area =

3. |cnv Michel Khoury Constraction Manager 5895028,

4 | ARCO | Adel Monsef Project Manager 3564892

5 |ARCO | Maged Wadie Construction Manager 5856045

3.5 Noise monitoring,

3.5.1 Periodic noise monitoring will be carried durin,

abutment,

3.5.2 Whenever noise level exceeds the 85 (dba) and up to 110(dba),

to wear PPE (earplugs),

ig Construction of Berth # 5 construction of the

all employees will be instructed

3.5.3 The noise level range produced by the construction equipment will be as follows:

Equipment “ony wanes

Floating crane 70-94

‘Mobile crane /Loader 97-102

Dump truck Less than 85

Generator / Welding set/ Air 62-92

compressor

3.6 Dust control,

3.6.1 Personnel exposed to dust shall wear dust masks.

4.0 RESOURCES

41 Equipment

4.1.1 The main equipment envisaged for the above works includes the following:

Table 4.1 Plant List

Equipment Make/Size a Task

Jack-Hammer Cat.330 or equivalent_[ 1 | Demolishing of crown

wall and concrete road.

Floating Crane ‘Lima 2400/136 Tons | 7 | Removal and installation

of rocks and concrete

Ef armour cubes

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref. ry

STATEMENT O176MS-04 Revision 4 Page 6 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Conerele Armour

Blocks

aaaan 7 N =

Equipment Make/Size 2 Task

Mobile erane 30 Tons or bigger 1 | Removal and installation

concrete armour cubes.

Transport barge Lesvosi3.Kriti2/1000 | 2 | Transport of rocks and

‘Tons capacity cach concrete armour cubes.

Land crawler crane Manitowoc 4100 /150 | 1 | Onshore handling of

a tons concrete armour cubes.

Gantry Crane Casagrande/120 tons | 1 | Onshore handling of

4 | concrete armour cubes,

Dump tracks 16m3 4 | Loading of rocks.

Excavator ~ | Cat 330 or equivalent) 2 Loading and Placing of

rocks

Tug boats 1000 HP 2 | For Marine operations

Roller compactor 10 Tons _ 1 | Structural fill compaction

| Water tanker 10000 Litres 1 | Structural fill compaction

412

413

414

42

42.1

422

4.2.3

Water, lubrication and fuel services, to above equipment will be provided from Archirodon

facilities at the temporary Project Lay down Area, located inside Ras Laffan Port

Workshop services to equipment will be provided from the workshop facilities at the Project

Lay down Area, located inside Ras Laffan Port.

All equipments shall be holding valid certificate from a thid party inspector and shall be

subject to CTIV inspection.

Personnel — Responsibility ~ Work pattern,

The Construction Manager is responsible for the organization and coordination of the entire

work.

‘The Marine Foreman will be in charge for the co-ordination of activities between the project

cam and each of the vessels. He is responsible for instructing the Deck Foremen about the

‘Faluirements of the contrat, including all restrictions, safety regulations, the work-scope and

time schedule. In addition, he will supervise vessel movements and be responsible for related

logistic matters. Onboard the vessels and equipment, each Deck Foreman will be in charge of

the staff and vessel operation. He will be instructed as per this MS to camry out this activity. He

is also responsible for coordination with other contractors working in the vicinity and KC

Harbour Master for the movement of the LNG tankers, ships and boats,

The Safety Officers are responsible to assist the construction team to develop safe methods of

working and to monitor implementation of the controls put in place.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref. a

[_ STATEMENT 0176-MS-04 Revision 4 Page 7 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

= J

4.2.4 The Project Manager is responsible for the ‘management and co-ordination of all the sub-

contractors and concerned authorities, so as the works ‘on the project will be carried out in a

safe and environmentally friendly way to meet contract requirements, in particular time and

quality

42.5 ‘The manpower for this work includes but not limited to the following:

_ Manpower Deployment Schedule

Description

Marine foreman

|Site Engineer

Foreman

Deck foreman

Surveyor

Excavator operator

Crane operator

Dump truck driver

Trailer operator

Welders

Transportation Foreman

Asst. transportation Foreman

Floating crane operator

Seamen

Tug boat operator

Labourers

| Safety officer for each shift

Divers

Note: Safety Officer shall be permanently on Barge

Zi

é

a) oe] of 8) 8) 9} 9] A] eo) ro} a) ra] wo} eo) a} rol

5.0 REFERENCES

5.1 Archirodon procedures and plans

* System procedure CORP-SYS-01 Quality Planning

¢ System procedure CORP-SYS-02 Control of Documents and Data

* General procedure CORP-GEN-04 Procurement of Materials and Services

* General procedure CORP-GEN-12 Hazard Analysis and Environmental Impact

Assessment

General procedure CORP-GEN-15 “Requirements for Safe working at Night”

General procedure CORP- TEC - 02 “Control of Pollution”

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref. ae

STATEMENT | _ol7eMS-04 Revision 4 Page 8 of 11

5.2

33

60

61

6.1

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete ‘Armour |

Blocks

General procedure CORP-TEC- 09 “Control of Marine Vessel Access”

General procedure CORP- TEC - 04 “Requirements for safe lifting by Crane”

Project procedure 0176-SP-01 Control of Inspection and Testing

Project procedure 0176-SP-02 Control of Quality Records

Project plan 0176-PQP-01 Project Quality Plan

Project plan 0176-PSP-01 Project Health, Safety &Security Plan

Project plan 0176-PEP-01 Project Environmental Plan

Project plan 0176-WP-01 Emergency Response Plan

General procedure CORP-GEN-I1 “Control of Diving Operations”

Project procedures and documents

* CTV procedure QGX/20/00/QA/PC/NA/002 Inspection Coordination Procedure (With

Subcontractor)

* CTIV procedure QGX/20/00/QA/PC/NA/020 Q4/OC Requirements for Subcontractors

* CTIV specification for conerete material, mix and construction QGX/120/00

/CUDBINA/008

CTIV specification for lifting procedure QGX/120/00/SA/PC/NA/104

QGX/27/74/MO/TS/NA/550 E1- Foundation and Substructure

(QGX/27/74/MO/TS/NA/S53 E2- Abutment

List of IFC drawings

1, |General Layout-Abutment and

Loading Platform QGX/27/74/MO/DR/PLI611. | E2

[2 Abutment Slopes-Sections and Details | QGX/27/74/MO/DR/SV/620 | £2

METHODOLOGY

Schedule of Work

Construction activities will be carried on a 24-hours basis, and each shift has total duration of

12 “hrs but actual working hours will be for 10 hrs(Refer to Night shift procedure

CORP-GEN-15 Rev. 1 Appendix D).

The activities will be coordinated closely between Archirodon and CTJV and RLC port

authorities.

Archirodon will adhere to RLC safety rules and regulations applicable in the port area.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

|

METHOD Document Ref.

STATEMENT. 0176-MS-04

Revision 4 Page 9 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Conerete Armour |

Blocks

6.2

63

6.4

65

Removal of Antifer Armoured Cubes from Land and from sea

‘The removal of the existing Antifer armoured cubes will be executed from land for the upper

Cubes using a Mobile crane that will be standing on the southern side of the breakwater

concrete road. The removed Antifer armoured cubes will be stored temporaty in the adjacent

area. Cares will be taken to place them in a safe way not to be broken so we can replace them

in the tie in as indicated in drawing QGX/27/74/MO/DR/PL/611. The lower and underwater

Antifer armoured cubes will be removed by the use of a floating crane and the help of the

divers .A diving PTW will be available and signed before any diving activity commence,

Stocks will be placed on a supply barge and transported by sea to the laydown area where

they will be properly stocked to be used later as the previous ones.

Demolish of the Crown Wall Blocks

Demolishing of the crown wall blocks will be executed using jack hammer, The area to

demolished will be marked by the surveying team as indicated in drawing

QGX/27/74/MO/DRIPL/611.The eut off concrete materials will be loaded on dump trucks

and disposed in designated area approved by RLC authorities.

Installation of sereened quarry run

The approved screened quarry run will be transported to work location by supply barges and

placing of this quarry run will be by the use of a loader and direct dumping on the slopes to

form the core of the abutment. The surveying team will guide the fill by placing buoy on the

edges and developing the cross section to ensure the correct progress of the works. The slope

will be formed by the slope stability of the rock and the floating crane will assist for the correct

formation of the slopes at the required envelops. This operation will be for the first 50 meters

of the abutment, For the remaining part where the piles are completed the floating crane will

install the quarry run with the use of a bucket or the scraper as the barge can not enter in

between the piles up to the sea level. Placing of quarry run from the sea level up to final

elevation will be by clamshell and/or skip to avoid any damage on piles.

In tidal zone and wave zone sea level (-1.00 to +3.00) the temporary profile will be protected

by the installation of armour rocks that will be removed to proceed with the works as required

after the completion of the loading platform.

Installation of rubble material and temporary timber jackets

At the front in the abutment a ten meters horizontally layer of rubble material class H (2-20Kg)

will be placed by the use of floating crane,

At each step when the level of the rubble materials will reach the bottom level of the timber

jacket, the timbers will be installed to protect the piles from the rock impact.

Protection by armour rocks will follow on which the Concrete Armour Cubes will take place.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD | Document Ref. :

STATEMENT 0176-MS-04 Revision 4 Page 10 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

6.6

6.7

68

Installation of armour rock

The Armour rock will be placed by pieces with the bucket of the floating crane using the

Global Positioning System according to drawing coordinates. The armour rock bigger than

1000 Kgs will be placed individually with the clamshell. The divers* team will assist and help

the Placing according to drawings requirement as indicated in Drawing

QGX/27/74/MO/DR/SV/620 for the first 50 meters of the abutment. A diving PTW will be

issued to cover this activity. For the remaining part where the piles are completed the floating

crane will install the armoured rock with the use of a bucket up to sea level. Placing of

armoured rock from sea level up to final elevation will be by clamshell to avoid any damage on

piles due to rock impact.

Tidal zone will be treated as described in 6.4 above,

Installation of concrete armour cubes

Concrete Armour Cubes Type I, II and IIT will be placed by the floating carne using the Global

Positioning System and the help of the divers’ team for underwater placing and the rocks

placing foreman for placing above water, according to required porosity for the first 50 meters

of the abutment. For the remaining part where the piles are completed the floating crane will

install the concrete armour cubes up to sea level. Placing of concrete armour cubes from sea

level up to final elevation will be by floating crane,

Tidal zone will be treated as described in 6.4 above.

After completion of the concrete armour blocks placing the gunny bags will be places to fill the

remaining gaps up to the bottom 1" beam of the loading platform and be used as a support to

the compacted structural fill encased with the Geotextile membrane as indicated in drawing

QGX/27/74/MO/DRISV/620,

Placing and compaction of structural fill

The last portion of the abutment will have to be completed together with the loading platform

deck, removal of armour rock as temporary protection will take place prior starting. this

activity, works in stages and steps will be performed to reach the level of installation of the

Geotextile membrane and the above it structural fill. Small equipment and hand operation will

be utilised for a portion of the work under the concrete deck ie. the Gunny Bags.

Geotextile membrane will be installed as per specification and according to manufacturer

recommendation,

Structural fill will be placed according to project specifications and will be compacted in layers

by using of 10 tons roller as per project specifications requirement including the frequency of

tests.

No subsequent layer will be placed if the compaction test of the under layer is not satisfactory.

The structural fill will be compacted to a minimum of 95 % of MDD as per

QGX/27/74/MO/TS/NA/SS3 E2.

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA.

METHOD Document Ref, i

STATEMENT t176MS-D4 Revision 4 Page 11 of 11

Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour

Blocks

70 QUALITY CONTROL

7.1 The construction and installation works will be surveyed and inspected in accordance with

IFC drawings, Project specifications and approved ITP’s.

7.2 All surveys, inspection and testing will be controlled by the project procedure Control of

Inspection and Testing.

73 Records generated by the inspections and tests will be controlled by the project procedure

Control of Quality Records.

- END OF TEXT -

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD Document Ref, Issue 1 | See sections 2.2 & 2.3 for

STATEMENT 0176-MS-04 control of this appendix

Construction of the Abutment by Placing Quarry Run, Armour Rock and

Conerete Armour Blocks

APPENDIX A

HAZARD CONTROL PROGRAM

| fe Title

Reference Rev. | Pages

[ Job Safety Analysis

0176-MS-04 -JSA 3 5

g 404 VSM-0-SW-9L10 ' ON VSP

“umpecord rqueuuoanua pue ADIES SED JEIED PUE APL Ul Punoy oq Ue ELOWeanbes LeUIVOIAUO PLE (ye sEUEZeH “Sid hayes uD SEC,

‘{ueseoo0u oe sjeaus euoypre 887)

>uoW aif anode OB Sn JSLUBEAY e}AENPUI \PLO WENA ‘epzEzeY eojNeYO 10 je=ISAud "eOIBOIOIG GONOAY SYSHY AL 0 AUR HON

‘2888727/ON SNOHASTTaL KONBOURWA OTH

"HOM 0) uunsas a10}0q 3SHS APL HIM YOeuD Won 2 2e0}0 He MOURA -id0C 3SHS ANLO OF Patiodad ae suosied Burs,

“H9120M Ie Jo} uncoee Josyuodng ‘uon=eup pu Bubpreued auled Jan

‘Ad3d ALBAYS APLO

vst

#07 pur yaveay of using sian Jorwiadns woud Ho UowNS wom dens ‘Sfuna300u ADNBOUSHE 8 SNOILIENOO OMIONYHO

[aid homme Te ‘SeNOSSOUT LINWS NOM AIO SHI NTS TVIS0 WHOM SOCHYZYH Nod CSUNDSW WAGHSAY]

AML TOMS TUL (y

gma Te

Fe THM pore mom Served (04

sossei6 Ajejes(6|

sie s00 usn2o%9|

‘quBi9y ye Bupjiom) ssourey Apog yn (1|

oper (aojaa 3811) S180}

AHA pur edias uaa Knog apr ue 809 poeds(o| yon. Gnwawoo) enmewesaidey asHs|

‘syseusieng (g Jonoin, at (Aro) eanequaseidey asHs|

7 he We (719) wuepuequyedng sundiosig

oa arabs Suey

Bese SE GA DonwaiOS Ons or Ag pouueye) emponsdy RuoREPY|

amen “FEO | __ mmnwnd soning soe

sd

Bad NOWWOO| oozrere to 2asrTm| :ka war}

sunswnne sor Tana0| ava ereuBis oan THIRAORIEE UON

auoped

So Sr payeulBu0 uopsegquouniedeg

"S00|e INOUNIY Sye190D Pub YooY INOUAyUnY AUeND Bulselg Aq WeUANGY Si Jo UOTINISUOD pazkjeue Bujeq gor 50 odAI|

$30 | ava as wan Ld Ver7e-e-9210 ON US@WINN Ver]

AuOUIYDENY LOL/YNDAhYS/00/0ZKOD

gz YSI-0-SW-9L40 = ON Sr

‘pofoydep

Peo} vopses SSH Lopomuary] 09 [MA e;nsodKe [ovo] ooiou YY BunEOHPU suBls SSH ZH

eo} uanoes 36H Lapowua.y| “BuoWoU! Jepun oq Wm Sore] BSN 19 1246) 8S10N OF

‘soupy 38 ‘esodind fouetowe

vuewe1o euveyy wopoaory|

Bo} uonoes 3SH Lopouary|

‘Bunwoip ‘20s ein ow

‘vewai9g euvey| uopaiyory} yuouidinbe aig jmuoo jpn S80} dows 20 j pue LaWsyLEG tusuucinbe pue jeuuosied jo Buytes St

"s.9e Wes “SerKonDeTy “0! UOREIDKYOP

Jeawo |SH wopoIary) ——_jo2ueuRBAR 30} IS UO pepIAOA Og IY PIE AEA

‘suones

‘wewiai0, euveyy uopoiyory] jem pus “sue Ya ‘pepnraid 6g yn seeve pepEyS

‘vewai0, euseyy uopaaouy| ‘oyenig Joye enBy Um feUUOSIEC Ty

‘sroedsut

POH Uonses SH Uepouyoiy] ruowdnbe APLO PUE Sxcioedsu fied puna Aq UoRDedsUI E'E'y

‘suede

‘oueBrawe jo 0880 u yo) 9q 4 saseds 9 er

Uewei0y cousyoy uopomry} ued ei ed se 10 poured oq 1m eoueURILIENN

suyoodsu dousHoM

uwewsio ewweyt uopoausiy|uopoauaiy Je du ein LANA UeWB.04 SUEY KqUoREC

ewarog ewer uopomsnry

roy uop2es 35H UpeMry| oro ue a prepa JenoueN 1

“souyes suowdinbs €°4

_ Mi non BUHON

hes canon > | Sianeeromueiog

£9 (0) woronnsuoo uoposnoiy o Wo sisaTwNy ALzdvs aor = a

Fane aE

e-wOUWoENY LOL/YNIOdYS/O0/0ZKOD

swe ‘WSt-P0-SW-9210 : ON VSP

‘siopadsut

Uuewexo, | osivacng uspouyery| yueuidnba APLO pue Jowoedeu Kued pun kg uoppodsy} e2|

| sede: Kouefuewe yo ese u rdex oq wm seveds enue

sums uenonvopontay) outing a sed omy pono oq accumu 2]

umuoio, Jspvedng uoponry pdeysn yn veins amen Aquoeesy 162 ‘ne, wouidnby 62

uawong /1oyvedng wopanuory

Peo} uonoes SH Uoponyaiy| pleog s0N0 us ZZ

uueweio4 j osuvedng uopautazy| ‘uoyezedo say uo pesn eq jm UsUIEES Reus,

HOM jo powesueUIL

Jnbeuey uoronsuo9 uopouyaiy| ‘sou senued ye Aq pout 81 Mid OT ensu3 MALd sPOLRMA BUDLONA |Z

‘Pepoo :0}0 pue Pou

tom pue seanace Bury e1njoq paroedsu oq Pn 38

68 /spedng uopeuyry| Z't

reuvosied peouayecx

‘Pur poures fq pevopuow pus paryoeye AsnoURLcD

‘ueweles J osyuedng uspoiyaiy) 99 YK 10 aMeUpAyute Jo Aenb pue uoneiedo eu09 e1'1

ueweio, / osiuedng uopouoiy| ‘3uo1 jo ues 0 s0ud payooy> eq i se804 Ry ZH

nq

Summ ease! omni p asians mere nmis 11 |oeo omen pease

“sauvZvH

AWILNSLOG

29 (0) uonongjsuop wopoaosy W4Os SISATNY ALZdVS aor

e-AUOULOERY LOLIYN/OdMYSIOOIOZIKOD

gy WSI-p0-SW-9L10 “ON Yr

no

_atByooming wopomony| wo ns pu este Umno ued Daa LEMAR TY 707

rsuoneede

.288hy /.osyuedns uoposvony] Culp Pesyuedns Wm peuReD fed PUL puE peu ioULoEed Lez] Yoelgo Supe / piszeY Buy Bz

uewer04 / osvuedng uopouyory] ‘Bere Bunj2om 043 oyu! Parnoye oq IIMA jouUOsed PeUIER AUD p12}

rpuuosied peousuod pue peu fa poicwuous pue paxceYD

unwerog/s8iuedng wopeausny] —_AencunLce og Mo yneiphuyeo yen pus uogtssd oeu09 €'2|

"yim yo wee oud payoeyo oq vn eoao4 FY Z'2|

-Bupes eunesaid yoe.i00/ee04 Jo ypBuaNs eyenbepe einsuy |'/°2| ¥Sinq esoy OyNBIpAY PeZUNESeLd LZ

{26rdzeeraynanos)

$e J00m yr yuowdnbo 0 ese Eunjom sooroy

‘GUS 12 paoeid eq ju esnsodke jexsjosou YBy Bunedipul

yveyoun sopun 69

ueweie / osyuodng Uoposcsy) "Buy ut perodwe og im 19684 poynsog fed PAL ALO SEE]

uewaiog swede uoposuony] _enoge pur iow zs peeds pur ein ypeddos og um Guns yee]

"esodind KouB691u0 Jo} Lone}

unwoio, euzey uoposuory] 200 0 AIuoH a4 agpyeNe ope og WH OH ponds peddinbs 62

‘sage oF Suununs Jo preDues

Joyo 36H vopoaueny] wn a eam oy ouuosieg posn og ay siNOET oi ponaxtdy 752|

‘sefipe

24.0} e270 0m; BunuOMUIe WuEAGIM o) “AROE SER U PONIORLE

ueweio4 j zosvuedns uopomsiy|

29 (0) uoponasuog wopoutsy ¢ wuod SisATwNy ALBdvS €or Rez

eAUOLUYORNY LOL/YNIDAYS/ON/OZKOD

‘sysew yenp epeydosde

Ing uopomzy| AM Pepto: 9g kn HOM UoRSECCS U| PERENUY JeLLESIed 172]

ng uopomry| 186) uoHPediueD exp uLOHEd yn UOsied KeyesoRE PeysLEO Y ZZ}

eee

"2a Rinaoe eo ues

‘re}008

{ain Bunyan eoakordw oxy fa pateID} 09 HA (SASH)

Ing uopemony| suunize;nvew ox; fq peuonuew suoyneoeid Keyes ep IY Z|

‘SOSH 8 U pas se uonoerd Kies! apo.

mm pew opps 000 oun AMA BuLEN sookodurs 1-19

24 Aunnoe onoqe owes,

2 Aungoe anoge owes

09 (0) wononsysu0s uo}

eAUOLULDENY LOLIVN/DAYSIOOINZXOD

VSt-¥0-SN-9140 : ON WS

ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA

METHOD, Document Ref. Issue 1 | See Sections 2.2 & 2.3 for

STATEMENT 0176-MS-04 Se | | control of this appendix

Construction of the Abutment by Placing Quarry Run, Armour Rock and Conerete

Armour Blocks

APPENDIX B

ENVIRONMENTAL IMPACT

STATEMENT

Title

Reference _| Rey. | Pages

Environmental Impact Assessment

0176-MS-04 1 8

a ARCHIRODON GROUP NV

CORPORATE MANAGEMENT SYSTEM

Cw ‘General Procedure CORP-GEN-12 Hazard Analysis and Environmental Impact Assessment

Environmental Impact Statement

Project _@176 ~ Berth #5 — Marine Works

SECTION A- WORK ANALYSIS

Part Al Name of Company _Archirodon Construction (Overseas) Co. S.A

Date Prepared _03/01/2007 Document Ref. _0176-MS-04

Name of Supervisor in Charge _Maged Wadie

Numbers and Disciplines of Personnel Carrying Out the Task _1+70

Workshop / Transport / General Construction Skilled Labour

Part A2 Scopeof Work Removing Antifer blocks and placing Quarry run, Armour rock

and Concrete Armour Blocks.

Part A3_ Sequence of the Work and Significant Potential Adverse Environmental Impacts

‘Activity 1 Removal of Antifer Cubes from Land and from sea.

Impact "Oil leakage/ spillage from the mobile crane and floating crane barge.

Activity 2 “Installation of screened quarry run. i

Impact Oil spillage/Leakage from the mobile crane and Floating crane barge. _

Activity 3 Installation of rubble material,

Jmpact _Oil spillage/Leakage from the mobile crane and Floating crane barge.

Activity 4 “Installation of armoured rock.

Impact Oil spillage/Leakage from the mobile crane and Floating crane barge.

Activity 5 _Installation of concrete armoured cubes.

Impact "Oil spillage/Leakage from the mobile crane and Floating crane barge

Activity 6 “installation of structural fill,

Impact "Oil spillage/Leakage from the mobile crane and Floating crane barge.

Part A4 Details of Equipment to be Used

Cranes _Floating Crane barge, Mobile crane

Plant Dump trucks, Transport barges, Crane barge, Excavator, Loaders , Flat barges and Tug

Boats

Lifting Tackle - Only 3” party certification lifting tackle will be used

Portable Equipment Survey instruments, Diesel Welders, Oxy-Acy cutting set, Light Tower,

Hand Tools.

a ARCHIRODON GROUP NV

‘CORPORATE MANAGEMENT SYSTEM

Goma Procadre CORPGEN-2 Hazan Anns el Brose impact Assessment

Environmental Impact Statement

Part AS Cheek List Response delete inapplicable responses Response

1 Hazardous materials No | 9 Dustpollution No

2 Material storage No | 10 Oilpoltution Yes

3 Waste disposal No | 11 Chemical pollution No

4 Toxic waste No | 12 Emergency contingency plan Yes

5 Hazardous waste No | 13. Erosion No

6 Biological waste No | 14 Turbidity No

7 Chemical waste No | 15 Sedimentation No

8 Noise No | 16 Training required Yes

Part A6 Provide further information if Yes to any of the above, or as necessary

10. Oil pollution from mobile crane and floating crane should there be any leakages.

12, Emergency Contingency Methods will be spill trays & Plastic sheets placed under

Machinery. A Contingency plan will be placed on site.

16. Training for the Workforce on Environmental aspects for site construction personnel,

Environmental Contingency plan, Prevention of oil Spills & Ground Contamination,

Reduction & minimising noise levels & proper Waste Disposal

Wore 7 ‘Identify any Material Safety Data Sheets in Part A7

Note2 Provide details of any third parties involved, e.g. scaffolders, electricians etc.

Part A7 _ List the name of each attachment and the number of pages

pages

pages

_. Pages

Pages

pages

Total number of pages including this Environmental Impact Statement pages

Part A8_Review and approval

‘A8a Prepared Name _Roda Tawiik Company Archirodon

Position _Section Engineer Signature QL Cow/ Date 03/01/2007

‘ABbHSE review Name _PP Suresh Kumar Company ~Archirodon

Position _HSES. $.H Signature __7°Zineger Date _ 03/01/2007

‘Ric Approved Name _ Maged Wadie Company —Archirodon

Construction Manager Signature Zag f Date _05/0172007

Part A9 This Environmental Impact Statement has been communicated to and understood by all

personnel associated with the task.

Approved Name _Adel Monsef Cospegny _Archirodon as

Project Manager Signature ee” * Date _03/01/2007

Document Ref 0176-MS-04

C49 COLEINED AOD Ios wownsocy :

peduy PAM = sd edu eqeajor= fq — edu oresopour= eq —_roedum yoUEISNs= za ed a|qeIBJONN— 14 _'sopod auOLUSSESsE ysTY

or

6

3

on i ae Z|

9

¢

e[F] a ra ‘BreyTds [0 Jo Iaxo oy ur Ban Xpear soy eBlog SUID BuBOH amp PIEOG Wo dey Sq OTA] AMTUTETUOD [ATG |

rir[rlele lle "HO Hulyeay Sy) UreT0S OF sURIS Sip JOpun sous TASHA Jo Bupeards Ken dup wHudeoy | —¢

t[rlrlelri Pe ‘Sub Sip BUNTeIS a10ySq auwio om Jo woRSSdsay | —c

epee rete "RifoRBSY Suid HUUOY pUR SUE oqo aii jo osieuRTERA | T

a{ 1/4] 0] s]OIN

TARGA PAOD SUT A 4SNA 91p aonpoy 03 saamsvoyy JoxU0-y

ol

6

3

i

3

gs

¥

ce i €

z

Tro

clelelelel ele BERHOHANG | _pue pun os Sunnyod eunso Soy puw aoes9 azgou wey saye0) 10 | 1

a{1/alols N an

sana TOATUOD a107q ATA ‘ASH IE 81 38M 40 OMA Sauns¥ayA] [oNUOD axoyaq syEdmIy [UsHOMIMONANY VsIApY sUEIyTBES

Wy WON pur 1

Lovzioeo 8% Poe] wo soqng sapHUy JO PAOMRY | “ON ANANOY PO-SW-9LIO. Joy wouMoog

SHUNSVAW TOWLNOO GNV INGWSSASSV MSTY - d NOTLIIS

juoworeig seduT peyMoMUOS AUT

—_ uoussessy oduy ouauuoauut pao seGoUy paLeoy ZL-NErEHOD AMPED

ae] WWAISAS LNENOWNVIN SLV¥OAUOO a

He ANNOYS NOGOMHON aw

we oS

CARE COPE NAD-HOD ‘fos tuouinsog

yoda jen =sq sedan ayqexsjor= rq —joedumayexepou eq youd enueisqns=zq —ordum o|quIBTONN = Tq _“sapoo qMOUISSESSE SPY

im

"THES 10 Jo aBe9 UT Gan Kpeas voy otiaq amp pioq WO Wd aq OF Ny MOMIUTETTOS [AIS

“Si exfo0] sip UIEIGOD CH Bue oxy sopUN Ken apse|A wisays/cen dup w BUoSy,

‘BUI dif HUIS AIOJaq SuRID otf jo woNDSdsUT

“Auejnidar euen Supeoy pu apqou ap Jo soTeUSTEAL

“TuoIp sip 01 palroday 6q jinm juaumToAU op OF SSeuLTEp ESTED

Pinoo semp sSuypuy Ary “suonesedo Jo ezeyo uy ‘weuseso,4 / eeUIBug

Hold Point (signature required for release); W = Witness Point (attendance is expected but ‘signature not required); S = Surveillance (random attendance at site, signature not required), R = Submit Record for review Area / Work ready on Day & Date i AtTime Section / Assistant Engineer Name Signature Received by QC Inspector Name Signature Date Time Remarks 2 PART 2 ~ TO BE COMPLETED BY CTJV /QGiI Received by CTIV Rep Name Date Received by QGI Rep Name ate Z RESULT OF INSPECTION / TEST / SURVEY. Pass [| Fail [] Pass with comments [__] (ie, notall areas complicd) Remarks - 1 Date # - CTJV Rep. Signature _ Date QGII Rep. Signature a PART 3~TO BE COMPLETED BY ARCO QUALITY SECTION RESULT OF INSPECTION /TEST/SURVEY Acceptable Not Acceptable |__| Re-inspection Yes[_] No Partially Acceptable ["] (ic. nota areas complied) Remarks e Name Signature Date Document ref. 0176-SP-01-FO! Rev.1 ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA 0176-MS-04 METHOD i Document Ref. STATEMENT Issue 1 See sections 2.2 & 2.3 for control of this appendix. Construction of the Abutment by Placing Quarry Run, Armour Blocks APP ENDIX D DRAWINGS Armour Rock and Concrete ial Title Reference | Rew cae ssued for Construction Drawin, 1, |General LayoutAbutment and Loading | enaymODRIPLI6I ey Platform 2. Abutment Slopes-Sections and Details QGX/27/74/MO/DR/SV/620 | E3 suey row AE ‘QATARGAS I DEVELOPMENT PROJECT (a Ugates Gs Caney sn Uns sh crV/_ COWL CLP. PHASE. 4. BERTH 5 GENERAL LAYOUT IMENT AND LOADING ae sar ¢ i oral Ce ries oo | se " SEOHRL BR I00 ioe Sig mete mc SE eo ah ROE T exaT/raMORIOTIEIA, peeLeeee ees . So Taal | i ‘eaten Sonal san Sai Oe ae i Soe or SSRs | Sea a 4 | See 3 y (issued Fon constRuctin] sam | ibid q oe Le om | y Ey ae . Cs e car | aces AYRE PRSGL DeLeon tim Sete I H] gauss s-- aT AS =a ems nme «|. —T t eoueere aie sone na. Seo th =. Hetey r sb) He aa saya ih ; | : ah peu uommerte Pee wees amen t eugemaee SECLION c-C._1» 200 c an . Sea cei, ey ARCHIRODON CONSTRUCTION (OVERSEAS) Co. SA METHOD STATEMENT _| Document Ref. 0176-MS-04 ieee See sections 2.2 & 2.3 for conirol of this appendix Construction of the Abutment by Placing Quarry Run, Armour Rock and Concrete Armour Blocks APPENDIX E NIGHT SHIFT PROCEDURE Title __ Reference Rev, Pages ‘Night Shift Procedure CORP-GEN-15 | 1 5 ARCHIRODON GROUP NV GENERAL PROCEDURE Document Ref CORP-GEN-15 Revision 1 Page 1 of 5 CORPORATE MANAGEMENT SYSTEM a 7 QUALITY, ENVIRONMENTAL AND SAFETY MANAGEMENT SYSTEM REQUIREMENTS FOR SAFE WORKING AT NIGHT ‘This procedure has been printed from a network server or CD-ROM and has therefore not been issued as a controlled copy by the Corporate Quality Manager (see system procedure Control of Documents and Data). Accordingly, it is the responsibility of the user of this document to verify that it is the current version. This may be done by checking its stats in the register on a network server or by contacting the Comporate Quality Manager at the Ajman Regional Office on + 971 6 526 3454 ext. 119. Tssued for use. Document reference changed from GEN-SD-030, Issue Status & ; Amendments to incorporate the requirements of ISO 14001:1996 and Description | OHSAS 18001:1999. Prepared by | Reviewed by | Approved Corporate | Steerin Chie Document. | Rev Issue Date Quay ‘Grou aed Manager Officer CORP-GEN-IS | 1 | 38 February 3004 | Aa Nicklinson N Theodora unter eee db ARCHIRODON GROUP NV PRocenonn | oamat ket | Revision 1 Page 2 of S REQUIREMENTS FOR SAFE WORKING AT NIGHT LIST OF CONTENTS Page 1.0 Purpose 2.0 Scope ... 3.0 Document Control ... 4.0 Definitions, Terms and Abbreviations . 5.0 Responsibility 3 60 References 70 Procedure 38.0 Records .. ARCHIRODON GROUP NV GENERAL Document Ree a PROCEDURE | CORP-GEN-15 | Revision 1 Page 3 of 5 REQUIREMENTS FOR SAFE WORKING AT NIGHT 1.0 PURPOSE LL To outline the requirements and responsibilities for any work or activity that ‘occurs during the hours of darkness, whether programmed or not. 2.0 SCOPE 2.1 This general procedure applies to all projects (it is expected that a CFY will have pemanent arangements for lighting). 3.0 DOCUMENT CONTROL 3.1 This general procedure is @ controlled document as required by the Corporate Quality Manual and issued in accordance with the system procedure Control of Documents and Data. 3.2 Revisions of this document will be issued in accordance with that general procedure when the main text changes or when an appendix is added. Revised appendices for substitution will be issued separately and, winero appropriate, will include a separate schedule of contents, 33 Document revision and appendix issue status are shown in the Register of Corporate Management System Documents, a copy of which may be obtained from the Corporate Quality Manager upon request. 4.0 DEFINITIONS, TERMS AND ABBREVIATIONS 4.1 Lumen The unit representing the amount of light emitted by source or received on a surface. 4.2 Lux — One lumen per square metre, 5.0 RESPONSIBILITY 5.1 The Project Manager has overall responsibilty for implementation of this general procedure 5.2 The HSE Advisors responsible for: * Ensuring that Section Supervisors and subcontractor management are familiar with this general procedure, © Ensuring that any work carried out during the night complies with the requirements of this general procedure. © Monitoring site conditions and measuring the lighting provided to ensure it ‘meets the minimum standards given in this general procedure. ARCHIRODON GROUP NV GENERAL Document Ref a PROCEDURE | _CORP-GEN-15_| Revision 1 Page 4 of 5 REQUIREMENTS FOR SAFE WORKING AT NIGHT 53 54 6.0 Engineers and Section Supervisors are responsible for: © Ensuring that the HSE Advisor has been informed of the intention to work at night and that he is satisfied that all ofthe necessary arrangements are in place. * Issuing of any necessary permits to work. * Planning the work as far as practicable to eliminate the need for night working and to have contingency plans and arrangements in place to carry out the work safely during the night, if this is necessary. + For activities such as radiography (see general procedure Control of Radiography) they will ensure that signs, barriers and flashing lights are provided as well as adequate lighting and that the relevant persons have been informed. * Provision of instructions particularly with regard to the movement of vehicles (@g. concrete trucks) within the areas of work. * Ensuring that adequate barriers are provided around areas where hazards may exist (See technical procedure Requirements for Warning Signs and Barriers), and that such hazards are clearly lit. ‘+ Ensuring that lighting is adequate and personnel are not working in shadows. Subcontractors shall ensure that: They are aware of the contents ofthis general procedure, ‘They have authorisation from the Project Manager to work during the night. Their employees are provided with suitable and sufficient personal protective equipment (Gee technical procedure Requirements for Personal Protective Equipment). * There is adequate medical attendance by @ doctor, medic or nurse present on site when working at night, dependent on the work and number of personnel, REFERENCES ‘System procedure CORP-SYS-02 Control of Documents and Data General procedure CORP-GEN-03 Management of Plant & Equipment General procedure CORP-GEN-10 Control of Radiography Technical procedure CORP-TEC-O1 Requirements for Personal Protective Equipment Technical procedure CORP-TEC-13 Permit to Work Scheme Technical procedure CORP-TEC-16 Requirements for Warning Signs and Barriers * Technical procedure CORP-TEC-17 Requirements for Safe Temporary Electrics * 180 9001:2000 Quality management systems - Requirements * ISO 14001:1996 Environmental management systems ~ Specification with guidance for use * OHSAS 18001:1999 Occupational health and safety management systems - Specification ARCHIRODON GROUP NV GENERAL Document Ree a PROCEDURE _| CORP-GEN-15_| Revision 1 Page 5 of 5 REQUIREMENTS FOR SAFE WORKING AT NIGHT 7.0 PROCEDURE 7.1 Where possible, construction should take place during daylight hours, Some activites, however, are planned for night work and some unavoidably continue into the hours of darkness. In these circumstances the following sections describe the actions tobe taken to ensure safe working conditions, 7.2 The minimum degre of ilumination at any location shall be 100Lux. 7.3. Allpoints of ext, pathways and muster points shall be cleanly uminated. 74 Ladder access and egress shall be cleay illuminated, 75 Bayonet type light bulbs used as. stringers for illuminating passageways and Stairways shall be protected by cages. Lights provided for this purpose shall be sited to avoid glare and spaced to provide adequate light for the areas covered, 7.6 The illumination shell be measured prior to the work being caried out by a light ‘meter, calibrated in Lux. 7-7 Tower lighting shall be sited in a manner that illuminates all pats of the area where the work is taking place. 7.8 Lighting should be provided in confined spaces subject to any requirements on a Permit to work (se technical procedure Permit to Work Scheme) 7.9 Generators provided shall be checked prior to use to ensure that they meet the requirements given in the general procedure Management of Plant & Equipment. 7.10 Lightning poles and other metal poles shall be earthed and the circuit fitted with earth leakage circuit breakers (ELCBs). 7.11 Cables employed for the purpose of temporary lighting shall be routed to ensure that they do not present a trip hazard or other obstruction and shall otherwise be installed in accordance with the technical procedure Requirements for Safe Temporary Electries. 8.0 RECORDS 8.1 There are no records generated by this general procedure 8.2 Records generated by referenced procedures are to be managed in accordance with the originating procedure, ~~ END OF TEXT - -

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5807)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1091)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (842)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (590)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (897)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (346)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (122)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (401)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2259)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (266)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (74)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- Piping Support DesignDocument27 pagesPiping Support DesignOmar TocmoNo ratings yet

- Support Rev-E8Document132 pagesSupport Rev-E8Omar TocmoNo ratings yet

- PGLN Yk FDZZZ 900002 - 1 - 001Document1 pagePGLN Yk FDZZZ 900002 - 1 - 001Omar TocmoNo ratings yet

- Pgln-Yk-Fdzzz-900005 A 001 IfirDocument1 pagePgln-Yk-Fdzzz-900005 A 001 IfirOmar TocmoNo ratings yet

- PGLN Yk FDZZZ 900001 - 1 - 001Document1 pagePGLN Yk FDZZZ 900001 - 1 - 001Omar TocmoNo ratings yet

- Project Specification For Fire and Gas SystemDocument16 pagesProject Specification For Fire and Gas SystemOmar TocmoNo ratings yet

- Safety 2Document17 pagesSafety 2Omar TocmoNo ratings yet

- 1108-DES-005 Rev02Document1 page1108-DES-005 Rev02Omar TocmoNo ratings yet

- Hvac Precommisioning ExecutionDocument13 pagesHvac Precommisioning ExecutionOmar TocmoNo ratings yet

- QGX T CS Arn 00222Document51 pagesQGX T CS Arn 00222Omar TocmoNo ratings yet

- QGX T CS QR 05657Document53 pagesQGX T CS QR 05657Omar TocmoNo ratings yet

- Fabrication Verification ChecklistDocument1 pageFabrication Verification ChecklistOmar TocmoNo ratings yet

- QGX T Arn CS 00005Document38 pagesQGX T Arn CS 00005Omar TocmoNo ratings yet

- Fire Water Demand PDFDocument28 pagesFire Water Demand PDFOmar TocmoNo ratings yet

- QAQC Department Flow SchemeDocument1 pageQAQC Department Flow SchemeOmar TocmoNo ratings yet

- Pipe Welding ConsumablesDocument1 pagePipe Welding ConsumablesOmar TocmoNo ratings yet

- Fire and Gas Detection Philosophy PDFDocument22 pagesFire and Gas Detection Philosophy PDFOmar Tocmo100% (3)

- QGX T QR CS 04524Document32 pagesQGX T QR CS 04524Omar TocmoNo ratings yet

- Nitrogen RejectionDocument7 pagesNitrogen RejectionOmar TocmoNo ratings yet

- Erection MethodologyDocument13 pagesErection MethodologyOmar TocmoNo ratings yet

- LR90STDDocument1 pageLR90STDOmar TocmoNo ratings yet

- Appendix A - Specification For Fabrication and Erection of PipingDocument15 pagesAppendix A - Specification For Fabrication and Erection of PipingOmar TocmoNo ratings yet

- Pipe SupportsDocument18 pagesPipe SupportsOmar TocmoNo ratings yet

- QGX T CS CCS 00353Document22 pagesQGX T CS CCS 00353Omar TocmoNo ratings yet

- Piping Connection EquipmentDocument19 pagesPiping Connection EquipmentOmar TocmoNo ratings yet