Professional Documents

Culture Documents

7 - Control Valve Characteristics

Uploaded by

Ahmed ShahabiOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

7 - Control Valve Characteristics

Uploaded by

Ahmed ShahabiCopyright:

Available Formats

Experiment No - 7

Control Valve Characteristics

IPC LAB, Dept. of Chemical Engineering, NITW Page 1

7A. Study of valve flow coefficient

AIM: To study the valve flow coefficient (Cv) for Linear, Equal percentage and Quick opening

control valves.

THEORY:

Valve is essentially a variable orifice. Control valve is a valve with a pneumatic,

hydraulic, electric (excluding solenoids) or other externally powered actuator that

automatically, fully or partially opens or closes the valve to a position dictated by signals

transmitted from controlling instruments.

Control valves are used primarily to throttle energy in a fluid system and not for shutoff

purpose. The figure shows basic elements and internal parts of typical pneumatic control

valve. Depending upon the valve plug design the control valves can be classified as quick

opening, linear and equal percent type.

Fig. Control valve (air to open)

Types of plugs of a pneumatic control valve

IPC LAB, Dept. of Chemical Engineering, NITW Page 2

LINEAR CONTROL VALVE:

Flow is directly proportional to valve lift i.e., Q = ky

Where, Q = flow at constant pressure drop, y = valve opening, k = constant.

EQUAL PERCENTAGE VALVE:

Flow changes by a constant percentage of its instantaneous value for each unit of valve lift.

Q = b × e ay

Where, Q = flow at constant pressure drop, y = valve opening, e = base of natural logarithm,

a and b are constants.

Constants a and b can be evaluated to give more convenient form

Q = Q0 × e{(log R ymax )× y }

Where,

Q0 = Flow at constant drop at zero stroke, R = Flow range of valve, maximum to minimum

at constant drop, ymax = maximum rated valve opening.

QUICK OPENING VALVE: Flow increases rapidly with initial travel reaching near its

maximum at a low lift. It is generally not defined mathematically.

VALVE ACTIONS AND ACTUATOR MECHANISM:

IPC LAB, Dept. of Chemical Engineering, NITW Page 3

Different types of actuators are used to control the stem travel of the valve, like

electrical actuators, pneumatic actuator, Hydraulic actuators etc. In this product, pneumatic

actuators are used for control valves. Spring opposed diaphragm actuator positions the valve

plug in response to the controller signals. Mostly the controller signals are in the range of 3 -

15 psig.

Direct acting actuator (air to close):

Direct acting actuators basically consist of a pressure tight housing sealed by a

flexible fabric reinforced elastomer diaphragm. A diaphragm plate is held against the

diaphragm by a heavy compression spring. Signal air pressure is applied to upper diaphragm

case that exerts force on the diaphragm and the actuator assembly. By selecting proper spring

rate or stiffness, load carrying capacity, and initial compression, desired stem displacement

can be obtained for any given input signal.

Reverse acting actuator (air to open):

In case of reverse acting actuators the stem gets retracted with increase in pressure.

Control valve flow coefficient:

A control valve regulates the flow rate in a fluid delivery system. In general a close

relation exists between the pressure along the pipe and the flow rate so that if pressure is

changed, then the flow rate is also changed. A control valve changes the flow rate by

changing the pressure in the flow system because it introduces the constriction in the delivery

system so we can say that the flow rate through the constriction is given by

Q = K ∆P

The correction factor K in above equation allows selection of proper size of valve to

accommodate the rate of flow that the system must support. This correction factor is called as

valve coefficient and is used in valve sizing.

Valve coefficient

G

C v = 1.16 × Q × (In SI units)

∆P

Where G is specific gravity of liquid, Q flow in m3/h, ∆P pressure drop in bar.

PROCEDURE:

1) Start up the set up. Open the flow regulating valve of the control valve to be studied

(Linear/ Equal%/quick opening). Open the respective hose cock for pressure indication.

(Close the flow regulating valves and hose cocks of other control valves).

IPC LAB, Dept. of Chemical Engineering, NITW Page 4

2) Ensure that pressure regulator outlet is connected to the valve actuator of the control valve

under study. Keep the control valve fully open by adjusting air regulator.

3) Adjust the regulating valve and set the flow rate. (Set 400 LPH flow for linear/equal%

valve or 600 LPH for quick opening valve).

Note: for measuring flow rates below rotameter minimum range use measuring jar.

OBSERVATIONS: Tabulate readings for all the three control valves.

Sl.No. Pressure drop ∆P (mm of H2o) Flow(LPH) Valve coefficient, Cv

1

2

3

CALCULATIONS:

G

C v = 1.16 × Q ×

∆P

where, Q = Flow (m3/h)= Q in LPH/1000

∆P = Pressure drop across valve (bar)= ∆P in mm of H2OX1.013/(10.33X103).

G = Specific gravity = 1 for water.

CONCLUSIONS:

IPC LAB, Dept. of Chemical Engineering, NITW Page 5

7B. Study of inherent characteristics

AIM: To study the inherent characteristics of Linear, Equal percentage and Quick opening

control valves.

THEORY:

VALVE CHARACTERISTICS:

The amount of fluid passing through a valve at any time depends upon the

opening between the plug and seat. Hence there is relationship between stem position, plug

position and the rate of flow, which is described in terms of flow characteristics of a valve.

Inherent and Installed are two types of valve characteristics.

Inherent characteristics:

The inherent flow characteristic of control valve is the relation between the flow

and the valve travel at constant pressure drop across the valve. Following are the inherent

characteristics for different types of valves.

Installed characteristics:

The Inherent characteristics of the valves described are subject to distortion due to

variations in pressure drop with flow. Line resistance distorts linear characteristics towards

that of quick opening valve and equal% to that of linear.

PROCEDURE:

1) Start up the set up. Open the flow regulating valve of the control valve to be studied

(Linear/ Equal%/quick opening). Open the respective hose cock for pressure indication.

(Close the flow regulating valves and hose cocks of other control valves.)

2) Ensure that pressure regulator outlet is connected to the valve actuator of the control valve

under study. Keep the control valve fully open by adjusting air regulator.

IPC LAB, Dept. of Chemical Engineering, NITW Page 6

3) Adjust the regulating valve and set the flow rate. (Set 400 LPH flow for linear/equal%

valve or 600 LPH for quick opening valve).

Note: for measuring flow rates below rotameter minimum range use measuring jar.

4) Note the pressure drop at control valve at full open condition.

5) Slowly increase/decrease air pressure by regulator and close the control valve to travel the

stem by 4mm. Note the pressure drop at control valve and corresponding flow rate.

6) Repeat above step and take the readings at each 2mm-stem travel till the valve is fully

closed.

OBSERVATIONS: Tabulate readings for all the three control valves.

Sl.No. Lift Flow Pressure drop ∆P Valve coefficient Lift Cv

(mm) (LPH) (mm of H2o) Cv (%) (%)

1

2

Plot the graph of valve coefficient versus lift to obtain inherent characteristic of the control

valve.

CALCULATIONS:

G

C v = 1.16 × Q ×

∆P

where, Q = Flow (m3/h)= Q in LPH/1000

∆P = Pressure drop across valve (bar)= ∆P in mm of H2OX1.013/(10.33X103).

G = Specific gravity = 1 for water.

CONCLUSIONS:

1. The inherent valve characteristics plotted for each valve fairly tallies with theoretical valve

characteristics.

2. Inherent characteristics of control valve can also be studied by keeping constant pressure

drop across the control valve.

a. Keep the valve fully open and adjust the flow rate. (400 LPH for linear/equal%

valve or 600 LPH for quick opening valve). Note the pressure drop.

b. Gradually close the control valve in steps of 4mm of stem travel. The pressure

drop across the valve increases. Manipulate flow rates to maintain pressure drop

constant. Note the flow rates.

3. Plot the graph of flow versus lift. Note that the nature of the graph is same as inherent

valve characteristics.

IPC LAB, Dept. of Chemical Engineering, NITW Page 7

7C. Study of installed characteristics

AIM: To study the installed characteristics of Linear, Equal percentage and Quick opening

control valves.

THEORY:

VALVE CHARACTERISTICS:

The amount of fluid passing through a valve at any time depends upon the

opening between the plug and seat. Hence there is relationship between stem position, plug

position and the rate of flow, which is described in terms of flow characteristics of a valve.

Inherent and installed are two types of valve characteristics.

Inherent characteristics:

The inherent flow characteristic of control valve is the relation between the flow

and the valve travel at constant pressure drop across the valve. Following are the inherent

characteristics for different types of valves.

Installed characteristics:

The Installed characteristics of the valves described are subject to distortion due to

variations in pressure drop with flow. Line resistance distorts linear characteristics towards

that of quick opening valve and equal% to that of linear.

PROCEDURE:

1) Start up the set up. Open the flow regulating valve of the control valve to be studied

(Linear/ Equal%/quick opening). Open the respective hose cock for pressure indication.

(Close the flow regulating valves and hose cocks of other control valves.)

2) Ensure that pressure regulator outlet is connected to the valve actuator of the control valve

under study. Keep the control valve fully open by adjusting air regulator.

IPC LAB, Dept. of Chemical Engineering, NITW Page 8

3) Adjust the regulating valve and set the flow rate. (Set 400 LPH flow for linear/equal%

valve or 600 LPH for quick opening valve).

Note: for measuring flow rates below rotameter minimum range use measuring jar.

4) Note the flow rate at full open condition.

5) Slowly increase/decrease air pressure by regulator and close the control valve to travel the

stem by 4mm. Note the flow rate.

6) Repeat above step and take the readings at each 4mm stem travel till the valve is fully

closed.

OBSERVATIONS: Tabulate readings for all the three control valves.

Sl.No. Lift Flow Pressure drop ∆P Valve coefficient Lift Flow

(mm) (LPH) (mm of H2o) Cv (%) (%)

1

2

Plot the graph of flow versus lift to obtain installed characteristic of the control valves.

CONCLUSIONS:

1. Installed characteristics of linear valve slightly approaches to the characteristic of quick

opening valve because of the pipe friction and other resistance to the flow.

2. Installed characteristics of equal % valve approaches to the characteristics of linear valve

because of the pipe friction and other resistance to the flow.

IPC LAB, Dept. of Chemical Engineering, NITW Page 9

7D. Study of Hysteresis of Control Valve

AIM: To study the Hysteresis effect of control valve.

THEORY:

Hysteresis of control valve

Hysteresis is a predictable error resulting from the differences in the transfer

functions when a reading is taken from above and below the value to be measured. In case of

control valves for same actuator signal different stem travel (hence valve coefficients) are

obtained depending upon the direction of change in the signal. The maximum error in stem

travel (or valve coefficient) expressed in % for same actuator pressure while opening and

closing the valve is indicated as hysteresis.

PROCEDURE:

1. Start up the set up. Open the flow regulating valve of the control valve to be studied

(Linear/ Equal%/quick opening). Open the respective hose cock for pressure indication.

(Close the flow regulating valves and hose cocks of other control valves.)

2. Ensure that pressure regulator outlet is connected to the valve actuator of the control valve

under study. Keep the control valve fully open by adjusting air regulator.

3. Adjust the regulating valve and set the flow rate. (Set 400 LPH flow for linear/equal%

valve or 600 LPH for quick opening valve). Note for measuring flow rates below rotameter

minimum range use measuring jar.

4. Note the pressure drop at control valve at full open condition.

5. Slowly increase/decrease air pressure in the step of 3 psi by regulator to close the control

valve fully. Note the actuator pressure, pressure drop across the control valve and the flow

rate. (Do not try to correct the actuator pressure by reversing the regulator direction if it

inadvertently exceeds desired value.)

IPC LAB, Dept. of Chemical Engineering, NITW Page 10

6. Slowly decrease/increase air pressure in the step of 3 psi by regulator to open the control

valve fully. Note actuator pressure, pressure drop across control valve and the flow rate.

OBSERVATIONS: Tabulate readings for all the three control valves.

Plot the graph of actuator pressure versus valve coefficient. Ratio of maximum

difference between flow coefficients at same actuator pressure, to that of maximum flow

coefficient is termed as hysteresis.

CALCULATIONS:

G

C v = 1.16 × Q ×

∆P

where, Q = Flow (m3/h)= Q in LPH/1000

∆P = Pressure drop across valve (bar)= ∆P in mm of H2OX1.013/(10.33X103).

G = Specific gravity = 1 for water.

CONCLUSIONS:

IPC LAB, Dept. of Chemical Engineering, NITW Page 11

You might also like

- Control Valves in Process PlantDocument8 pagesControl Valves in Process Plantmukramah.yusufNo ratings yet

- Control Valve CharacteristicsDocument9 pagesControl Valve CharacteristicsSiddhartha SharmaNo ratings yet

- Control ValvesDocument95 pagesControl ValvesHardik Acharya100% (1)

- Kwu Governing SystemDocument25 pagesKwu Governing SystemLakshmi Narayan100% (2)

- Control Valves: Air To Open Valve: (Fail Close)Document12 pagesControl Valves: Air To Open Valve: (Fail Close)Vignesh RajanNo ratings yet

- Plumbing-Max FajardoDocument175 pagesPlumbing-Max Fajardoaj80% (5)

- Schematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic SystemDocument2 pagesSchematic: 311B, 312B, and 312B L Excavators Two Pump Flow (Attachment) Hydraulic Systemlevinton jose tobias genesNo ratings yet

- SK 19 SK 26 (Old)Document13 pagesSK 19 SK 26 (Old)FranNo ratings yet

- Dynamic Testing of CheckvalveDocument10 pagesDynamic Testing of Checkvalveamirthraj74No ratings yet

- PNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGFrom EverandPNEUMATICS AND AIR CIRCUITS UNDERSTANDING THE CASCADE VALVE AND PLC UNDERSTANDINGNo ratings yet

- NEW CV SizingDocument23 pagesNEW CV SizinglavchemicalNo ratings yet

- Control Valve Question and Answer - 2Document13 pagesControl Valve Question and Answer - 2TATA STEELNo ratings yet

- 77-1141 Valve Selection and SizingDocument20 pages77-1141 Valve Selection and SizingAntonio LebrunNo ratings yet

- Tyco Control Valve ManualDocument55 pagesTyco Control Valve Manualtxlucky80100% (1)

- Contorl ValvesDocument8 pagesContorl ValvesGaurav MishraNo ratings yet

- Ipc 15 Valve CharacteristicsDocument41 pagesIpc 15 Valve CharacteristicsHarsh RavalNo ratings yet

- NFPA 13 2-Day Lagos FinalDocument188 pagesNFPA 13 2-Day Lagos FinalMama Cass100% (1)

- Fluid Mechanics and Hydraulics - GillesaniaDocument308 pagesFluid Mechanics and Hydraulics - Gillesaniajaamartinez50% (2)

- MMC 16101 - Positive Displacement Pump - 01Document19 pagesMMC 16101 - Positive Displacement Pump - 01HET DEDHIANo ratings yet

- Process Instrumentation Lab Report 4Document4 pagesProcess Instrumentation Lab Report 4Abu Rectify50% (4)

- Guidelines For Selecting The Proper Valve CharacteristicDocument6 pagesGuidelines For Selecting The Proper Valve CharacteristicIamPedroNo ratings yet

- Allowable Vapor Control ValveDocument9 pagesAllowable Vapor Control Valvejohn VilladaNo ratings yet

- Prevention of Actuator Emissions in the Oil and Gas IndustryFrom EverandPrevention of Actuator Emissions in the Oil and Gas IndustryNo ratings yet

- NPSH For Metering PumpsDocument7 pagesNPSH For Metering PumpsRahul S. ChandrawarNo ratings yet

- Control Valve Characteristics PDFDocument20 pagesControl Valve Characteristics PDFPrem SagarNo ratings yet

- Control Chapter 5 - RemoteDocument86 pagesControl Chapter 5 - RemoteWilmar Antonio Zuluaga ArangoNo ratings yet

- Rotameter Calibration SetDocument5 pagesRotameter Calibration SetnidhidarklordNo ratings yet

- Control Valve & Actuator Sizing27012004173744Document23 pagesControl Valve & Actuator Sizing27012004173744Raju NaiduNo ratings yet

- Cepde - Valve Sizing (U16ch036, U16ch037, U16ch083)Document15 pagesCepde - Valve Sizing (U16ch036, U16ch037, U16ch083)VRUSHABHNo ratings yet

- Lecture 4Document160 pagesLecture 4Ahmed ShahabiNo ratings yet

- Flow Control ValvesDocument24 pagesFlow Control Valvesmk_chandru100% (1)

- Control Valve CharacteristicsDocument16 pagesControl Valve Characteristicsdivyansh kashyapNo ratings yet

- Control Valve Characteristics ReportDocument10 pagesControl Valve Characteristics ReportHimanshu JatNo ratings yet

- Characteristics of Control ValveDocument9 pagesCharacteristics of Control ValvecomodusNo ratings yet

- Control ValveDocument11 pagesControl Valve700rcchNo ratings yet

- Valve ModelingDocument10 pagesValve ModelingmsNo ratings yet

- CV Exp 6Document7 pagesCV Exp 6Mohd RehanNo ratings yet

- CEB3062 Chemical Engineering Laboratory 3 September 2020: Experiment: Group: Group MembersDocument13 pagesCEB3062 Chemical Engineering Laboratory 3 September 2020: Experiment: Group: Group MembersLimNo ratings yet

- ChE 404-Chapter 08Document38 pagesChE 404-Chapter 08aliNo ratings yet

- VPT-Kalatjari (Sazeh Engineering Consultants)Document16 pagesVPT-Kalatjari (Sazeh Engineering Consultants)cristianNo ratings yet

- Control Valve 2Document30 pagesControl Valve 2gagandeepsinghgxdNo ratings yet

- 8 299efi9fi9ef6545505tkkg, MBG BM M KMB KMGTKBMV, GTG, BVFV FGV 02iDocument19 pages8 299efi9fi9ef6545505tkkg, MBG BM M KMB KMGTKBMV, GTG, BVFV FGV 02idhruvNo ratings yet

- Hydraulics and Pneumatics Lab: Amee 310: Laboratory Handout Experiment 6: "Pressure Drop Vs Flow Relationship"Document12 pagesHydraulics and Pneumatics Lab: Amee 310: Laboratory Handout Experiment 6: "Pressure Drop Vs Flow Relationship"info5280No ratings yet

- Lab 4Document15 pagesLab 4Madhumita KumarNo ratings yet

- Experiment No 7Document7 pagesExperiment No 7Faizan Ahmed67% (3)

- Method of Flow Measurement ..Document12 pagesMethod of Flow Measurement ..anuj kanadeNo ratings yet

- 1.1.1 Functions of Flow-Control ValvesDocument24 pages1.1.1 Functions of Flow-Control Valvesatashi baran mohantyNo ratings yet

- D - Two-Phase Flow Lab ManualDocument23 pagesD - Two-Phase Flow Lab ManualdanielNo ratings yet

- REPORTpp 1Document16 pagesREPORTpp 1gajulavamshikrishna02No ratings yet

- Chapter 4Document35 pagesChapter 4Pink FloydaNo ratings yet

- CL3601Document10 pagesCL3601md.jimshad.3883No ratings yet

- Valve Characteristic Is The Relation Between The Flow Through The Valve and The Valve Stem PositionDocument13 pagesValve Characteristic Is The Relation Between The Flow Through The Valve and The Valve Stem PositionPortia ShilengeNo ratings yet

- Computational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveDocument4 pagesComputational Fluid Dynamic Analysis of Flow Coefficient For Pan Check ValveMax KocourNo ratings yet

- Lab Report: Instrumentation and ControlDocument7 pagesLab Report: Instrumentation and ControlmjunaidNo ratings yet

- Experiment 2 - Flow Measurement: Page 1 of 6Document6 pagesExperiment 2 - Flow Measurement: Page 1 of 6fadyaNo ratings yet

- Fluid Mechanics Lab ManualDocument25 pagesFluid Mechanics Lab Manualeklavya kumarNo ratings yet

- Dee - E4 - Lecture18b - Control Valve Positioners & Valve SizingDocument3 pagesDee - E4 - Lecture18b - Control Valve Positioners & Valve SizingizzarhmanNo ratings yet

- Actuators: Version 2 EE IIT, Kharagpur 1Document29 pagesActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranNo ratings yet

- Actuators: Version 2 EE IIT, Kharagpur 1Document29 pagesActuators: Version 2 EE IIT, Kharagpur 1Khaled MahranNo ratings yet

- Control ValvesDocument11 pagesControl Valvespranjal priyeNo ratings yet

- Objective: The Main Objective of This Experiment To Understand The Characteristics of A Flow Transducer As Position Tranducer. AbstractDocument4 pagesObjective: The Main Objective of This Experiment To Understand The Characteristics of A Flow Transducer As Position Tranducer. Abstractmubashar husain ansarNo ratings yet

- Volume Flow Rate GuideDocument8 pagesVolume Flow Rate Guidetfkthe46No ratings yet

- DiscussionDocument3 pagesDiscussionAbdul AzimNo ratings yet

- Im316 Flow MeasurementDocument67 pagesIm316 Flow MeasurementSelvarajNo ratings yet

- SS 09Document3 pagesSS 09Ajaykumar TiwariNo ratings yet

- Boiler Water LVL DP CellDocument10 pagesBoiler Water LVL DP CellParthiban Nagarajan100% (1)

- 07 Fluid Transports EquipmentsDocument12 pages07 Fluid Transports EquipmentsarfpowerNo ratings yet

- 5 - Measurement of Liquid LevelDocument7 pages5 - Measurement of Liquid LevelAhmed ShahabiNo ratings yet

- Aeration and AgitationDocument69 pagesAeration and AgitationAhmed ShahabiNo ratings yet

- This Is A System-Generated Statement. Hence, It Does Not Require Any SignatureDocument2 pagesThis Is A System-Generated Statement. Hence, It Does Not Require Any SignatureAhmed ShahabiNo ratings yet

- Cell KineticsDocument83 pagesCell KineticsAhmed ShahabiNo ratings yet

- Lecture - 6Document238 pagesLecture - 6Ahmed ShahabiNo ratings yet

- Lecture 5Document72 pagesLecture 5Ahmed ShahabiNo ratings yet

- Lecture 2Document172 pagesLecture 2Ahmed ShahabiNo ratings yet

- Lecture 3Document113 pagesLecture 3Ahmed ShahabiNo ratings yet

- Check List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Document2 pagesCheck List For Installation and Incoming Materials For Pipe Sleeves (Sanitary & Plumbing Works)Imho TepNo ratings yet

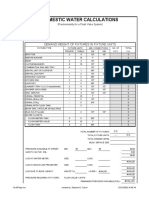

- Domestic Water Calculations: Demand Weight of Fixtures in Fixture UnitsDocument2 pagesDomestic Water Calculations: Demand Weight of Fixtures in Fixture UnitsJohn ANo ratings yet

- ME8694 HydraulicsandPneumaticsQuestionBank PDFDocument15 pagesME8694 HydraulicsandPneumaticsQuestionBank PDFVikram mNo ratings yet

- BABM Techdoc WebDocument30 pagesBABM Techdoc Webkruhak.dominikNo ratings yet

- Liquid Handling Pumps Information - Engineering360Document9 pagesLiquid Handling Pumps Information - Engineering360cristi.nicolaehotmail.comNo ratings yet

- Valves & Hose Bibs: How To Fix A Leaky Hose BibDocument2 pagesValves & Hose Bibs: How To Fix A Leaky Hose BibTheKeyNo ratings yet

- 5 Bro Sarns - Cent-Pump-Adap EngDocument2 pages5 Bro Sarns - Cent-Pump-Adap EngManigandan DhamodhiranNo ratings yet

- 160m Hyd TroubleshootDocument8 pages160m Hyd TroubleshootDaniel Rhasty-ghee AhmanorNo ratings yet

- Pilot LockoutDocument6 pagesPilot LockoutDu TrầnNo ratings yet

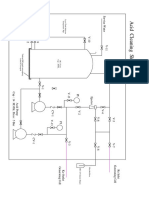

- P&ID Acid CleaningDocument1 pageP&ID Acid CleaningAxelrose04No ratings yet

- Microsoft Word - Man 2 Chap 11 Well Control EquipmentDocument77 pagesMicrosoft Word - Man 2 Chap 11 Well Control EquipmentЕмиль АббасовNo ratings yet

- Internship PresentationDocument12 pagesInternship Presentationsanjeev krishnaNo ratings yet

- 10-JOS-E, JBS, JLT ManualDocument22 pages10-JOS-E, JBS, JLT ManualUJJAL KUMAR BHATTACHARYAYNo ratings yet

- FittingsDocument15 pagesFittingsNiraj PandeyNo ratings yet

- Sample Bill of MaterialsDocument2 pagesSample Bill of MaterialsRajan Banda100% (1)

- Manual Valvula de Alivio RciDocument3 pagesManual Valvula de Alivio RciGonzalo DominguezNo ratings yet

- Foot Valves UsesDocument8 pagesFoot Valves UsesRaja Pathamuthu.GNo ratings yet

- Accumulators and Accumulator CircuitsDocument7 pagesAccumulators and Accumulator Circuitsjasonmani90No ratings yet

- Automatic Control Valves Suggested List Price Effective April 6, 2015 (Rev: 2)Document42 pagesAutomatic Control Valves Suggested List Price Effective April 6, 2015 (Rev: 2)Rishita Sahoo LadliNo ratings yet

- G BrassFittingsDocument22 pagesG BrassFittingsHermanNo ratings yet

- Material Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFDocument4 pagesMaterial Schematic Hydraulic System Track Type Tractors d8r Dozer Caterpillar PDFvasanth kumar100% (1)

- Bermad: Fire ProtectionDocument4 pagesBermad: Fire ProtectionMarcioNo ratings yet