100% found this document useful (1 vote)

457 views12 pagesKaizen Report: Process Improvement Analysis

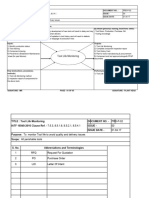

This document outlines a Kaizen report that was implemented to improve productivity. The report details problems that were identified, such as operators walking long distances to retrieve dies and insufficient curing time causing anti-rust spillage. Solutions implemented include providing a die rack at the cell to reduce walking and adding a stand to allow for proper curing time. One improvement combined bending and notching operations into a single die and press, eliminating the need for two separate presses. The report evaluates the measurable benefits and cost savings realized from implementing these Kaizen improvements.

Uploaded by

Afzal RafeequeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd

100% found this document useful (1 vote)

457 views12 pagesKaizen Report: Process Improvement Analysis

This document outlines a Kaizen report that was implemented to improve productivity. The report details problems that were identified, such as operators walking long distances to retrieve dies and insufficient curing time causing anti-rust spillage. Solutions implemented include providing a die rack at the cell to reduce walking and adding a stand to allow for proper curing time. One improvement combined bending and notching operations into a single die and press, eliminating the need for two separate presses. The report evaluates the measurable benefits and cost savings realized from implementing these Kaizen improvements.

Uploaded by

Afzal RafeequeCopyright

© © All Rights Reserved

We take content rights seriously. If you suspect this is your content, claim it here.

Available Formats

Download as XLS, PDF, TXT or read online on Scribd