Professional Documents

Culture Documents

Hoh Tot

Uploaded by

qethOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Hoh Tot

Uploaded by

qethCopyright:

Available Formats

We classify as turbomachines all those devices in which energy is transferred either to, or from, a continuously

flowing fluid by the dynamic action of one or more moving blade rows. The word turbo or

turbinis is of Latin origin and implies that which spins or whirls around. Essentially, a rotating blade

row, a rotor or an impeller changes the stagnation enthalpy of the fluid moving through it by doing

either positive or negative work, depending upon the effect required of the machine. These enthalpy

changes are intimately linked with the pressure changes occurring simultaneously in the fluid.

Two main categories of turbomachine are identified: firstly, those that absorb power to increase the

fluid pressure or head (ducted and unducted fans, compressors, and pumps); secondly, those that produce power

by expanding fluid to a lower pressure or head (wind, hydraulic, steam, and gas turbines).

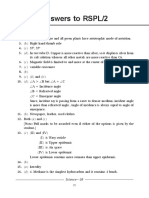

Figure 1.1 shows, in a simple diagrammatic form, a selection of the many varieties of turbomachines

encountered in practice. The reason that so many different types of either pump (compressor) or turbine

are in use is because of the almost infinite range of service requirements. Generally speaking, for a given

set of operating requirements one type of pump or turbine is best suited to provide optimum conditions

of operation.

Turbomachines are further categorised according to the nature of the flow path through the passages

of the rotor. When the path of the through-flow is wholly or mainly parallel to the axis of rotation, the

device is termed an axial flow turbomachine [e.g., Figures 1.1(a) and (e)]. When the path of the throughflow is

wholly or mainly in a plane perpendicular to the rotation axis, the device is termed a radial flow

turbomachine [e.g., Figure 1.1(c)]. More detailed sketches of radial flow machines are given in

Figures 7.3, 7.4, 8.2, and 8.3. Mixed flow turbomachines are widely used. The term mixed flow in this

context refers to the direction of the through-flow at the rotor outlet when both radial and axial velocity

components are present in significant amounts. Figure 1.1(b) shows a mixed flow pump and Figure 1.1(d)

a mixed flow hydraulic turbine.

One further category should be mentioned. All turbomachines can be classified as either impulse or

reaction machines according to whether pressure changes are absent or present, respectively, in the

flow through the rotor. In an impulse machine all the pressure change takes place in one or more nozzles, the

fluid being directed onto the rotor. The Pelton wheel, Figure 1.1(f), is an example of an

impulse turbine.

You might also like

- Hydraulics and Pneumatics: A Technician's and Engineer's GuideFrom EverandHydraulics and Pneumatics: A Technician's and Engineer's GuideRating: 4 out of 5 stars4/5 (8)

- Bernard Le Méhauté (Auth.) - An Introduction To Hydrodynamics and Water Waves-Springer Berlin Heidelberg (1976)Document326 pagesBernard Le Méhauté (Auth.) - An Introduction To Hydrodynamics and Water Waves-Springer Berlin Heidelberg (1976)rafdi80% (5)

- Fundamentals of Turbomachinery by William W. PengDocument16 pagesFundamentals of Turbomachinery by William W. PengH_AbdelMeguid0% (2)

- Basic Equation of Energy in Fluid MachinesDocument28 pagesBasic Equation of Energy in Fluid Machinesabhigoyal1989No ratings yet

- Pumps and Turbines - Cheruiyot PDFDocument40 pagesPumps and Turbines - Cheruiyot PDFMwiti TizianoNo ratings yet

- CICADA2017Document60 pagesCICADA2017adu666No ratings yet

- Turbomachinery FullDocument40 pagesTurbomachinery FullAshween Royos DoutalNo ratings yet

- Turbo MachineryDocument4 pagesTurbo MachineryRoshan ShanmughanNo ratings yet

- Chap 1 Types of TurbomachinesDocument8 pagesChap 1 Types of TurbomachinesNorvinyeLorlortorYekoNo ratings yet

- TURBO MACHINES: Fundamentals, Applications, ClassificationsDocument13 pagesTURBO MACHINES: Fundamentals, Applications, ClassificationsC Venkataramana ReddyNo ratings yet

- Basic Principles of TurbomachinesDocument85 pagesBasic Principles of TurbomachinesAhmed Adel IbrahimNo ratings yet

- Basic Principles of Turbo MachinesDocument6 pagesBasic Principles of Turbo Machinesbinho58100% (1)

- Turbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversityDocument58 pagesTurbomachineries School of Mechanical and Industrial Engineering Debre Markos UniversitybirlieNo ratings yet

- Energy Systems: Classification of TurbomachineryDocument24 pagesEnergy Systems: Classification of TurbomachineryAbhiNo ratings yet

- Classificaitons of Fluid MachinesDocument4 pagesClassificaitons of Fluid MachinesaadhanNo ratings yet

- Turbo Machinery (ME 5001) - Unit 1 - WWW - Rgpvnotes.in PDFDocument11 pagesTurbo Machinery (ME 5001) - Unit 1 - WWW - Rgpvnotes.in PDFMohammed AhmedNo ratings yet

- Module 1 - Basic Principles of Turbo MachinesDocument12 pagesModule 1 - Basic Principles of Turbo Machinesnagendrags100% (1)

- Pumps, Compressors, Fans or BlowersDocument5 pagesPumps, Compressors, Fans or BlowersNagarjuna KunchamNo ratings yet

- Introduction to TurbomachinesDocument38 pagesIntroduction to TurbomachinesmohamedovicNo ratings yet

- Basic Principles of TurbomachinesDocument41 pagesBasic Principles of TurbomachinesMuralikrishna ArigondaNo ratings yet

- Turbo MachineryDocument182 pagesTurbo MachineryAnkit GandhiNo ratings yet

- Chapter One / IntroductionDocument17 pagesChapter One / Introductionامير ماجد العامريNo ratings yet

- Tourbo...Document6 pagesTourbo...appannusaNo ratings yet

- Fluid MachinesDocument161 pagesFluid MachinesHaroon GhaniNo ratings yet

- Basics of Turbo Machines in 40 CharactersDocument14 pagesBasics of Turbo Machines in 40 CharactersBF3nobelNo ratings yet

- Fluid TurbomachineryDocument7 pagesFluid TurbomachinerySuraj YadavNo ratings yet

- Axial Compressor - Wikipedia, The Free EncyclopediaDocument11 pagesAxial Compressor - Wikipedia, The Free EncyclopediaSurendra ReddyNo ratings yet

- Unit 4 Fme1202Document23 pagesUnit 4 Fme1202Muthuvel MNo ratings yet

- Prinsip Thermo MekfluDocument31 pagesPrinsip Thermo MekfluGhany RadifanNo ratings yet

- Mce 513Document5 pagesMce 513Temiloluwa KalaroNo ratings yet

- Lecture Compounding in Impulse TurbineDocument8 pagesLecture Compounding in Impulse TurbineAbdul Sami Abdul LatifNo ratings yet

- Introduction To Turbo Machinery: November 2017Document73 pagesIntroduction To Turbo Machinery: November 2017anwar anwaryNo ratings yet

- Chapter:5 Steam Turbine I.: Principle of OperationDocument21 pagesChapter:5 Steam Turbine I.: Principle of OperationKrishna ChauhanNo ratings yet

- Fluid Machineries IntroductionDocument37 pagesFluid Machineries IntroductionAiza AlbuferaNo ratings yet

- Turbo Machine: Radial Rotor (Impeller) Shroud Blade Axial Flow Out Axial Flow in or Vane Flow OutDocument6 pagesTurbo Machine: Radial Rotor (Impeller) Shroud Blade Axial Flow Out Axial Flow in or Vane Flow OutKaushal SharmaNo ratings yet

- Unit 5 FHMDocument73 pagesUnit 5 FHMeyobNo ratings yet

- Axial Flow CompressorDocument50 pagesAxial Flow CompressorSunil Panwar100% (1)

- The Pelton WheelDocument32 pagesThe Pelton WheelJoseph GazaletNo ratings yet

- Trumbo AssignmentDocument19 pagesTrumbo AssignmentTemesgen ErenaNo ratings yet

- Types of Hydraulic MachinesDocument23 pagesTypes of Hydraulic MachinesAlaa MohamedNo ratings yet

- The Pelton WheelDocument29 pagesThe Pelton WheelJoseph GazaletNo ratings yet

- About Pumps and Turbines PDFDocument5 pagesAbout Pumps and Turbines PDFabdullahaafaqNo ratings yet

- Hydropower Equipment and Generation StatiDocument54 pagesHydropower Equipment and Generation StatiAytac GuvenNo ratings yet

- Turbomachanies & ClassificationDocument7 pagesTurbomachanies & ClassificationVinay ChandwaniNo ratings yet

- CE202 HM NotesDocument6 pagesCE202 HM NotesVisal PiscelNo ratings yet

- Turbo Machinery: Chapter-OneDocument80 pagesTurbo Machinery: Chapter-OneMichael MesfinNo ratings yet

- 5) Module-1 Introduction To TurbomachineryDocument82 pages5) Module-1 Introduction To TurbomachineryA48Rayan PereiraNo ratings yet

- Introduction To Fluid MachineryDocument15 pagesIntroduction To Fluid MachinerymyravganacNo ratings yet

- Introduction to Turbomachinery: Types and ApplicationsDocument3 pagesIntroduction to Turbomachinery: Types and ApplicationsSparsh SolankiNo ratings yet

- Applied Thermo Prac Ass 2Document3 pagesApplied Thermo Prac Ass 2Alexander MugabeNo ratings yet

- Hydraulic Machines - ME 311 by Dr. Muhammad UsmanDocument33 pagesHydraulic Machines - ME 311 by Dr. Muhammad UsmanMuhammad Farhan Waqar ButtNo ratings yet

- Experiment Centrifugal PumpDocument14 pagesExperiment Centrifugal PumpmahabubNo ratings yet

- Turbo Machine NotesDocument83 pagesTurbo Machine NotesmulualemNo ratings yet

- Turbomachines Intro 1Document22 pagesTurbomachines Intro 1Mukul Goyal0% (1)

- How to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesFrom EverandHow to Select the Right Centrifugal Pump: A Brief Survey of Centrifugal Pump Selection Best PracticesRating: 5 out of 5 stars5/5 (1)

- EED 5 Unit 8Document45 pagesEED 5 Unit 8Reinaliza FerraroNo ratings yet

- Apes Gum LabDocument3 pagesApes Gum Labapi-409641205No ratings yet

- Science 10 - Set 2 - DS 1Document10 pagesScience 10 - Set 2 - DS 1DhejehNo ratings yet

- Buet MSCDocument2 pagesBuet MSCZarin Tasnim ChowdhuryNo ratings yet

- Plane Wave Reflection Coefficient From Near Field MeasurementsDocument7 pagesPlane Wave Reflection Coefficient From Near Field MeasurementsraulreyesvillagranaNo ratings yet

- Gas Lift Design With Self-Well GasDocument12 pagesGas Lift Design With Self-Well GasMohanad HussienNo ratings yet

- Nidia Mindiyarti: Projects Big Data and Machine LearningDocument1 pageNidia Mindiyarti: Projects Big Data and Machine Learningnidia mindiyartiNo ratings yet

- S - 1.3 E A Big "O" Truncation Error: O (H) Order of ApproximationDocument5 pagesS - 1.3 E A Big "O" Truncation Error: O (H) Order of ApproximationMohammed SalahNo ratings yet

- 23 Samss 060Document14 pages23 Samss 060Cherukunnon JubuNo ratings yet

- DS - Module: Team EmertxeDocument113 pagesDS - Module: Team EmertxevijaykumarsinganaNo ratings yet

- Exam - Inhinyero - Student Portal - DesignDocument30 pagesExam - Inhinyero - Student Portal - DesignJacob SantosNo ratings yet

- CHM 256: Basic Analytical Chemistry: Evaluation of Experimental DataDocument42 pagesCHM 256: Basic Analytical Chemistry: Evaluation of Experimental DataSPMUSER9ANo ratings yet

- ESD Merged Till CS6Document237 pagesESD Merged Till CS6Rahamtulla MohammadNo ratings yet

- Ad 7780Document16 pagesAd 7780alcplmNo ratings yet

- Indc CCP 432Document182 pagesIndc CCP 432SteveAbonyiNo ratings yet

- SAP BW ExtractionDocument161 pagesSAP BW ExtractionKuldeep Jain100% (3)

- 033 2010 Abstracts Chemreactor 19 VienaDocument637 pages033 2010 Abstracts Chemreactor 19 VienaChau Mai100% (1)

- DFT QuestionsDocument8 pagesDFT QuestionsAdhi SuruliNo ratings yet

- High Productivity Scalable Pick-and-Place HandlerDocument2 pagesHigh Productivity Scalable Pick-and-Place HandlermhafizanNo ratings yet

- SAIVEERA ACADEMY’S GUIDE TO 12TH CHEMISTRY UNIT 1 METALLURGYDocument26 pagesSAIVEERA ACADEMY’S GUIDE TO 12TH CHEMISTRY UNIT 1 METALLURGYKrish Krishn100% (1)

- Euclids GeometryDocument10 pagesEuclids GeometryChitturi SushanthNo ratings yet

- ISO 9001 certified burner control box technical guideDocument6 pagesISO 9001 certified burner control box technical guideVijay BhureNo ratings yet

- Adventures in Lead Times PDFDocument20 pagesAdventures in Lead Times PDFAvinash RoutrayNo ratings yet

- Update On The Modeling of Semiautogenous Grinding Processes in A Moly-Cop Tools EnvironmentDocument15 pagesUpdate On The Modeling of Semiautogenous Grinding Processes in A Moly-Cop Tools EnvironmentTecnoExpress CHILENo ratings yet

- Hysteretic Energy DissipationDocument22 pagesHysteretic Energy Dissipationdharma raj upadhyayaNo ratings yet

- Icd Aidc Ver3Document95 pagesIcd Aidc Ver3Alvin Guillermo Rodriguez ArguelloNo ratings yet

- Spring Boot ServicesDocument27 pagesSpring Boot ServicesMarcosNo ratings yet

- Circle Theorem June/July 2021Document4 pagesCircle Theorem June/July 2021Sachin MangarNo ratings yet