Professional Documents

Culture Documents

How Turbocharger Works

Uploaded by

Curtler Paquibot0 ratings0% found this document useful (0 votes)

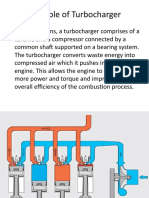

11 views1 pageThe turbocharger is bolted to the engine's exhaust manifold, where the exhaust spins the turbine which is connected by shaft to the compressor located between the air filter and intake manifold. The compressor pressurizes intake air into the cylinders. The exhaust spins the turbine blades, causing the turbine and attached compressor to spin, pumping more air into the cylinders. The turbine shaft spins at up to 150,000 rpm and is supported by a fluid bearing using a thin layer of oil to allow low-friction spinning and cool the shaft.

Original Description:

Original Title

How Turbocharger works

Copyright

© © All Rights Reserved

Available Formats

DOC, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThe turbocharger is bolted to the engine's exhaust manifold, where the exhaust spins the turbine which is connected by shaft to the compressor located between the air filter and intake manifold. The compressor pressurizes intake air into the cylinders. The exhaust spins the turbine blades, causing the turbine and attached compressor to spin, pumping more air into the cylinders. The turbine shaft spins at up to 150,000 rpm and is supported by a fluid bearing using a thin layer of oil to allow low-friction spinning and cool the shaft.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

11 views1 pageHow Turbocharger Works

Uploaded by

Curtler PaquibotThe turbocharger is bolted to the engine's exhaust manifold, where the exhaust spins the turbine which is connected by shaft to the compressor located between the air filter and intake manifold. The compressor pressurizes intake air into the cylinders. The exhaust spins the turbine blades, causing the turbine and attached compressor to spin, pumping more air into the cylinders. The turbine shaft spins at up to 150,000 rpm and is supported by a fluid bearing using a thin layer of oil to allow low-friction spinning and cool the shaft.

Copyright:

© All Rights Reserved

Available Formats

Download as DOC, PDF, TXT or read online from Scribd

You are on page 1of 1

How Turbocharger works

The turbocharger is bolted to the exhaust manifold of the engine.

The exhaust from the cylinders spins the turbine, which works like a

gas turbine engine. The turbine is connected by a shaft to the

compressor, which is located between the air filter and the intake

manifold. The compressor pressurizes the air going into the pistons

The exhaust from the cylinders passes through the turbine blades,

causing the turbine to spin. The more exhaust that goes through the

blades, the faster they spin.

On the other end of the shaft that the turbine is attached to, the

compressor pumps air into the cylinders. The compressor is a type of

centrifugal pump -- it draws air in at the center of its blades and

flings it outward as it spins. In order to handle speeds of up to

150,000 rpm, the turbine shaft has to be supported very carefully.

Most bearings would explode at speeds like this, so most

turbochargers use a fluid bearing. This type of bearing supports the

shaft on a thin layer of oil that is constantly pumped around the

shaft. This serves two purposes: It cools the shaft and some of the

other turbocharger parts, and it allows the shaft to spin without

much friction

You might also like

- 03 Principle of TurbochargerDocument19 pages03 Principle of TurbochargerSky RNo ratings yet

- TurbochargerDocument17 pagesTurbochargerdinucv83% (6)

- Propulsion Lab 1Document4 pagesPropulsion Lab 1Muhammad Ishaq KhanNo ratings yet

- Diesel Engine: Heavy VehiclesDocument33 pagesDiesel Engine: Heavy VehiclesAvinash GangadharanNo ratings yet

- Jet EnginesDocument3 pagesJet EnginesYemaneDibetaNo ratings yet

- EMEg 5221 Chapter 12 13 14Document51 pagesEMEg 5221 Chapter 12 13 14Yoseph MershaNo ratings yet

- TurbochargerDocument21 pagesTurbochargerJo VialNo ratings yet

- ICE Engineering IDocument16 pagesICE Engineering Izhafran1513No ratings yet

- Unit - 3 Types of Gas Turbine EnginesDocument4 pagesUnit - 3 Types of Gas Turbine EnginesAnonymous VKv75qe98100% (1)

- How A Gas Turbofan Engine WorksDocument4 pagesHow A Gas Turbofan Engine WorksAndrewNo ratings yet

- How A Jet Engine WorksDocument7 pagesHow A Jet Engine WorksJesús Juan Ignacio BornicesNo ratings yet

- Section 6 TRESDocument2 pagesSection 6 TRESAndrès MendozaNo ratings yet

- Engine Turborging23Document2 pagesEngine Turborging23Pagg Dē TygerNo ratings yet

- Twin-Scroll TurbochargerDocument24 pagesTwin-Scroll TurbochargerJih Yan LaiNo ratings yet

- Below Is An Overview of The Fuel System Intake OperationDocument8 pagesBelow Is An Overview of The Fuel System Intake OperationchigauNo ratings yet

- Chapter 12 Supercharging TurbochargingDocument33 pagesChapter 12 Supercharging Turbochargingdesie yalewNo ratings yet

- How A Turbo WorksDocument2 pagesHow A Turbo WorksSubhojit SamontaNo ratings yet

- TurbochargerDocument17 pagesTurbochargerAravindhRaj100% (1)

- Turbo Super Charger SystemDocument10 pagesTurbo Super Charger Systemsanju_17No ratings yet

- Video Opus-Centrifugal Compressor Principles. Duracion - 3:00 MinDocument3 pagesVideo Opus-Centrifugal Compressor Principles. Duracion - 3:00 MinPaolita GonzalezNo ratings yet

- 5-Supercharging and Turbocharging of I-C Engine - GROUP 9-1Document38 pages5-Supercharging and Turbocharging of I-C Engine - GROUP 9-1azlaljamil17No ratings yet

- Race Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeDocument7 pagesRace Cars: Induction System. They Compress The Air Flowing Into The Engine (SeeharryNo ratings yet

- Cycles Used in Jet Engines: Class 5Document28 pagesCycles Used in Jet Engines: Class 554314621No ratings yet

- Compressors LectureDocument33 pagesCompressors LectureEric CookNo ratings yet

- Assignment 3 (Gte1) Group 8Document3 pagesAssignment 3 (Gte1) Group 8dato rihNo ratings yet

- Types of Jet EnginesDocument2 pagesTypes of Jet EnginesSafi Ullah WarraichNo ratings yet

- Assignment On Aircraft EnginesDocument14 pagesAssignment On Aircraft EnginesSimran TyagiNo ratings yet

- Asi Unit 3Document21 pagesAsi Unit 3Raja RamNo ratings yet

- TurboDocument9 pagesTurboPedro Alejandro Campos CatrianNo ratings yet

- Turbochargers in Diesel EnginesDocument6 pagesTurbochargers in Diesel EnginesSrini VasanNo ratings yet

- CondensersDocument18 pagesCondensersShadabNo ratings yet

- Aim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryDocument8 pagesAim:-To Study Various Types of Compressors Used For Refrigeration Cycle. TheoryAamer MohammedNo ratings yet

- Basic's of Aircraft EnginesDocument5 pagesBasic's of Aircraft Enginesvenu991No ratings yet

- MEng3102 Chapter 11Document15 pagesMEng3102 Chapter 11dagimawgchew777No ratings yet

- Description: Necessity of Turbocharger and SuperchargerDocument16 pagesDescription: Necessity of Turbocharger and SuperchargerNazrul Aizat ZunaidiNo ratings yet

- Impeller Compressor Rotating: Rolls-Royce Trent 900 Turbofan EngineDocument2 pagesImpeller Compressor Rotating: Rolls-Royce Trent 900 Turbofan EngineYIPNo ratings yet

- 12 TurbochargerDocument14 pages12 TurbochargerAisha Zaheer100% (5)

- Static Pressure - The Pressure of A Fluid On A Body When The Body Is at Rest Relative To The FluidDocument4 pagesStatic Pressure - The Pressure of A Fluid On A Body When The Body Is at Rest Relative To The FluidJhiGz Llausas de GuzmanNo ratings yet

- Soriano, Steven R. Jet EngineDocument3 pagesSoriano, Steven R. Jet EngineKiel HerreraNo ratings yet

- Aircraft EnginesDocument20 pagesAircraft EnginesMuhammad AbidNo ratings yet

- Gas Turbine For Power Generation: Dates Back To 1939Document6 pagesGas Turbine For Power Generation: Dates Back To 1939Wakwkaka JssjaaNo ratings yet

- Turbo NotesDocument18 pagesTurbo NotescleousNo ratings yet

- Four Stroke Engine Cycles and TimingDocument27 pagesFour Stroke Engine Cycles and TimingOğuz Çavdar100% (1)

- 1 DirtyDozenWeb TraducidoDocument77 pages1 DirtyDozenWeb TraducidoKevin Arteaga100% (1)

- The Turbojet Engine Is A Reaction EngineDocument3 pagesThe Turbojet Engine Is A Reaction EngineSze MingNo ratings yet

- Turbocharger and SuperchargerDocument65 pagesTurbocharger and Superchargerzia malikNo ratings yet

- Components of CarburetorDocument4 pagesComponents of Carburetorjunjun patagNo ratings yet

- Engish 202 Turbocharger Technical DescriptionDocument3 pagesEngish 202 Turbocharger Technical DescriptionMuthukumar GovindasamyNo ratings yet

- Jet PropulsionDocument20 pagesJet Propulsionruthvik mocharlaNo ratings yet

- Turbocharger 4Document18 pagesTurbocharger 4safwansd750% (2)

- Jet Engine Types, Functions and ConstructionDocument10 pagesJet Engine Types, Functions and ConstructionTushar ShingadeNo ratings yet

- Turbo ChargerDocument19 pagesTurbo ChargerHamimi AkmalNo ratings yet

- Chapter No 3 Air CompressorsDocument59 pagesChapter No 3 Air Compressorsahsan8arshad-4No ratings yet

- Steam TurbineDocument7 pagesSteam TurbineakmalNo ratings yet

- Reciprocating: CompressorDocument12 pagesReciprocating: CompressorAkbar HartawanNo ratings yet

- Turbocharger and SuperchargerDocument16 pagesTurbocharger and SuperchargerPrajwal ZinjadeNo ratings yet

- Module 14 NotesDocument4 pagesModule 14 NotesHamad H.ANo ratings yet

- 2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .Document20 pages2.3 Turbo Chargers (WGT, VGT), Engine Emission Control by Three Way Catalytic Converter System, Emission Norms (Euro and BS) .DEEPAK S SEC 2020No ratings yet

- GovernorDocument4 pagesGovernorCurtler PaquibotNo ratings yet

- Steam Quality - Dec 2006Document13 pagesSteam Quality - Dec 2006Curtler PaquibotNo ratings yet

- Woodward 828Document4 pagesWoodward 828Curtler PaquibotNo ratings yet

- Sulzer ZAV 40Document59 pagesSulzer ZAV 40Curtler Paquibot100% (1)

- Steam Trapping - Dec 2006Document41 pagesSteam Trapping - Dec 2006Curtler PaquibotNo ratings yet

- Steam Quality & Corrosion Control - Dec 2006Document17 pagesSteam Quality & Corrosion Control - Dec 2006Curtler PaquibotNo ratings yet

- Boilers: 9-1. Minimum Maintenance Activities For BoilersDocument12 pagesBoilers: 9-1. Minimum Maintenance Activities For BoilersLacshay ShekharNo ratings yet

- 12 Air Starting of Diesel EnginesDocument26 pages12 Air Starting of Diesel EnginesCurtler PaquibotNo ratings yet

- Conversion TableDocument30 pagesConversion TableCurtler PaquibotNo ratings yet

- HF Series Oil Boiler - Start Up, Service and CleaningDocument28 pagesHF Series Oil Boiler - Start Up, Service and CleaningCurtler PaquibotNo ratings yet

- Steam Distribution - Dec 2006Document17 pagesSteam Distribution - Dec 2006Curtler PaquibotNo ratings yet

- 2051 TPL ADocument4 pages2051 TPL ACurtler PaquibotNo ratings yet

- What Is Steam - Dec 2006Document10 pagesWhat Is Steam - Dec 2006Curtler PaquibotNo ratings yet

- ABControlsDocument16 pagesABControlsCurtler PaquibotNo ratings yet

- Ingersol Rand Model3000Document19 pagesIngersol Rand Model3000Curtler PaquibotNo ratings yet

- TurbochargerDocument95 pagesTurbochargerCurtler PaquibotNo ratings yet

- Compressor SurgingDocument2 pagesCompressor SurgingCurtler PaquibotNo ratings yet

- Bearing Damage Analysis BDAPosterDocument1 pageBearing Damage Analysis BDAPosterCurtler PaquibotNo ratings yet

- Firing OrderDocument5 pagesFiring OrderCurtler PaquibotNo ratings yet

- 2053 TC MaintenanceDocument6 pages2053 TC MaintenanceCurtler PaquibotNo ratings yet

- 3BUS094321 en ABB Review Security 2005 3Document6 pages3BUS094321 en ABB Review Security 2005 3Curtler PaquibotNo ratings yet

- BMW Camshaft CoresDocument1 pageBMW Camshaft CoresCurtler PaquibotNo ratings yet

- Flexible Hose, Water: Component DescriptionDocument4 pagesFlexible Hose, Water: Component DescriptionCurtler PaquibotNo ratings yet

- KW 46Document1 pageKW 46Curtler PaquibotNo ratings yet

- Crankshaft W46F On 15-02-08Document3 pagesCrankshaft W46F On 15-02-08Curtler PaquibotNo ratings yet

- Wartsila 46F Project Guide 2009Document1 pageWartsila 46F Project Guide 2009Curtler PaquibotNo ratings yet