Professional Documents

Culture Documents

Cocrete Pour Card 3

Uploaded by

Anil UdaleOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cocrete Pour Card 3

Uploaded by

Anil UdaleCopyright:

Available Formats

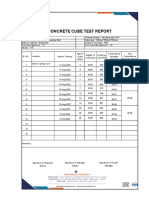

Arvind Smartspaces Ltd. RECORD NO.

CONCRETE POUR CARD BUILDING

LOCATION

PROJECT : PHASE : DATE

NAME OF CONTRACTOR : SHEET NO

FLOOR: MEMBER

REF GFC ARCH DRAWING : QTY[CUMT]

REF GFC STRCTURAL DRAWING : GRADE

Pour Started ……………………………………………….. Pour Completed………………………… WEATHER

Theoretical Cement Bags.................................Actual Cement Bags Consumed.............................

A BEFORE STARTING THE CONCRETING Yes No. REMARKS

1 Checklist for Reinforcement approved.

2 Checklist for formwork and scaffold approved.

3 Checklist for Electrical conduiting work approved.[For slab]

4 Plumbing sleeves are at place as required.

Materials like Coarse Aggregates ,Fine aggregates,cement, Plastisizer,water are adequate in

5

stock.

6 Mix Design Board on display and visible at mixer location.

7 Grade of concrete to be checked based on structural drawing

8 Machineries like Batching plant, lift,mixer ,vibrator , needles are checked and found in working

condition.

9 Pouring Height known

10 Slump cone and cube moulds are at mixer plant .[ 9 cube sample to be taken per job ]

11 Manpower found ok as per the pour qty for the job.

12 Mixer speed checked [ 20-22 RPM ]Mixer blade gap welded adjusted to 30mm.

13 Batch entry Card at place.

B CONCRETE POURING

14 Buttering of mixer done before 1st batch .

15 Every batch mix should be mixed upto 1.5 minutes.

16 Admixture doze specified.

Slump Test done and the Required slump checked as per the mix design. [ Column – 80-100,

17

Slab/beams – 90-100 ]

18 Concrete placing observed and compaction by needle vibrator is satisfactory.

19 Stopper placed at,where the concrete is to be stopped for construction joint.

20 Check whether admixture are properly added to concrete

21 Cube Samples taken as per the method.

C INSPECTION AFTER FINAL FINISH

22 Deshuttering Started as per the IS - 456 2000 SPECS.[Page -25]

23 Hacking started [ at least 1.5" appart and 4mm deep with min 80 nos per sqft range.

Honey-combing found within acceptable limit : Loose aggregates removed and grouting done as

24

per the specs.

25 Honey-combing seen beyond the acceptable limit . Asked to dismantle the member and to recast.

Slab broom finished as per th instruction. Any shrinkage cracks treated immediately with cement

26

sand mortar slurry .

27 Curing started as soon as deshuttering totally done. By water ponding/ Hassian cloth wraping .

28 Slab covered after concrete setting to avoid direct heat .

Curing date written on the member .[ Start and End date on the same place ].Column min 10days

29

and slab min 7 days.

Supports under the beam and slab being removed as per IS -456 2000. Deshuttering being done

30

props left under.

31 Finishing of slab found ok.No nails left after deshuttering .

32 Cube Compressive strength as per given grade.

SIGNATURE OF CONTRACTOR DATE

SIGNATURE OF EXECUTION ENGINEER DATE

SIGNATURE OF QC ENGINEER SIGN

You might also like

- Amendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering WorksDocument8 pagesAmendment N - I MA Y 2002 IS 1200 (PART 8) : 1993 Methods Measurement of Building and Civil Engineering Worksraviteja036No ratings yet

- Tiles Laying AgreementDocument1 pageTiles Laying AgreementmgrvprasadNo ratings yet

- Cover Block Method StaDocument1 pageCover Block Method StaRavi kumarNo ratings yet

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocument4 pagesFosroc Nitobond EP - Epoxy bonding agent for concreteganmosesNo ratings yet

- Fosroc Nitobond EP - Epoxy bonding agent for concreteDocument4 pagesFosroc Nitobond EP - Epoxy bonding agent for concreteSanjeev KumarNo ratings yet

- 3812 1 PDFDocument14 pages3812 1 PDFइंजि कौस्तुभ पवारNo ratings yet

- HardcreteDocument2 pagesHardcreteapi-3823524100% (1)

- QCP-Soil Investigation WorksDocument9 pagesQCP-Soil Investigation WorksManash Protim GogoiNo ratings yet

- Aggregate Testing Report FormDocument1 pageAggregate Testing Report FormGilbert chuks100% (2)

- Concrete dispatch slip quality planDocument1 pageConcrete dispatch slip quality planShesha ShayanNo ratings yet

- Fosroc Nitocote EM 300 protects concrete from corrosionDocument2 pagesFosroc Nitocote EM 300 protects concrete from corrosionAarish Khan100% (1)

- Method Statement For Granite FrameDocument7 pagesMethod Statement For Granite FrameMonali Varpe100% (1)

- External NCR MonitoringDocument7 pagesExternal NCR MonitoringGhayas JawedNo ratings yet

- Strip Chart StructureDocument5 pagesStrip Chart StructureBrijesh MishraNo ratings yet

- Gsb-II Mix DesigntDocument5 pagesGsb-II Mix DesigntMohammed AyazNo ratings yet

- AAC BLOCK SUNKEN FILLING CHECKLISTDocument1 pageAAC BLOCK SUNKEN FILLING CHECKLISTASHOKKUMARNo ratings yet

- cOVER BLOCKSDocument4 pagescOVER BLOCKSPrashant Mankar100% (1)

- DEV RMC LLP Concrete Delivery Challan Survey No.142 Hissa No.1 Village JuchandraDocument1 pageDEV RMC LLP Concrete Delivery Challan Survey No.142 Hissa No.1 Village JuchandraVishal WarghatNo ratings yet

- Concrete Lab ManualDocument42 pagesConcrete Lab ManualVENKATA RANGANADHNo ratings yet

- Anti-Termite Treatment MethodDocument4 pagesAnti-Termite Treatment Methodbeshnu garanaikNo ratings yet

- Approval of Concrete Curing CompoundDocument4 pagesApproval of Concrete Curing Compoundsalman tariqNo ratings yet

- Cube Test ReportDocument1 pageCube Test ReportShubham MareNo ratings yet

- Basement Floor Screed ConcreteDocument5 pagesBasement Floor Screed ConcreteQAQC NandanamNo ratings yet

- NR Letter Submission of ITP For HSFG BoltsDocument2 pagesNR Letter Submission of ITP For HSFG BoltsLakhwant Singh KhalsaNo ratings yet

- Method Statement For Exterrnal PlasteringDocument7 pagesMethod Statement For Exterrnal PlasteringSagar ParabNo ratings yet

- Inspection & Test Plan (Itp) : Road WorkDocument1 pageInspection & Test Plan (Itp) : Road WorkLOPA THANDARNo ratings yet

- PSC Girder Before Concreting MIPL CL 32Document2 pagesPSC Girder Before Concreting MIPL CL 32Rayudu VVS100% (1)

- DLC Methodology - Nagpur MumbaiDocument13 pagesDLC Methodology - Nagpur MumbaiGanesh Kumar TulabandulaNo ratings yet

- Mix Design M-25 GradeDocument9 pagesMix Design M-25 Gradeenjoy begening lifeNo ratings yet

- Moisture Correction SheetDocument4 pagesMoisture Correction SheetSasanka SekharNo ratings yet

- Kerb Construction Methodology GuideDocument2 pagesKerb Construction Methodology GuideAnish PanchalNo ratings yet

- Alccofine 1106 TDS V2Document3 pagesAlccofine 1106 TDS V2Siddhesh Kamat MhamaiNo ratings yet

- Concrete Inspection and Testing PlanDocument3 pagesConcrete Inspection and Testing PlanMohammed Ghareib NasrNo ratings yet

- CAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic EtherDocument2 pagesCAC-Hyperfluid R150: Superplasticiser For High Performance Concrete Based On Poly-Carboxylic Ethermohsin shaikh100% (1)

- Checklist-Bearing Fixing and GroutingDocument1 pageChecklist-Bearing Fixing and Groutingajit karandikar100% (1)

- SP Fashion Fero Scan ReportDocument16 pagesSP Fashion Fero Scan ReportMd SohagNo ratings yet

- L&T Quality Quiz-Sample 1Document3 pagesL&T Quality Quiz-Sample 1balaNo ratings yet

- Checklist-Structural Concrete Post PouringDocument1 pageChecklist-Structural Concrete Post Pouringajit karandikarNo ratings yet

- 0005 India Regulation On CoatingDocument33 pages0005 India Regulation On Coatingagustinusset100% (2)

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- Compressive Strength of Concrete Cube ReportDocument1 pageCompressive Strength of Concrete Cube ReportAnees RahmanNo ratings yet

- 23) Invoice No-729697096 DT 21.03.2020 IOCLDocument1 page23) Invoice No-729697096 DT 21.03.2020 IOCLkmuraliNo ratings yet

- Sub-soil Pipe ChecklistDocument1 pageSub-soil Pipe ChecklistRaman IyerNo ratings yet

- MS 05 Cast-In-place Concrete Pile Method Statement (Bored Pile)Document18 pagesMS 05 Cast-In-place Concrete Pile Method Statement (Bored Pile)Abdullah Al MarufNo ratings yet

- Sand Calibration FormetDocument2 pagesSand Calibration FormetAnish PanchalNo ratings yet

- Manzini to Mbadlane (MR3) Highway Project (Lot 1) Tack Coat Application RatesDocument3 pagesManzini to Mbadlane (MR3) Highway Project (Lot 1) Tack Coat Application RatesSoundar PachiappanNo ratings yet

- Ultrasonic Pulse Velocity Test: Observation SheetDocument1 pageUltrasonic Pulse Velocity Test: Observation SheetAhteshaam MullaNo ratings yet

- CONCRETE MIX DESIGN FOR M55 GRADE CONCRETEDocument1 pageCONCRETE MIX DESIGN FOR M55 GRADE CONCRETELegendary GamingNo ratings yet

- Is 777 For Glazed TilesDocument15 pagesIs 777 For Glazed TilesMadhu BabuNo ratings yet

- Concrete Cube Test Report FormatDocument1 pageConcrete Cube Test Report FormatNaiyer AzamNo ratings yet

- Methodology-TG DECK-rev0 (4feb12)Document11 pagesMethodology-TG DECK-rev0 (4feb12)beshnu garanaik100% (1)

- Method Statement: Granular Sub Base (GSB) Layer Compaction ProcessDocument1 pageMethod Statement: Granular Sub Base (GSB) Layer Compaction ProcessjitendraNo ratings yet

- Paver Block ChecklistDocument6 pagesPaver Block ChecklistAnkur BarsainyaNo ratings yet

- Draft Letter Permission For Casting Percast Girder PDFDocument2 pagesDraft Letter Permission For Casting Percast Girder PDFSachin RamaniNo ratings yet

- CPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemDocument3 pagesCPC-18 Measurement of Hardened Concrete Carbonation Depth: Rilem Recommendations Recommandations de La RilemmanuelisantosNo ratings yet

- LAB EQUIPMENT INVENTORYDocument17 pagesLAB EQUIPMENT INVENTORYPalla Bhaskara RaoNo ratings yet

- Concrete Pavement Sub-Base SpecificationsDocument9 pagesConcrete Pavement Sub-Base SpecificationsAmit AbhangNo ratings yet

- Checklist For Anti Termite TreatmentDocument1 pageChecklist For Anti Termite TreatmentRachitanand HiremathNo ratings yet

- Basf Masterpolyheed 8118 TdsDocument2 pagesBasf Masterpolyheed 8118 Tdsaji arafat100% (2)

- Tank Fabrication ProcedureDocument11 pagesTank Fabrication ProcedureNurul100% (2)

- FT Mopur3 enDocument9 pagesFT Mopur3 enAnil UdaleNo ratings yet

- Smartcare Textured Crack Filler PDFDocument2 pagesSmartcare Textured Crack Filler PDFtusharthakreNo ratings yet

- FLEXCRETE polymer improves cementitious mortar and screedDocument1 pageFLEXCRETE polymer improves cementitious mortar and screedAnil UdaleNo ratings yet

- TTPL Surface Texture LLP HGDocument9 pagesTTPL Surface Texture LLP HGAnil UdaleNo ratings yet

- General Requirements For Design and Construction of Foundations in Soils - Code of PracticeDocument20 pagesGeneral Requirements For Design and Construction of Foundations in Soils - Code of Practiceyedida viswanadh100% (1)

- India Crete RMC: A. Mix StipulationDocument2 pagesIndia Crete RMC: A. Mix StipulationAnil UdaleNo ratings yet

- 150mm Thick FloorDocument11 pages150mm Thick FloorAnil UdaleNo ratings yet

- Ashoka Buildcon LTD.: Design Stipulation Code RefferedDocument1 pageAshoka Buildcon LTD.: Design Stipulation Code RefferedAnil UdaleNo ratings yet

- M20 Tremix RDCDocument1 pageM20 Tremix RDCAnil UdaleNo ratings yet

- Fact-Data: ManufacturerDocument2 pagesFact-Data: Manufacturersandrapat45No ratings yet

- Mekanika Kekuatan Material: Axial LoadingDocument20 pagesMekanika Kekuatan Material: Axial LoadingYusron Bachtiar ArdhiNo ratings yet

- 99 Gravriljuk - HighNitrogenSteels PDFDocument387 pages99 Gravriljuk - HighNitrogenSteels PDFharoldopintoNo ratings yet

- Elasticity of Solid, Liquid and Modulus of MaterialsDocument3 pagesElasticity of Solid, Liquid and Modulus of MaterialsHinata CosaNo ratings yet

- Conf paperManufacturingRefractorySilicaBricksfromSilicaSand PDFDocument16 pagesConf paperManufacturingRefractorySilicaBricksfromSilicaSand PDFJdjdjdiuf D8didifiififNo ratings yet

- ShaliFloor SL TC 4EDocument3 pagesShaliFloor SL TC 4EPrashant BaruaNo ratings yet

- BS en 50368 Cable CleatDocument27 pagesBS en 50368 Cable CleatNima dawa SherpaNo ratings yet

- Piping Class B2Document5 pagesPiping Class B2Yousab JacobNo ratings yet

- 6.2 Arch Drawing For Elv4-EDocument38 pages6.2 Arch Drawing For Elv4-ErollyNo ratings yet

- Presentation On Underground Metro: Prepared By-Yusuf RampurawalaDocument71 pagesPresentation On Underground Metro: Prepared By-Yusuf RampurawalaYusuf RampNo ratings yet

- Applications of Polymers PDFDocument3 pagesApplications of Polymers PDFProf C.S.Purushothaman57% (7)

- Document B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Document9 pagesDocument B: Specific Guidance For Hostels and Shared Houses in Multiple Occupation (Hmo)Ngonidzashe MhukaNo ratings yet

- HT PoleDocument8 pagesHT PolemanishNo ratings yet

- Nioec SP 50 59Document9 pagesNioec SP 50 59aminNo ratings yet

- OBO CatalogDocument5 pagesOBO CatalogDani Good VibeNo ratings yet

- Hilti Hvu HasDocument12 pagesHilti Hvu HasAMCRUZ77No ratings yet

- A Comprehensive Review On The Vibration Analyses of Small-Scaled Plate-Based Structures by Utilizing The Nonclassical Continuum Elasticity TheoriesDocument110 pagesA Comprehensive Review On The Vibration Analyses of Small-Scaled Plate-Based Structures by Utilizing The Nonclassical Continuum Elasticity Theoriesazerty wxcvbNo ratings yet

- PP Trilene Hi10hoDocument2 pagesPP Trilene Hi10hoLaili AzkiyahNo ratings yet

- Draw Management: Executive SummaryDocument13 pagesDraw Management: Executive SummaryJose HernandezNo ratings yet

- Stone Construction Services: Camas, WA 98607 (900) 555-1111 WA Licence #STONECS000W 111 Ocean AvenueDocument1 pageStone Construction Services: Camas, WA 98607 (900) 555-1111 WA Licence #STONECS000W 111 Ocean AvenueMuhammad Zaimmuddin100% (1)

- Instrument Technician Questions and AnswersDocument4 pagesInstrument Technician Questions and AnswerszhangyiliNo ratings yet

- Bituminous Pavement Engineering: J. Murali Krishnan CE3015 2021Document40 pagesBituminous Pavement Engineering: J. Murali Krishnan CE3015 2021testerNo ratings yet

- European Recommendations For Sandwich Panels: Part I: DesignDocument62 pagesEuropean Recommendations For Sandwich Panels: Part I: DesignSilvo ŠtihNo ratings yet

- Rock and Soil AnchorsDocument28 pagesRock and Soil Anchorsmevice63No ratings yet

- Chapter - 1 - Surface Hardening Processes PDFDocument16 pagesChapter - 1 - Surface Hardening Processes PDFRajaSekarsajja100% (2)

- Transeals Identifying Hydraulic SealsDocument28 pagesTranseals Identifying Hydraulic Sealsvikram_007No ratings yet

- Service parts for 74mm screw compressorsDocument1 pageService parts for 74mm screw compressorsPrince RajaNo ratings yet

- Design of Hydraulic Road BlockerDocument52 pagesDesign of Hydraulic Road BlockerAbdalhady Joharji100% (1)

- Ferroelectrics Go BananasDocument3 pagesFerroelectrics Go BananasAnastasiosPaterasNo ratings yet

- Elastocrete P8J Waterproofing Kit Technical Data SheetDocument3 pagesElastocrete P8J Waterproofing Kit Technical Data SheetZèlia FláviaNo ratings yet